Maintaining the functionality of any riding lawn mower requires a keen understanding of its various elements. A critical section involves those mechanisms responsible for ensuring smooth navigation and overall control. Without these, operating such machinery can become not only difficult but potentially unsafe. Ensuring proper care and understanding of how these systems work is key to extending the lifespan of the machine.

Over time, specific parts may wear down or require adjustment. Knowing which components contribute to precise movement and control will help owners and technicians alike to diagnose potential issues. Familiarity with these elements allows for quicker repairs and more effective maintenance routines, which, in turn, keeps the equipment running smoothly throughout the seasons.

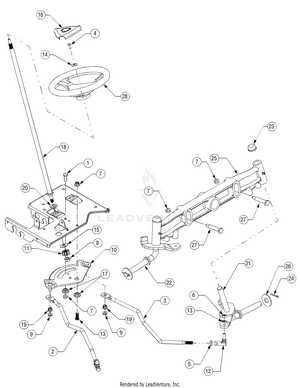

Overview of the Cub Cadet LT1045 Steering System

Maintaining effective maneuverability is crucial for any lawn maintenance machine. The handling assembly plays a vital role in ensuring smooth directional control, allowing the operator to navigate with precision around obstacles and uneven terrain. The entire mechanism, built to withstand wear and tear, provides reliable performance, ensuring that the vehicle responds accurately to input from the operator.

Key components of the control system are designed to work in unison, creating a cohesive structure that efficiently directs the movement of the machine. Proper upkeep of these elements ensures long-lasting performance, reducing the need for frequent adjustments and repairs. Understanding the functionality of each piece allows for easier maintenance and troubleshooting.

