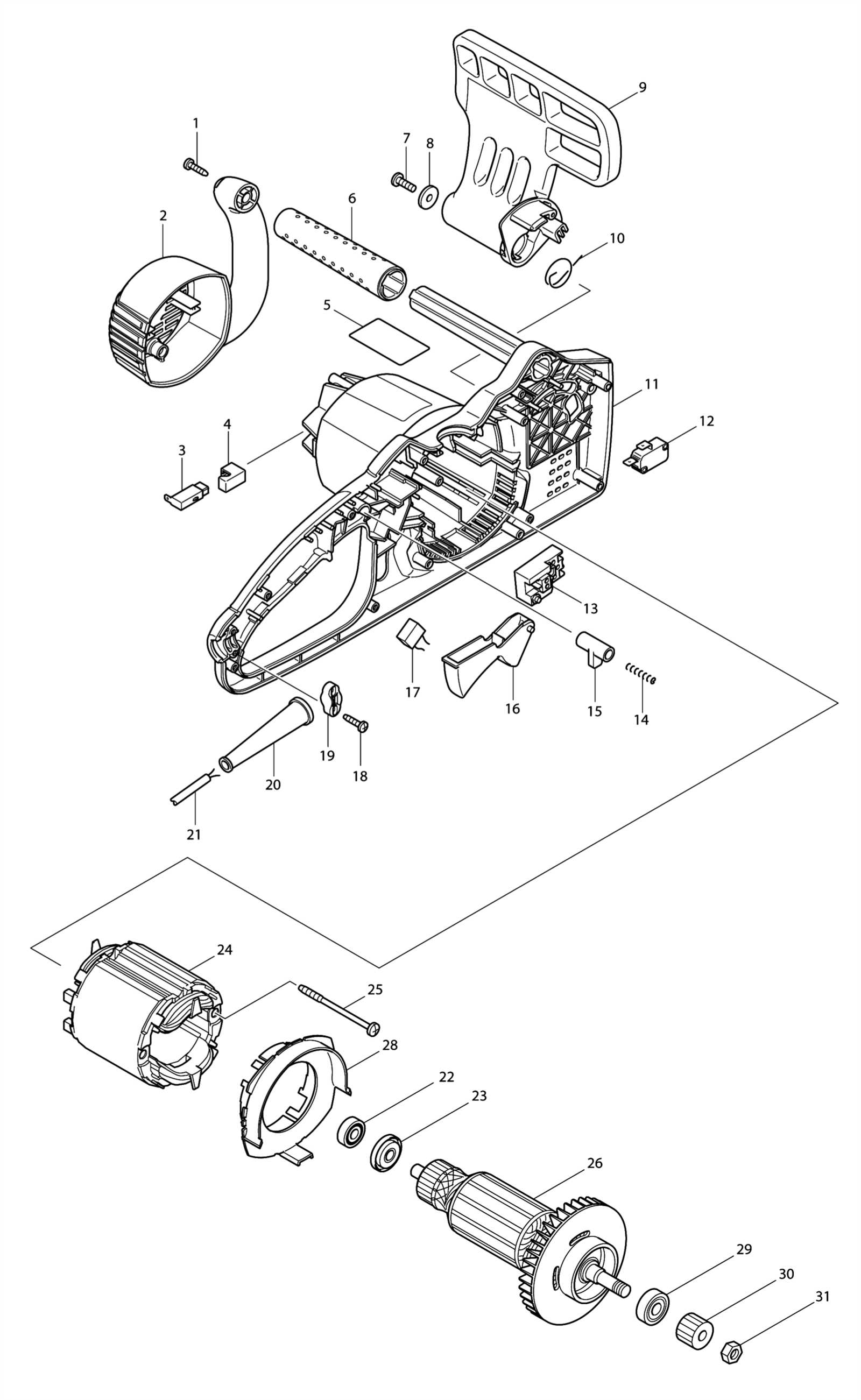

When maintaining a powerful cutting tool, having a clear visual reference of its individual elements is crucial for optimal performance. This section aims to provide an insightful overview of the essential components that make up your equipment, ensuring you have a comprehensive understanding of each part’s role and functionality.

