In the realm of outdoor machinery, having a comprehensive grasp of its individual elements is essential for optimal performance and maintenance. Whether you are a seasoned professional or a passionate hobbyist, familiarizing yourself with the internal workings of your tools can greatly enhance their longevity and functionality.

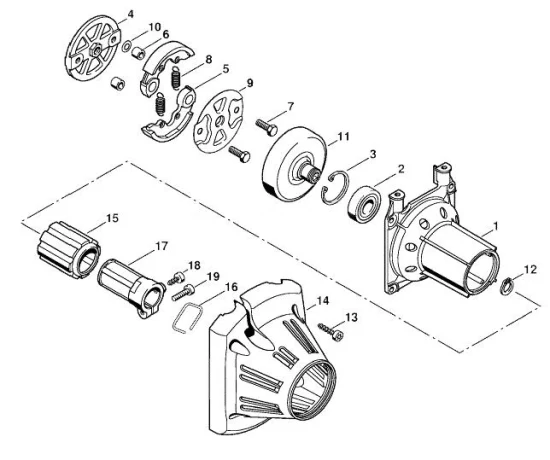

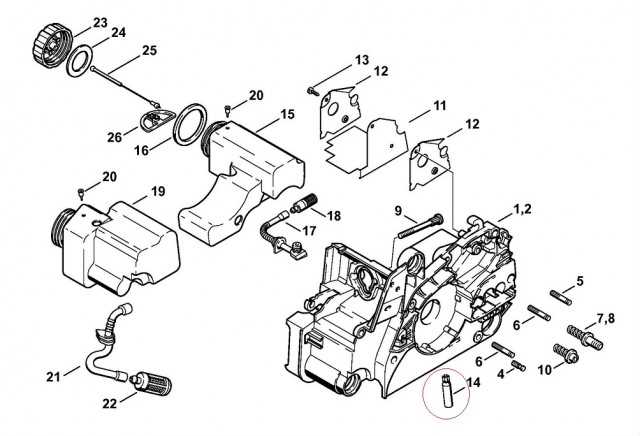

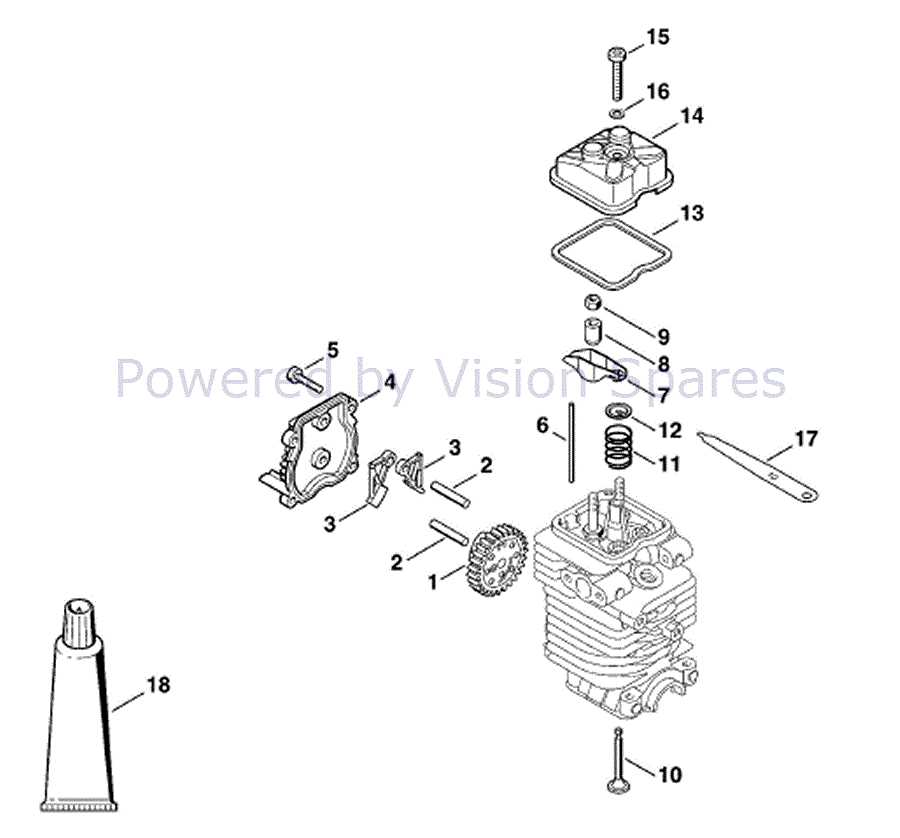

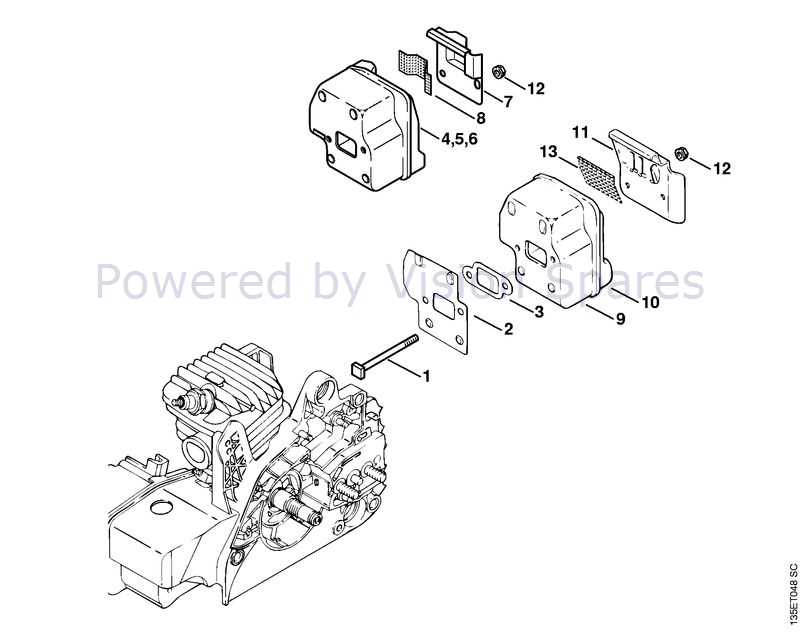

Utilizing detailed visual guides allows users to pinpoint each component and understand its role within the overall system. Such resources can be invaluable for troubleshooting issues or planning repairs, enabling owners to take informed actions when the need arises. With clear illustrations, identifying specific items becomes a straightforward task, simplifying the process of restoration or upgrading.

Access to these informative resources is crucial for anyone looking to ensure their equipment runs smoothly. From novices learning the basics to experts seeking advanced knowledge, having a clear reference at hand can save time and effort, paving the way for effective maintenance strategies. Embrace the opportunity to delve into the intricacies of your tools and empower yourself with the knowledge necessary for successful upkeep.

