When working with heavy machinery, a clear understanding of its assembly and individual components is essential for efficient operation and maintenance. Every piece of equipment is made up of various elements, each playing a crucial role in its functionality. Familiarity with these components not only aids in troubleshooting but also enhances the overall performance of the machine.

Visual representation of equipment layouts allows operators and technicians to pinpoint specific sections quickly. This knowledge facilitates easier repairs and replacements, minimizing downtime. An organized view of the internal structure can serve as a valuable resource for both novice users and seasoned professionals.

Moreover, having access to a comprehensive outline of machinery can significantly impact the maintenance schedule. Regular inspections become more manageable when one can identify which parts require attention or are prone to wear and tear. Understanding the interconnectedness of components helps in planning service routines effectively, ensuring the longevity of the equipment.

Understanding Bobcat ZT219 Components

Gaining insight into the various elements of machinery is essential for effective maintenance and operation. Each component plays a crucial role in ensuring the overall functionality and efficiency of the equipment. Familiarity with these parts allows operators and technicians to troubleshoot issues and perform necessary repairs with confidence.

| Component | Description |

|---|---|

| Engine | The powerhouse that drives the entire system, converting fuel into mechanical energy. |

| Hydraulic System | Facilitates movement and control of various attachments through pressurized fluid. |

| Chassis | The frame that supports all components, providing stability and structural integrity. |

| Transmission | Transfers power from the engine to the wheels, affecting speed and torque. |

| Control Panel | The interface for operators to monitor and control the machine’s functions. |

By understanding these fundamental elements, users can better appreciate the complexities of the equipment and enhance their operational efficiency.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations of each element enable users to identify parts quickly, ensuring that any issues can be addressed efficiently. These illustrations serve as essential tools for both novice and experienced technicians, streamlining the troubleshooting process and minimizing downtime.

Facilitating Maintenance

One of the primary advantages of these visual aids is their role in simplifying routine upkeep. By providing clear images of the various components, users can easily follow maintenance protocols, ensuring that each element is properly serviced. This leads to enhanced performance and longevity of the equipment.

Aiding in Repairs

In the event of a malfunction, these visual guides become invaluable. They help in pinpointing the specific area that requires attention, allowing for precise diagnostics. Consequently, repairs can be conducted more swiftly, reducing the risk of further damage and associated costs.

| Benefit | Description |

|---|---|

| Efficiency | Quick identification of components saves time during repairs. |

| Clarity | Visual aids provide a clear understanding of complex assemblies. |

| Training | New users can learn quickly through detailed illustrations. |

| Cost Savings | Reduced downtime leads to lower operational costs. |

Key Features of ZT219 Model

This model stands out for its exceptional performance and innovative design, catering to the needs of various users in demanding environments. Its robust construction ensures durability while maintaining efficiency, making it an ideal choice for both professionals and enthusiasts.

One of the primary attributes includes an advanced engine that delivers impressive power and torque, allowing for smooth operation across diverse terrains. Additionally, the intuitive control system enhances user experience, providing seamless maneuverability and precision in every task.

The compact size facilitates easy transport and storage, while the versatile attachments expand functionality, enabling users to tackle a wide range of jobs effectively. Coupled with a reliable maintenance schedule, this model promises longevity and sustained performance.

