When maintaining or repairing equipment, having a clear understanding of how its internal elements are structured is essential. The proper arrangement of various mechanical and electrical units not only ensures smooth operation but also helps in troubleshooting any potential issues. Understanding how each component interacts with others is key to keeping your machine running efficiently.

This guide provides detailed insights into the key mechanisms and assemblies that make up a compact engine model. From the primary power-generating systems to the smallest functional details, we’ll explore how these elements work together, offering clarity on their arrangement and specific roles within the larger system.

Whether you’re conducting routine checks or tackling a repair project, knowing the layout and function of individual elements will simplify your task, saving time and reducing effort. In the following sections, we’ll dive deep into each segment of this machine to help you navigate through its various configurations.

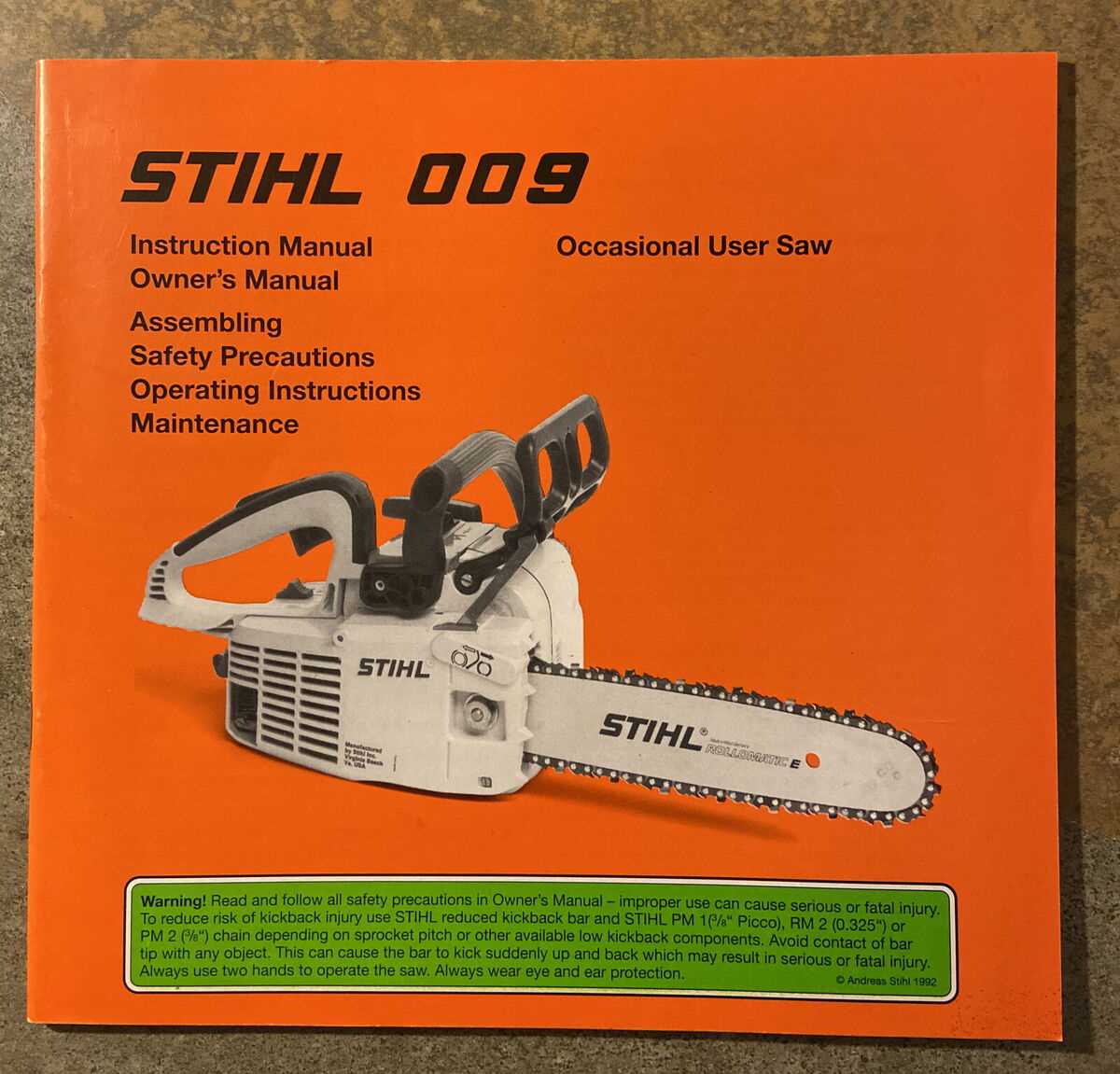

Exploring the Components of the Stihl 009L

Understanding the individual elements that make up this chainsaw model is essential for both maintenance and repair. Each component plays a specific role in ensuring smooth operation and longevity. Below is a breakdown of the primary mechanical and functional elements that contribute to the overall performance of the device.

- Engine Assembly: The core of the unit, driving the cutting mechanism through efficient fuel combustion.

