In the realm of outdoor power tools, having a clear understanding of individual components is essential for effective maintenance and operation. Each element plays a crucial role in ensuring that the machinery functions smoothly and efficiently. This knowledge not only aids in troubleshooting but also enhances the overall longevity of the tool.

By exploring the various sections and functionalities of your equipment, one can delve deeper into the intricate workings that keep it performing at its ultimate best. Familiarizing oneself with the layout and connection of each part empowers users to make informed decisions when repairs or replacements are necessary.

Whether you are a seasoned professional or a novice user, comprehending the configuration of essential elements will undoubtedly lead to better handling and care of your machinery. In the following sections, we will break down the key components, offering insights that are beneficial for all types of users.

Understanding the Stihl MS271 Parts Diagram

Grasping the layout of essential components in machinery is crucial for effective maintenance and repair. Familiarity with the configuration not only aids in identifying parts but also enhances overall functionality and longevity of the equipment.

Key Components

- Engine Assembly

- Fuel System

- Air Filtration

- Chain Mechanism

- Housing and Frame

Importance of Component Knowledge

- Facilitates easy troubleshooting.

- Improves efficiency during repairs.

- Enhances safety by ensuring proper handling.

Ultimately, comprehending the structure enables users to delve deeper into operational effectiveness and promotes better care of the equipment.

Key Components of the Stihl MS271

This section explores the essential elements that contribute to the efficiency and functionality of a high-performance chainsaw. Understanding these components is crucial for maintenance and optimal operation.