In the realm of outdoor machinery, familiarity with the intricate assembly can significantly enhance your ability to troubleshoot and perform routine maintenance. By examining the various elements, users can identify wear and tear, ensuring their tool remains efficient and reliable.

Moreover, delving into the specifics of these components not only aids in repairs but also empowers users to make informed decisions when purchasing replacements. Knowledge of how each piece interacts contributes to a smoother operational experience and ultimately prolongs the life of your trusted tool.

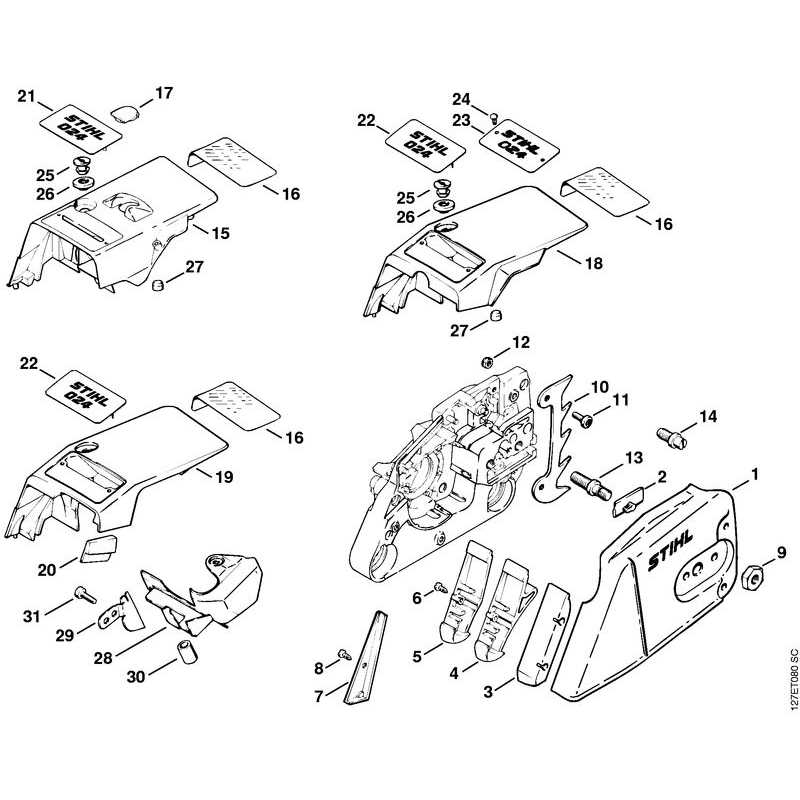

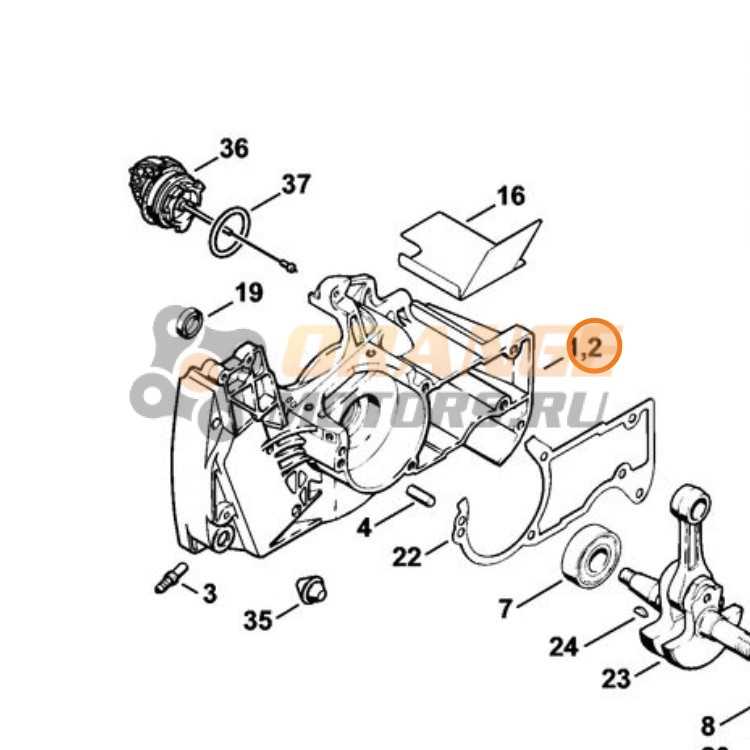

Understanding Stihl 024 Chain Saw

This section aims to provide a comprehensive overview of a popular model in the realm of cutting equipment, emphasizing its key features, components, and operational insights. Understanding how each element functions is essential for effective maintenance and optimal performance.

