Agricultural machinery plays a crucial role in enhancing productivity, ensuring efficiency, and maintaining land management. Understanding how each element fits into the larger system is vital for optimal operation. This section focuses on the essential mechanical elements and their interconnections, providing a detailed view of their organization.

The proper arrangement of various mechanical components ensures smooth functionality and durability. By familiarizing yourself with the layout and positioning of these elements, you can enhance your understanding of how each piece contributes to the overall performance.

This guide will walk you through the crucial elements, emphasizing their roles and interactions within the larger structure of farming tools. Recognizing these connections will allow for more efficient maintenance, repairs, and upgrades, ensuring your equipment runs smoothly.

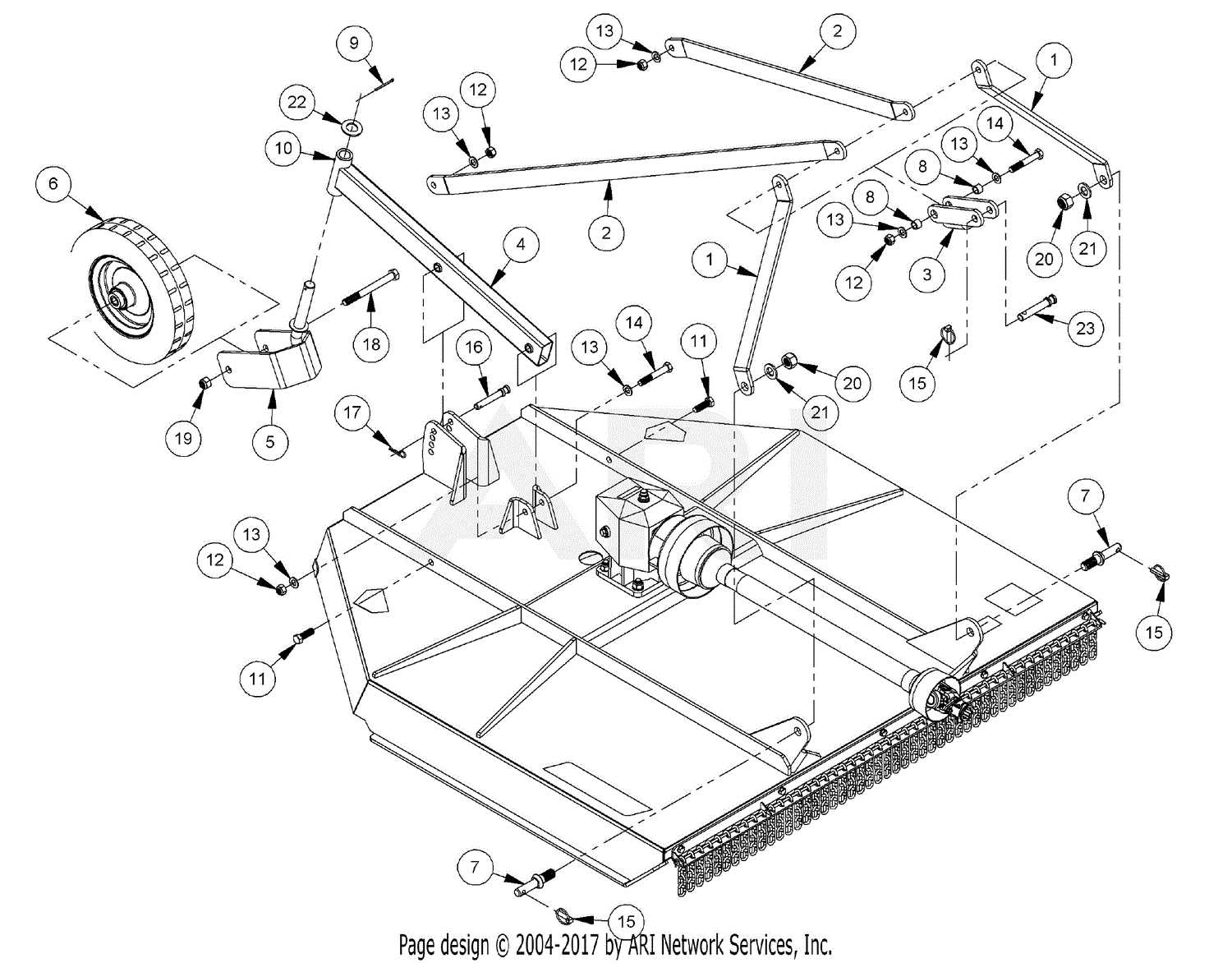

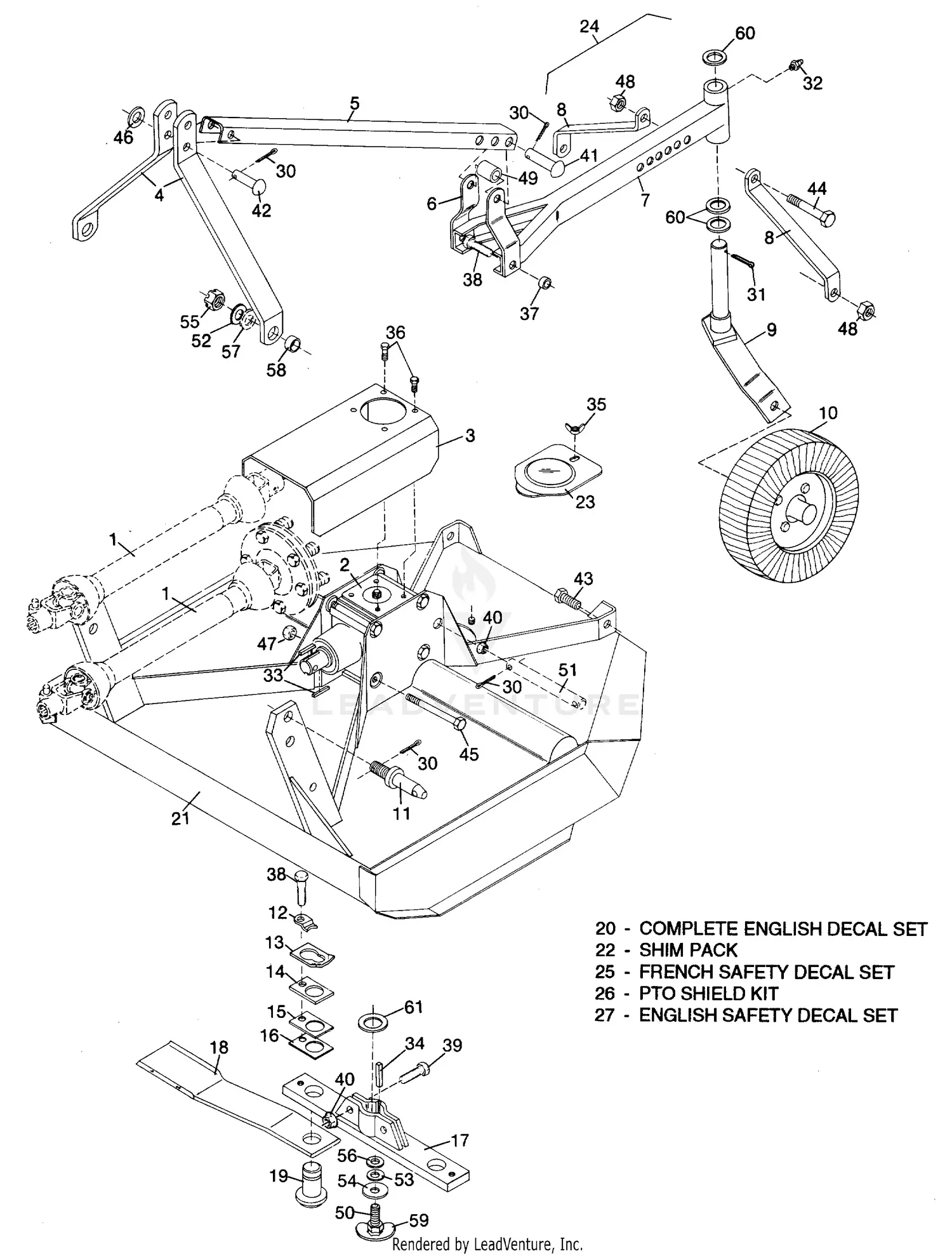

Overview of Woods Bush Hog Components

The equipment used for land clearing and vegetation control consists of several key elements that work together to ensure optimal performance. These units are engineered to handle tough terrain and overgrown areas, making them essential for maintaining large fields, farms, and commercial properties.