| Component | Description |

|---|---|

| Engine | Powers the saw and determines cutting performance. |

| Bar | The guide for the chain, essential for precise cuts. |

| Chain | Interacts with the bar to achieve cutting action. |

| Air Filter | Prevents debris from entering the engine, ensuring longevity. |

| Fuel Tank | Holds the mixture of fuel and oil for operation. |

| Throttle Trigger | Regulates power output and speed of the chain. |

| Clutch | Engages and disengages the chain during operation. |

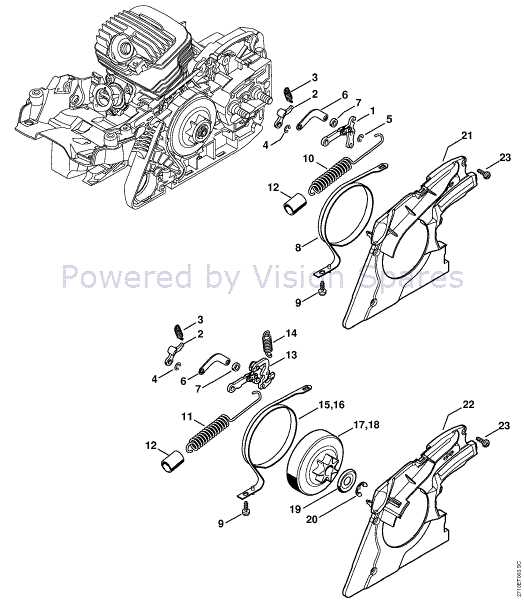

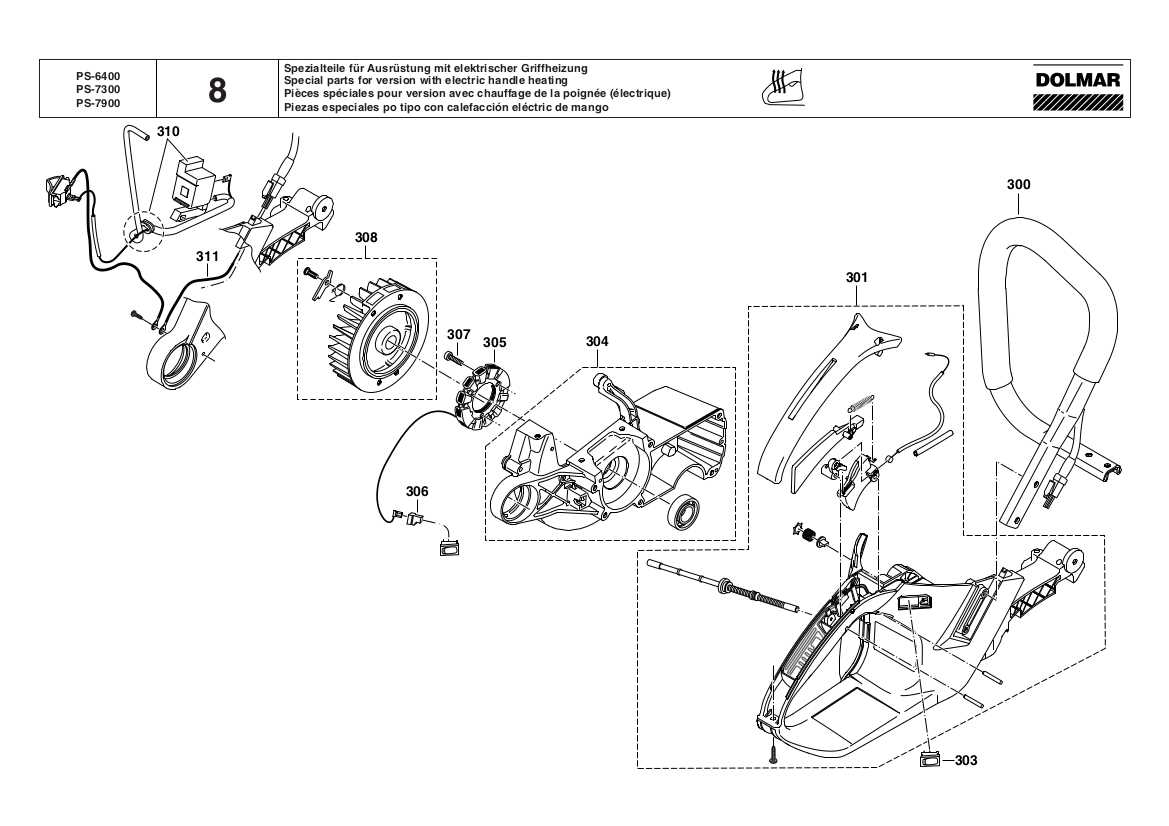

How to Read the Parts Diagram

Understanding a schematic can significantly enhance your ability to maintain and repair equipment. These visual representations break down the components, providing insight into their arrangement and functionality. By familiarizing yourself with the layout and symbols, you can easily identify each element’s role and how they interact.

Start by examining the legend, which explains the symbols used in the schematic. This will help you interpret the various components accurately. Next, trace the connections between parts to understand how they work together. Paying attention to numbering or labeling can also aid in locating specific items quickly.

Lastly, practice is essential. Regularly referring to the schematic while performing maintenance will reinforce your understanding, ultimately making repairs more efficient.

Common Issues with MS271 Parts

Every piece of machinery can encounter problems over time, and this model is no exception. Understanding the frequent complications associated with its components can significantly enhance performance and longevity. Addressing these issues promptly not only maintains efficiency but also prevents further damage.

Wear and Tear: Regular use often leads to deterioration of essential elements. Components like the chain or bar can become less effective, resulting in poor cutting performance. Regular inspections are crucial to identify signs of wear before they escalate into more significant concerns.

Fuel System Problems: Clogging in the fuel delivery system can hinder operation. This can be caused by debris or old fuel. Ensuring clean fuel lines and regularly replacing fuel can help maintain smooth functionality.

Electrical Failures: Issues with the ignition system may lead to starting difficulties. Corrosion or loose connections in electrical components can prevent the engine from firing up. Regular checks can help spot and rectify these problems early on.

Overheating: Excessive heat can result from blocked air filters or low oil levels. This not only affects performance but can also cause severe damage to the engine. Keeping filters clean and oil levels adequate is essential for preventing overheating.

Vibration Issues: Excessive vibration can indicate misalignment or loose parts. This can lead to operator discomfort and potential safety hazards. Regular maintenance ensures that all components are securely fastened and aligned correctly.

By being proactive about these common challenges, users can enhance the reliability and effectiveness of their machinery, ensuring it performs optimally for years to come.

Maintaining Your Stihl Chainsaw

Regular upkeep is essential for ensuring the longevity and performance of your cutting tool. A well-maintained saw not only operates more efficiently but also enhances safety during use. This section provides practical tips for keeping your equipment in optimal condition.

- Clean the Air Filter: A clogged filter restricts airflow, affecting performance. Clean or replace it regularly.

- Inspect the Bar and Chain: Check for wear and damage. Keep the chain sharp and ensure proper tension.

- Lubricate Moving Parts: Regularly apply oil to the chain and other moving components to prevent friction and wear.