Key components of this cutting tool include:

- Engine: The powerhouse that drives the entire mechanism.

- Guide Bar: The long metal strip that directs the chain and facilitates cutting.

- Chain: The loop of sharp links that performs the actual cutting action.

- Fuel System: A vital part that ensures the engine receives the necessary energy to operate.

- Air Filter: Helps maintain engine efficiency by preventing debris from entering the combustion chamber.

- Handle: Provides grip and control, ensuring safe operation.

Regular maintenance is crucial for longevity and efficiency. Recommended practices include:

- Regularly check and replace the air filter to maintain airflow.

- Inspect the guide bar and chain for wear and replace as needed.

- Ensure the fuel system is clean and free of obstructions.

- Sharpen the chain frequently for optimal cutting performance.

- Store the equipment in a dry, secure location to prevent damage.

By understanding the essential components and maintenance requirements, users can enhance the lifespan and functionality of their cutting equipment, ensuring reliable performance for various tasks.

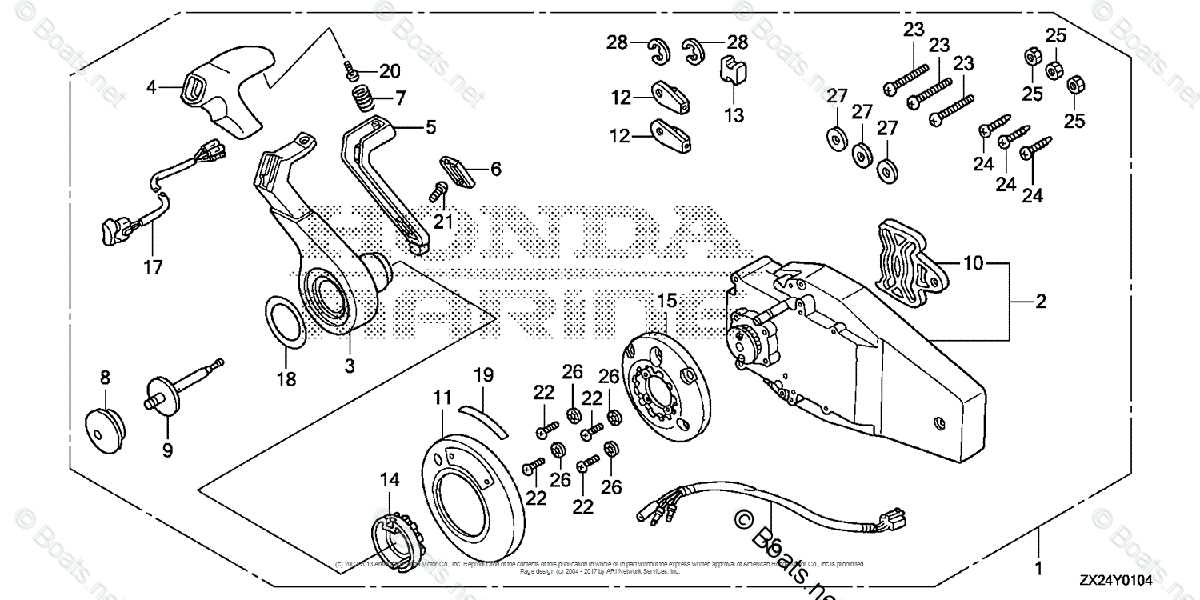

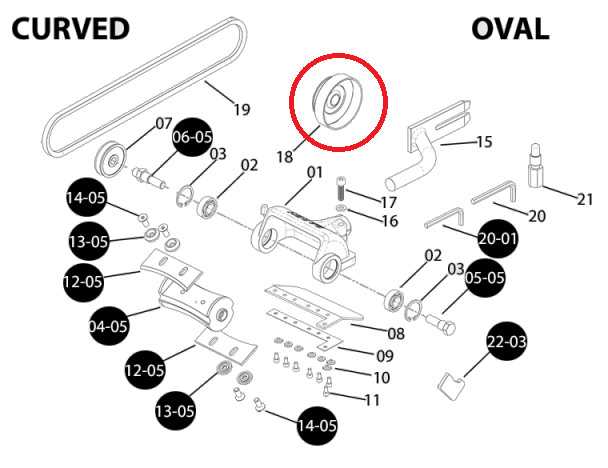

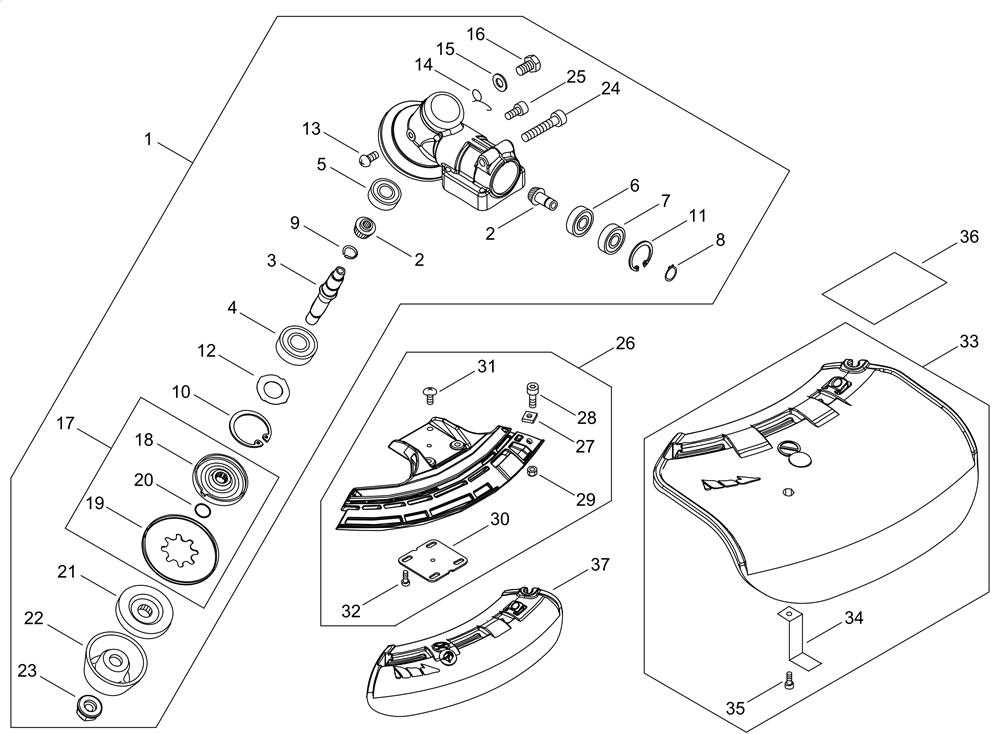

Importance of Parts Diagrams

Understanding the intricate layout of machinery components is crucial for effective maintenance and repair. Visual representations that detail the arrangement and functionality of each element serve as essential tools for technicians and enthusiasts alike. These illustrations not only simplify the identification of individual components but also enhance the overall comprehension of the assembly.

Clarity and Precision are paramount when tackling complex machinery. By utilizing visual guides, users can easily locate specific elements, ensuring that tasks such as replacement or adjustment are executed accurately. This minimizes the risk of errors and promotes a smoother workflow.

Moreover, educational value cannot be overlooked. For those new to equipment servicing, these visuals provide an invaluable resource for learning. They illustrate how different parts interact, fostering a deeper understanding of the machine’s operation and enabling users to troubleshoot issues more effectively.

Additionally, having access to these representations can significantly improve efficiency. When technicians have a clear reference, they can save time during repairs, leading to quicker turnaround and enhanced productivity. This is especially beneficial in professional settings where time is of the essence.

In summary, visual schematics are vital for anyone involved in equipment maintenance. They not only facilitate accurate repairs and enhance learning but also contribute to overall operational efficiency.

