In the world of outdoor power equipment, comprehending the intricacies of machinery is crucial for effective maintenance and repair. Whether you’re a seasoned technician or a DIY enthusiast, familiarizing yourself with the intricate layouts and assembly of various models can significantly enhance your operational efficiency. The availability of detailed visual aids can simplify this process, providing clarity and insight into the construction of your equipment.

Exploring these visual resources not only aids in identifying individual elements but also promotes a deeper understanding of how each part contributes to the overall functionality. With a comprehensive overview, users can troubleshoot issues more effectively, ensuring that every component functions harmoniously. This foundational knowledge empowers individuals to tackle repairs with confidence and precision.

Additionally, having access to clear and organized illustrations can streamline the process of sourcing replacements when necessary. By recognizing the specific components that need attention, users can save time and resources, making the experience of upkeep more manageable. In essence, these visual guides serve as essential tools for anyone looking to maintain the longevity and performance of their equipment.

Understanding Stihl 009L Components

The intricate design of outdoor power equipment relies on a variety of essential elements that work together to ensure optimal performance. Each component plays a specific role, contributing to the overall functionality and efficiency of the machine. By familiarizing oneself with these elements, users can better appreciate how their equipment operates and can troubleshoot issues more effectively.

Central to the functionality of this equipment is the engine, which powers the entire system. It is accompanied by a fuel delivery mechanism that ensures a steady supply of energy, enhancing performance during operation. Additionally, the ignition system is crucial for starting and maintaining engine operation, while the exhaust system efficiently expels byproducts generated during combustion.

Another vital set of components includes the cutting mechanism, which is designed for precision and effectiveness. The quality and sharpness of the cutting blade directly influence the equipment’s performance, making maintenance of this element essential for optimal results. Furthermore, the housing and frame provide structural integrity, supporting the various parts while protecting them from external damage.

Lastly, user-friendly features, such as controls and safety mechanisms, are integrated to enhance usability and ensure the operator’s safety during use. Understanding each of these components allows users to maximize the capabilities of their equipment and maintain it for long-lasting performance.

Benefits of Using Official Diagrams

Utilizing authentic visual guides for machinery and tools offers numerous advantages that enhance both maintenance and repair processes. These resources provide accurate representations, ensuring that users can identify components and understand their functions with ease. This clarity fosters efficient handling, ultimately extending the lifespan of equipment.

Enhanced Accuracy

Official resources are designed with precision in mind. By relying on these visuals, users can:

- Minimize errors during assembly or disassembly.

- Ensure compatibility when sourcing replacement elements.

- Follow manufacturer-recommended procedures effectively.

Time and Cost Efficiency

Investing time in studying authentic visuals can lead to significant savings in both time and expenses. Key benefits include:

- Reducing the likelihood of costly mistakes.

- Streamlining the repair process, thus minimizing downtime.

- Providing a clear roadmap for troubleshooting issues.

How to Access PDF Diagrams

Accessing visual references for machinery can significantly enhance your understanding of its components and assembly. These resources provide detailed insights, allowing users to efficiently navigate repair or maintenance tasks. Below are methods to find and utilize these invaluable materials.

- Official Websites: Start by visiting the manufacturer’s official website. They often have a dedicated section for documentation where you can search for your specific model.

- Online Forums: Engage with communities that focus on machinery. Users often share links or files that may not be readily available elsewhere.

- Retailer Resources: Check websites of authorized dealers. They frequently provide access to manuals and schematics for the products they sell.

- Search Engines: Utilize specific search queries. Include your model and terms like “manual,” “schematic,” or “technical guide” to find relevant documents.

Once you locate the desired document, ensure you have a PDF reader installed to view it properly. Familiarizing yourself with the layout of these resources will help you quickly find the information you need for efficient repairs.

