When embarking on a creative journey, having a clear understanding of your essential tools is paramount. Each element plays a crucial role in ensuring that your projects come to life seamlessly. Familiarity with these elements not only enhances your crafting experience but also boosts your confidence in utilizing your equipment effectively.

Exploring the intricacies of your tool allows you to identify potential challenges and address them proactively. A comprehensive overview reveals how various components interact and contribute to the overall functionality, making it easier to troubleshoot issues as they arise.

In this guide, we will delve into the specifics of each segment, offering insights into their significance and interrelationships. By understanding these vital aspects, you’ll be better equipped to achieve the ultimate results in your crafting endeavors.

Understanding Viking Sewing Machines

This section delves into the intricacies of a renowned brand known for its innovative fabric manipulation tools. These devices have gained acclaim for their reliability and performance, catering to a wide range of users from hobbyists to professionals. By exploring the fundamental components and their functions, we can appreciate how they contribute to the overall effectiveness of these instruments.

At the heart of these creations lies a complex interplay of mechanisms designed to facilitate various tasks. Each element plays a critical role, ensuring that users can achieve precise results with ease. Understanding these components enhances the user experience and empowers individuals to make the most of their equipment.

| Component | Function |

|---|---|

| Needle | Penetrates fabric to create stitches. |

| Bobbin | Holds the lower thread, providing tension and support. |

| Feed Dogs | Move the fabric through the system for even stitching. |

| Presser Foot | Holds the fabric in place during operation. |

| Tension Mechanism | Controls the tightness of threads for consistent stitching. |

By gaining insights into these essential elements, users can troubleshoot issues, optimize their techniques, and elevate their craft to new heights. A comprehensive understanding of these instruments can lead to a more fulfilling creative experience.

Key Components of Sewing Machines

Understanding the essential elements of textile apparatuses is crucial for both beginners and experienced crafters. Each component plays a significant role in the functionality and efficiency of the device, influencing the quality of the final product. Below are the primary features that contribute to the overall performance.

- Needle: This is the vital tool that pierces the fabric, allowing for the interlocking of threads.

- Bobbin: A small spool that holds the lower thread, working in conjunction with the needle.

- Presser Foot: This part holds the fabric in place as the stitching occurs, ensuring precision and stability.

- Feed Dogs: These are metal teeth that move the fabric forward during the stitching process, enabling consistent movement.

- Tension Mechanism: This controls the tightness of the threads, ensuring balanced stitches on both sides of the fabric.

Each of these components interacts harmoniously to create the desired outcomes in textile projects. Familiarity with these features can significantly enhance one’s crafting skills and project results.

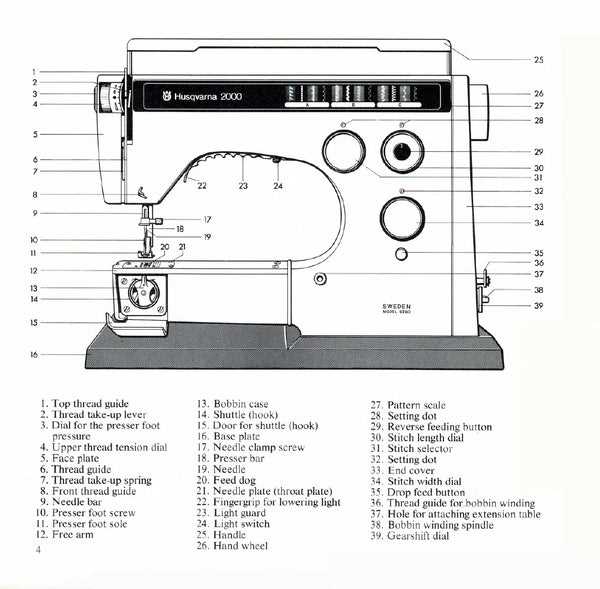

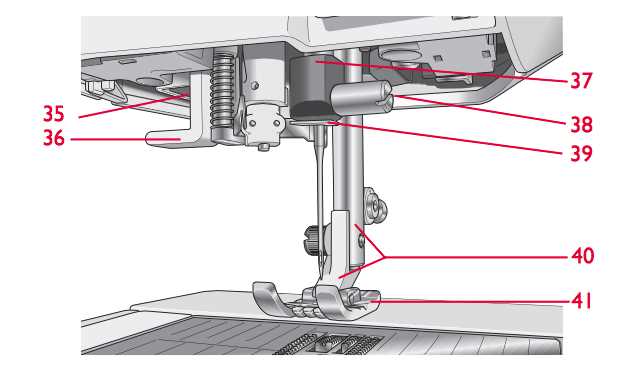

How to Read Machine Diagrams

Understanding technical illustrations is essential for anyone working with intricate devices. These visuals provide a blueprint for assembly, maintenance, and troubleshooting. By familiarizing yourself with common symbols and notations, you can navigate these resources effectively, leading to improved performance and longevity of the equipment.

