Maintaining a powerful cutting tool requires a thorough understanding of its intricate components. Every piece plays a vital role in ensuring the machine operates efficiently and reliably. Familiarity with the internal structure is crucial for both repair and optimization.

By exploring the various elements of your cutting device, users can enhance performance and extend longevity. A clear representation of these components aids in identifying issues and streamlining maintenance. This comprehensive overview not only empowers users but also promotes safer operation.

Ultimately, having a well-organized visual reference serves as an invaluable resource. It allows both novices and seasoned operators to delve deeper into their equipment’s workings, ensuring that every aspect is understood and appreciated. Embracing this knowledge can lead to more effective use and enjoyment of your tool.

Understanding the Stihl MS311 Components

Grasping the various elements of a power tool is essential for effective operation and maintenance. Each part plays a crucial role in the overall performance and longevity of the equipment. This section delves into the fundamental components, elucidating their functions and significance in the tool’s functionality.

Key Functional Elements

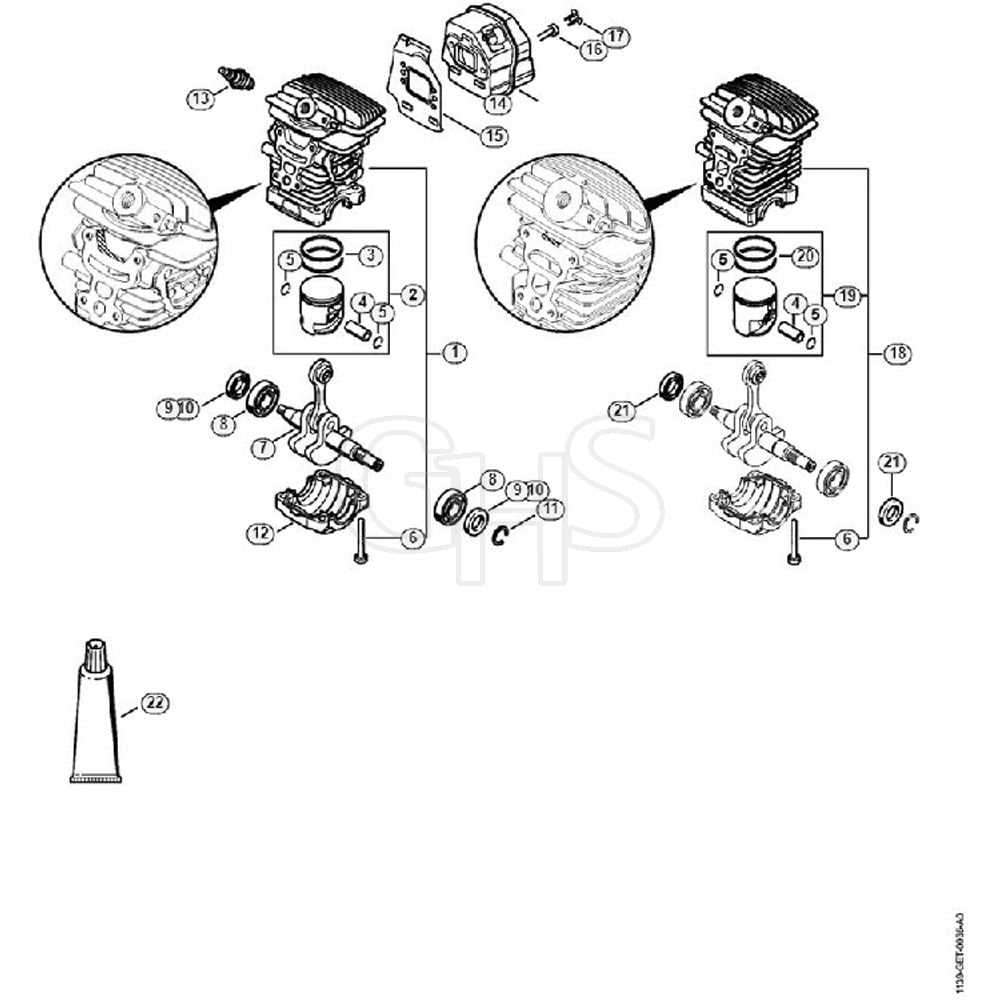

The core assembly of any cutting instrument includes vital components such as the engine, which powers the machine, and the cutting mechanism, responsible for the actual cutting action. Understanding how these key elements interact is pivotal. For instance, the ignition system initiates the engine, while the carburetor regulates the fuel-air mixture, directly influencing performance.