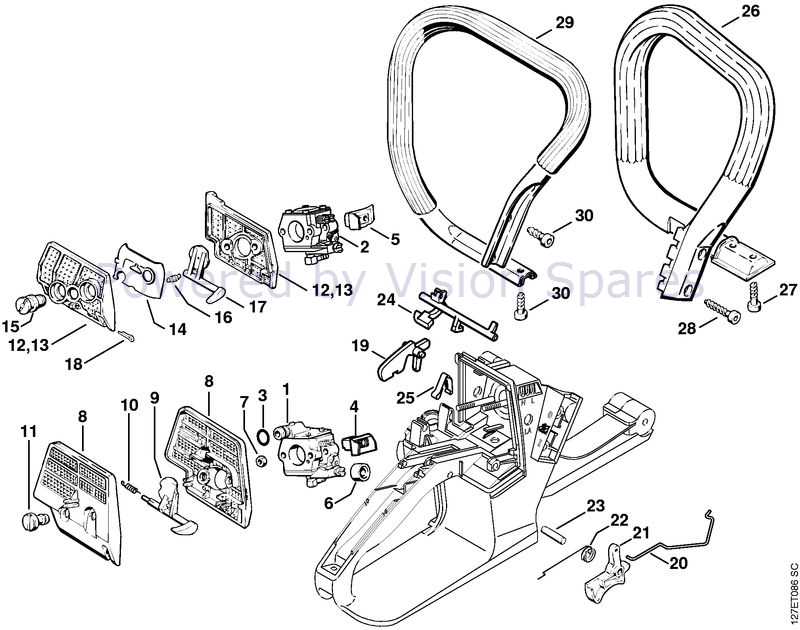

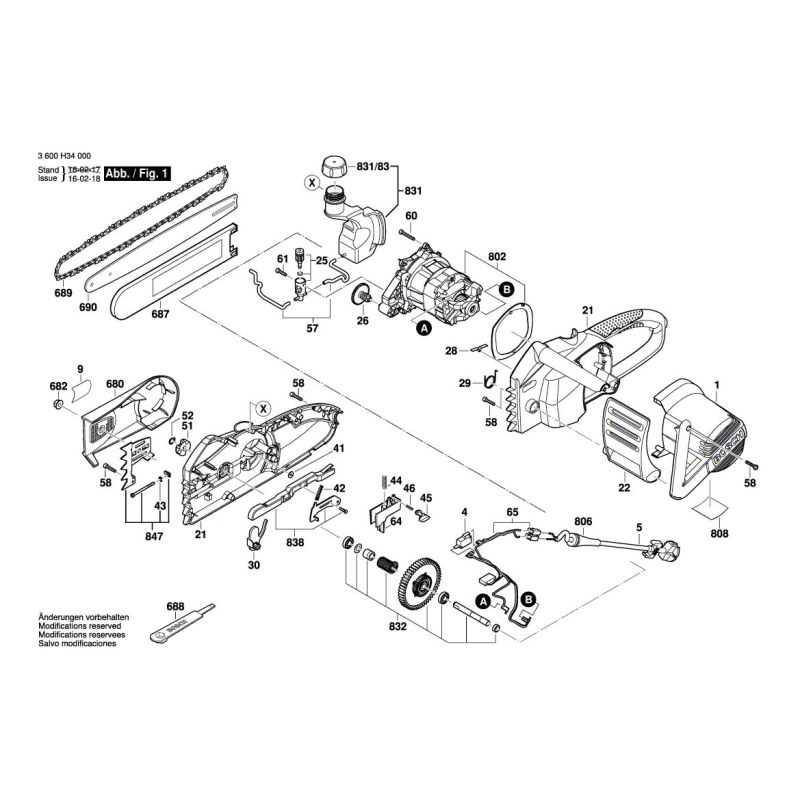

Key Components of Stihl 024

This section explores the essential elements of a popular chainsaw model, highlighting their significance and functionality. Understanding these key components is crucial for maintenance and optimal performance.

- Engine: The powerhouse that drives the entire system, ensuring efficient cutting performance.

- Bar: A critical part that supports the cutting chain, available in various lengths for different tasks.

- Chain: The cutting element that rotates around the bar, featuring sharp teeth designed for effective slicing through wood.

- Clutch: Engages and disengages the chain from the engine, allowing for safe operation and control.

- Air Filter: Protects the engine from dust and debris, maintaining optimal airflow and performance.

- Fuel System: Comprises the tank and lines, delivering the necessary mixture of fuel and oil for smooth operation.

