When exploring the intricate workings of a textile creation apparatus, it’s essential to grasp the various elements that contribute to its functionality. Each component plays a pivotal role in ensuring smooth operation and optimal performance, making it vital for users to familiarize themselves with these individual parts.

Having a clear visual representation of the arrangement and connection between these elements can greatly enhance one’s comprehension. This understanding not only aids in efficient utilization but also empowers individuals to perform maintenance tasks effectively, ensuring longevity and reliability in their equipment.

Delving into the specifics of how each segment operates can provide valuable insights, allowing users to troubleshoot issues and enhance their crafting experience. A thorough knowledge of these components ultimately leads to a more satisfying and productive engagement with the device.

This section aims to provide a comprehensive overview of the various elements that make up the structure of a certain fabric creation tool. By understanding these components, users can enhance their experience and improve the functionality of their device. Each element plays a crucial role in the overall operation, contributing to the efficiency and effectiveness of crafting projects.

| Component | Description |

|---|---|

| Needle Holder | This part secures the needle in place, allowing for precise stitching. |

| Bobbin Case | A container that holds the bobbin, essential for creating the lower thread tension. |

| Foot Pedal | A control device that regulates the speed of the operation, enabling hands-free management. |

| Feed Dogs | These are small teeth-like components that move the fabric through the tool during stitching. |

| Thread Tension Dial | Allows the user to adjust the tension of the thread for different fabric types and stitching styles. |