Main Structural Elements

- Frame: The foundation that supports all other components and ensures stability during operation.

- Blades: Critical for cutting through dense vegetation, these are designed to be durable and efficient.

- Gearbox: A vital mechanism that transfers power from the tractor to the rotating parts, enabling smooth operation.

- Deck: Provides protection by housing the blades and directing debris away from the operator.

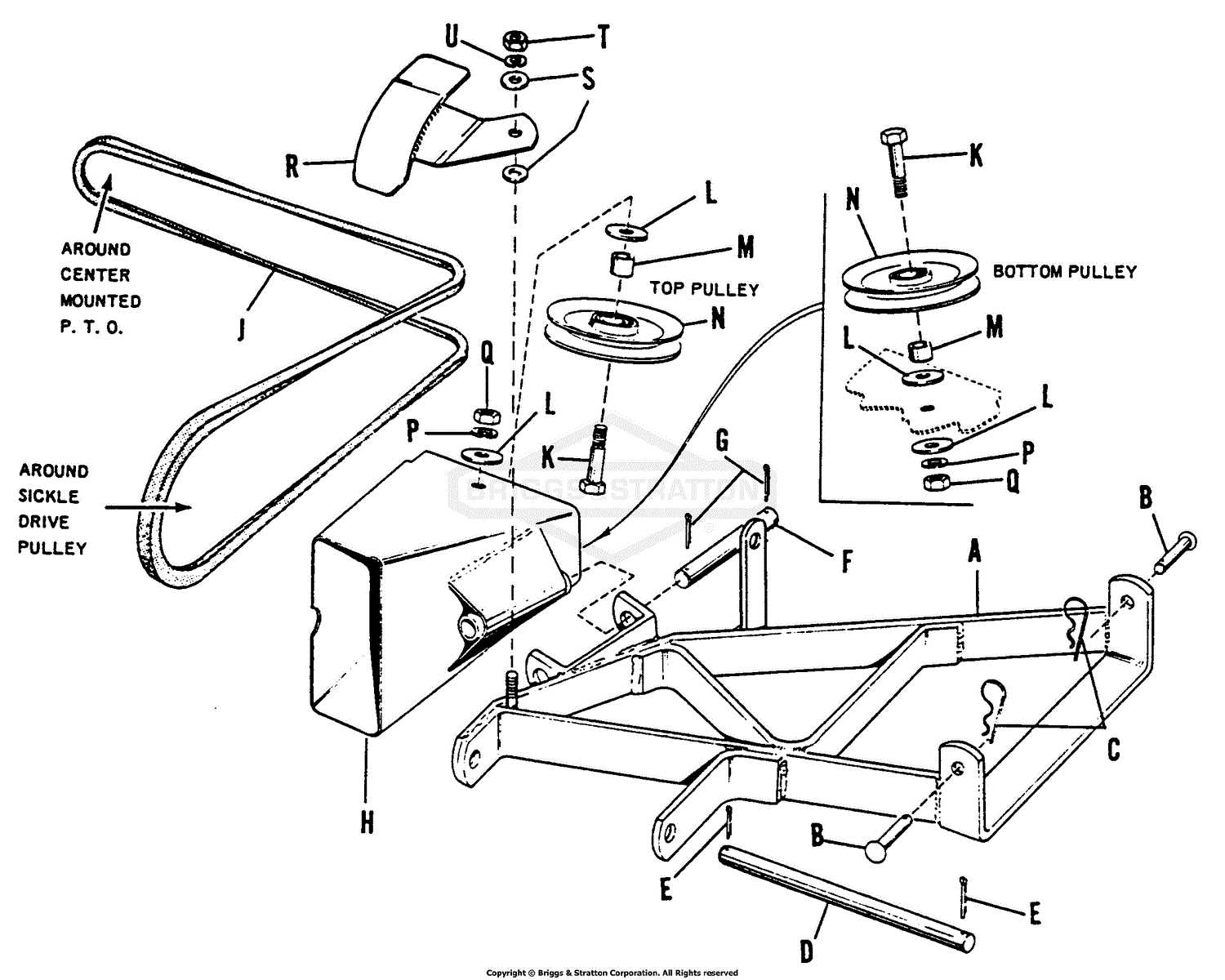

Power and Control Systems

- PTO Shaft: This connects the machine to the tractor’s power output, transmitting the necessary energy for blade rotation.