Each component plays a vital role in ensuring the efficiency and reliability of the equipment, making regular checks and maintenance essential for longevity.

How to Read Parts Diagrams

Understanding technical illustrations is essential for anyone looking to repair or maintain machinery. These visuals provide a clear representation of the components involved, helping users identify and locate each piece within the overall structure. Mastering how to interpret these illustrations can significantly enhance your efficiency and accuracy during maintenance tasks.

Step 1: Begin by familiarizing yourself with the layout. Most visuals are organized systematically, often starting from the main assembly and branching out to individual components. Pay attention to the numbering or labeling system used, as this will guide you in referencing specific items.

Step 2: Next, examine the symbols and notations used in the illustration. Different shapes or lines may indicate various functions or connections. Understanding these markings will aid you in grasping how components interact with one another.

Step 3: Cross-reference the visual with any accompanying documentation. Manuals or guides often provide additional details that enhance your comprehension of the components’ roles and installation processes.

Step 4: Finally, practice makes perfect. The more you engage with these technical illustrations, the more proficient you will become at quickly locating and identifying the necessary items for your projects. With time, you’ll navigate these resources with confidence and ease.

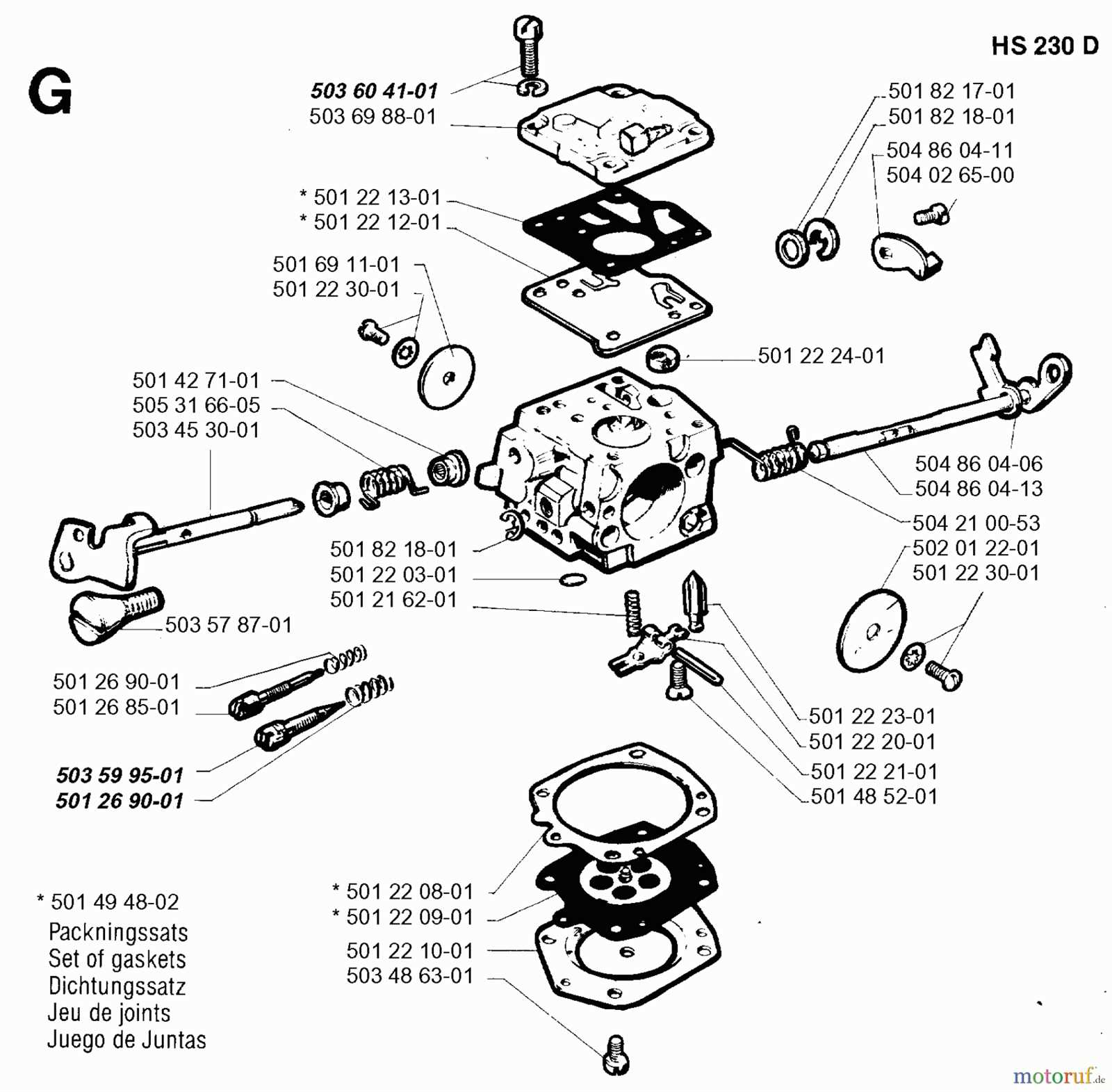

Common Issues and Solutions

When working with outdoor power tools, encountering challenges is quite common. Understanding frequent problems and their remedies can enhance performance and longevity, ensuring your equipment operates smoothly.

Engine Performance Issues

One of the most prevalent concerns is poor engine performance, often manifesting as difficulty starting or irregular idling. Solution: Check the air filter for clogs and clean or replace it as necessary. Ensure the fuel is fresh and the correct mixture is used. Additionally, inspect the spark plug for wear and replace it if needed.

Chain and Bar Malfunctions

Chain and bar issues can lead to inefficient cutting and safety hazards. Solution: Regularly inspect the chain tension and adjust it according to the manufacturer’s guidelines. Lubrication is crucial; ensure the oil reservoir is filled and the oiling system is functioning properly to prevent wear.

Where to Find Replacement Parts

