The intricate assembly of various elements in specialized machines serves crucial functions in a wide range of fields. These devices are meticulously crafted to support essential processes, offering users both convenience and efficiency. To fully comprehend how these mechanisms operate, it’s important to explore each segment that contributes to the overall performance. By breaking down the structure into its key sections, we gain valuable insights into the core functionality of the system.

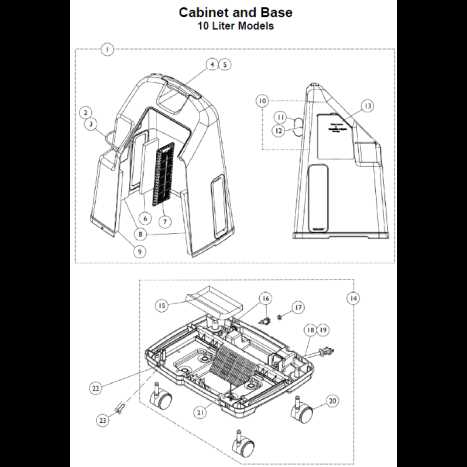

Every component plays a role in ensuring the proper operation of these devices. From the main processing unit to the smaller auxiliary modules, each piece is interconnected, creating a network that works together seamlessly. By examining the design and placement of these units, we can better understand how the system achieves its intended purpose and maintains reliability over time.