First, it’s important to identify the various components depicted in the illustration. Each part is usually labeled with a specific code or number, which correlates to a list or key provided alongside the visual. This helps in quickly locating the necessary elements during repairs or adjustments.

| Symbol/Notation | Description |

|---|---|

| Circle | Indicates a component that is removable or adjustable. |

| Arrow | Shows direction of movement or flow within the system. |

| Square | Represents a fixed part that is not meant to be altered. |

| Dotted Line | Denotes an optional or secondary connection. |

Next, pay attention to the layout and organization of the visual. Components may be grouped by function or assembly order, allowing for a logical approach to repairs. Always refer to the accompanying key for clarifications, as these resources are designed to enhance comprehension.

Lastly, practice is key. The more you work with these illustrations, the more intuitive reading them will become. Familiarize yourself with different styles and formats, and soon you will be able to interpret them with confidence, ensuring effective maintenance and usage of your equipment.

Common Viking Parts Explained

This section delves into the essential components that contribute to the functionality and efficiency of these creative tools. Understanding the various elements will enhance your ability to maintain and troubleshoot effectively. Each component plays a pivotal role in the overall performance and user experience.

Key Components

Here are some of the fundamental elements that every user should be familiar with:

| Component | Description |

|---|---|

| Needle | The crucial element that penetrates the fabric, available in various sizes and types to suit different materials. |

| Foot | A device that holds the fabric in place during the stitching process, with various styles for different techniques. |

| Feed Dogs | Teeth-like components that move the fabric forward, allowing for precise and even stitching. |

| Bobbin | A small spool that holds the lower thread, essential for creating stitches by interlocking with the upper thread. |

| Tension Discs | Parts that control the tightness of the thread, influencing the quality of the stitching. |

Maintenance Tips

Regular upkeep of these key components can significantly extend the life of your tool. Ensure that you clean and oil the mechanisms regularly, check for wear and replace any damaged items promptly. Familiarizing yourself with these elements not only enhances performance but also leads to a more enjoyable creative process.

Maintenance Tips for Your Machine

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. By implementing simple yet effective practices, you can enhance functionality and reduce the likelihood of issues arising during use.

Begin with routine cleaning to eliminate dust and debris that can hinder operation. Use a soft brush or cloth to access tight spots, ensuring all components remain free from obstruction.

Lubrication is crucial; apply appropriate oils to moving parts as recommended by the manufacturer. This minimizes friction and promotes smooth operation, extending the life of the device.

Check for any signs of wear and tear regularly. Inspect belts, needles, and other critical elements, replacing them when necessary to maintain efficiency.

Lastly, refer to the user manual for specific maintenance guidelines tailored to your device. Following these recommendations will help you achieve the ultimate performance and reliability.

Replacing Worn-Out Parts Efficiently

Maintaining optimal performance requires timely replacements of components that show signs of wear. This process not only enhances functionality but also extends the lifespan of the equipment.

To ensure a smooth replacement experience, consider the following steps:

- Identify the components needing attention.

- Gather the necessary tools and new elements.

- Consult the user manual for guidance on disassembly and reassembly.

- Follow best practices to avoid further damage during replacement.

- Test the equipment after installation to confirm proper operation.

By adhering to these guidelines, you can effectively manage the replacement of crucial elements and maintain peak performance.

Where to Find Replacement Components

Locating suitable components for your fabric apparatus can significantly enhance its functionality and longevity. There are various avenues to explore for acquiring the necessary replacements, ensuring your device operates smoothly.

Online Retailers

Numerous online platforms specialize in offering a wide range of alternatives. Websites dedicated to crafting supplies often stock these essential items, allowing for easy comparison and selection based on your specific needs.

Local Craft Stores

Your nearby crafting supply shops may also have what you’re looking for. Engaging with store staff can provide insights and recommendations for obtaining the correct items, ensuring a seamless repair process.

Benefits of Using Original Parts

Utilizing authentic components for your equipment ensures optimal performance and longevity. These specialized items are designed to meet specific standards, providing a seamless fit and reliable functionality. Investing in genuine replacements can lead to a range of advantages that enhance your overall experience.

Quality Assurance

Original components are manufactured under strict quality controls, ensuring they meet high performance standards. This results in:

- Enhanced durability and reliability

- Reduced risk of malfunction

- Consistent performance over time

Perfect Compatibility

When you choose authentic replacements, you can be confident in their compatibility with your equipment. This leads to:

- Smoother operation

- Fewer adjustments required

- Longer intervals between servicing

In conclusion, opting for genuine components not only supports better performance but also contributes to a more enjoyable and efficient user experience.

Troubleshooting Common Issues

When working with textile creation devices, encountering challenges is a common experience. Understanding the typical problems and their solutions can enhance your crafting experience and extend the life of your equipment. Below are some frequent issues and practical approaches to resolve them.

- Skipped Stitches:

- Check the needle for damage or incorrect size.

- Ensure the thread is threaded properly.

- Inspect the tension settings for adjustments.

- Unusual Noises:

- Examine for any foreign objects lodged in the mechanism.

- Lubricate moving parts as per the manual.

- Ensure all screws and bolts are tight.

- Thread Bunching:

- Verify the threading path is correct.

- Adjust the upper and lower tension settings.

- Use quality thread suitable for your fabric.

- Inconsistent Stitch Length:

- Check the stitch length setting.

- Make sure the feed dogs are functioning correctly.

- Replace the needle if it is bent or worn.

By systematically addressing these concerns, you can maintain optimal performance and enjoy a smoother crafting journey.