Maintenance and Troubleshooting

Regular upkeep is paramount for sustaining efficiency. Familiarity with the various components allows users to identify potential issues early. For example, a worn chain can lead to decreased cutting efficiency, while a clogged air filter may cause overheating. Recognizing these parts helps in addressing problems swiftly, ensuring optimal operation.

Key Parts of the MS311 Chainsaw

Understanding the essential components of a cutting machine is crucial for effective operation and maintenance. Each element plays a vital role in ensuring optimal performance and safety while using the tool.

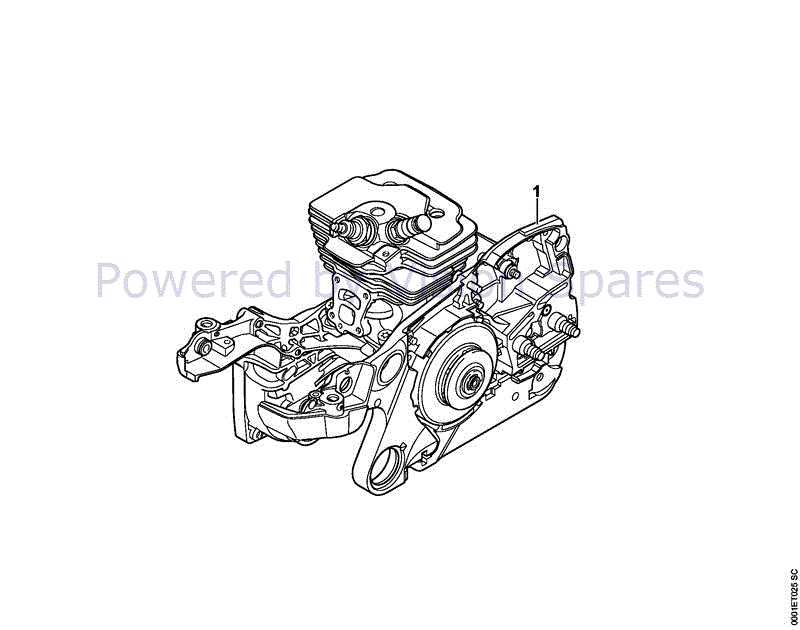

Engine and Power Source

The heart of the device is its engine, which provides the necessary power for cutting tasks. A well-functioning motor ensures smooth operation and efficiency during use.

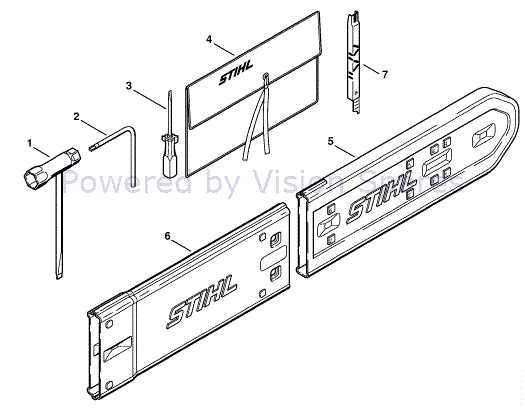

Cutting Mechanism

The cutting mechanism consists of the chain and bar, which are critical for executing precise cuts. Regular inspection and maintenance of these parts help extend their lifespan and improve overall effectiveness.

