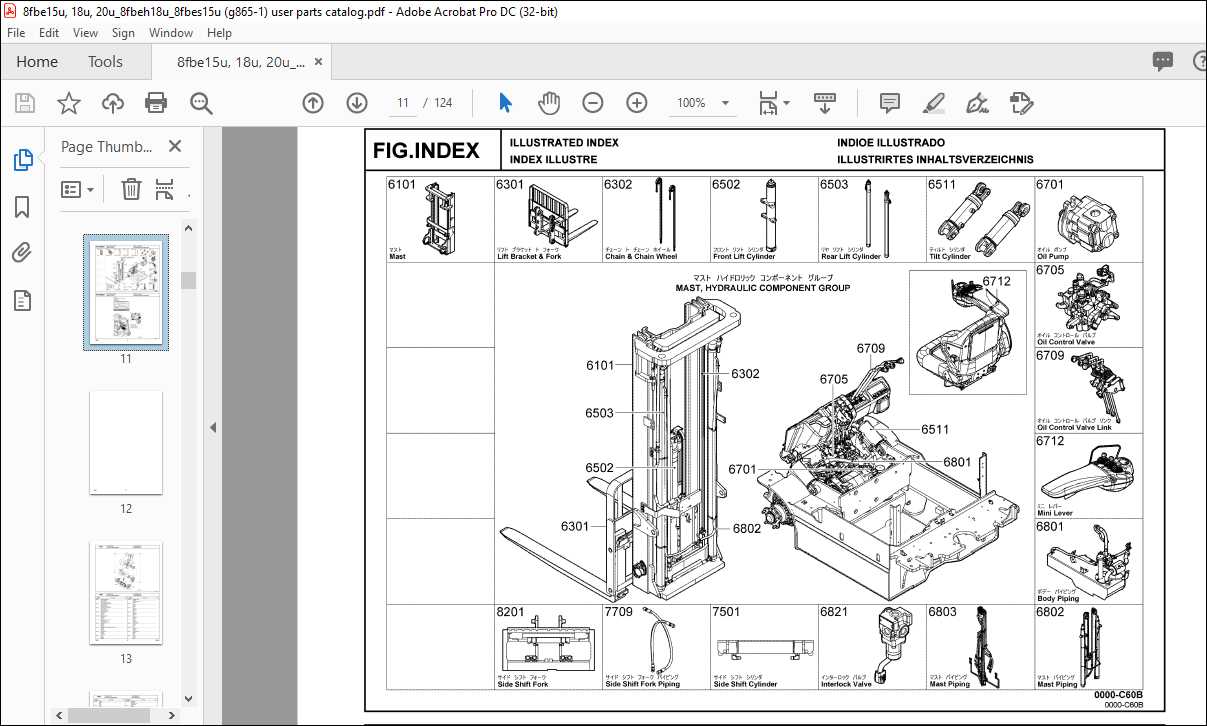

In the realm of industrial equipment, a comprehensive understanding of machinery components is crucial for efficient operation and maintenance. Each element plays a significant role in ensuring the smooth functioning of heavy-duty vehicles, often utilized in various sectors such as logistics and construction. A clear representation of these components can greatly aid technicians and operators in identifying issues and performing necessary repairs.