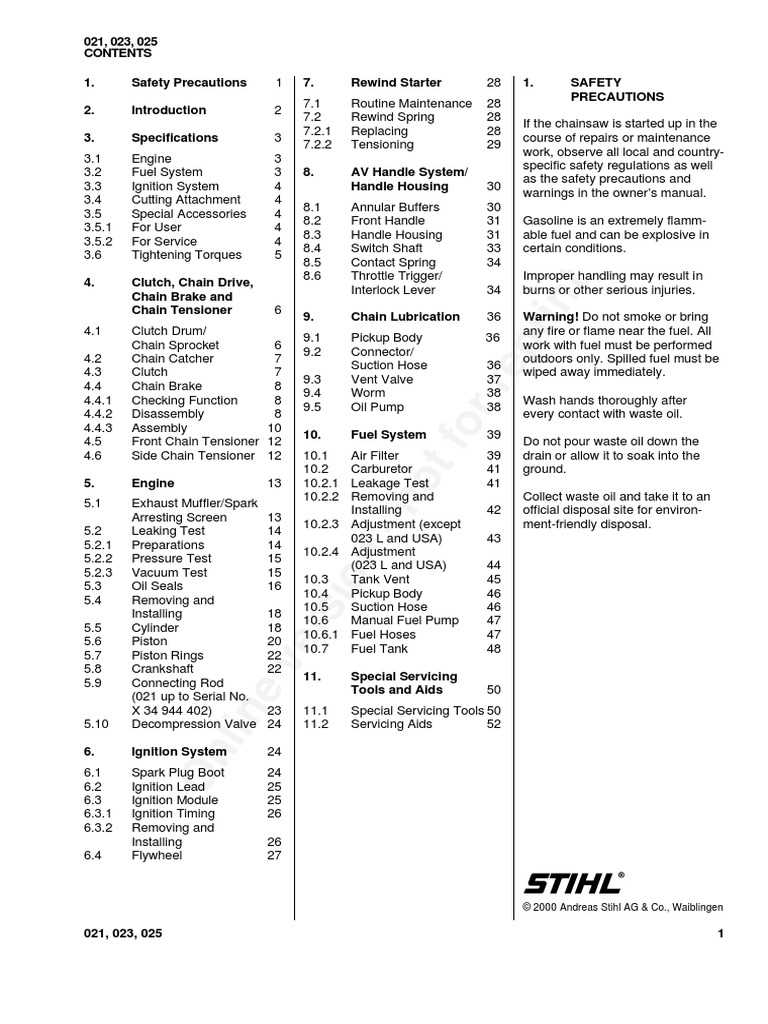

Understanding Stihl 025 Chainsaw Parts

When operating a powerful cutting tool, familiarity with its components is essential for efficient use and maintenance. Each element plays a crucial role in the overall functionality, ensuring that the machine performs optimally and safely. Knowing the various segments helps users troubleshoot issues and make informed decisions regarding repairs and replacements.

Below is a breakdown of the main components typically found in these machines, providing insights into their functions and importance:

| Component | Description |

|---|---|

| Engine | The powerhouse that drives the entire unit, converting fuel into mechanical energy. |

| Bar | The long metal piece that supports the cutting chain, essential for guiding the cut. |

| Chain | A loop of sharp links that rotates around the bar, enabling the cutting action. |

| Fuel Tank | Holds the mixture of fuel and oil needed for engine operation. |

| Oil Pump | Distributes oil to the chain and bar, ensuring proper lubrication during use. |

| Throttle Trigger | Controls the engine speed and cutting power, allowing for precise operation. |

| Handle | Provides a grip for the operator, contributing to control and stability during cutting tasks. |

Understanding each component not only aids in enhancing performance but also promotes safety and longevity of the equipment. Regular checks and maintenance of these elements are crucial for effective operation and reducing the risk of malfunctions.

Importance of a Parts Diagram

A visual representation of components is crucial for understanding the intricate assembly of any mechanical device. Such illustrations provide users with the necessary insight into the organization and functionality of various elements, making maintenance and repairs more efficient. By having a clear overview, one can easily identify specific components and their relationships within the entire system.

Facilitating Maintenance

Having an accurate illustration aids significantly in routine upkeep. Users can pinpoint wear and tear, ensuring that each part receives the attention it requires. This not only prolongs the lifespan of the equipment but also enhances its performance, leading to more reliable operation.

Streamlining Repairs

When it comes to fixing issues, a detailed illustration becomes an invaluable resource. It allows individuals to quickly locate the faulty elements and understand the correct procedures for disassembly and reassembly. This reduces the likelihood of errors and speeds up the repair process, ultimately saving time and resources.

How to Access PDF Diagrams

Obtaining detailed visual guides is essential for effective maintenance and repair tasks. These resources offer a clear view of the components and their arrangement, aiding in troubleshooting and assembly. Here’s how you can easily locate these valuable documents online.

Step-by-Step Guide

Follow these steps to find the necessary materials:

| Step | Description |

|---|---|

| 1 | Search reputable websites that specialize in equipment manuals. |

| 2 | Use the model name and number in the search bar for specificity. |

| 3 | Look for sections labeled ‘Manuals’ or ‘Resources’ on the site. |

| 4 | Download the file in the desired format for easy access. |

Additional Tips

Always ensure the site is secure and trustworthy. Bookmark valuable resources for future reference to streamline your process.

Common Stihl 025 Replacement Parts

Maintenance and repair of outdoor power equipment often require specific components to ensure optimal performance. Understanding which elements are most frequently replaced can save time and improve efficiency. Below are some of the essential items that users typically need to consider when servicing their machines.

Essential Components

- Chainsaw Bar: The cutting component that guides the chain and must be replaced periodically to maintain cutting efficiency.

- Chain: The moving part that cuts through wood, requiring regular inspection for wear and tear.

- Air Filter: Keeps dirt and debris from entering the engine, needing replacement to ensure proper airflow.

- Spark Plug: Essential for ignition; replacing it can enhance starting reliability and engine performance.

Additional Accessories

- Fuel Filter: Prevents contaminants in fuel from reaching the engine, helping to prolong its life.