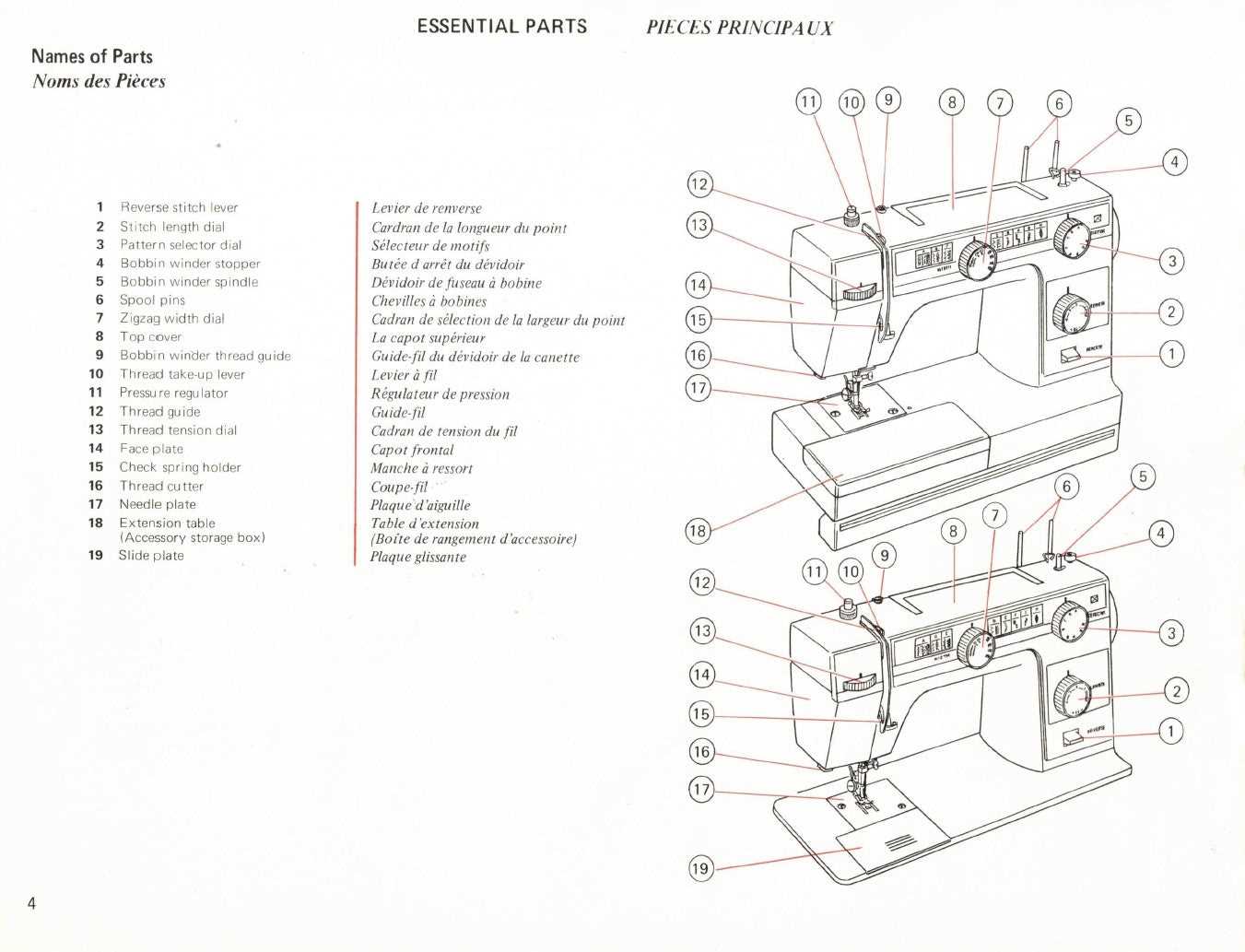

Essential Parts of Janome Models

Understanding the fundamental components of various textile crafting tools is crucial for both novice and experienced users. These elements work together to facilitate a seamless and efficient crafting experience, allowing individuals to create intricate designs and functional items with ease. Each component plays a unique role, contributing to the overall performance and versatility of the device.

Key components include the needle holder, which securely positions the needle, and the feed mechanism, responsible for moving fabric through the setup. The bobbin assembly ensures proper thread tension, while the control panel allows users to select different functions and settings. Additionally, the housing encases the internal mechanisms, providing stability and protection during operation.

Familiarity with these essential elements not only enhances the user experience but also aids in troubleshooting and maintenance. A comprehensive understanding of each component’s function can lead to more effective usage and care, ultimately extending the longevity of the device.