- Cutting System: Comprising the chain and guide bar, this system ensures precise and powerful cuts through wood and other materials.

- Fuel and Oil Systems: A combination of tanks and valves that manage the flow of fuel and lubrication, ensuring continuous and effective operation.

- Control Mechanism: Handles and triggers that provide the user with full control over

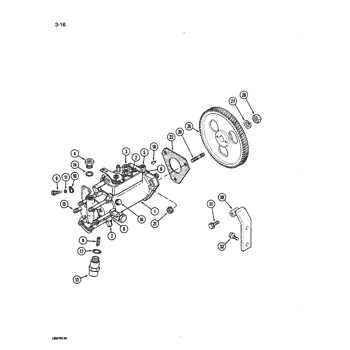

Key Features of the Stihl 009L Engine

This model’s engine is known for its durability, efficiency, and compact design. It has been engineered to meet the demands of various tasks, offering reliable performance across a range of operating conditions. Below, we highlight the key characteristics that make this engine stand out, particularly in terms of functionality and ease of maintenance.

Efficient Power Delivery

The internal combustion mechanism is optimized to provide a balance between power output and fuel consumption. Its performance allows for smooth operation even during prolonged use, with minimal vibration and consistent power delivery.

Maintenance and Longevity

One of the notable advantages is the ease of maintenance. Key components are designed for easy access, allowing users to perform routine upkeep without specialized tools. This focus on user-friendly design contributes to the overall longevity of the engine.

Feature Benefit Compact Design Lightweight and easy to maneuver Fuel and Oil System Layout Overview