- Oil Pump: Distributes lubrication to the chain; a malfunctioning pump can lead to excessive wear.

- Gaskets and Seals: These components help maintain the integrity of the engine and prevent leaks.

- Starter Assembly: Responsible for engine ignition; wear can lead to starting issues.

Regularly inspecting and replacing these components can significantly enhance the longevity and performance of your equipment, ensuring it operates smoothly and efficiently during use.

Tips for Identifying Parts Quickly

Recognizing components efficiently is essential for effective maintenance and repair tasks. By employing a systematic approach, you can minimize downtime and enhance your understanding of the equipment. Here are some strategies to help you identify elements swiftly and accurately.

Utilize Visual References

Having access to clear visual references can significantly streamline the identification process. Diagrams or images showcasing the components in detail can aid in associating parts with their functions. Additionally, marking critical features can help in quick recognition.

Familiarize Yourself with Terminology

Understanding the specific terminology used in the industry can accelerate your identification skills. Take time to learn the common names and functions of various components. Knowing the lingo will not only enhance communication but also facilitate quicker recognition when referring to resources or discussing with peers.

Maintenance and Repair Procedures

Regular upkeep and troubleshooting are essential for optimal performance and longevity of your equipment. Proper techniques and a thorough understanding of the components involved will ensure smooth operation and prevent costly breakdowns.

| Procedure | Description | Frequency |

|---|---|---|

| Air Filter Cleaning | Remove and clean to ensure proper airflow. | Every 10 hours of use |

| Spark Plug Inspection | Check for wear and replace if necessary. | Every 25 hours of use |

| Chain Lubrication | Apply lubricant to keep the chain functioning smoothly. | Before each use |

| Fuel System Check | Inspect for leaks and ensure fuel is clean. | Every 50 hours of use |

Adhering to these procedures will not only enhance performance but also extend the life of your machinery.

Where to Buy Authentic Parts

Ensuring the longevity and performance of your equipment relies on using genuine components. Finding reliable sources for these essentials is crucial for maintaining optimal functionality. Authentic products not only guarantee compatibility but also provide peace of mind through quality assurance.

Here are some trusted avenues for sourcing genuine components:

| Source | Description |

|---|---|

| Authorized Dealers | Visit certified retailers who specialize in equipment and accessories. They typically stock a comprehensive range of genuine components. |

| Official Website | Explore the manufacturer’s official online store for an extensive selection of authentic items. This ensures direct access to the latest offerings. |

| Specialty Repair Shops | Local repair facilities often have connections to genuine suppliers and can provide you with authentic components tailored to your needs. |

| Online Marketplaces | Reputable platforms can be useful for sourcing genuine items, but always check seller ratings and reviews for credibility. |

By choosing these reliable sources, you can ensure that your equipment remains in top condition with components that meet the highest standards of quality and performance.

Frequently Asked Questions About Stihl 025

This section aims to address common inquiries related to the popular model known for its reliability and performance. Whether you’re a seasoned user or new to this equipment, understanding its features and maintenance is essential for optimal operation.

What are the key specifications of this model?

The device is designed with a powerful engine, typically featuring a displacement that enhances its cutting capabilities. It often includes adjustable features for improved user comfort and efficiency. Knowing these specifications helps users select the right tools for their tasks.

How can I ensure proper maintenance?

Regular upkeep is crucial for longevity. This includes cleaning the air filter, checking the spark plug, and ensuring the fuel system is in good condition. Following the manufacturer’s guidelines can prevent common issues and enhance performance. Always refer to the user manual for specific maintenance schedules and tips.

Stihl 025 Parts Compatibility Guide

This section provides essential information on the interchangeability and suitability of various components for a specific model of outdoor power equipment. Understanding which elements can be replaced or upgraded is crucial for maintaining optimal performance and longevity.

When seeking replacements, consider the following factors:

- Manufacturer Specifications: Always refer to the manufacturer’s guidelines to ensure compatibility.

- Model Variations: Different versions may have slight modifications that affect fit and function.

- Quality of Components: Opt for original or reputable aftermarket options to guarantee reliability.

Here’s a quick reference for commonly exchanged items:

- Air Filters

- Fuel Lines

- Chains

- Sprockets

- Carburetors

By considering these aspects, users can make informed decisions and ensure their equipment operates smoothly and efficiently. Always consult your user manual or a professional for guidance on specific replacements.