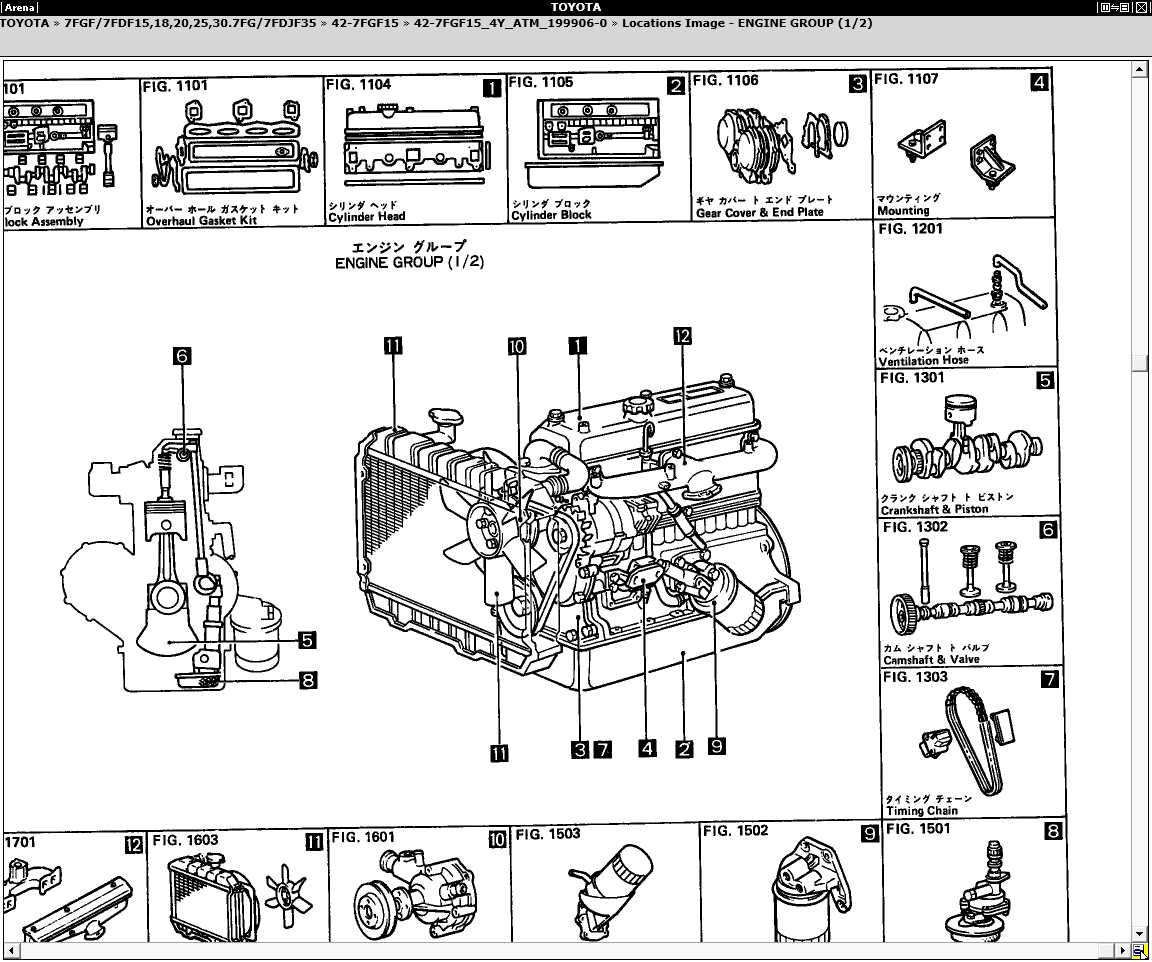

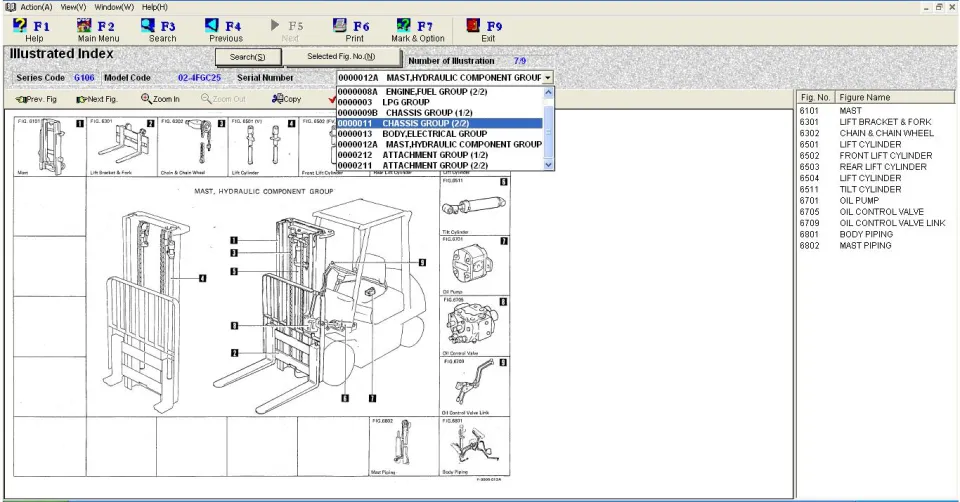

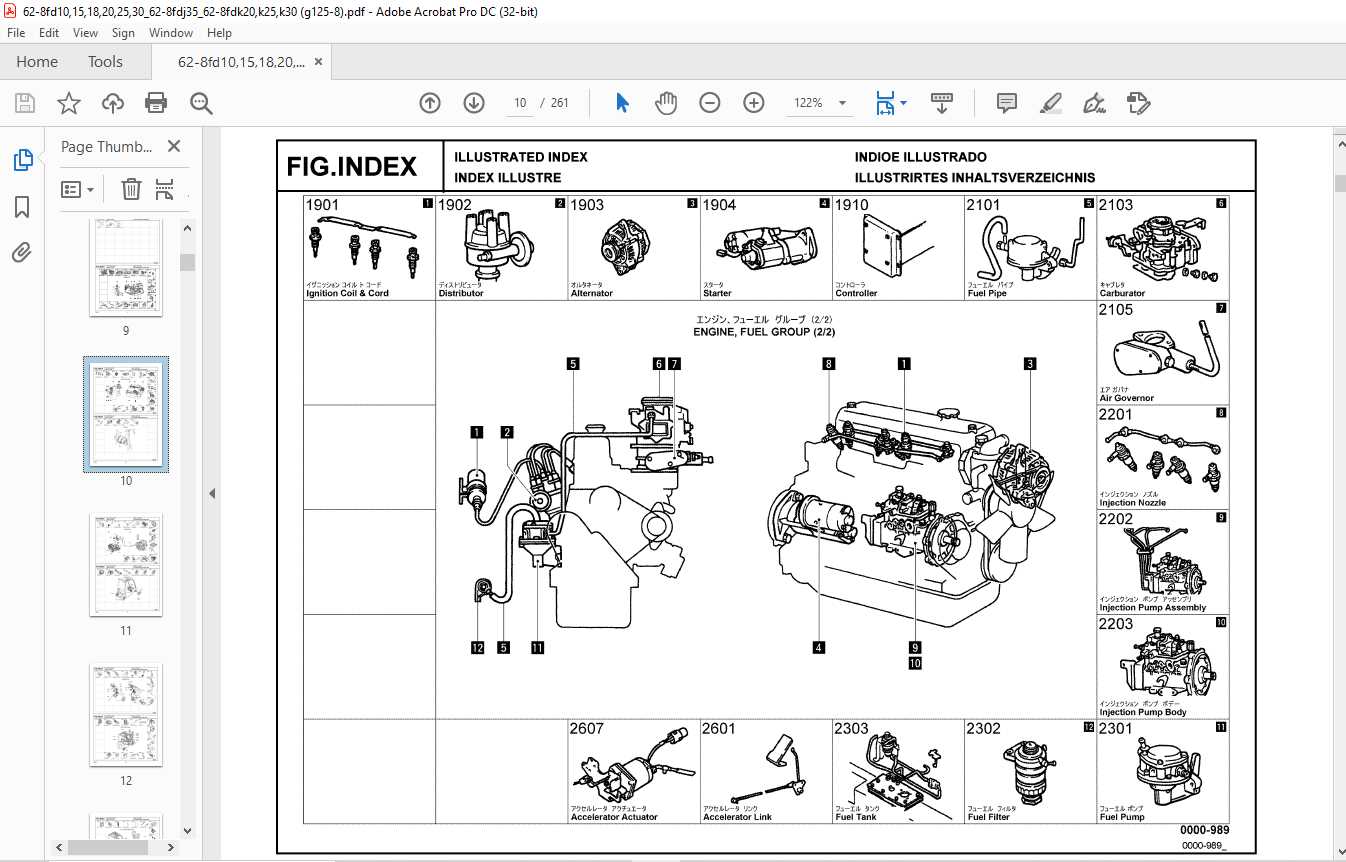

Visual representations serve as valuable tools for anyone involved in the upkeep and operation of such machinery. They provide a detailed overview, showcasing how different elements interconnect and function harmoniously. By examining these illustrations, individuals can enhance their knowledge, leading to improved troubleshooting skills and informed decision-making.

Moreover, having access to these graphical guides fosters a deeper appreciation of the engineering behind heavy machinery. It highlights the complexity and precision involved in their design, reminding us of the importance of regular maintenance and timely repairs to prolong their lifespan and optimize performance.