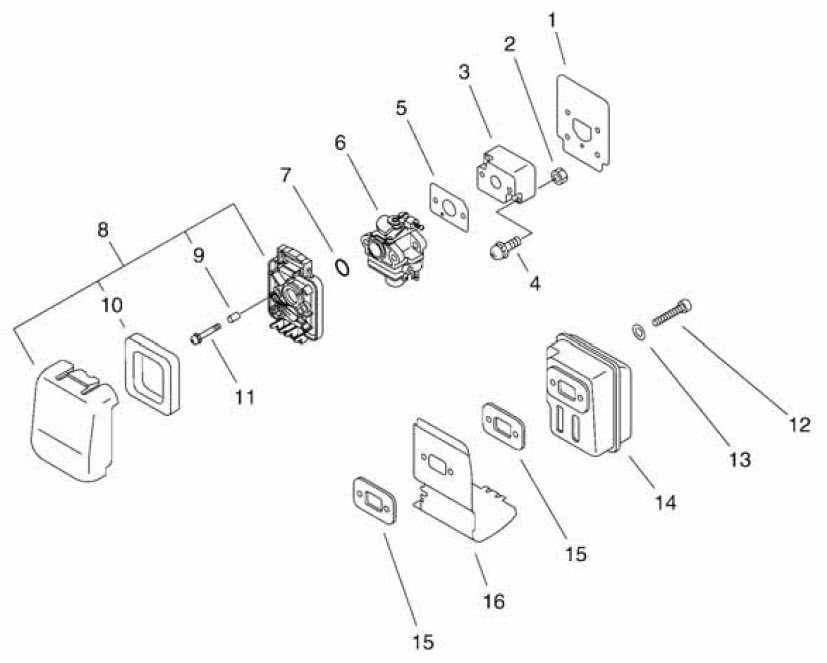

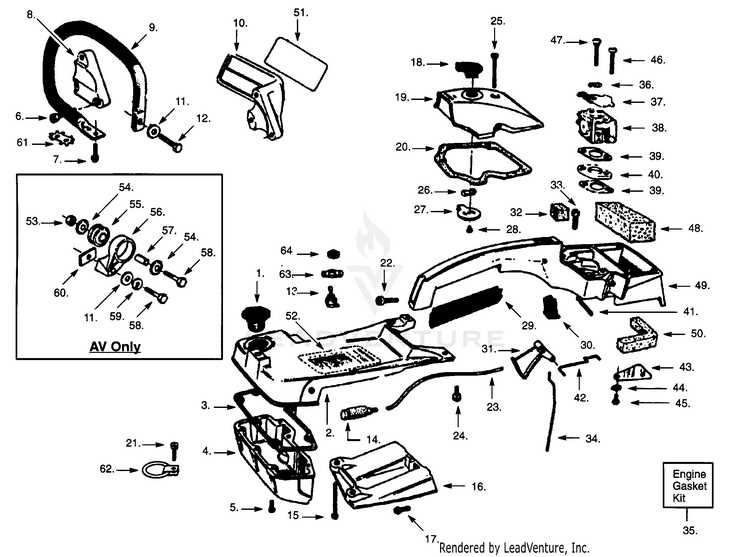

In this section, we will explore the essential components and pathways responsible for handling the engine’s energy source and lubrication. These systems are critical for ensuring smooth operation and longevity, and they function in tandem to maintain efficient performance.

- The energy supply pathway starts with a container that stores the combustible liquid. This container is connected to a conduit system, leading the fluid to the mixing unit.

- A control mechanism regulates the flow, ensuring the right balance between air and fuel for optimal combustion.

- Parallel to this, the lubrication mechanism delivers protective fluid to critical moving parts, reducing wear and extending the machinery’s lifespan.

- The distribution of the lubricating fluid is managed through a separate channel system, with specific valves maintaining consistent flow and pressure.

- Both systems are supported by filters, preventing any unwanted particles from interfering with the smooth operation of the engine.