Common Parts for Stihl 009L

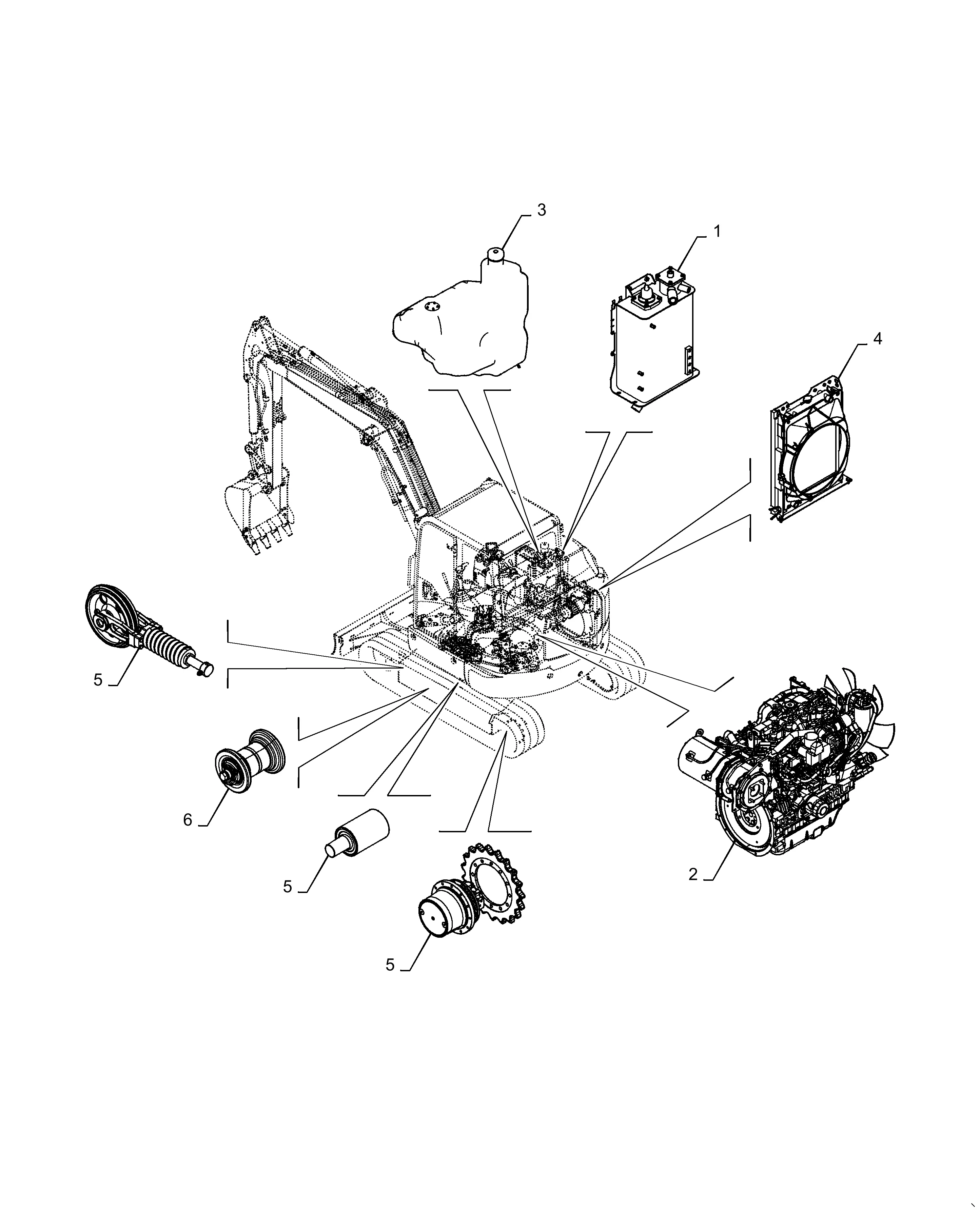

This section explores the essential components that are frequently utilized in the maintenance and repair of a popular chainsaw model. Understanding these elements is crucial for anyone looking to enhance performance or address issues effectively.

Key Components

Familiarity with specific elements can significantly ease the troubleshooting process and help maintain optimal functionality. Below are some of the vital components:

| Component | Description |

|---|---|

| Fuel Tank | Stores fuel needed for operation, ensuring the engine runs smoothly. |

| Air Filter | Prevents debris from entering the engine, maintaining efficiency and longevity. |

| Chain Brake | A safety feature that stops the chain quickly in emergencies, protecting the user. |

| Bar and Chain | Essential for cutting, these components need regular inspection and maintenance. |

Maintenance Considerations

Regular checks and replacements of these components are vital to ensure reliability and safety during use. Keeping an eye on wear and tear can prevent larger issues down the line.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to effectively troubleshoot and fix common issues with your equipment. By following these steps, you will enhance your understanding and skills, ensuring a smoother repair process.