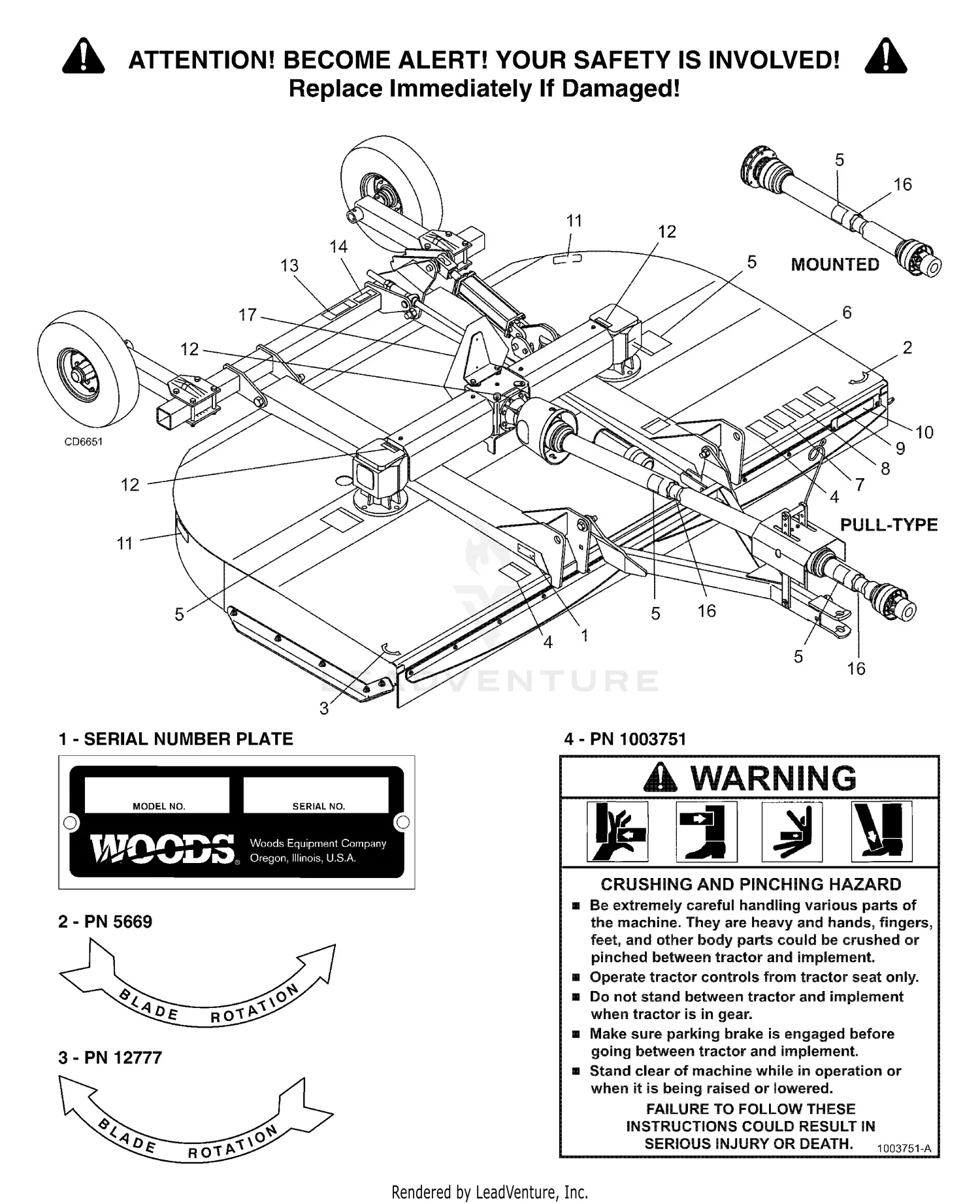

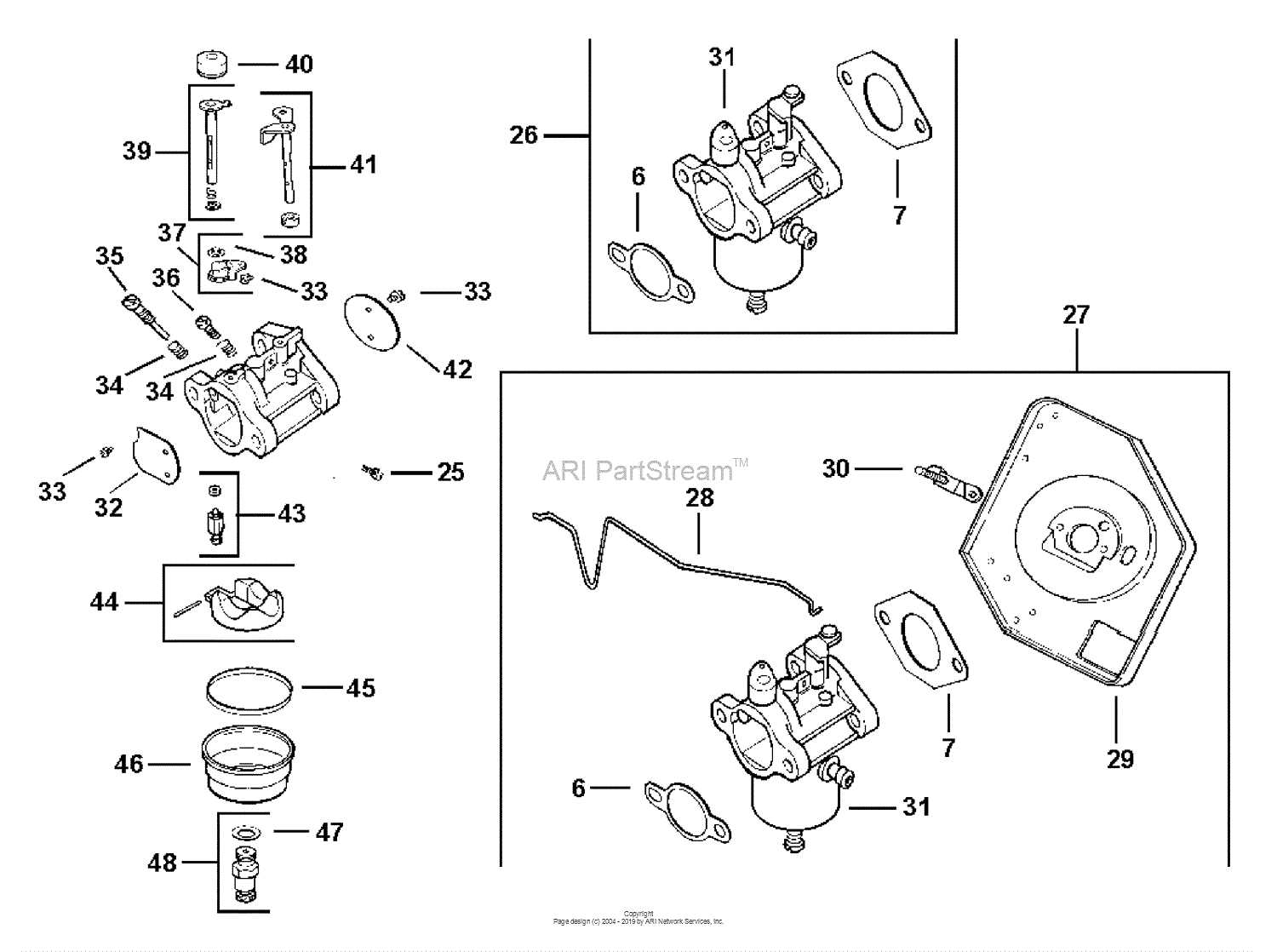

- Identifying Key Parts in the Diagram

The illustration showcases essential components of the equipment, each playing a crucial role in its operation. By examining the visual representation, users can understand how different mechanical elements work together to ensure smooth functionality. Recognizing the placement and connection of these elements is vital for troubleshooting and maintenance purposes.