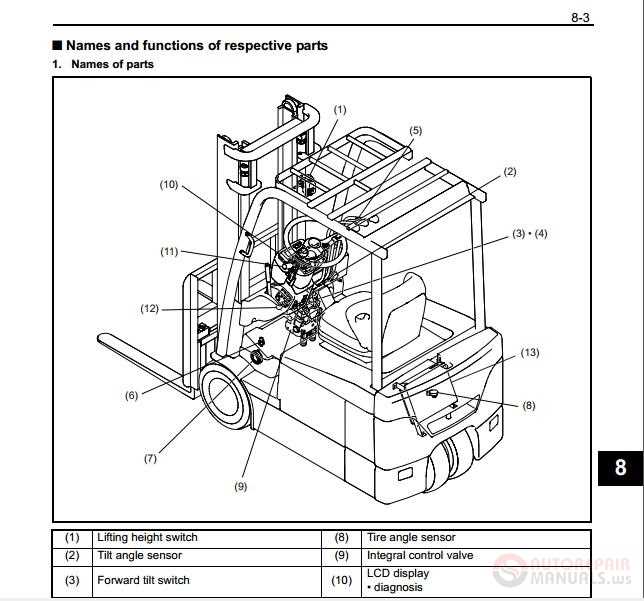

Understanding Toyota Forklift Components

In the realm of material handling, familiarity with the individual elements that comprise a lifting vehicle is essential for optimal performance and maintenance. Each component plays a crucial role in ensuring efficiency and safety during operations. This section delves into the various sections of these machines, highlighting their functions and interconnections.

Main Elements of Lifting Machinery

The structure of lifting vehicles includes several key sections, each designed to work in harmony with the others. Understanding these components is vital for effective troubleshooting and servicing. The primary elements include:

- Power Unit: This section includes the engine or electric motor, which provides the necessary force for operation.

- Mast Assembly: Responsible for lifting and lowering loads, this component consists of vertical and horizontal sections.

- Load Handling Attachments: Various tools and accessories that assist in moving different types of cargo.

- Chassis: The frame that supports the entire structure, crucial for stability and strength.

- Control System: The interface used by operators to maneuver and control the vehicle effectively.

Maintenance Considerations

Regular maintenance of these key components ensures longevity and reliability. Essential tasks include:

- Routine inspections of the power unit for signs of wear or leaks.

- Checking the mast assembly for any signs of damage or misalignment.

- Ensuring load handling attachments are secure and functioning properly.

- Inspecting the chassis for cracks or structural issues.

- Maintaining the control system for responsiveness and accuracy.

By comprehensively understanding these essential elements, operators can enhance their skill set and ensure safe, efficient handling of materials.