Key Components of the LT1045 Steering Assembly

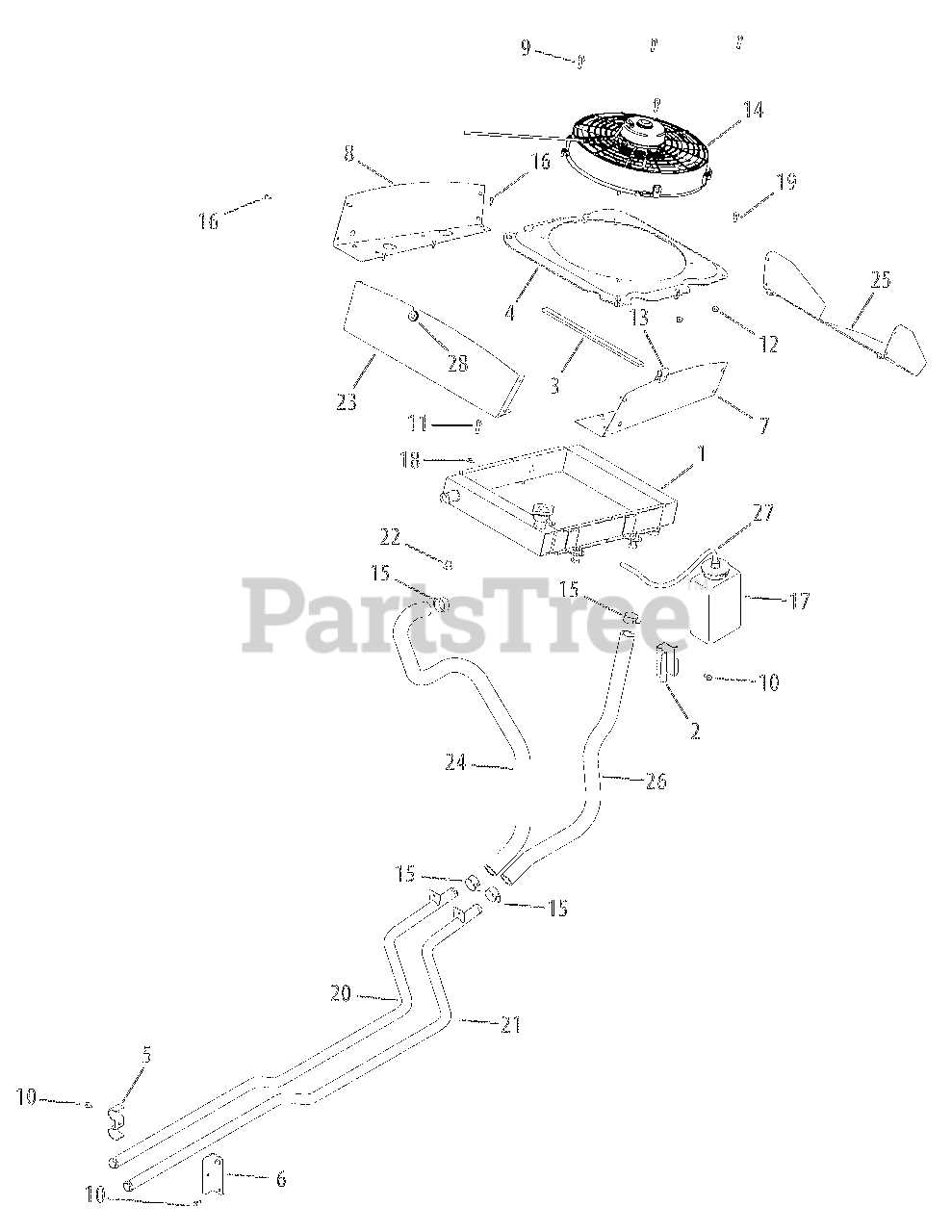

The system responsible for maneuvering the vehicle is composed of several crucial elements that work together to ensure smooth navigation and control. These elements form a coordinated mechanism designed to handle the demands of various terrains and provide precision handling during operation.

Main Elements of the System

- Control Linkage: This component connects the operator’s inputs to the wheels, allowing precise movement in response to directional changes.

- Movement Rods: These rods translate the force applied by the operator, ensuring smooth transitions when navigating curves and turns.

- Adjustable Column: Designed for optimal control, this section can be fine-tuned to suit the user’s preferences, enhancing overall comfort and control.

Supporting Components

- Fastening Joints: These conne

Common Issues with the Steering Mechanism

The control system of lawn tractors often encounters various challenges during regular use, especially when the equipment operates over uneven terrain or for extended periods. Identifying and addressing these concerns is essential to ensure smooth maneuverability and longevity of the machine.

Signs of Wear and Tear

- Difficulty in changing direction smoothly

- Unusual noises during movement, indicating component degradation

- Resistance when attempting to navigate tight turns

Components Prone to Damage

- Linkages that can become loose or misaligned over time

- Bushings that wear out and reduce efficiency

- Gears that may experience excessive friction or stripping

Replacement and Maintenance for Steering Linkages

Ensuring the optimal performance of your machine’s control system involves regular attention to the connection elements that link the user’s input with wheel movement. Over time, these components may experience wear, leading to reduced handling efficiency. Understanding when to replace and how to maintain these critical linkages is key to preventing larger mechanical issues and ensuring smooth operation.

Signs of Wear and Need for Replacement

Identifying early signs of deterioration in the connectors, such as excessive looseness or difficulty in maneuvering, can prevent sudden malfunctions. Regular inspection for visible damage, rust, or bent sections is essential. If the system feels less responsive, replacing the worn parts promptly will restore proper functionality.

Steps for Proper Maintenance

To extend the lifespan of the linkage components, periodic lubrication of moving parts is recommended, as well as ensuring that all fasteners are securely tightened. Regular cleaning of these areas will prevent the buildup of debris, which could otherwise hinder movement and contribute to premature wear.

Understanding Steering Column Adjustments

The ability to fine-tune the system that controls your vehicle’s direction is essential for smooth and precise handling. Adjusting this key component can improve your control and enhance overall driving comfort. Familiarizing yourself with how these adjustments work will allow you to maintain optimal performance and extend the lifespan of your equipment.

Common Adjustment Points

There are several critical areas where modifications can be made. These include the mechanisms that connect the control system to the wheels, allowing for smooth rotation and responsive movements. Each adjustment point has a specific purpose, from maintaining alignment to ensuring ease of use when turning.

Tools and Techniques

To properly modify the system, you will need basic tools that fit various fasteners. It’s crucial to follow a step-by-step approach, starting with loosening components, adjusting their positions, and securely fastening them again. Paying attention to the smallest details during these adjustments ensures that the system functions as intended, providing stability and control.