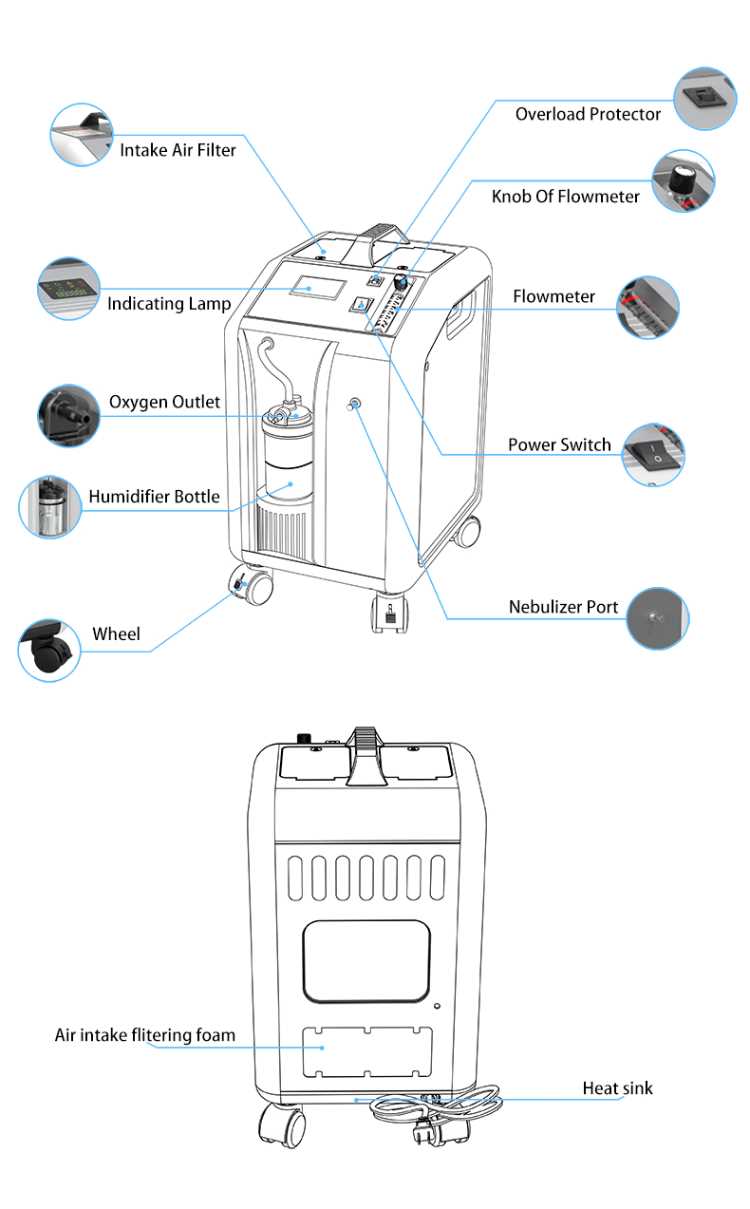

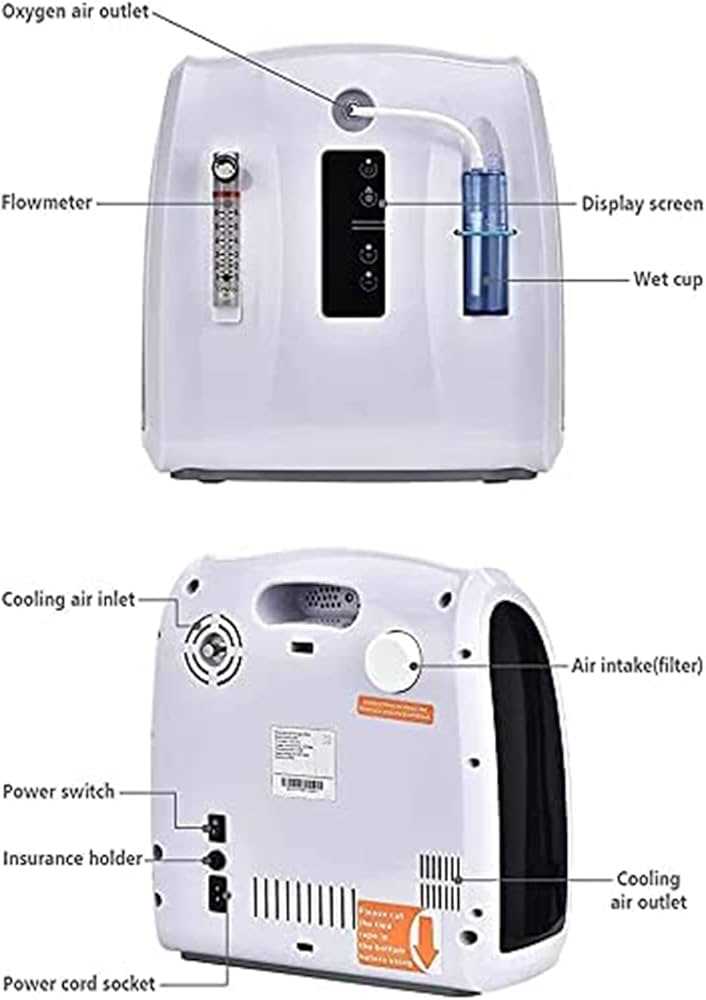

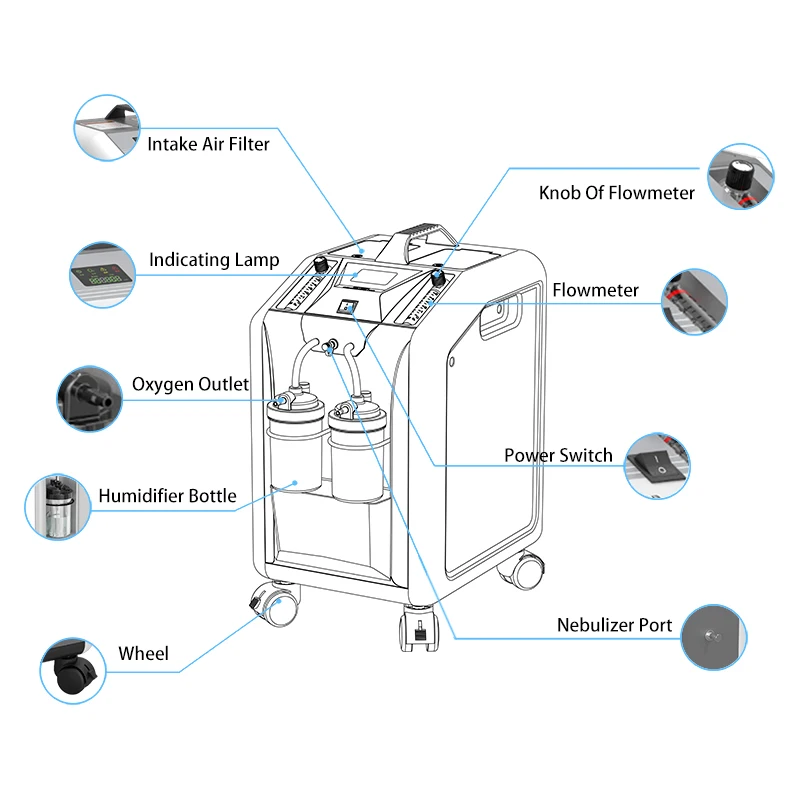

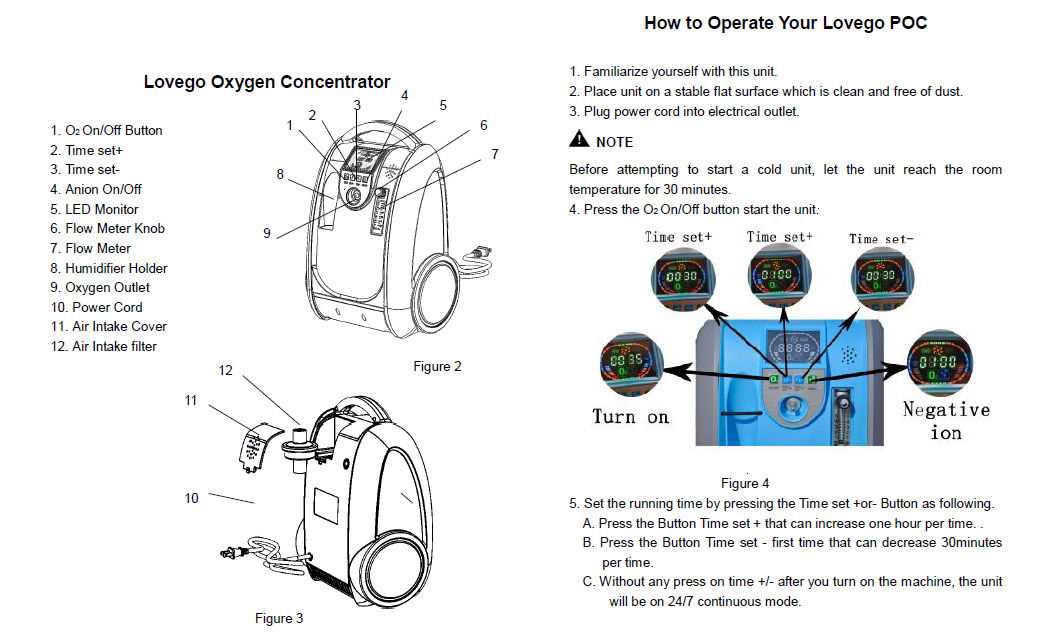

Key Components of Oxygen Concentrators

These systems consist of several essential elements that work together to ensure the smooth delivery of purified air. Each element serves a unique role in the process, contributing to the efficiency and effectiveness of the overall function.

At the core of the system, there is a device responsible for filtering and separating specific gases from the surrounding air. This part ensures that only the necessary components are extracted for further use. Additionally, the machine is equipped with a compression mechanism that allows the necessary elements to be delivered at the required rate.

The system also includes a regulator, which carefully controls the output, ensuring a steady and consistent flow of purified air. Supporting this, there are various channels and tubes that guide the flow through different stages of the process, maintaining the integrity of the system from start to finish.

Understanding Air Filtration Systems

Air filtration systems play a critical role in ensuring the purity and quality of the air in various applications. These systems are designed to capture unwanted particles, contaminants, and impurities, improving the overall air composition. The efficiency of the filtration process depends on the materials used and the specific mechanism that drives the separation of unwanted elements from the air.

The filtering process often involves multiple stages, each serving a different purpose. Pre-filters typically catch larger particles, while finer filters handle smaller impurities, providing a more thorough cleaning. Understanding how these stages interact helps optimize the system’s performance, leading to cleaner and healthier air output.

Proper maintenance of these systems is essential to keep them functioning at peak efficiency. Regular cleaning or replacement of filters ensures that the system continues to work effectively, preventing blockages and maintaining a consistent flow of purified air.