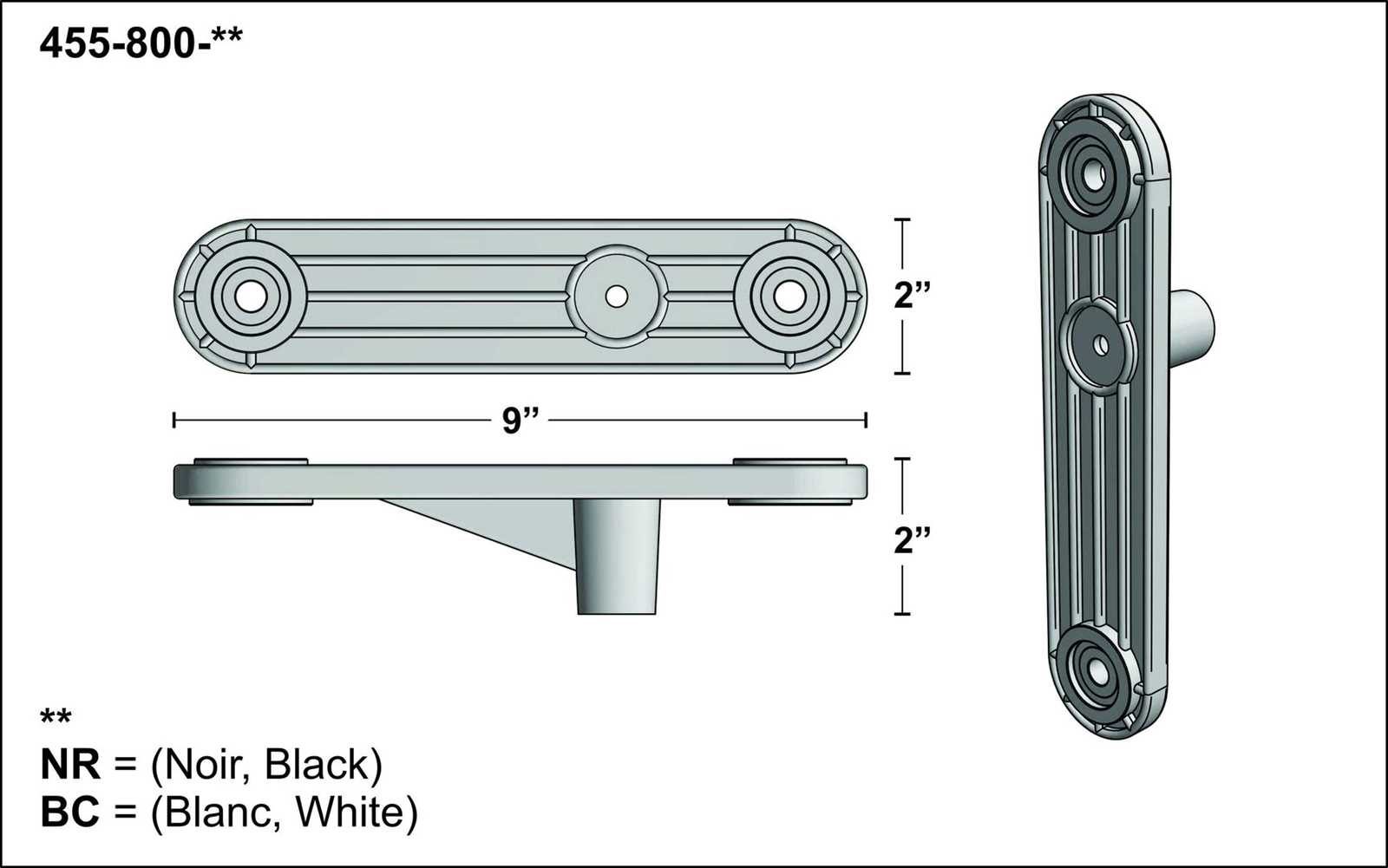

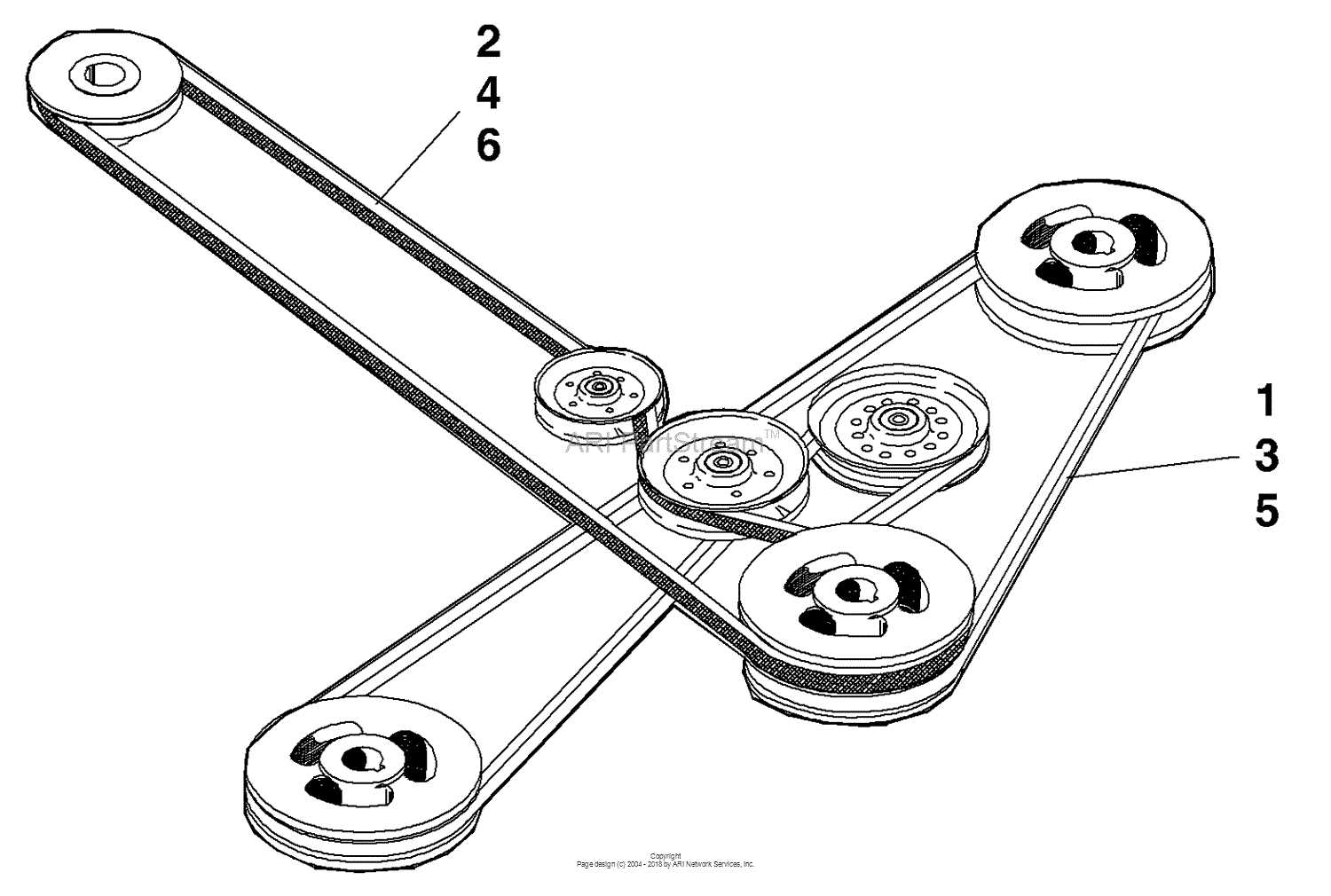

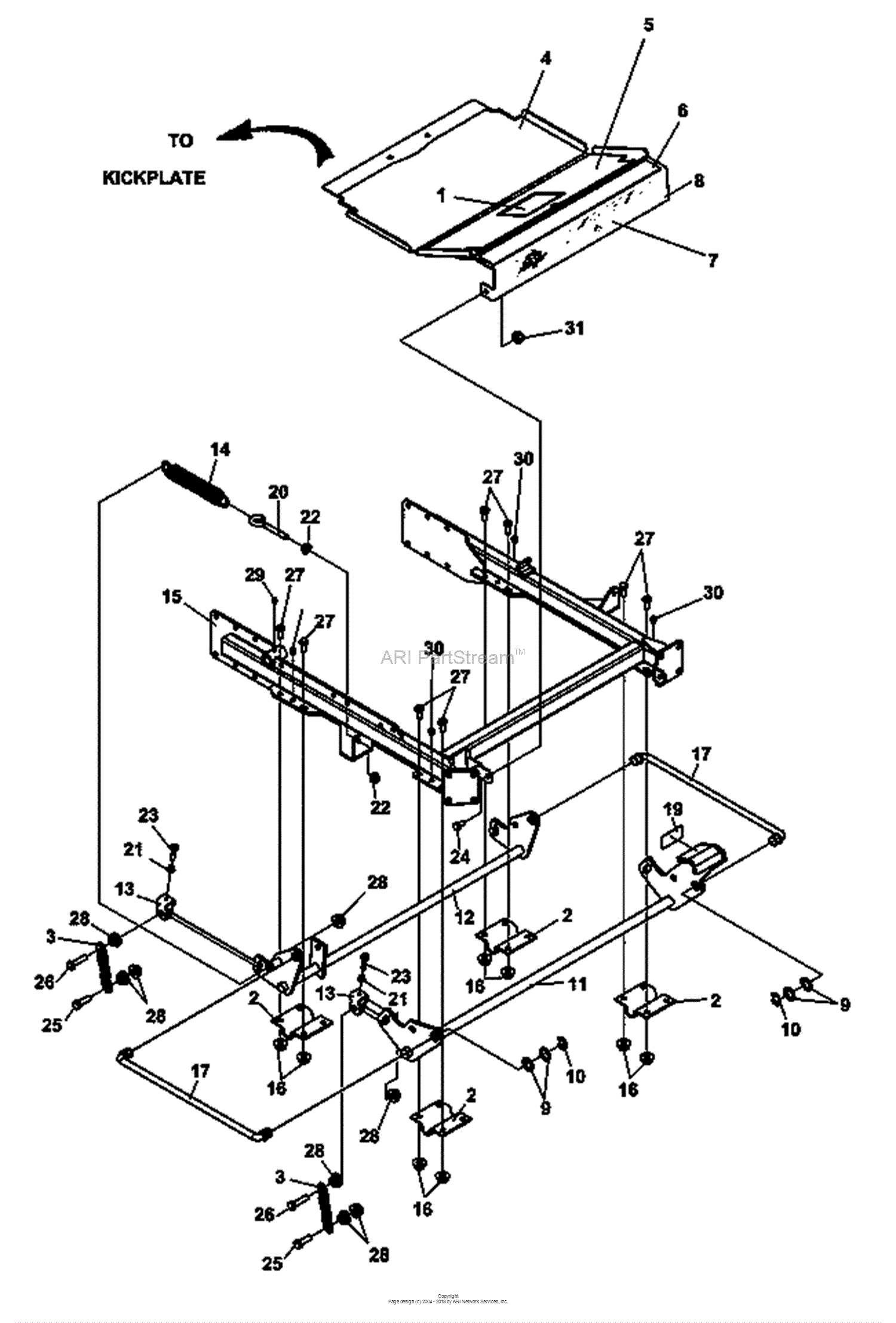

How to Interpret Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair tasks. These illustrations provide a clear layout of various elements and their relationships, helping users identify what is needed for specific repairs or replacements.

Here are key steps to effectively interpret these visuals:

- Familiarize Yourself with Symbols: Different representations often use unique symbols. Take time to learn what each symbol stands for to avoid confusion.

- Identify Key Components: Look for labeled parts that indicate their function. This will help you understand how each element contributes to the overall system.

- Check the Legend: Many illustrations include a legend or key that explains symbols and color codes. This is a valuable resource for accurate interpretation.