Each segment within the layout is designed with specific functions in mind. It is important to identify these pieces based on their shape, location, and relation to surrounding parts. This knowledge helps ensure correct assembly and effective performance of the equipment.

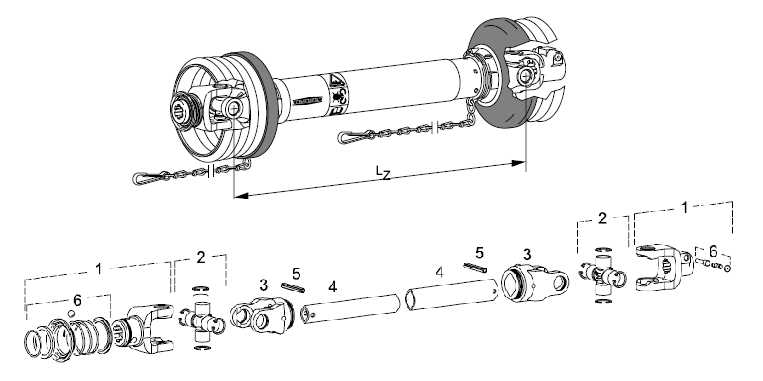

Understanding the Function of Blades and Shafts

Blades and shafts are essential components in rotary mowers, responsible for the cutting and mechanical motion that makes vegetation control efficient. These elements work together, delivering the power and precision needed to manage overgrown areas. Proper understanding of how blades and shafts operate is crucial for ensuring optimal performance and long equipment lifespan.

Blades: Cutting Mechanism

The blades are the primary tools responsible for trimming vegetation. They rotate at high speeds, slicing through grass, weeds, and other plants with precision. The material, size, and sharpness of the blades affect the quality of the cut, as well as their resistance to wear. Regular maintenance, such as sharpening and checking for damage, helps in maintaining their effectiveness over time.

Shafts: Power Transmission

Shafts serve as the connecting elements between the motor and the blades. They transmit the rotational force necessary to spin the blades at the desired speed. A properly aligned and well-maintained shaft ensures that the force is evenly distributed, preventing vibrations and maintaining the balance of the equipment. Different types of shafts are designed to accommodate various power requirements and field conditions.

Common Wear and Tear Points to Watch

Mechanical equipment used for land management often experiences gradual degradation in several key areas. Monitoring these points can help extend the lifespan of your equipment and prevent costly repairs. Regular inspection ensures that performance remains optimal and unexpected breakdowns are minimized.

Blades and Cutting Edges

Blades are subject to significant wear due to frequent contact with soil, rocks, and other debris. Over time, they can become dull or unevenly worn, reducing efficiency. Sharpening or replacing the cutting edges regularly helps maintain smooth operation and clean cuts.

Drivetrain and Transmission

The drivetrain, including gearboxes and universal joints, often faces wear due to friction and movement. Lack of lubrication or exposure to dirt and moisture can accelerate the wearing process. Ensure that all moving components are properly greased, and check for signs of grinding, unusual noises, or decreased performance.

Component Signs of Wear Maintenance Tips for Longevity of Components

Ensuring the durability and extended lifespan of machinery components requires regular attention and care. Routine upkeep is essential for preventing unexpected breakdowns and maximizing efficiency. By following a few essential practices, you can reduce wear and tear, ultimately leading to a more reliable operation.

Lubrication is a critical aspect of maintenance that cannot be overlooked. Make sure all moving elements are properly greased to minimize friction and prevent overheating. Regular checks ensure that each component operates smoothly without excessive resistance.

Inspection is another key practice. Periodically examine each part for signs of wear, such as cracks, bending, or other damage. Early detection allows for timely replacements and helps avoid more serious problems that can affect the entire system.