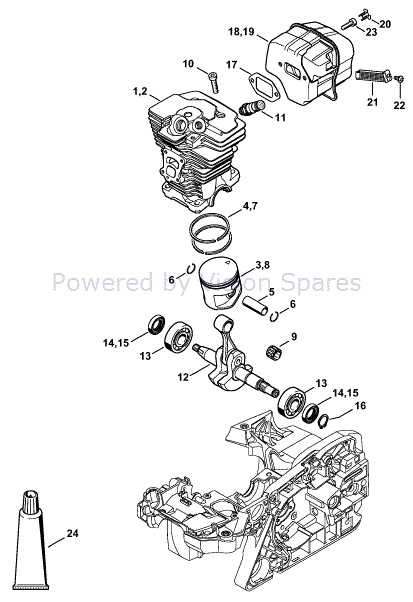

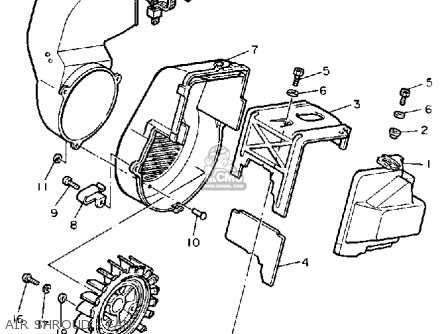

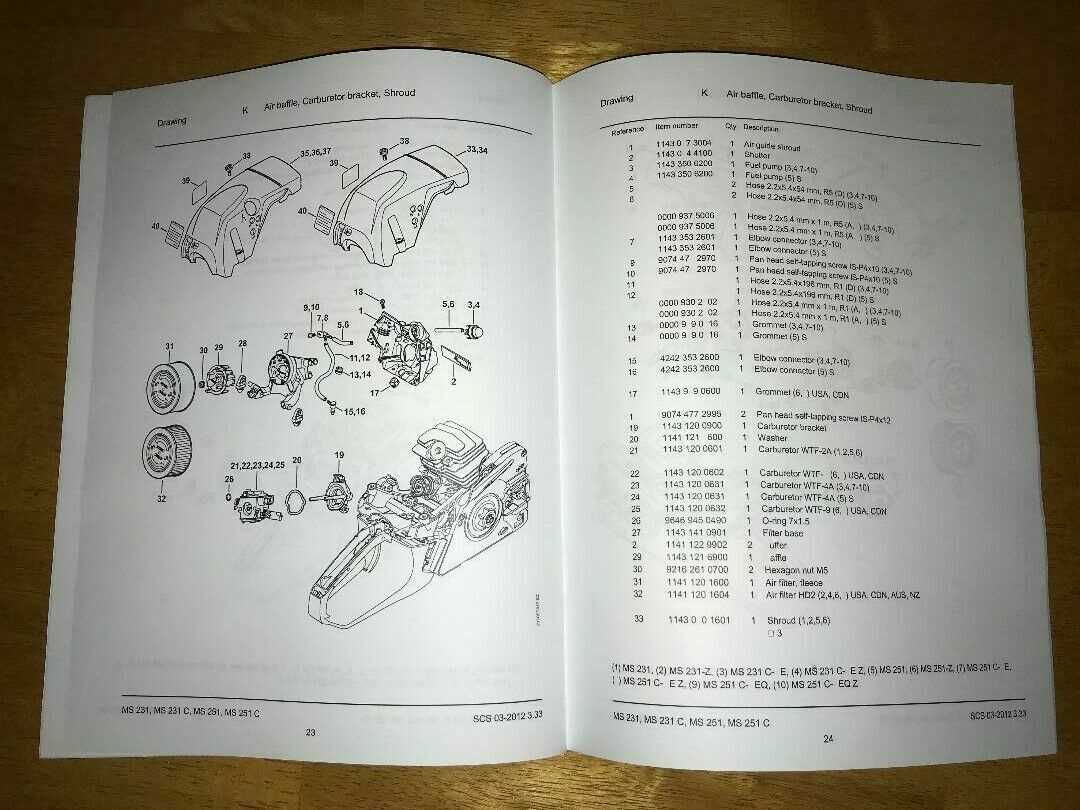

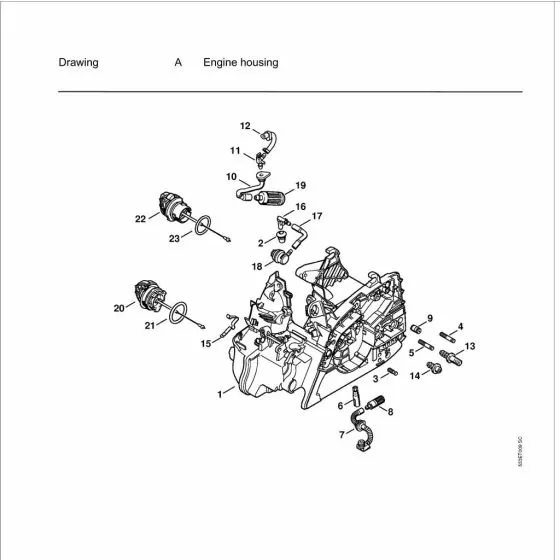

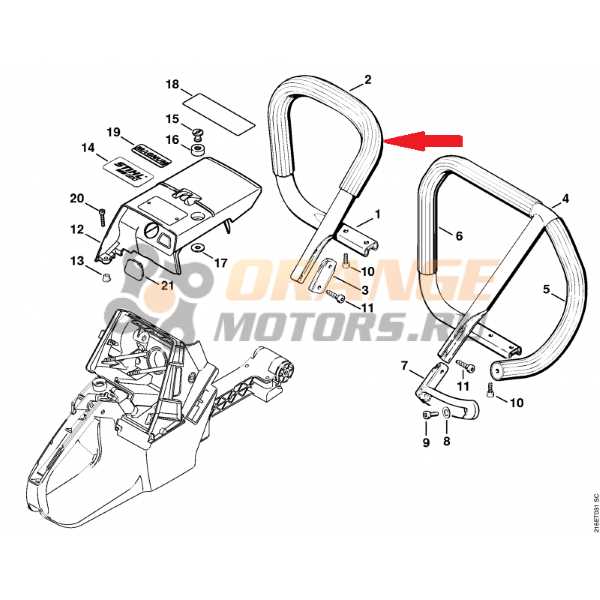

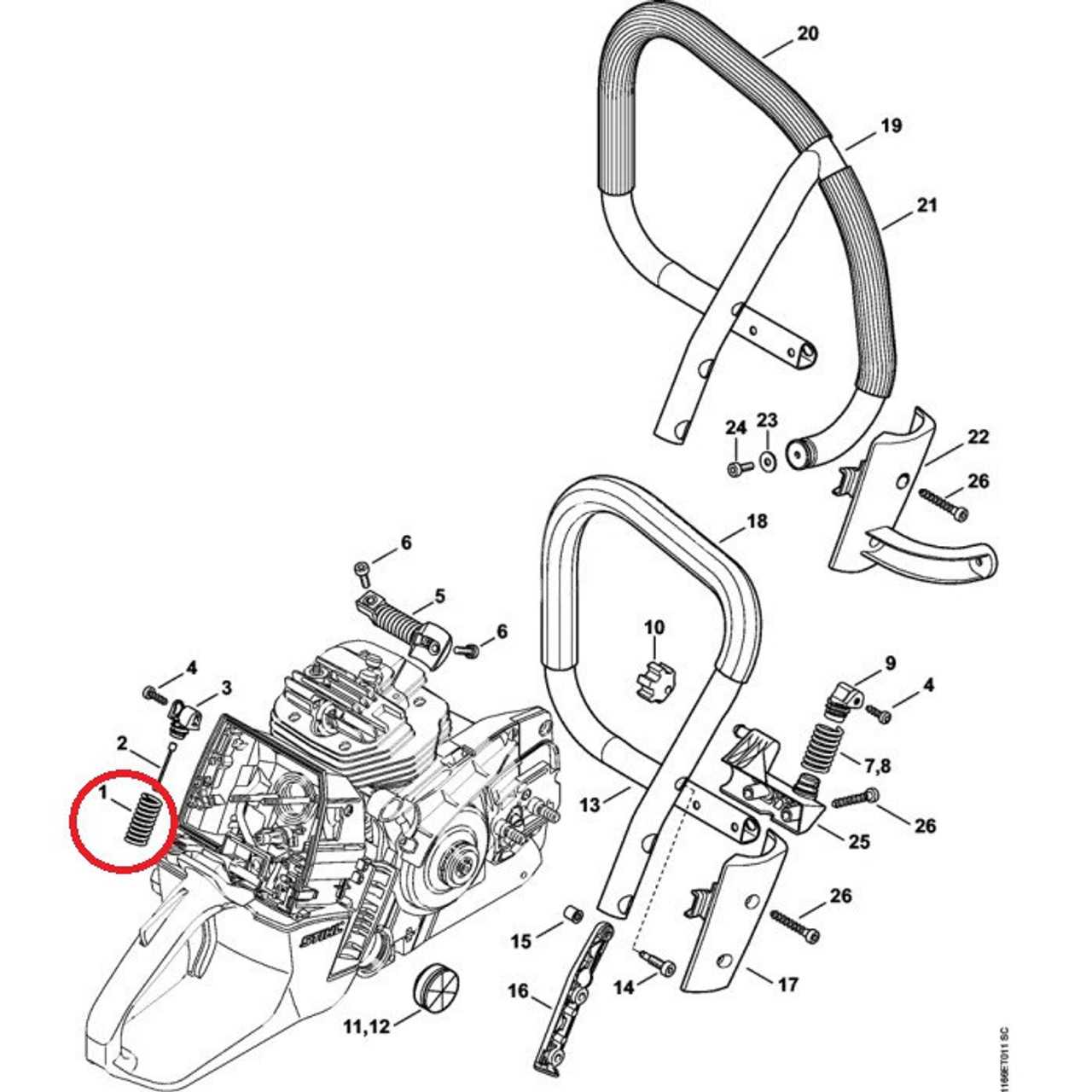