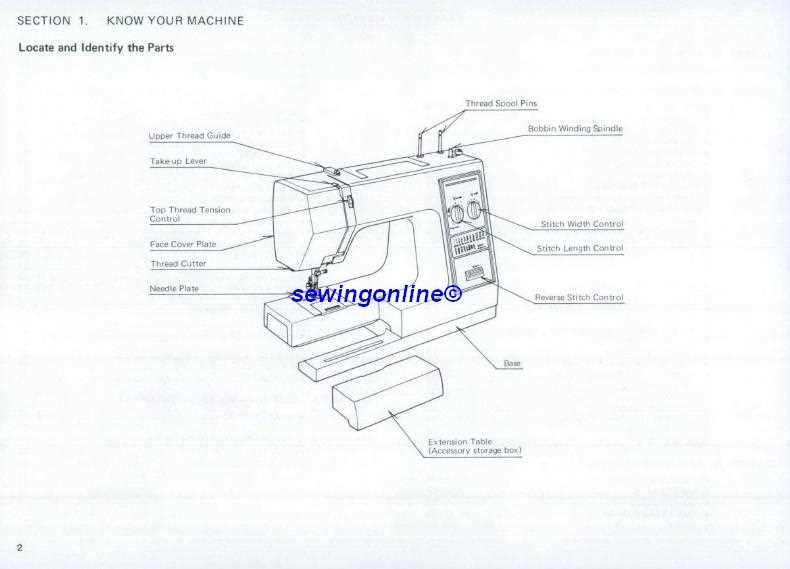

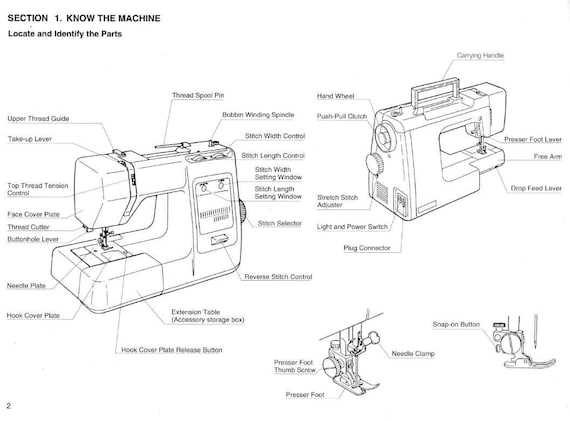

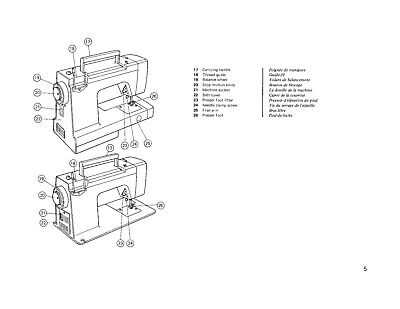

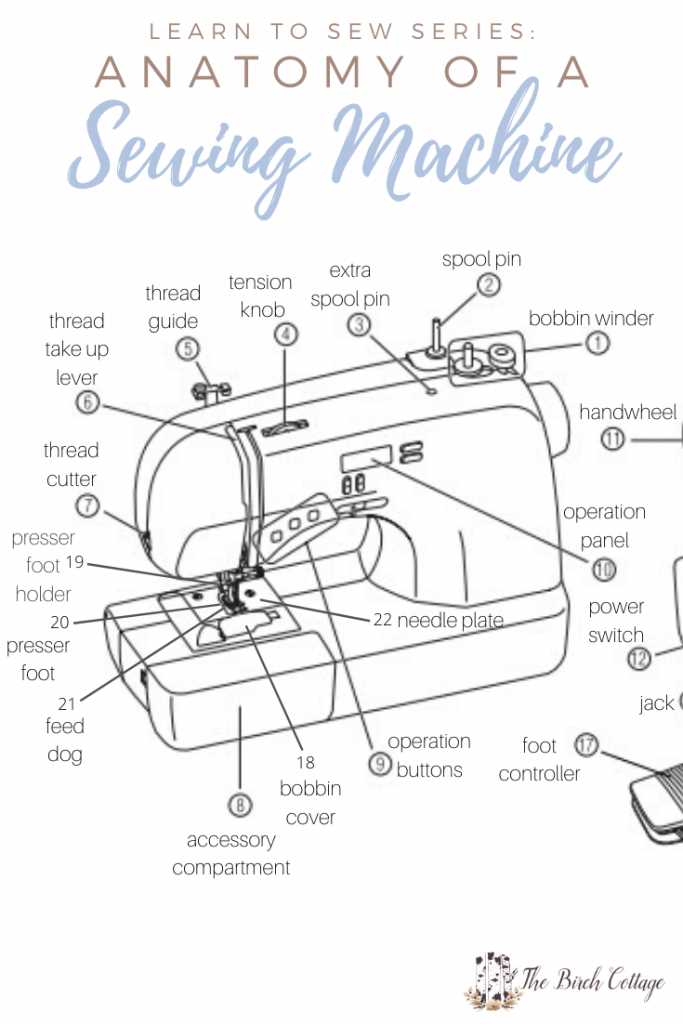

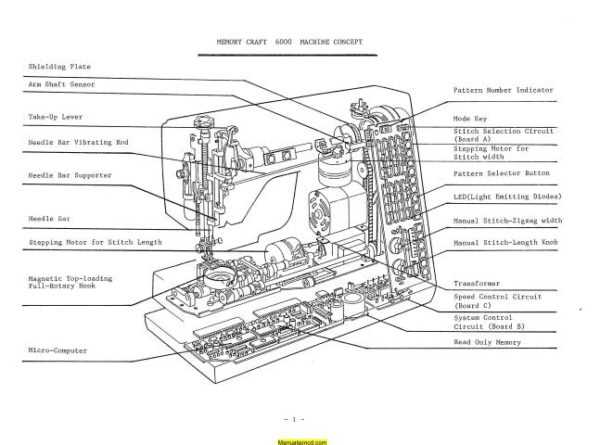

Diagram Overview and Labels

This section provides a comprehensive look at the various components of the textile device, highlighting their functions and interconnections. Understanding these elements is essential for effective utilization and maintenance, as it aids in recognizing how each component contributes to the overall operation.