Understanding how these sys

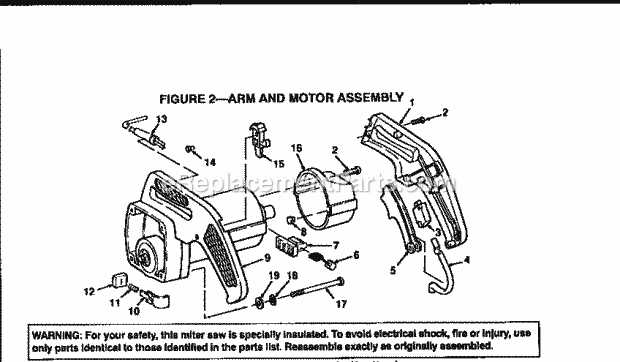

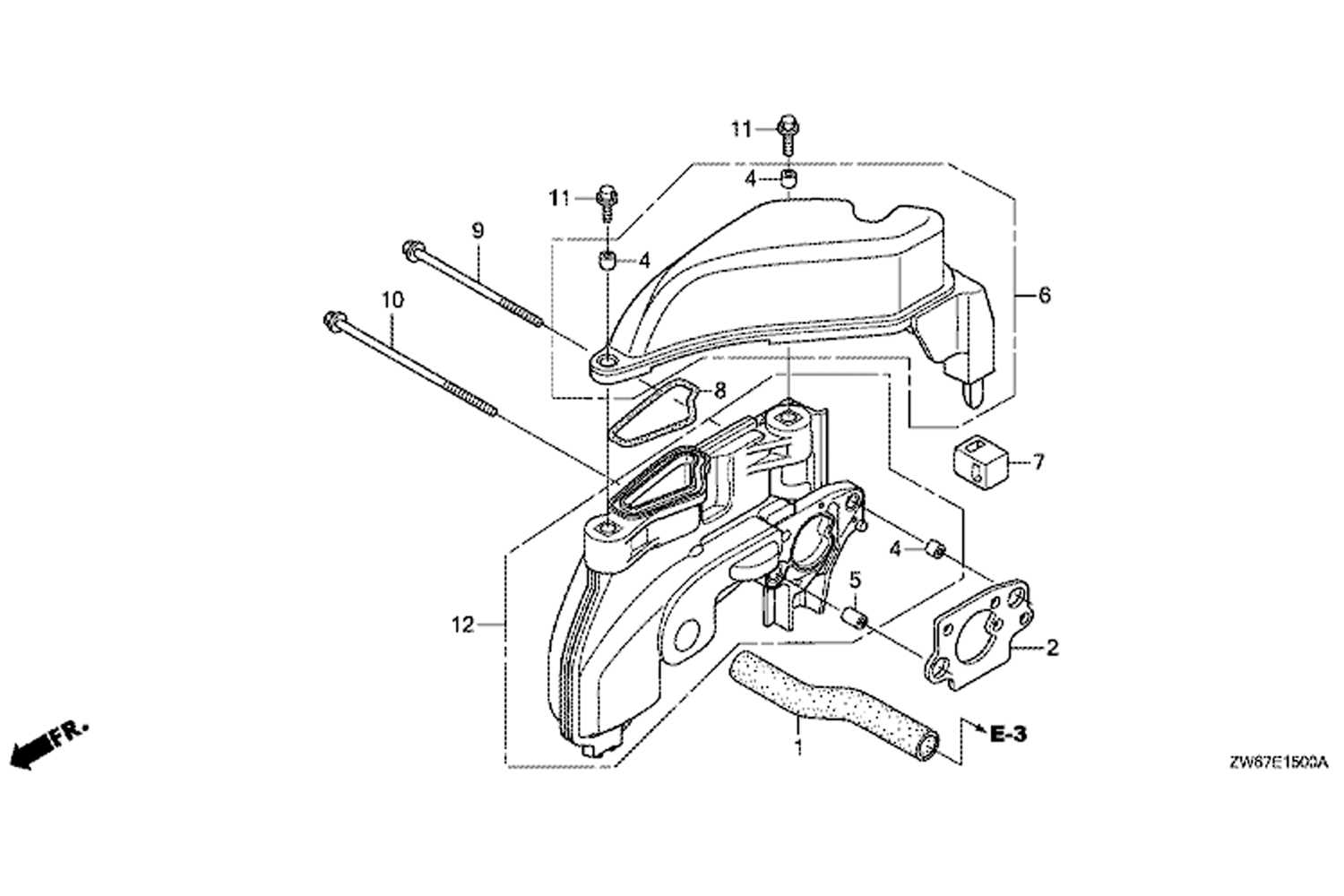

Understanding the Ignition System in Detail

The ignition mechanism plays a crucial role in ensuring the efficient start-up and continuous operation of an engine. It serves as the critical link between fuel delivery and the combustion process, allowing the engine to run smoothly. A well-maintained ignition ensures reliability and reduces the risk of malfunctions during operation.

At the core of this system, several key components interact to generate the necessary spark that ignites the fuel mixture. These components are synchronized to work in unison, enabling proper engine function.

Component Function Spark Generator Produces the spark needed to ignite the fuel-air mixture. Timing Mechanism Brake Assembly and Safety Mechanisms