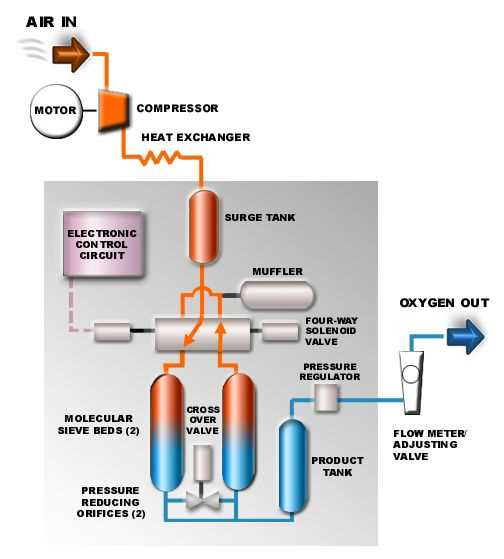

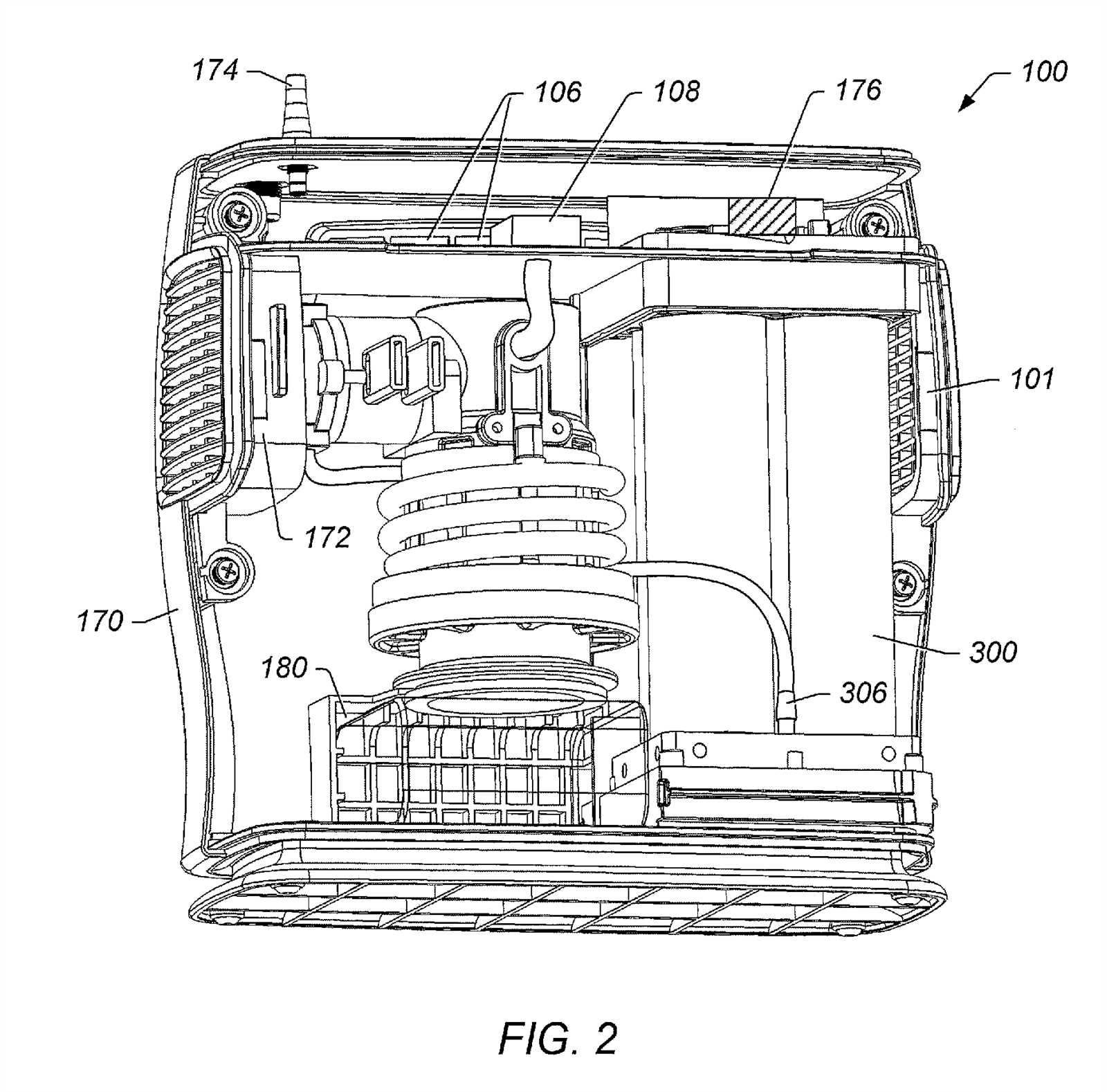

Compressor and Pressure Mechanism Overview

The core functionality of the system relies on the efficient movement of air, driven by a mechanical unit designed to create the necessary pressure levels. This component plays a key role in maintaining consistent flow, ensuring that the overall process operates smoothly and effectively. The mechanism responsible for regulating air compression is fundamental to achieving the desired output in a reliable manner.

At the heart of this process is a compression unit, which increases the pressure of incoming air to a specific level. By doing so, it enables the entire setup to function optimally, providing the required air movement and control. This balanced interaction between pressure and flow ensures the stability of the system, making it essential for continuous operation.

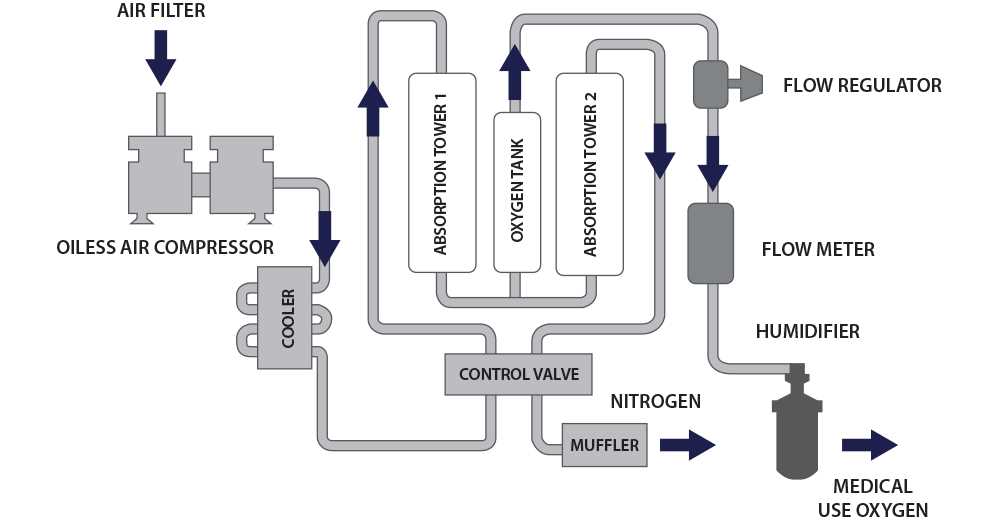

Exploring the Oxygen Generation Process

The process of extracting vital elements from the surrounding environment involves several key steps. Understanding how these elements are separated and concentrated for human use can shed light on the efficiency and functionality of such systems. By breaking down the components and their roles, we can gain insights into how this essential transformation takes place.

- First, air is drawn in through a specialized intake mechanism, filtering out unwanted particles and impurities.

- Next, the system isolates the desired element, separating it from other gases using advanced filtration techniques.

- Following this, the purified form is channeled through a system designed to regulate output, ensuring a steady supply.

- Finally, the generated flow is made available for use, typically delivered at specific concentrations and rates.

Each stage plays a crucial role in ensuring the system’s overall effectiveness, transforming ambient air into a usable resource for various applications.