- Check Fuel and Oil Levels: Use the recommended fuel mixture and maintain adequate levels to ensure smooth operation.

- Examine Spark Plug: A clean spark plug is vital for efficient ignition. Replace it if it shows signs of wear.

Following these guidelines will help you maintain your cutting tool effectively, ensuring it remains a reliable companion for all your cutting tasks.

Where to Buy Replacement Parts

Finding suitable components for your outdoor equipment can be crucial for maintaining its performance and longevity. Various sources offer these items, each with distinct advantages. Whether you prefer shopping online or visiting a local store, understanding your options will help you make an informed choice.

| Source | Advantages | Considerations |

|---|---|---|

| Authorized Dealers | Genuine items, expert advice | Potentially higher prices |

| Online Retailers | Wide selection, convenience | Check seller ratings and return policies |

| Local Hardware Stores | Immediate availability, personal service | Limited inventory compared to larger retailers |

| Second-Hand Marketplaces | Lower prices, unique finds | Quality and compatibility can vary |

By exploring these various avenues, you can effectively locate the necessary components to keep your equipment in top shape. Always consider the quality and compatibility of the items to ensure optimal performance.

Benefits of Genuine Stihl Parts

Using authentic components for your equipment ensures optimal performance and longevity. These original elements are specifically designed to fit seamlessly, enhancing efficiency and reducing the risk of mechanical issues.

One of the primary advantages of genuine products is their reliability. They undergo rigorous testing to meet stringent quality standards, ensuring they can withstand the demands of heavy use. This commitment to excellence translates to fewer breakdowns and less downtime.

Additionally, authentic components often come with a warranty, providing peace of mind. In case of any defects or issues, you can rely on the manufacturer’s support to address concerns promptly.

Investing in original components also supports the overall value of your machinery. By maintaining high standards, you contribute to a more efficient operation and potentially extend the lifespan of your equipment.

Ultimately, choosing genuine replacements is a decision that pays off in performance, reliability, and peace of mind, ensuring your tools remain in top condition for years to come.

Tools Needed for MS271 Repairs

When undertaking maintenance or repairs on your chainsaw, having the right tools is essential for efficient and safe work. A well-equipped toolkit can make the process smoother and help ensure that your equipment operates optimally.

Here’s a list of essential tools you will need:

- Wrench Set: A variety of wrenches will help you loosen and tighten different fasteners.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for accessing various components.

- Torque Wrench: This tool is crucial for applying the correct tension on bolts to avoid damage.

- Chain File: Maintaining the sharpness of the cutting chain is vital for performance.

- Oil Can: Proper lubrication is key; an oil can helps you apply lubricant where needed.

- Safety Gear: Don’t forget gloves, goggles, and ear protection to ensure your safety during repairs.

Additionally, consider having the following items on hand:

- Cleaning Brush: For removing debris and ensuring all parts are free of obstructions.

- Multimeter: Useful for checking electrical components and diagnosing issues.

- Replacement Parts: Having a few commonly replaced items will save time during repairs.

By gathering these tools, you’ll be well-prepared to handle any maintenance tasks that arise, ensuring your equipment remains in peak condition.

Tips for DIY Chainsaw Maintenance

Maintaining your cutting tool is essential for its longevity and performance. Regular upkeep ensures safe operation and enhances efficiency, allowing you to tackle tasks with confidence. Following a few straightforward practices can help keep your equipment in top condition.

1. Clean the Bar and Chain: After each use, remove debris from the guide bar and chain. This prevents buildup that can hinder performance.

2. Lubricate Regularly: Ensure the chain is adequately lubricated to minimize friction and wear. Check the oil reservoir and top it off as needed.

3. Check the Chain Tension: Proper tension is crucial. A loose chain can derail, while an overly tight chain can cause damage. Adjust as necessary for optimal performance.

4. Sharpen the Chain: A sharp chain cuts more efficiently and safely. Invest in a good sharpening tool and check the chain regularly to maintain its edge.

5. Inspect for Wear: Periodically examine your tool for signs of wear or damage, especially on the chain, guide bar, and sprocket. Replace worn parts promptly to ensure reliability.

6. Store Properly: After use, clean and store your equipment in a dry, secure place. This protects it from the elements and prolongs its lifespan.

By incorporating these practices into your routine, you can delve deeper into effective maintenance and enjoy the ultimate performance from your tool.