- Understand Connections: Pay attention to lines and arrows that indicate how components interact. Understanding these relationships is crucial for troubleshooting.

- Use a Reference Guide: Having a separate guide that describes the functionality of each part can enhance your understanding of the illustration.

By following these steps, you will be able to decipher visual layouts more effectively, making the process of maintenance and repair smoother and more efficient.

Common Issues with Bobcat ZT219

Many users encounter a range of challenges when operating this particular piece of equipment. Understanding these frequent problems can help in troubleshooting and maintenance, ensuring optimal performance and longevity.

| Issue | Description | Potential Solution |

|---|---|---|

| Engine Stalling | The engine may stop unexpectedly during operation. | Check fuel levels and replace the fuel filter if necessary. |

| Uneven Cutting | The cutting deck may not level properly, leading to inconsistent results. | Adjust the deck height and check for worn blades. |

| Hydraulic Issues | Problems with the hydraulic system can lead to slow or unresponsive movements. | Inspect hydraulic fluid levels and look for leaks in hoses. |

| Electrical Failures | Malfunctions in electrical components may cause starting issues. | Examine wiring and replace any faulty connections or fuses. |

Maintenance Tips for ZT219 Parts

Proper upkeep of your machinery is essential for optimal performance and longevity. Regular maintenance can prevent wear and tear, ensuring that all components function efficiently. Here are some valuable suggestions to help you keep your equipment in top shape.