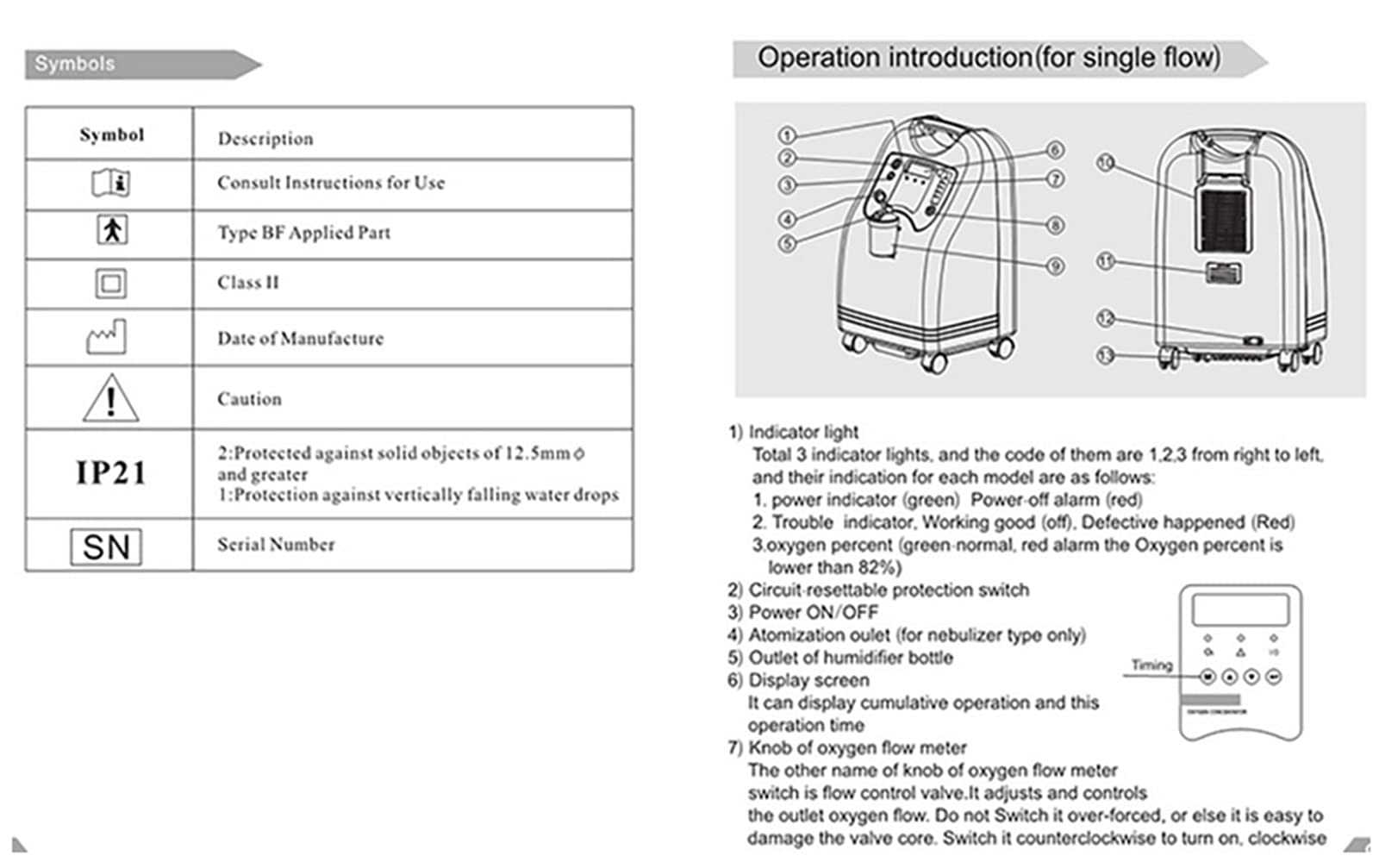

How Oxygen Flow Control Works

The mechanism governing the distribution of breathable air involves a carefully designed system that regulates how much of the vital gas is delivered at any given moment. This system is essential for adjusting the rate of supply based on specific needs, ensuring an efficient and safe experience for users.

Flow adjustment is achieved through a series of valves and dials that modulate the output levels. By finely tuning these components, users can select the desired level of supply, creating a tailored experience. The setup also includes safety measures to prevent overuse or under-supply, providing a balanced and reliable performance.

To achieve smooth regulation, the internal structure utilizes a blend of sensors and mechanical controls that communicate with one another, constantly monitoring the current output and making adjustments as needed. This dynamic system ensures consistency and precision in delivering the appropriate quantity.