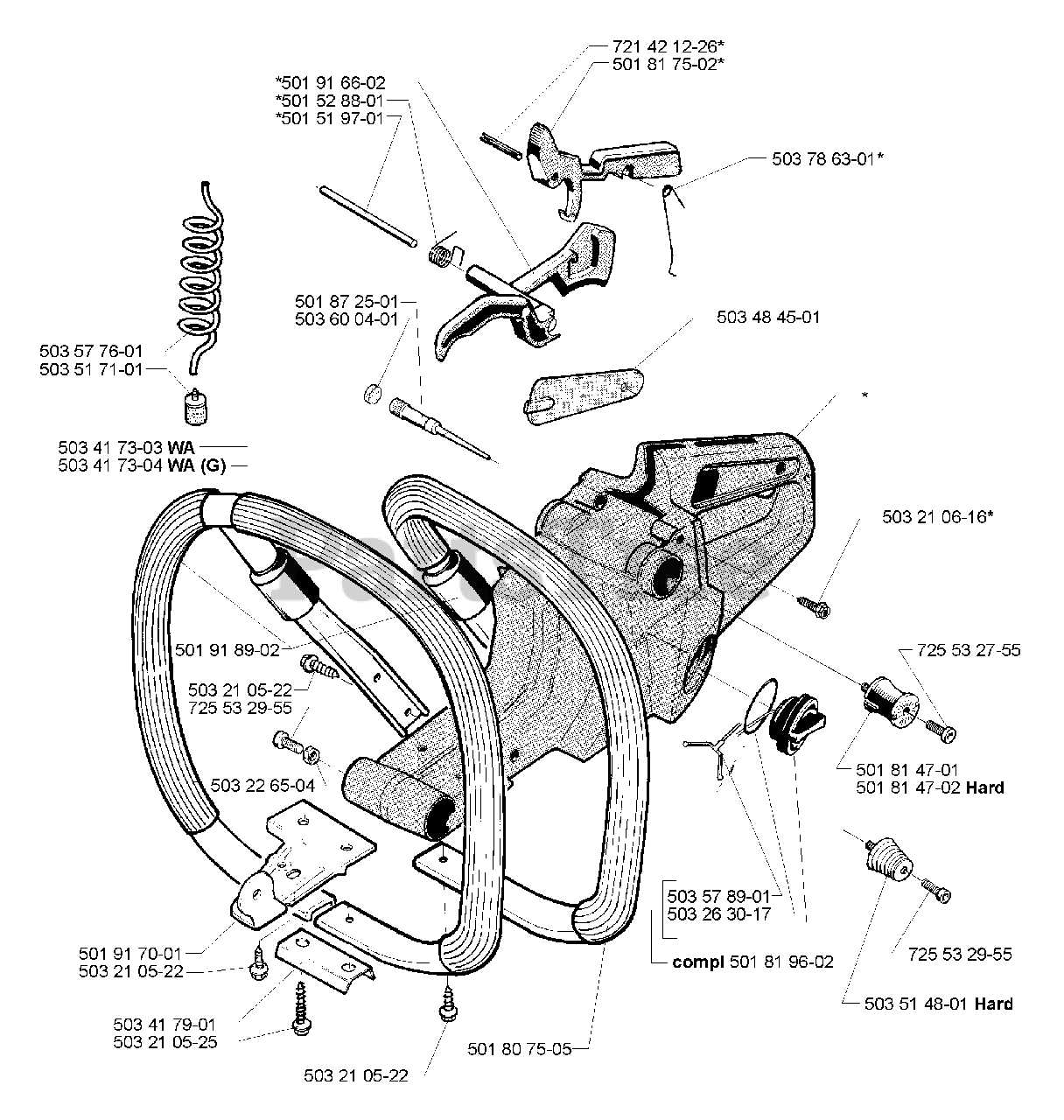

The braking system plays a crucial role in ensuring operator protection and smooth operation. The components responsible for this feature are designed to quickly halt movement, preventing any potential hazards. In this section, we will explore how the braking system functions and the importance of its maintenance.

Key Components and Functionality

The main elements of the braking mechanism are engineered to engage rapidly upon activation. By applying pressure to the appropriate parts, the device is brought to a stop within seconds. This not only enhances operational control but also ensures an additional layer of protection.

Safety Features and Maintenance

Regular inspection of the safety mechanisms is essential. These features are designed to prevent malfunctions and ensure the machine stops as required. Ensuring the components are clean, free of debris, and properly adjusted will help maintain optimal performance and reduce the risk of accidents.

Chain Tensioning Mechanism and Adjustments

Ensuring optimal performance of your equipment involves keeping the cutting element properly aligned and adjusted. A well-calibrated setup not only extends the lifespan of the device but also improves its overall efficiency during operation. The system that maintains the correct balance plays a crucial role in preventing issues such as excessive wear or operational delays.

Components Involved in the Process

The system responsible for maintaining the right tension includes several key elements. These components work together to ensure the cutting element is neither too loose nor too tight. Proper engagement of each piece allows for smoother and safer operation.

Step-by-Step Adjustment Procedure

To achieve the ideal balance, it’s essential to follow a precise adjustment process. Start by loosening the fasteners that hold the guide in place. Gradually turn the control mechanism until the cutting component is properly positioned. Once everything is in place, secure the fasteners to lock the setting, ensuring the system remains stable during

Guide Bar and Chain Compatibility

The relationship between the guide bar and the cutting chain is essential for smooth operation and performance. Ensuring that the dimensions and design of both components align perfectly will not only improve efficiency but also prolong the lifespan of the equipment. The correct pairing of these elements enhances safety and minimizes wear during use.