-

Preparation:

- Gather necessary tools, such as screwdrivers, wrenches, and cleaning supplies.

- Ensure a clean and well-lit workspace for better visibility.

- Review safety precautions and wear appropriate protective gear.

-

Initial Assessment:

- Identify the symptoms and determine the possible causes of the malfunction.

- Consult the user manual for specific troubleshooting tips related to your model.

-

Dismantling the Equipment:

- Carefully remove outer casing and components as needed.

- Keep track of screws and small parts to avoid loss.

- Take notes or pictures during disassembly to aid in reassembly.

-

Inspection:

- Examine internal parts for wear, damage, or blockages.

- Clean any debris or buildup from critical areas.

-

Replacement and Repair:

- Replace worn or damaged components with new ones.

- Perform any necessary adjustments to ensure optimal performance.

-

Reassembly:

- Follow your notes or pictures to reassemble the equipment accurately.

- Ensure all screws and parts are securely fastened.

-

Testing:

- Power on the device to check for proper operation.

- Monitor for any unusual noises or behaviors during use.

-

Final Checks:

- Review all connections and components for stability.

- Store tools and clean the workspace to conclude the process.

By following these steps diligently, you will be able to tackle most repairs confidently, ensuring your equipment remains in optimal working condition.

Maintenance Tips for Longevity

Regular upkeep is essential for maximizing the lifespan and performance of any equipment. Implementing a few simple strategies can ensure that your tools remain reliable and efficient over time. This section will explore key practices that contribute to maintaining optimal functionality and preventing premature wear.

Routine Cleaning

Keeping your machinery clean is fundamental. After each use, remove debris and dirt, especially from air filters and cooling vents. This helps prevent overheating and ensures smooth operation. Utilize appropriate cleaning agents to avoid damaging sensitive components.

Regular Inspections

Conducting periodic inspections is crucial for identifying potential issues before they escalate. Check for signs of wear, loose connections, or damaged parts. Addressing these concerns promptly can save you from costly repairs and enhance the longevity of your equipment.

Where to Find Replacement Parts

Locating suitable components for your equipment can significantly enhance its performance and longevity. Various resources are available for sourcing high-quality items to ensure your machinery operates effectively.

| Source | Description |

|---|---|

| Authorized Dealers | Visit local retailers that specialize in equipment; they often stock genuine items and can provide expert advice. |

| Online Marketplaces | Websites such as eBay or Amazon offer a wide range of components from various sellers, allowing for comparison and convenience. |

| Manufacturer Websites | Check the official site for direct access to their inventory, which often includes detailed specifications and ordering options. |

| Salvage Yards | Local salvage yards may have used items at reduced prices, providing a cost-effective alternative for budget-conscious individuals. |

Comparing Stihl Models and Parts

When examining various models of outdoor power equipment, it is essential to consider their design, components, and functionality. Each model caters to specific tasks and user preferences, making it crucial to understand the distinctions and similarities among them. This comparison helps enthusiasts and professionals alike to make informed decisions based on their needs.

Here are some key factors to consider when comparing different models:

- Engine Type: Variations in engine design can affect power output and fuel efficiency.

- Weight: The weight of the unit impacts portability and ease of use, especially for extended tasks.

- Durability: Different materials and construction techniques contribute to the longevity and reliability of the equipment.

- User-Friendly Features: Considerations like vibration reduction, adjustable handles, and easy-start mechanisms can enhance the user experience.

- Maintenance Requirements: Some models may have simpler maintenance protocols, reducing downtime and overall cost of ownership.

In addition to these factors, examining the specific components within each model provides deeper insights into their functionality:

- Fuel System: Different configurations influence fuel delivery and efficiency.

- Air Filtration: Various systems can improve engine performance and extend operational life.

- Cutting Mechanism: The type and quality of cutting tools impact effectiveness and precision in various tasks.

- Safety Features: Advanced safety mechanisms can prevent accidents and enhance user confidence.

By thoroughly analyzing these aspects, users can determine which model aligns best with their specific tasks and preferences, ensuring optimal performance and satisfaction.