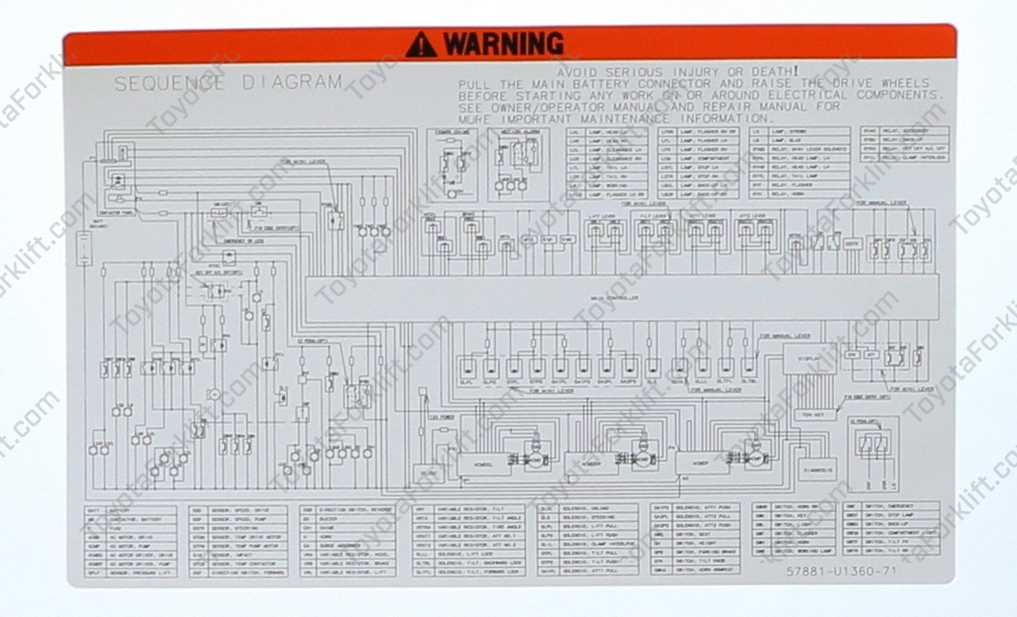

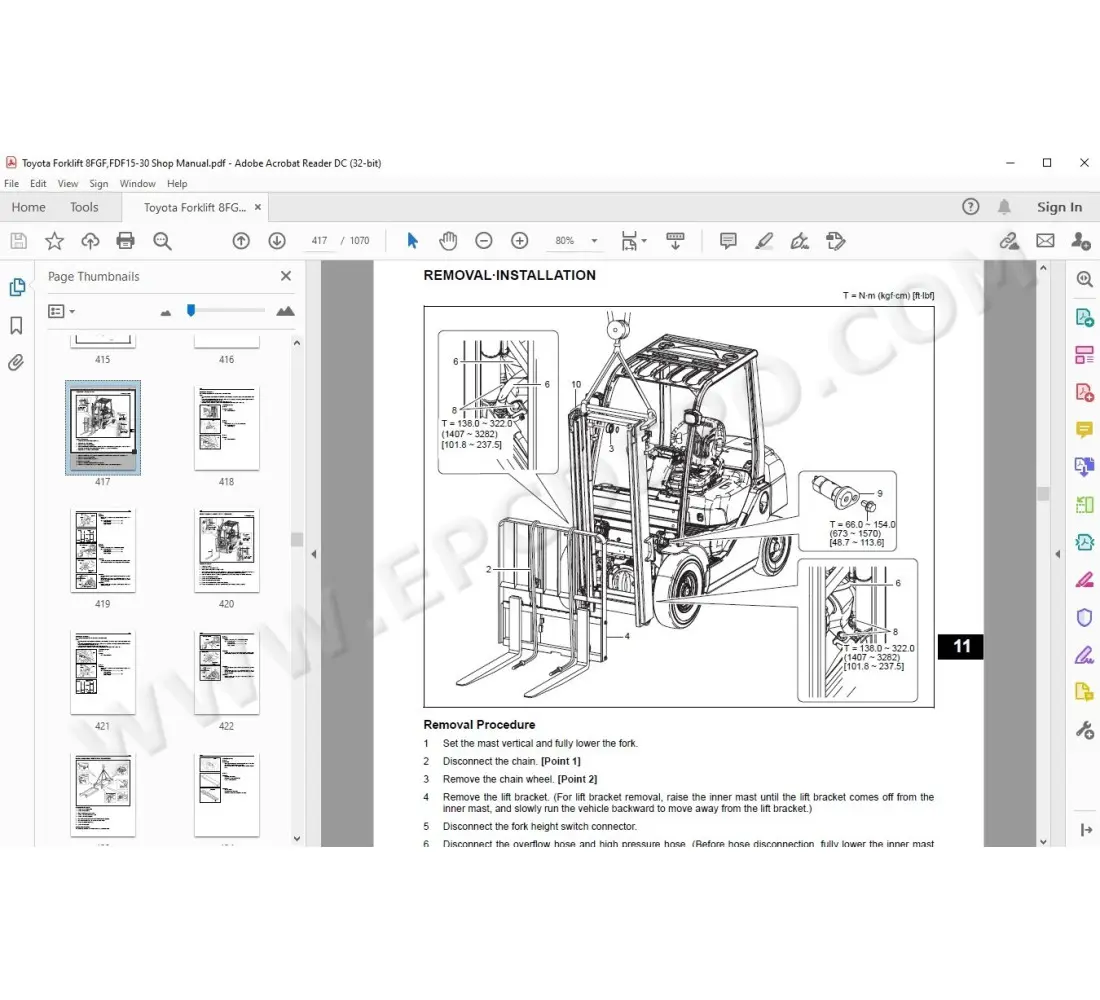

Importance of Accurate Parts Diagrams

Having precise visual representations of components is essential for effective maintenance and repair operations. These illustrations serve as vital tools for technicians, providing clear guidance on assembly and disassembly processes. When accuracy is prioritized, the likelihood of errors diminishes significantly, ensuring that machinery remains operational and safe.

Efficiency is greatly enhanced when individuals can quickly reference reliable visual aids. Technicians are able to identify necessary components swiftly, reducing downtime and streamlining workflows. This not only contributes to productivity but also minimizes the risk of misplacing or overlooking critical elements during repairs.

Furthermore, understanding the layout of a system is crucial for troubleshooting. Accurate visual aids allow professionals to pinpoint issues more effectively, leading to quicker resolutions and less strain on resources. As a result, businesses can maintain higher operational standards and improve overall performance.

In addition, these representations foster better training environments for newcomers. New technicians can learn more rapidly when they have access to clear, detailed visual resources. This foundational knowledge translates to improved competence and confidence in handling complex machinery.

In summary, the significance of precise visual representations cannot be overstated. They not only facilitate smoother operations but also contribute to a safer and more efficient working environment.