Locating components for your outdoor equipment can be essential for maintaining its performance and longevity. Several avenues exist for sourcing these items, whether you’re looking for original manufacturer offerings or quality aftermarket alternatives.

One of the most reliable options is to visit authorized dealers, who often stock genuine components that ensure compatibility and reliability. Additionally, many retailers offer online services, providing convenience and a wide selection of products at your fingertips.

Another avenue to explore is specialized websites dedicated to outdoor equipment, which frequently feature extensive catalogs. These platforms may also provide user reviews and ratings, helping you make informed decisions about the quality of the components you choose.

Local repair shops can also be a valuable resource. Many technicians have access to a range of parts and can offer insights on the best options for your specific needs. Moreover, they can assist with installation, ensuring that everything fits correctly and functions as intended.

Lastly, online marketplaces can offer a variety of options, including both new and used components. While this can present opportunities for cost savings, it’s crucial to verify the seller’s reputation and the quality of the items before making a purchase.

Maintenance Tips for Stihl 024

Regular upkeep is essential for the longevity and optimal performance of your outdoor power equipment. By following a structured maintenance routine, you can ensure that your machine operates smoothly, reducing the likelihood of breakdowns and costly repairs.

Routine Maintenance Tasks

- Clean the Air Filter: A clean air filter ensures proper airflow and engine performance. Inspect and clean it regularly.

- Check the Spark Plug: A worn spark plug can lead to poor ignition. Replace it as needed to maintain efficiency.

- Inspect Fuel Lines: Ensure there are no cracks or leaks in the fuel lines to prevent fuel loss and ensure proper operation.

- Sharpen the Blade: Keeping the blade sharp allows for cleaner cuts and reduces strain on the engine.

- Examine the Chain: Regularly check the chain tension and lubrication for optimal cutting performance.

Seasonal Considerations

- Winter Storage: Before storing the equipment for winter, clean it thoroughly and empty the fuel tank to prevent degradation.

- Spring Check-Up: After a long winter, inspect all components for wear and replace any damaged parts to prepare for the busy season.

Implementing these maintenance tips will help extend the life of your equipment and ensure it performs at its best for years to come.