Each labeled section serves as a guide, illustrating the location and purpose of individual elements. Familiarity with these identifiers can enhance the user’s ability to troubleshoot issues and perform necessary adjustments. Moreover, this knowledge empowers users to appreciate the intricacies of their equipment, ultimately leading to improved performance and longevity.

By exploring these visual representations, enthusiasts can gain insights into the mechanics involved, fostering a deeper connection with their craft.

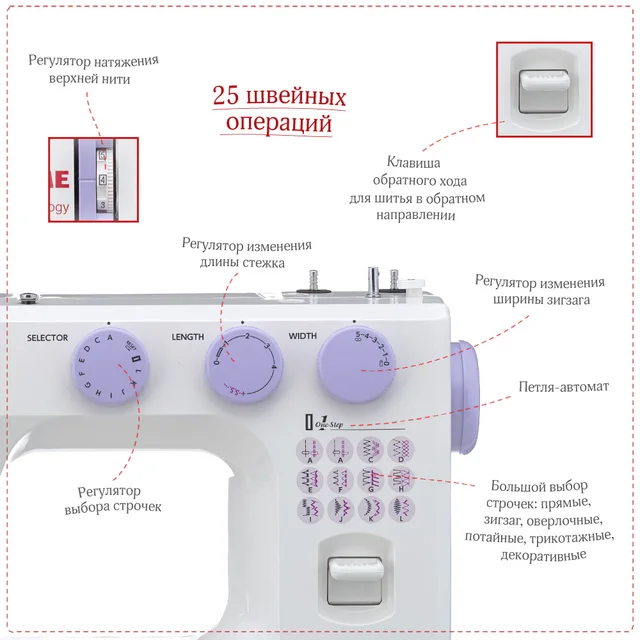

Functionality of Key Elements

The effectiveness of textile crafting tools hinges on the interplay of various components, each serving a distinct role in the overall operation. Understanding these functionalities is crucial for achieving optimal results in fabric manipulation and design creation.

- Needle: This vital component pierces the fabric, facilitating the insertion of thread to create stitches. Its type and size significantly influence stitch quality and fabric compatibility.

- Bobbin: Positioned beneath the main working area, it holds the lower thread, which interlocks with the upper thread to form a secure stitch. Proper bobbin tension is essential for balanced stitching.

- Presser Foot: This element applies pressure to the fabric, ensuring it remains in place during the stitching process. Different presser feet types cater to various techniques, enhancing versatility.

- Feed Dogs: These small teeth move the fabric through the workspace. Their height and positioning can be adjusted to accommodate different materials and stitching methods.

- Tension Discs: Responsible for regulating thread tension, these discs ensure the upper and lower threads maintain the appropriate tightness, preventing issues such as puckering or loosening.

- Stitch Selector: This feature allows users to choose from various stitch types and patterns, adding creative options to projects and facilitating tailored designs.

Each element contributes to the precision and efficiency of the crafting process. By familiarizing oneself with these components, users can enhance their skills and achieve desired outcomes in their textile projects.

Maintenance of Sewing Machine Parts

Regular upkeep is essential for ensuring the longevity and optimal performance of your equipment. Proper care not only enhances functionality but also prevents potential issues that could disrupt your creative process. Establishing a routine maintenance schedule is a smart approach to keep your tools in top condition.

Cleaning is one of the most critical aspects of maintaining your equipment. Dust and lint can accumulate over time, affecting performance. Regularly removing debris from the interior and exterior will help to maintain smooth operation. Use a soft brush or cloth to gently clean the surfaces, ensuring that all areas are accessible.