Key Factors for Selection

- Length Matching: It is crucial that the length of the bar corresponds with the size of the chain to ensure proper tensioning and smooth cutting action.

- Drive Link Compatibility: The chain’s drive links must fit perfectly within the groove of the guide bar to allow proper movement and reduce the risk of jamming or overheating.

- Pitch and Gauge: Matching the chain’s pitch and gauge with the guide bar ensures precision and optimal performance.

Common Compatibility Concerns

- Improper pairing of components may lead to uneven cutting, increased vibration, and potential safety hazards.

- Wear and tear on both the bar and chain can increase drastically if the specifications do not align.

- Regular mainten

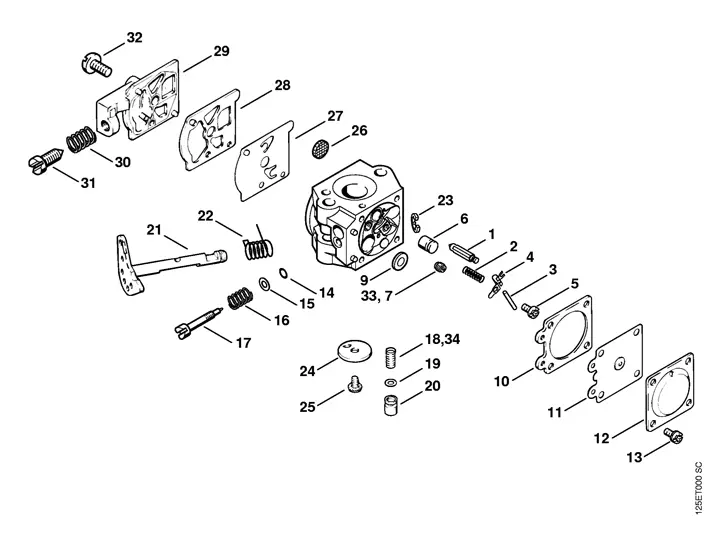

Carburetor Function and Tuning for Efficiency

The carburetor plays a crucial role in the operation of small engines, blending air and fuel to create a combustible mixture that powers the engine. Understanding its function is essential for optimizing performance and ensuring the engine runs smoothly. Proper tuning can significantly enhance efficiency, reduce emissions, and extend the lifespan of the engine.

At its core, the device works by using a venturi system, where airflow creates a vacuum that draws fuel into the airstream. This process ensures that the right amount of fuel is mixed with air, enabling effective combustion. An improperly tuned mechanism can lead to a range of issues, including poor performance, increased fuel consumption, and higher emissions.

Tuning involves adjusting several parameters, including the air-fuel mixture, idle speed, and throttle response. Fine-tuning these settings allows the engine to operate at its peak efficiency under varying load conditions. Regular maintenance, including cleaning and inspecting the components, is also vital to keep the mechanism functioning optimally.

In summary, a well-functioning carburetor is essential for achieving maximum efficiency in small engines. By understanding its operation and regularly fine-tuning it, users can ensure their equipment runs smoothly and reliably, delivering the best possible performance.

Maintenance Tips for the Stihl 009L Chainsaw

Proper upkeep is essential for ensuring optimal performance and longevity of your cutting tool. Regular maintenance not only enhances efficiency but also minimizes the risk of unexpected breakdowns. Here are some essential practices to keep your chainsaw running smoothly.

Regular Cleaning

Cleaning your equipment after each use helps prevent the buildup of debris and residues. Follow these steps:

- Remove sawdust and wood chips from the casing.

- Clean the air filter to ensure proper airflow.

- Inspect and clear the guide bar and chain from any obstruction.

Inspecting Components

Routine checks on various components can identify issues early on:

- Examine the chain tension and adjust as necessary to avoid wear.

- Check the condition of the spark plug and replace it if worn.

- Ensure that all screws and bolts are secure to prevent parts from loosening during operation.

By following these maintenance tips, you can enhance the efficiency and lifespan of your cutting tool, ensuring reliable performance when you need it most.