1. Regular Inspections: Conduct frequent checks on all key elements. Look for signs of wear, loose connections, or any unusual noises. Early detection can save you from more significant issues down the road.

2. Clean Components: Dirt and debris can accumulate over time, affecting performance. Regularly clean essential parts to maintain their functionality. Use appropriate cleaning solutions to avoid damage.

3. Lubrication: Ensure that moving parts are adequately lubricated. This reduces friction and prevents overheating. Follow manufacturer recommendations for the type and frequency of lubricant to use.

4. Replace Worn Parts: Don’t wait until a part fails completely. Replace worn components promptly to maintain efficiency and prevent further damage to the system.

5. Keep a Maintenance Log: Document all maintenance activities, including inspections, cleaning, and replacements. A detailed log helps track the health of your machinery and can be invaluable for troubleshooting.

6. Follow Manufacturer Guidelines: Adhere to the specific maintenance recommendations provided by the manufacturer. These guidelines are designed to maximize performance and extend the lifespan of your equipment.

By following these tips, you can ensure that your machinery operates smoothly and efficiently, minimizing downtime and enhancing productivity.

Where to Find Replacement Parts

Locating suitable components for your machinery can enhance its performance and longevity. Understanding various sources for these essentials can simplify the search process, ensuring you have access to quality replacements.

| Source | Description |

|---|---|

| Authorized Dealers | Official distributors provide genuine components, ensuring compatibility and reliability. |

| Online Marketplaces | Websites like eBay and Amazon offer a wide selection, often at competitive prices. |

| Local Repair Shops | Nearby technicians may have access to or recommend quality replacements based on experience. |

| Manufacturer’s Website | Direct purchasing options from the original manufacturer can guarantee authenticity and support. |

Upgrading ZT219 Components Effectively

Enhancing the efficiency and performance of your machinery requires a strategic approach to component upgrades. By focusing on key areas that impact operation, you can achieve significant improvements in productivity and reliability. Understanding which elements to prioritize will help ensure that your upgrades yield the best possible results.

First, consider the power system. Upgrading the engine or the fuel system can lead to improved horsepower and torque, enabling the equipment to perform better under load. Additionally, incorporating high-performance filters can enhance airflow and efficiency, reducing wear and tear on critical components.

Next, examine the suspension and traction systems. Implementing advanced shock absorbers and tires designed for specific terrains can greatly improve handling and stability. This ensures that your machinery can tackle a variety of conditions with ease, enhancing overall performance.

Furthermore, focusing on electrical components is essential. Upgrading wiring, connectors, and control systems can enhance responsiveness and reduce downtime. Reliable electrical systems ensure that your equipment operates smoothly, minimizing the risk of failures during critical tasks.

Lastly, investing in maintenance tools and practices can prolong the lifespan of upgraded components. Regular inspections and the use of quality lubricants will maintain optimal performance, allowing your machinery to operate efficiently for years to come.

Resources for Bobcat Owners

Owning heavy machinery comes with its own set of responsibilities and challenges. Having access to reliable resources can significantly enhance maintenance and operational efficiency. This section provides essential tools and references for equipment enthusiasts and operators.

Online Forums and Communities

Engaging with fellow machinery owners can offer invaluable insights. Online platforms allow users to share experiences, troubleshoot issues, and exchange advice.

Maintenance Guides

Comprehensive maintenance manuals are crucial for ensuring longevity and performance. These resources often detail best practices and preventive measures.

| Resource Type | Description | Link |

|---|---|---|

| Online Forum | A platform for discussion and advice sharing. | Visit Forum |

| Maintenance Manual | Detailed guidelines for upkeep and repairs. | Download Manual |

| Video Tutorials | Step-by-step instructions on various tasks. | Watch Videos |