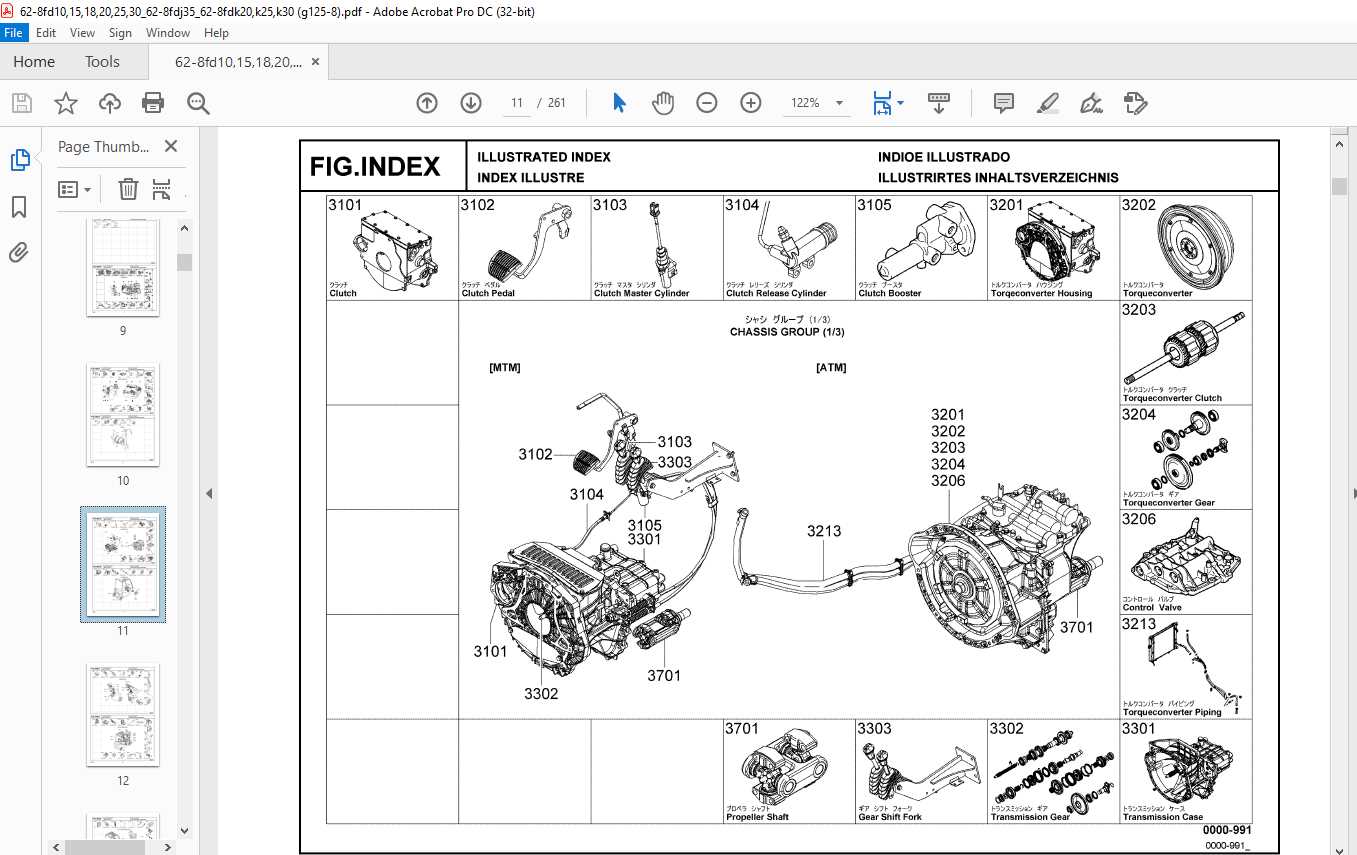

Common Forklift Models and Their Parts

Understanding various models of lifting machinery is essential for efficient operation and maintenance. Each design comes with unique features and components, crucial for optimal performance. Below are some prevalent types and their respective elements that operators should be familiar with.

Popular Models

- Electric Lifting Vehicle

- Internal Combustion Unit

- Reach Truck

- Pallet Jack

Key Components

- Power Source

- Mast Assembly

- Forks

- Wheels and Tires

- Hydraulic System

How to Read Parts Diagrams Effectively

Understanding visual representations of components is essential for maintenance and repairs. These illustrations provide a structured view of how elements are organized and interact with each other, making it easier to identify and locate specific items within a system.

