Every artisan knows the importance of having a comprehensive understanding of their equipment. Knowing how each element functions not only enhances creativity but also ensures optimal performance. This section will guide you through the intricate elements that make up a beloved crafting device.

Familiarity with the individual components allows for better maintenance and troubleshooting, leading to a more enjoyable and productive crafting experience. From the fundamental mechanisms that drive functionality to the more intricate details that contribute to precision, understanding these features can transform your approach to crafting.

Whether you’re a novice or a seasoned pro, a clear visualization of these elements can provide invaluable insights. Delving into the anatomy of your device will empower you to make informed decisions and elevate your projects to new heights.

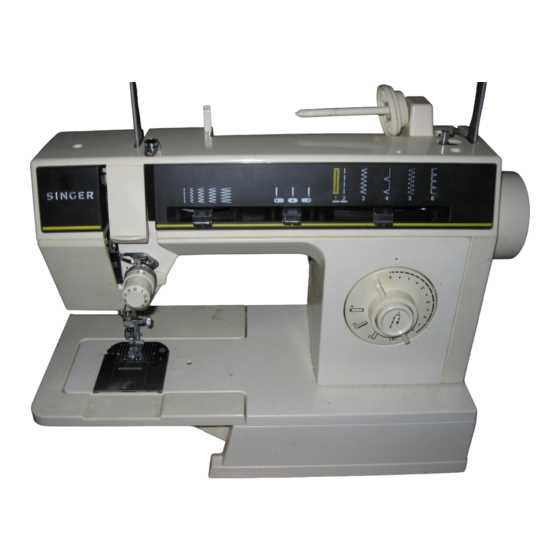

Singer Sewing Machine Overview

This section provides a comprehensive look at a well-known brand in the realm of textile crafting devices. These tools are celebrated for their reliability, efficiency, and innovative features that cater to both novices and seasoned artisans alike.

Renowned for their durability, these crafting instruments come with a variety of functionalities that enhance the creative process. Users appreciate the following aspects:

- Design and Build Quality: Crafted with robust materials to ensure longevity.

- User-Friendly Features: Simple controls and intuitive interfaces make operation straightforward.

- Versatility: Capable of handling diverse fabric types and project complexities.

- Accessibility: Available in various models to suit different skill levels and requirements.

In addition to their practical applications, these devices have evolved over time, incorporating advanced technology and functionalities that appeal to modern crafters. A range of accessories and add-ons further enhances their usability, allowing for a personalized crafting experience.

Understanding the components of these instruments is crucial for maintenance and optimal performance. Each element plays a vital role in the overall functionality, ensuring that users can achieve their creative visions efficiently.

Common Components of Singer Machines

Understanding the essential elements of these popular textile devices is crucial for effective operation and maintenance. Each component plays a significant role in the overall functionality, contributing to the seamless creation of various projects. Familiarity with these elements enhances not only user experience but also troubleshooting capabilities.

Needle: This slender tool is vital for piercing fabric and facilitating the stitching process. Choosing the right type and size is essential for achieving desired results.

Bobbin: Located beneath the fabric plate, this small cylindrical object holds the thread that forms the underside of stitches. Proper winding and placement are critical for smooth operation.

Presser Foot: This component holds the fabric in place while the needle performs its work. Various types of presser feet are available to accommodate different techniques and materials.

Feed Dogs: These metal teeth move the fabric through the device during operation. Their positioning and functionality are key for maintaining consistent stitch length and quality.

Thread Tension Mechanism: This adjustable feature controls the tightness of the upper thread, ensuring balanced stitches. Incorrect tension can lead to various stitching issues, making familiarity with this element important.

Stitch Selector: This feature allows users to choose different stitching styles and patterns, adding versatility to projects. Understanding how to navigate this component opens up creative possibilities.

By mastering these fundamental elements, users can improve their skills and achieve greater satisfaction with their creative endeavors.