Keep your machinery clean by removing dirt, debris, and other contaminants that can affect performance. A clean working environment reduces the risk of damage and promotes better functioning of all components.

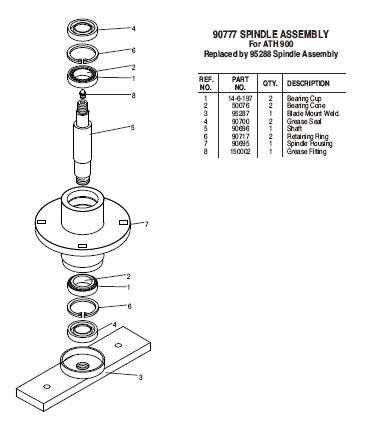

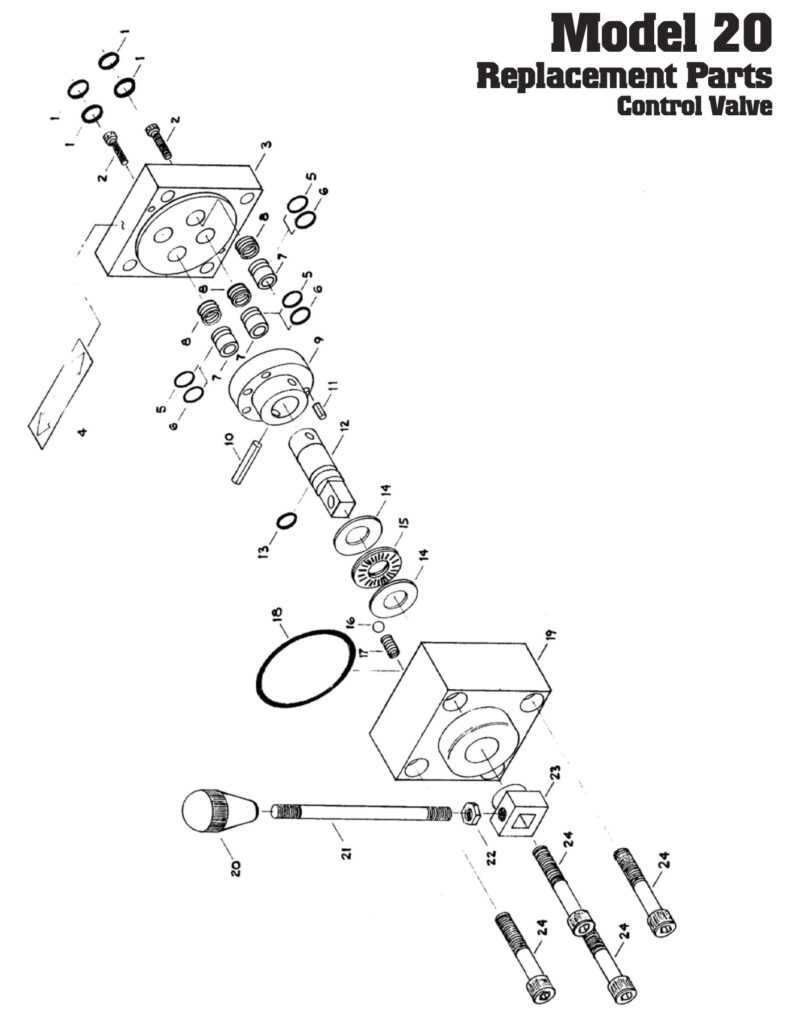

Proper Assembly of the Gearbox Mechanism

When assembling the gear system, precision and attention to detail are crucial to ensuring smooth operation. The components must be carefully aligned, with each part positioned to facilitate optimal interaction between gears, shafts, and other moving elements. Proper assembly minimizes wear and tear and extends the lifespan of the mechanism, reducing the risk of malfunction over time.

Start by ensuring that the casing is clean and free of debris or contaminants that could hinder the movement of internal components. Once the housing is prepared, carefully align the shafts and gears to ensure proper engagement. Each component should fit snugly but without excessive force, as misalignment can lead to friction or unnecessary strain on the parts.