Another important factor is lubrication. Keeping moving components well-lubricated reduces friction and wear, leading to a smoother performance. It is vital to use the appropriate oil recommended for your device, applying it sparingly to avoid excess buildup.

Additionally, checking and replacing worn or damaged elements is crucial. Regular inspections can help identify parts that may need to be replaced, ensuring that everything functions effectively. Keeping spare components on hand can prevent interruptions in your work.

By prioritizing these practices, you can significantly enhance the efficiency and lifespan of your equipment, allowing you to focus on your projects with peace of mind.

Common Issues with Components

In the realm of textile crafting tools, users often encounter a variety of challenges related to individual elements. These issues can stem from regular wear and tear, improper maintenance, or even user error. Understanding these common problems can help enthusiasts troubleshoot effectively and maintain optimal performance.

One frequent concern involves the failure of various attachments to operate smoothly. This can lead to frustrating experiences, such as uneven stitching or difficulty in fabric handling. Regular inspection and cleaning of these components can mitigate such issues.

Another typical problem arises from thread tension inconsistencies. When the tension is not properly adjusted, it can result in skipped stitches or loops on the underside of the fabric. Users should familiarize themselves with adjustment techniques to ensure proper functionality.

Additionally, electrical components may occasionally malfunction, impacting the overall operation. Signs of electrical issues include unexpected stops or failure to respond to controls. It is advisable to consult a professional for repairs to ensure safety and longevity.

By addressing these common challenges proactively, users can enhance their crafting experience and extend the life of their equipment.

Upgrading and Replacing Parts

Enhancing functionality and maintaining performance is essential for any crafting device. Regular updates and replacements can significantly improve the user experience and extend the longevity of the equipment. This process not only ensures smoother operation but also allows for the incorporation of advanced features and technology.

Identifying Components for Replacement

Recognizing which elements need to be upgraded is crucial for effective maintenance. Users should periodically assess the condition of their equipment, focusing on wear and tear, as well as any decrease in efficiency. Components such as needles, feed mechanisms, and other internal mechanisms may require attention. By staying aware of these aspects, users can enhance the overall performance and reliability of their tools.

Choosing Quality Upgrades

Selecting high-quality replacements is vital to achieving the desired improvements. Opting for reputable suppliers and ensuring compatibility with existing systems can make a significant difference. Investing in durable components will lead to a more satisfactory crafting experience and fewer issues in the long run. Careful consideration of upgrade options will result in a more efficient and reliable setup.

Where to Find Diagrams

Locating visual representations of components for various devices can enhance understanding and facilitate repairs. Many resources are available to assist users in finding the necessary illustrations for their specific needs.

- Official Manufacturer Websites: Often provide comprehensive guides and illustrations directly related to their offerings, ensuring accuracy and relevance.

- User Manuals: Printed or digital manuals frequently contain valuable visuals that detail the assembly and disassembly of different elements.

- Online Forums and Communities: Engaging with dedicated groups can yield shared resources and insights from fellow users, including helpful diagrams.

- YouTube Tutorials: Visual guides available on video platforms can demonstrate component layouts and functionalities, offering a practical approach to understanding.

- Third-Party Repair Sites: Websites specializing in repair resources often feature diagrams and detailed instructions tailored to various brands and models.

Tips for Efficient Use

To achieve optimal performance with your equipment, it is essential to follow some effective strategies. These practices can enhance your overall experience, leading to better results and increased satisfaction. Understanding the key elements that contribute to smooth operation is crucial for both beginners and experienced users.

Maintain Regularly

Consistent upkeep is vital for the longevity of your device. Clean and lubricate components as recommended to prevent wear and tear. Regular checks will help you identify any potential issues early on, allowing for timely repairs and adjustments.

Familiarize Yourself with Features

Take the time to learn about the various functionalities available. Each feature is designed to facilitate specific tasks, so knowing how to utilize them effectively can greatly enhance your workflow. Explore different settings to find what works best for your projects.