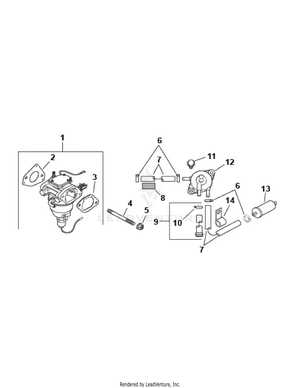

How to Replace Steering Gears and Bushings

Replacing the mechanism that controls the direction of your vehicle is a task that requires attention to detail and proper techniques. Over time, these components can wear out, leading to less precise handling. By carefully removing the old parts and installing new ones, you can restore optimal functionality and improve the driving experience.

Tools and Materials Needed

Before starting the replacement process, gather the necessary tools and materials. You will need a socket set, wrenches, screwdrivers, and replacement gears and bushings. Having these items on hand will streamline the procedure and minimize disruptions.

Step-by-Step Instructions

Begin by securely elevating the vehicle and ensuring stability. Remove any coverings or obstructions that might hinder access to the assembly. Carefully detach the old gears and bushings, taking note of their orientation for proper reassembly. Install the new components in the same configuration, ensuring a snug fit. Finally, reassemble any parts that were removed and conduct a test to verify that everything functions correctly.

Proper Lubrication for Smooth Steering Operation

Effective maintenance of mechanical components is essential for ensuring optimal performance and longevity. Regular application of the right lubricants minimizes friction, reduces wear, and enhances overall functionality. This practice is particularly crucial for the components involved in directional control systems, where precision and responsiveness are vital.

Choosing the Right Lubricant: It is important to select a lubricant that is suitable for the specific materials and conditions of use. Grease and oil types can vary significantly, so consulting the manufacturer’s recommendations is advisable to ensure compatibility and effectiveness.

Application Techniques: Proper application techniques can greatly influence the performance of the lubricants. Use a clean cloth to remove any debris or old lubricant from surfaces before applying a new layer. Ensure even distribution to cover all moving parts without over-lubricating, which can attract dirt and debris.

Maintenance Schedule: Establishing a regular maintenance schedule is key to sustaining performance. Regular inspections and timely reapplication of lubricants help prevent potential issues before they escalate, ensuring seamless operation of the directional control system.

Monitoring Performance: After lubrication, it’s essential to monitor the performance of the system. If any unusual noises or resistance are noted, further inspection may be needed to identify underlying issues that could be affecting the efficiency of the mechanism.

Steering Wheel Removal and Reinstallation Guide

This section provides a comprehensive approach to detaching and reattaching the control wheel on your mower. Whether you’re performing maintenance or replacing a worn component, understanding the steps involved will help ensure a smooth process and restore functionality to your equipment.

Preparation for Removal

Before you begin, make sure to gather the necessary tools, including a wrench set and a flathead screwdriver. Disconnect the battery to prevent any accidental starts. Carefully inspect the area for any obstructions that may hinder the removal process. Once you’re ready, locate the central nut securing the wheel and use the appropriate tool to loosen it.

Reinstallation Steps

After detaching the wheel, take a moment to clean the mounting surface and check for any signs of wear. Position the wheel back onto the shaft, ensuring it aligns correctly. Secure it with the central nut, tightening it firmly but not excessively to avoid damage. Finally, reconnect the battery and test the functionality of the wheel before resuming use.

Tips for Prolonging the Life of Steering Parts

Maintaining the functionality and durability of the directional components is essential for smooth operation and optimal performance. By following some straightforward guidelines, users can extend the lifespan of these crucial elements, ensuring reliable handling and reducing the need for replacements.

Regular Maintenance

- Inspect components regularly for wear and tear.

- Clean any dirt or debris that accumulates around the mechanism.

- Lubricate moving elements to minimize friction and enhance performance.

Proper Use and Storage

- Avoid sharp turns at high speeds to reduce stress on the system.

- Store equipment in a sheltered location to protect against harsh weather conditions.

- Ensure that tires are properly inflated to prevent uneven pressure on the components.