Key Elements to Look For

When examining these visual aids, pay attention to the following aspects:

| Element | Description |

|---|---|

| Labels | Clear text annotations that specify the names and numbers of components. |

| Lines and Arrows | Indicate connections, relationships, and flow between different parts. |

| Symbols | Represent specific functionalities or types of components, often standardized. |

Steps to Follow

To enhance your comprehension, consider these steps:

- Start with the legend to familiarize yourself with symbols and terminology.

- Identify major assemblies and how they are broken down into smaller units.

- Follow the connections illustrated to understand how components work together.

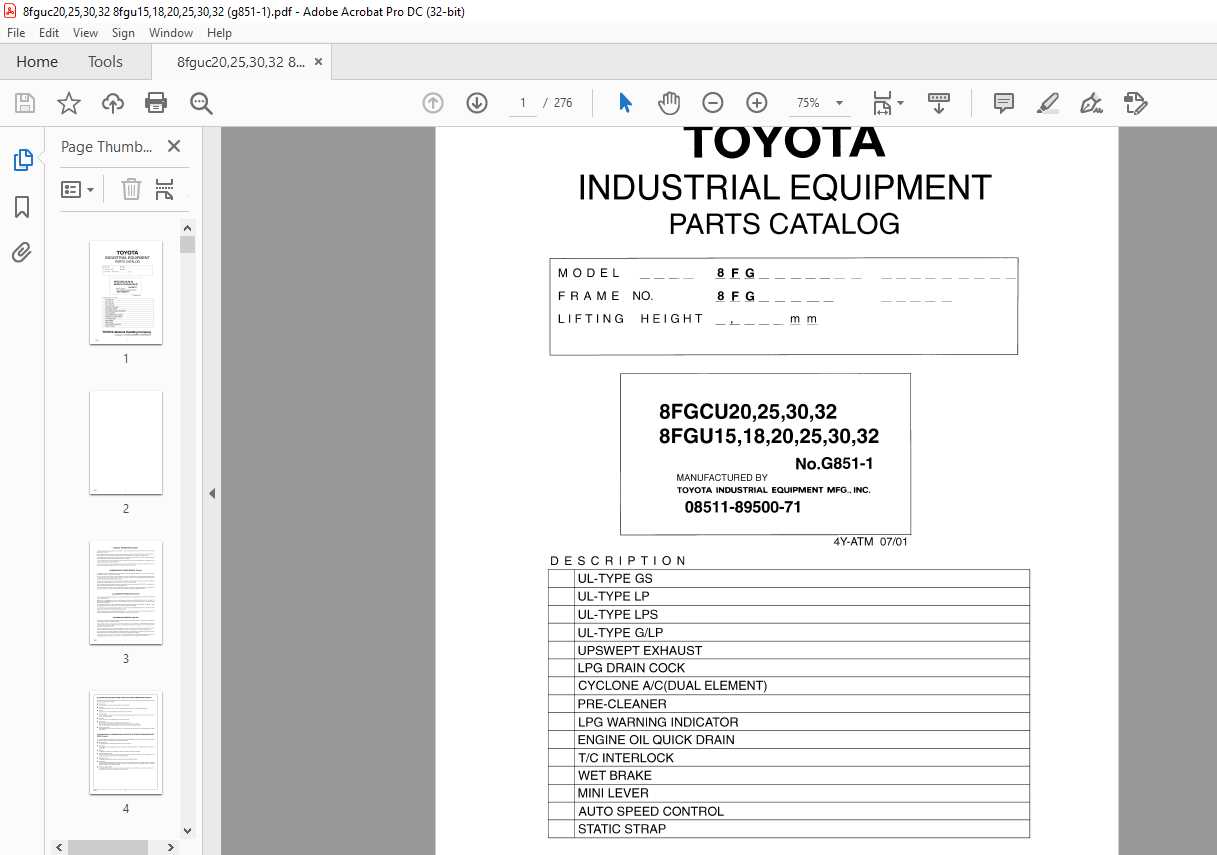

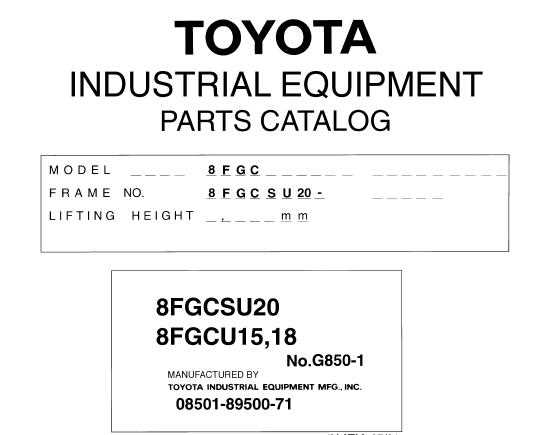

Finding Genuine Toyota Forklift Parts

Locating authentic components for heavy machinery is crucial for maintaining optimal performance and safety. Quality materials ensure longevity and reliability, significantly reducing the risk of malfunctions.