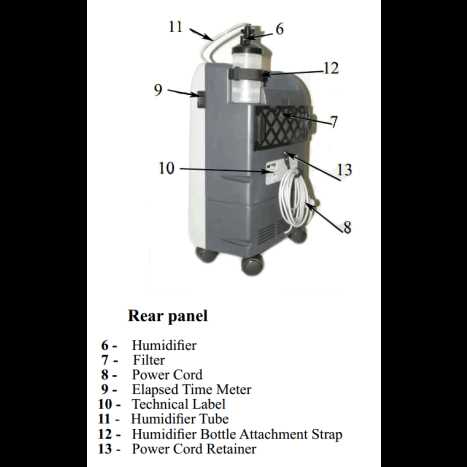

Moisture Control and Humidifier Integration

Effective management of humidity levels is essential for ensuring optimal performance and comfort in respiratory support systems. By incorporating advanced moisture control features and integrating humidifying components, these devices can provide a balanced environment that meets the user’s needs.

The Importance of Humidity Management

Maintaining appropriate moisture levels can significantly enhance the user experience. Here are some key benefits:

- Prevents dryness in airways, reducing discomfort and irritation.

- Enhances the effectiveness of respiratory therapy by ensuring that delivered air is not overly dry.

- Minimizes the risk of respiratory infections associated with dry air.

Humidifier Integration Techniques

Integrating a humidifier into the system involves various strategies to ensure consistent moisture delivery:

- In-line humidification: Placing a humidifying unit directly in the airflow path.

- Heated humidifiers: Utilizing heat to increase the water vapor capacity of the air.

- Passive humidifiers: Employing materials that naturally add moisture to the airstream.

By implementing these techniques, users can achieve a more comfortable and effective respiratory therapy experience, enhancing overall satisfaction and health outcomes.

Valve System and Its Role

The valve system serves as a critical component within the apparatus, ensuring the efficient regulation of airflow throughout the mechanism. By managing the direction and flow of gas, these valves contribute significantly to the device’s overall functionality and performance.

In essence, the valve mechanism operates by opening and closing at precise intervals, allowing for optimal gas distribution. This dynamic process is vital for maintaining consistent pressure levels and preventing backflow, which could disrupt the intended operation.

Furthermore, the effectiveness of the valve system directly impacts the reliability of the device. Any malfunction or blockage within this system can lead to reduced efficiency or complete failure, underscoring the importance of regular maintenance and inspection.

In summary, the valve assembly plays an indispensable role in the proper functioning of the device, facilitating the controlled movement of gas to ensure user safety and device reliability.

The Importance of Heat Dissipation Units

Effective thermal management is crucial for the longevity and performance of various devices. Heat dissipation units play a vital role in ensuring that equipment operates within safe temperature ranges, thus preventing potential damage and optimizing functionality. This section explores the significance of these components in maintaining efficient operation.

Role in Performance

Heat dissipation units are essential for several reasons:

- They help maintain optimal operating temperatures, which enhances performance.

- By minimizing overheating, they extend the lifespan of critical components.

- They contribute to overall energy efficiency, reducing power consumption.

Design Considerations

When designing effective heat dissipation solutions, several factors must be taken into account:

- Material Selection: The choice of materials significantly affects heat transfer efficiency.

- Surface Area: Increasing the surface area enhances the ability to dissipate heat.

- Airflow Management: Proper airflow is necessary to facilitate efficient heat removal.

Power Sources and Energy Efficiency

Understanding the various power sources and their impact on energy efficiency is crucial for optimal device performance. The choice of energy supply not only influences operational costs but also affects the sustainability of the equipment. Implementing energy-efficient solutions can lead to significant savings and improved functionality.

Several types of energy sources are commonly utilized in these devices:

- Electrical supply from the grid

- Battery-operated systems for mobility

- Renewable energy sources, such as solar power

Each source has its own advantages and considerations:

- Grid Power: Reliable and widely available, but may incur higher operational costs.

- Battery Systems: Offer portability and convenience, yet require regular charging and maintenance.

- Renewable Sources: Environmentally friendly and can reduce long-term costs, though initial setup can be expensive.

To enhance energy efficiency, manufacturers often incorporate features such as:

- Advanced power management systems

- Energy-efficient components

- Smart technology for monitoring and optimization

By selecting the right power source and utilizing energy-saving technologies, users can ensure optimal performance while minimizing environmental impact.