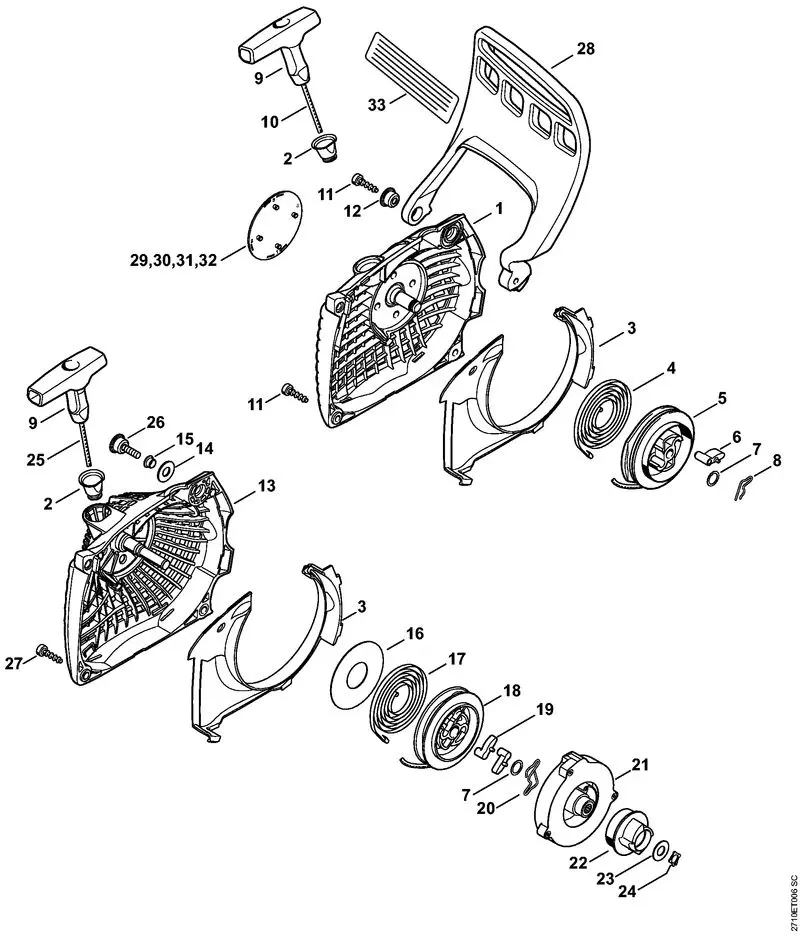

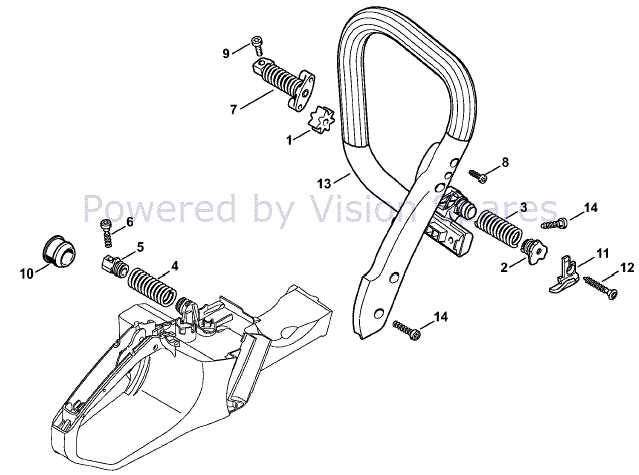

Visual Representation of MS311 Diagram

This section aims to provide a clear and informative visual guide that outlines the various components of a specific machinery model. Understanding the layout and arrangement of these elements can greatly enhance both maintenance and operational efficiency. A well-structured visual aid serves as a crucial reference for users, helping to simplify complex assembly processes.