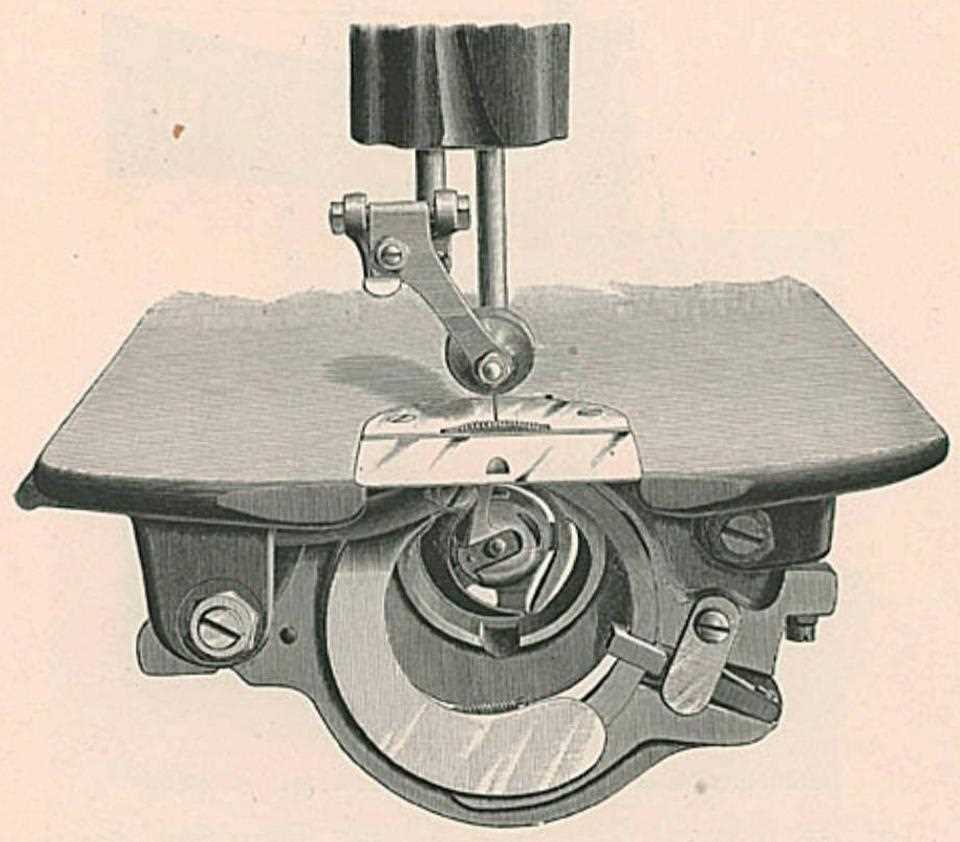

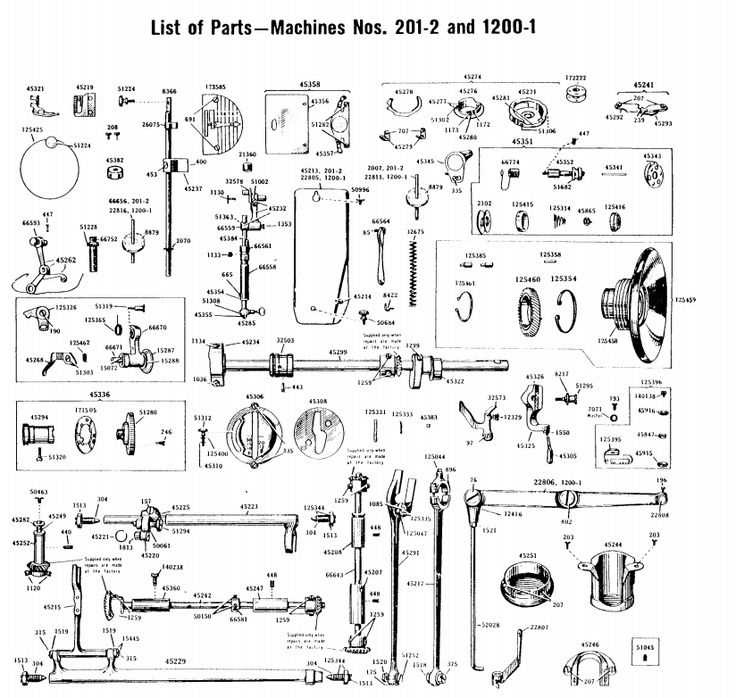

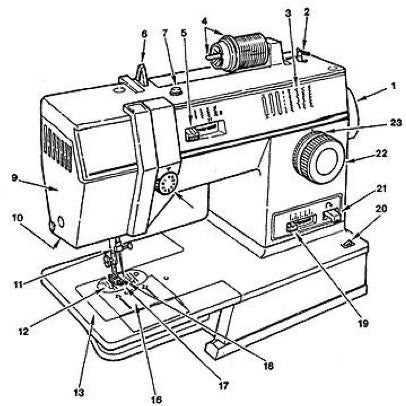

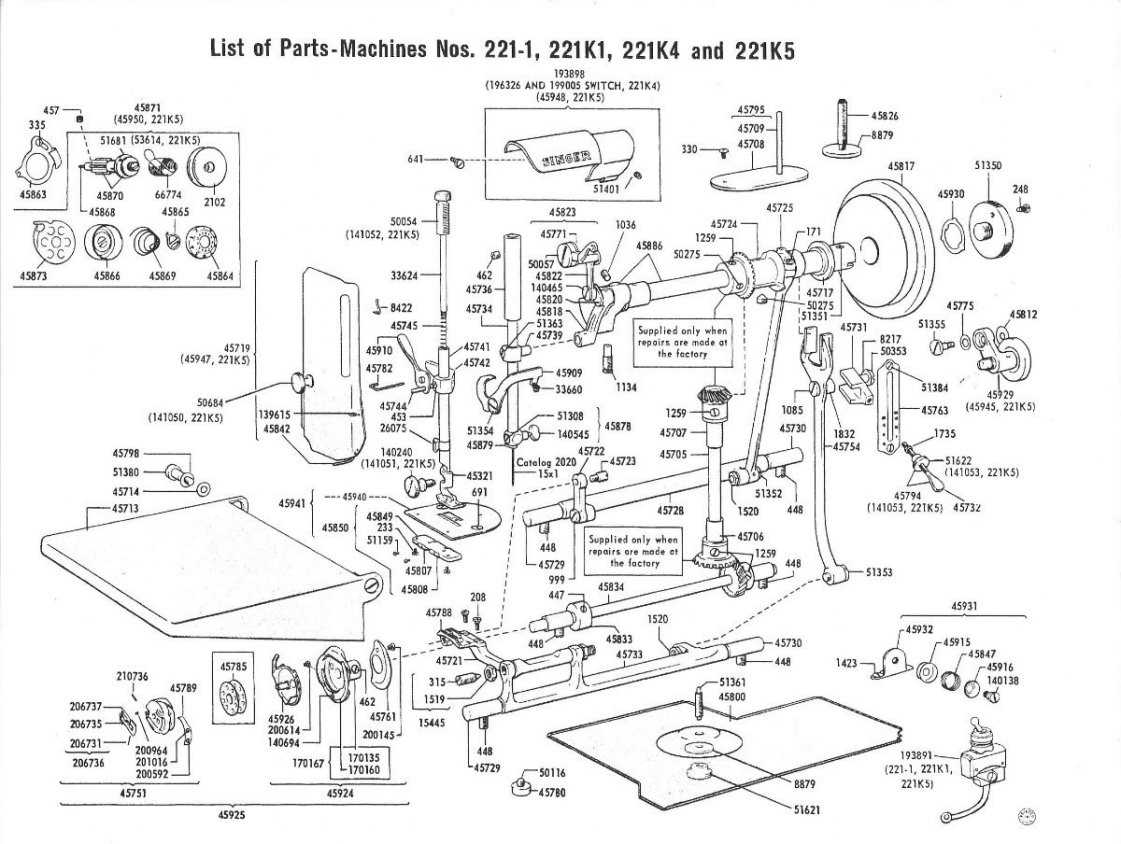

Understanding the Parts Diagram

Grasping the layout of a crafting device is essential for efficient operation and maintenance. This visual representation provides insight into each component’s function and interrelation, enabling users to troubleshoot issues effectively and perform necessary adjustments. Familiarity with the configuration can significantly enhance the overall experience of using the device.

The illustration typically breaks down the various elements into distinct sections, often categorized by their functions. This categorization aids users in quickly identifying and locating specific parts when needed. Below is a simplified representation of common components and their roles:

| Component | Description |

|---|---|

| Needle | The pointed element responsible for piercing the fabric. |

| Thread Tension Control | Regulates the tightness of the thread during operation. |

| Bobbin | Holds the lower thread and is essential for stitching. |

| Foot Pedal | Controls the speed of the operation, allowing for variable control. |

| Feed Dogs | These components move the fabric through the device as it operates. |

By understanding this visual guide, users can enhance their proficiency and troubleshoot problems with greater ease. A solid grasp of the configuration ensures smoother operation and extends the longevity of the device.

Key Functions of Each Component

Understanding the roles of various elements in a textile creation tool is essential for effective operation and maintenance. Each component contributes to the overall functionality, ensuring smooth and precise fabric manipulation. Below, we explore the primary functions of these vital parts.