- Research authorized dealers to guarantee the authenticity of your components.

- Verify the product codes and specifications to match your machine’s requirements.

- Consult user manuals for guidance on selecting the right items.

Utilizing these strategies can help you delve into the world of genuine replacements, ultimately enhancing your equipment’s functionality.

Maintenance Tips for Forklift Longevity

Ensuring the extended life of your heavy machinery requires diligent care and attention. Implementing regular maintenance practices can significantly enhance performance and reduce the likelihood of costly repairs.

- Routine Inspections: Conduct frequent checks for any signs of wear and tear. Look for leaks, cracks, and other potential issues that could lead to more significant problems.

- Fluid Levels: Regularly monitor and maintain hydraulic fluid, oil, and coolant levels. Proper lubrication is crucial for efficient operation.

- Tire Condition: Inspect tires for proper inflation and tread wear. Well-maintained tires contribute to better stability and handling.

- Battery Care: Keep the battery terminals clean and ensure that the battery is fully charged. Regularly check for corrosion and clean as necessary.

Following a structured maintenance schedule not only promotes safety but also enhances productivity. Consider these practices as foundational to preserving your equipment’s efficiency.

- Follow Manufacturer Guidelines: Adhere to the recommendations outlined in the owner’s manual for servicing intervals and specifications.

- Training Operators: Ensure that all operators are trained to use the machinery correctly. Misuse can lead to accelerated wear and potential accidents.

- Store Properly: When not in use, park in a dry, clean area to protect against environmental damage.

Implementing these strategies will ensure that your machinery remains reliable and efficient over the long term, ultimately contributing to better operational success.

Identifying Parts by Model Number

Recognizing components based on their model number is essential for effective maintenance and repair. This process not only streamlines the identification of individual elements but also ensures compatibility and optimal performance. By focusing on the specific model number, users can access accurate information regarding the required replacements or upgrades.

To facilitate the identification process, manufacturers typically provide detailed catalogs that associate each model number with its respective components. This organized approach aids technicians and operators in quickly locating the necessary items, ultimately minimizing downtime and enhancing operational efficiency.

| Model Number | Description | Common Issues |

|---|---|---|

| ABC123 | Hydraulic Pump Assembly | Leakage, reduced pressure |

| DEF456 | Drive Motor | Overheating, loss of power |

| GHI789 | Steering Column | Difficulty in maneuvering |

Benefits of Using OEM Parts

Utilizing original equipment manufacturer components ensures enhanced reliability and performance in machinery. These parts are specifically designed to fit and function seamlessly, leading to improved longevity and efficiency.

Quality Assurance: OEM components undergo rigorous testing to meet stringent standards, ensuring that users receive top-notch quality and reliability.

Perfect Compatibility: Using these components guarantees that every element works harmoniously, minimizing the risk of malfunction and breakdown.

Warranty Protection: Many manufacturers offer warranties on their products, providing peace of mind and protecting your investment against unforeseen issues.

Resale Value: Equipment that has been maintained with original components tends to retain its value better, making it a wise choice for future resale.

In summary, choosing OEM options not only enhances the performance of machinery but also contributes to a more efficient and cost-effective operation in the long run.

Resources for Forklift Repair Guides

When it comes to maintaining and fixing heavy machinery, having access to reliable resources is crucial. Whether you’re a seasoned technician or a DIY enthusiast, a wealth of information can guide you through troubleshooting and repairs. Understanding where to find accurate and comprehensive repair manuals can significantly enhance your efficiency and effectiveness in handling mechanical issues.

Online Manuals and Databases

Numerous websites offer extensive databases filled with manuals and repair guides for various machinery. These platforms often feature downloadable documents that cover everything from routine maintenance to complex repairs. Utilizing these resources allows you to reference specific models and their corresponding instructions, ensuring you have the right information at your fingertips.

Community Forums and Support Groups

Engaging with community forums can provide invaluable insights and tips from fellow users. These platforms often host discussions about common problems and solutions, allowing you to learn from the experiences of others. Participating in these groups can also lead to recommendations for trusted repair guides and techniques that have proven effective in real-world applications.