Key Elements Illustrated

The following list highlights the primary components featured in the visual representation:

- Engine Assembly

- Fuel System

- Electrical Components

- Cutting Mechanism

- Safety Features

Benefits of a Visual Guide

Utilizing an illustrated reference offers several advantages:

- Enhances understanding of machinery structure.

- Facilitates easier identification of individual parts.

- Assists in troubleshooting and repairs.

- Supports effective training for new users.

Importance of Genuine Stihl Parts

Utilizing authentic components is crucial for maintaining the performance and longevity of any power equipment. When it comes to ensuring reliability and safety, the use of original elements cannot be overstated.

Quality Assurance: Genuine components are designed specifically for each machine, ensuring a perfect fit and optimal performance. This leads to enhanced efficiency and reduces the likelihood of malfunctions.

Safety: Original parts undergo rigorous testing to meet safety standards. Using counterfeit alternatives may compromise safety, posing risks during operation.

Longevity: Authentic components are made from high-quality materials, contributing to the durability of the equipment. This ultimately saves money in the long run by reducing the need for frequent replacements.

Warranty Protection: Using original components often ensures that warranties remain valid, protecting the investment made in the equipment. Unauthorized parts can void warranties, leading to unexpected repair costs.

In conclusion, choosing authentic components is essential for anyone serious about their machinery. It not only enhances performance but also safeguards against potential issues, making it the ultimate choice for maintenance and repairs.

Common Issues and Parts Replacement

When working with outdoor power equipment, understanding the frequent problems that may arise is crucial for maintaining optimal performance. Identifying these challenges early can prevent more significant malfunctions and extend the lifespan of your tool. Additionally, knowing which components may require replacement ensures a smoother repair process.

One common issue is starting difficulties. This may stem from a clogged fuel filter or a malfunctioning ignition system. Regular inspection and timely replacement of the fuel filter can often resolve these issues.

Another frequent problem is poor cutting performance. Dull blades or chains can hinder efficiency and lead to frustration. Keeping a sharp edge is essential; therefore, routine sharpening and replacing worn components is recommended.

Additionally, vibrations during operation can indicate loose or damaged parts. Ensuring that all screws and bolts are properly tightened and inspecting for any wear can help mitigate this issue. If vibrations persist, examining the mounts and isolators is advisable.

Lastly, overheating can occur due to inadequate lubrication or a dirty air filter. Regular maintenance, including cleaning filters and checking oil levels, can prevent overheating and keep the equipment functioning smoothly.

By being aware of these common issues and knowing which components to replace, users can enhance the reliability and efficiency of their machinery.

Maintenance Tips for MS311 Owners

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By following a few simple practices, you can enhance its efficiency and reduce the likelihood of unexpected issues.

Routine Inspections

Conducting frequent checks on various components helps identify wear and tear early. Focus on the air filter, spark plug, and fuel system to ensure everything operates smoothly.

Cleaning and Lubrication

Keeping your machine clean and well-lubricated is vital. Remove debris after each use and apply appropriate lubricants to moving parts to minimize friction and wear.