Core Components

- Needle: Responsible for penetrating the fabric and creating stitches, its sharp tip ensures accuracy in alignment.

- Bobbin: Holds the lower thread, working in conjunction with the needle to form a complete stitch.

- Foot: Stabilizes the fabric during the stitching process, allowing for even pressure and control.

- Tension Discs: Regulate the tightness of the thread, ensuring consistent stitch quality and preventing breakage.

Supportive Mechanisms

- Feed Dogs: Move the fabric under the needle, enabling continuous stitching and varying stitch lengths.

- Presser Foot Lift: Facilitates easy insertion and removal of fabric by adjusting the foot height.

- Thread Guides: Direct the thread from the spool to the needle, ensuring a smooth flow without tangles.

- Motor: Powers the entire assembly, providing the necessary energy for operation and various speed settings.

Maintenance Tips for Longevity

Proper care and routine upkeep are essential for ensuring that your equipment remains efficient and durable over time. Regular attention not only enhances performance but also prevents unexpected breakdowns, extending the lifespan of your device. Below are several key practices to maintain its functionality.

| Tip | Description |

|---|---|

| Regular Cleaning | Dust and debris can accumulate, affecting performance. Clean the exterior and accessible areas frequently. |

| Lubrication | Apply appropriate oils to moving components to reduce friction and wear, following the manufacturer’s guidelines. |

| Proper Storage | Store in a dry, temperature-controlled environment to avoid moisture and heat damage. |

| Routine Inspections | Check for signs of wear or damage regularly. Early detection can prevent larger issues. |

| Using Quality Materials | Select high-quality supplies to minimize strain on the equipment and enhance performance. |

Troubleshooting Common Issues

When working with fabric handling tools, encountering difficulties can be frustrating. Understanding the frequent problems and their solutions can enhance your experience and ensure smooth operation. Here are some typical challenges you might face and how to address them effectively.

- Skipping Stitches:

- Check the needle for damage or improper installation.

- Ensure the correct type of needle is used for your fabric.

- Examine the thread tension settings and adjust if necessary.

- Thread Bunching:

- Re-thread the tool, making sure the thread path is followed correctly.

- Check for any obstructions in the threading mechanism.

- Adjust the tension on the top thread and bobbin.

- Fabric Jamming:

- Ensure the fabric is not being pulled too tightly.

- Inspect for tangled threads or debris in the feed dogs.

- Use the appropriate presser foot for the fabric type.

- Uneven Stitching:

- Check the alignment of the fabric as it feeds through.

- Make sure the needle is securely fastened and not bent.

- Examine the feed dogs for proper engagement.

By addressing these common issues with systematic troubleshooting, you can significantly improve performance and extend the lifespan of your equipment.

Finding Replacement Parts Online

When your crafting device needs some components replaced, the internet offers a wealth of resources to help you locate the necessary items. With just a few clicks, you can access various platforms that specialize in providing what you need for maintenance and repair.

To successfully navigate the search for your required elements, consider the following steps:

- Identify the Specific Component: Clearly determine which part requires replacement. Knowing the exact name or number will streamline your search.

- Utilize Search Engines: Enter relevant keywords into search engines to find online retailers or specialized websites that sell these items.

- Check Online Marketplaces: Explore popular e-commerce sites where various sellers list components. Read reviews to ensure reliability.

- Visit Manufacturer Websites: Many brands have official online stores where authentic items are sold, often with comprehensive information on compatibility.

- Join Online Forums: Engage with communities focused on similar hobbies. Members often share valuable recommendations on where to find specific elements.

By following these strategies, you can efficiently find and acquire the necessary components to keep your device running smoothly.

Upgrading Your Sewing Machine Parts

Enhancing your equipment can significantly improve your crafting experience and the quality of your creations. Whether you’re looking to boost performance, increase versatility, or simply modernize your setup, there are several options available that can make a notable difference in your projects.

When considering enhancements, it’s important to focus on components that align with your specific needs and skill level. Below is a table summarizing common upgrades and their benefits:

| Component | Benefits |

|---|---|

| Needles | Improved precision and adaptability for various fabrics. |

| Feet | Increased functionality for tasks like quilting, buttonhole making, and appliqué. |

| Motor | Enhanced speed and power for heavy-duty projects. |

| Light | Better visibility, reducing eye strain during detailed work. |

| Accessories | Expanded creative options with specialty tools and attachments. |

By carefully selecting which elements to upgrade, you can tailor your equipment to better suit your crafting style, making each session more enjoyable and productive.