Next, secure the bearings and other support structures that hold the gears in place. These should be installed with precision, as they play a vital role in maintaining the balance and stability of the entire system. Ensure that all fasteners are torqued to the manufacturer’s specifications, as under-tightening or over-tightening can cause issues down the line.

Finally, after assembling the gearbox, conduct a thorough inspection to ensure that all moving parts operate freely without obstruction. Test the mechanism to verify that the gears are engaging smoothly and efficiently. Any signs of irregular movement should be addressed promptly to prevent damage during operation.

How to Replace Damaged Bush Hog Parts

Repairing damaged components of your agricultural equipment is essential for maintaining its optimal performance. Whether it’s a worn-out blade, malfunctioning gearbox, or a broken shaft, replacing these faulty elements ensures that your machine continues to operate smoothly and efficiently. Proper maintenance and timely replacements can prevent further damage and improve the longevity of the equipment.

Step-by-Step Process

To begin, it’s crucial to identify the damaged component. Depending on the type of damage, some parts will require disassembly of the equipment, while others may simply need a direct swap. Start by turning off the machine and ensuring it is safely secured. Next, remove the necessary parts to access the damaged component. Once exposed, carefully remove the faulty part and replace it with a new one. Be sure to follow the manufacturer’s specifications for each replacement to ensure compatibility and proper function.

Tools Required

Tool Purpose Wrench Set For loosening bolts and nuts Screwdrivers To remove screws from equipment housing Socket Set For removing and securing components Grease For lubrication of moving parts Once the new part is securely in place, check for proper alignment and operation. Test the equipment slowly, ensuring everything functions correctly without any unusual noise or vibration. Regularly inspect and maintain all components to avoid future breakdowns and ensure a smooth operation.

Upgrading Woods Bush Hog for Better Performance

Enhancing the efficiency and durability of your land clearing equipment can make a significant difference in your productivity. By focusing on key components and making thoughtful upgrades, you can ensure that your machine performs optimally in even the toughest conditions. Whether you’re seeking to improve cutting power, reduce wear and tear, or enhance safety, strategic modifications can help you get the most out of your equipment.

Improving Cutting Efficiency is one of the most noticeable benefits of upgrading essential components. Upgrading the blades to higher-quality materials or more advanced designs can drastically improve the machine’s cutting capacity. Opting for sharper, heavier-duty blades ensures smoother operation, reducing the need for frequent maintenance.

Boosting Durability requires investing in stronger, more resilient materials for critical elements like the frame and gears. Reinforced components can withstand rough terrain and extended use, ensuring longevity and reducing downtime for repairs. Adding protective coatings to prevent rust and corrosion will also extend the machine’s lifespan.

Enhancing Safety is equally important when upgrading machinery. Installing additional safety features such as upgraded shields, more robust safety guards, and improved visibility options can help protect the operator and bystanders. Regular maintenance checks after each upgrade will ensure that safety remains a top priority during operation.

By carefully selecting and installing appropriate upgrades, your equipment will not only perform better but will also be more reliable and efficient over time.

Finding OEM and Aftermarket Parts for Woods Bush Hog

When maintaining or repairing heavy-duty mowing equipment, ensuring you have access to the correct replacement components is crucial for optimal performance. Whether you’re looking for original manufacturer parts or alternatives, understanding where to source them can save both time and money. There are several approaches to finding high-quality components for your machine, and making an informed decision can help extend the life of your equipment.

Original Manufacturer Components

For those seeking the highest quality, original equipment manufacturer (OEM) components are often the preferred option. These items are designed to match the specifications of the machine precisely, ensuring a perfect fit and reliable operation. OEM suppliers can be found through the manufacturer’s official channels, authorized dealers, or dedicated online retailers. One of the main advantages of choosing OEM is that these items are tested for durability and efficiency by the same company that designed the equipment.

Aftermarket Alternatives

On the other hand, aftermarket alternatives offer a wider range of options at potentially lower costs. While these parts are not made by the original manufacturer, many reputable aftermarket suppliers produce high-quality components that meet or exceed the performance standards of OEM items. It’s important to choose reputable aftermarket brands to avoid poor-quality components that could negatively affect the functionality of your equipment.