| Component | Maintenance Frequency | Notes |

|---|---|---|

| Air Filter | Every 10 hours | Clean or replace as needed |

| Spark Plug | Every 25 hours | Check for wear and replace |

| Fuel System | Every 50 hours | Inspect for leaks and clean |

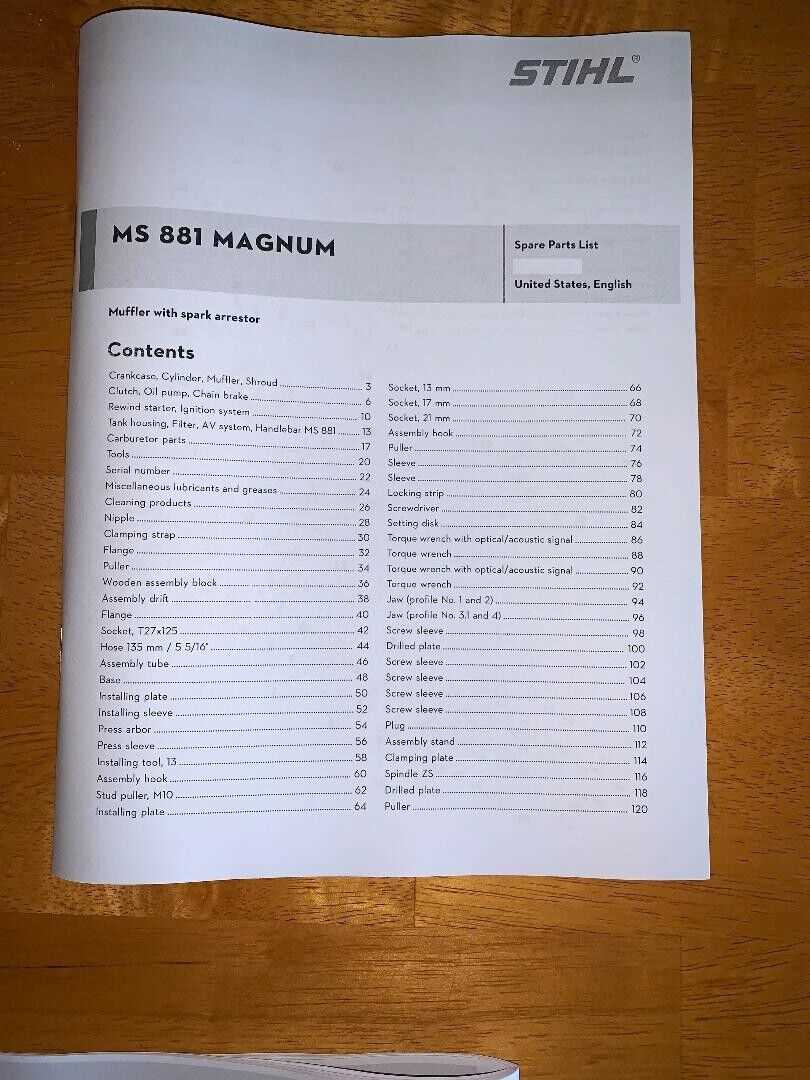

How to Access the Parts Diagram

Understanding the components of your equipment is essential for maintenance and repairs. Accessing the visual representation of these elements can significantly enhance your ability to troubleshoot and service your tool effectively.

Follow these steps to locate the necessary illustrations:

- Visit the official website of the manufacturer.

- Navigate to the support or service section.

- Look for a link related to documentation or resources.

- Use the search function to find your specific model.

- Download or view the visual guide directly from the site.

Alternatively, consider consulting local dealers or repair shops for physical copies or further assistance.

Troubleshooting Guide

This section provides essential steps for diagnosing common issues encountered with your equipment. Understanding these problems and their solutions can enhance performance and longevity, ensuring efficient operation during use.

| Issue | Possible Cause | Solution |

|---|---|---|

| Engine won’t start | Fuel blockage | Check fuel lines and replace as needed. |

| Loss of power | Dirty air filter | Clean or replace the air filter. |

| Excessive smoke | Incorrect fuel mixture | Adjust fuel mixture according to specifications. |

| Chain not moving | Chain brake engaged | Release the chain brake before use. |

Upgrading Components for Better Performance

Enhancing the functionality of your equipment can significantly boost its efficiency and lifespan. By focusing on key elements, you can achieve smoother operation and improved power output. This section explores the advantages of upgrading various components to unlock the full potential of your machinery.

One of the most impactful changes you can make is to upgrade the air filtration system. A high-performance filter allows for better airflow, which can lead to improved combustion and overall power. Investing in quality filters ensures that your engine runs cleaner and lasts longer.

Another crucial area for enhancement is the fuel system. Using premium injectors can enhance fuel delivery, resulting in a more efficient burn. Optimal fuel management not only increases performance but also contributes to better fuel economy.

Additionally, consider enhancing the ignition system. A high-quality spark plug can lead to more reliable starts and improved throttle response. Consistent ignition timing ensures that power is maximized when you need it most.

Lastly, upgrading the exhaust system can lead to reduced back pressure and improved engine performance. A free-flowing exhaust allows for quicker expulsion of gases, which enhances overall efficiency. These upgrades combined can truly transform your equipment into a powerhouse.