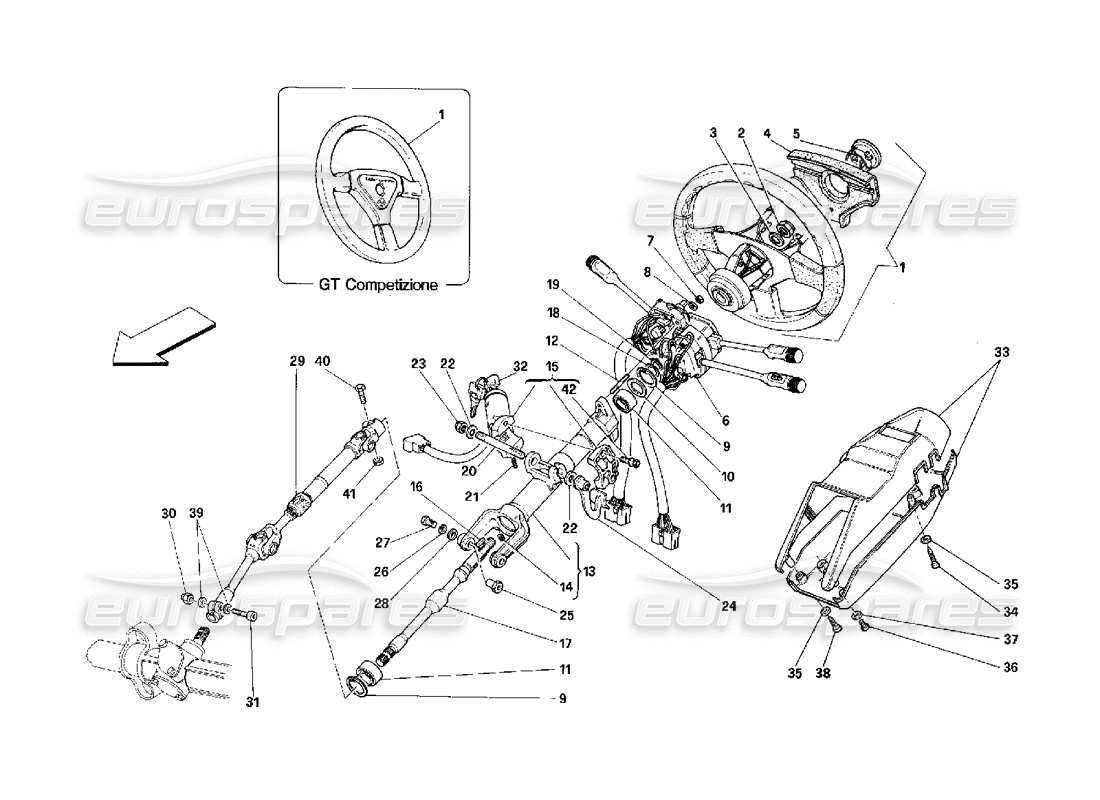

Upgrading Your Chain Saw

Enhancing your cutting tool can significantly improve its performance and longevity. By selecting the right components and accessories, you can optimize efficiency, increase safety, and tackle a wider range of tasks. This section explores key areas for enhancement and provides practical advice on how to implement these upgrades effectively.

Essential Upgrades to Consider

When looking to enhance your cutting equipment, consider the following key areas:

| Upgrade Type | Benefits |

|---|---|

| Bar and Chain | Improved cutting speed and efficiency. |

| Air Filter | Enhanced engine performance and longevity. |

| Sprocket | Better chain engagement and reduced wear. |

Installation Tips

Before installing new components, consult your user manual for compatibility. Ensure all parts are properly aligned and securely fastened to maximize performance. Regular maintenance checks will also help in identifying any additional areas for improvement, ensuring your tool remains in optimal condition.

Safety Precautions During Repairs

When undertaking maintenance on mechanical equipment, adhering to safety protocols is essential to ensure personal safety and prevent damage to the machinery. Awareness of potential hazards and the implementation of protective measures can significantly reduce the risk of accidents and injuries.

Essential Safety Gear

- Always wear safety goggles to protect your eyes from flying debris.

- Use gloves to shield your hands from sharp edges and hot components.

- Protective footwear is crucial; choose boots with non-slip soles to prevent falls.

- A hard hat can be beneficial in environments where overhead hazards exist.

Safe Work Environment

- Ensure your workspace is well-lit and organized to avoid tripping hazards.

- Keep flammable materials away from your repair area.

- Disconnect power sources before starting any work to prevent accidental starts.

- Utilize tools correctly and only for their intended purposes to avoid mishaps.

By following these guidelines, individuals can create a safer repair environment and minimize risks while working on their machinery.