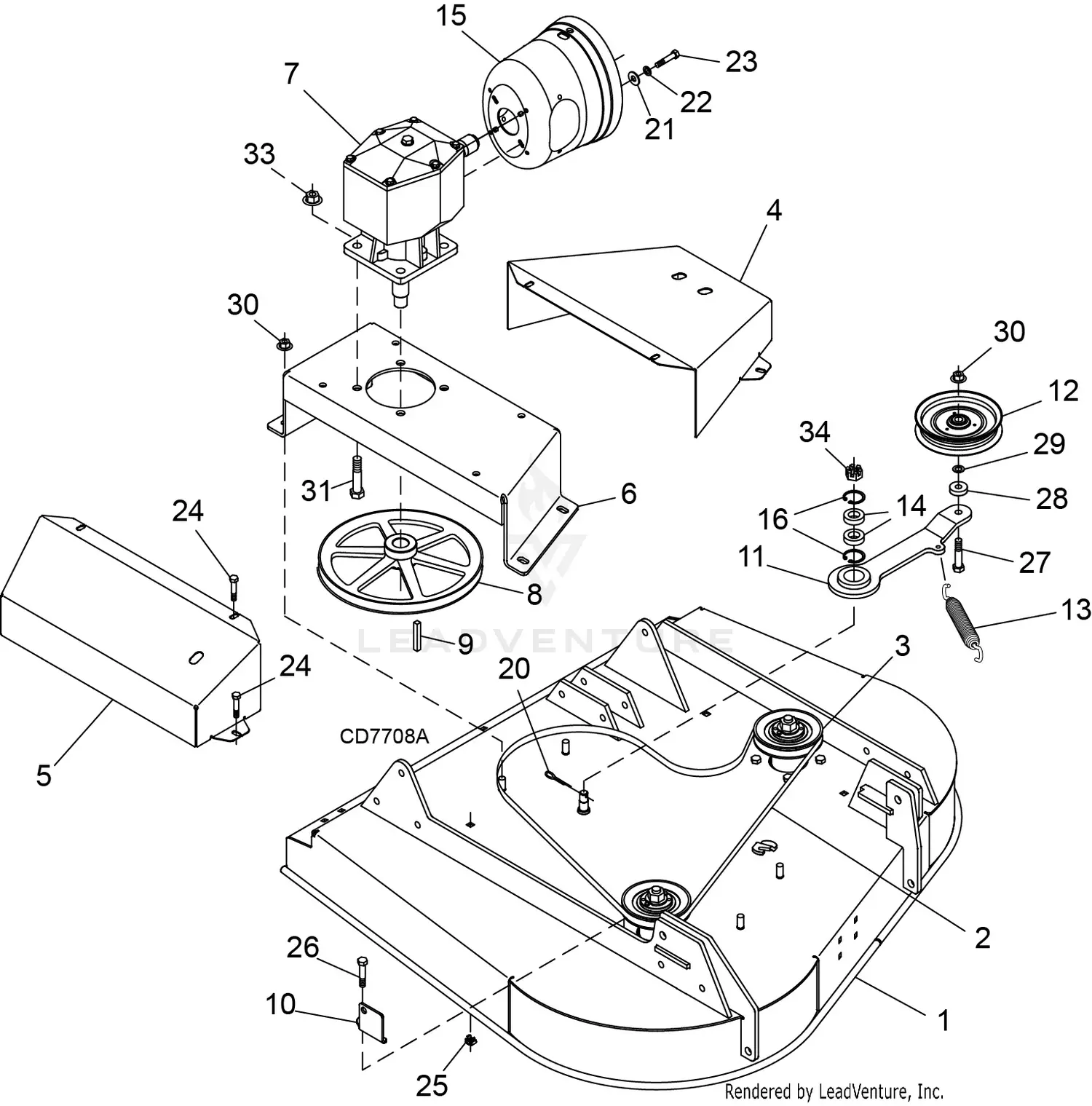

In the realm of landscape maintenance, efficient equipment plays a pivotal role in achieving optimal results. Understanding the intricate elements that contribute to the functionality of these machines is essential for both operators and enthusiasts. This section delves into the various components of a specific type of agricultural implement, shedding light on their arrangement and interaction.

By exploring the assembly of these tools, users can enhance their maintenance practices and troubleshoot potential issues more effectively. Each element, from the cutting mechanism to the support framework, serves a unique purpose, contributing to the overall performance and durability of the equipment. Gaining insight into these components fosters a deeper appreciation for the technology behind landscape management.

In this discussion, we will provide a detailed overview of the specific configurations and functionalities of these essential tools. Understanding the layout of these systems can empower users to make informed decisions regarding repairs and upgrades, ultimately ensuring the longevity of their equipment.

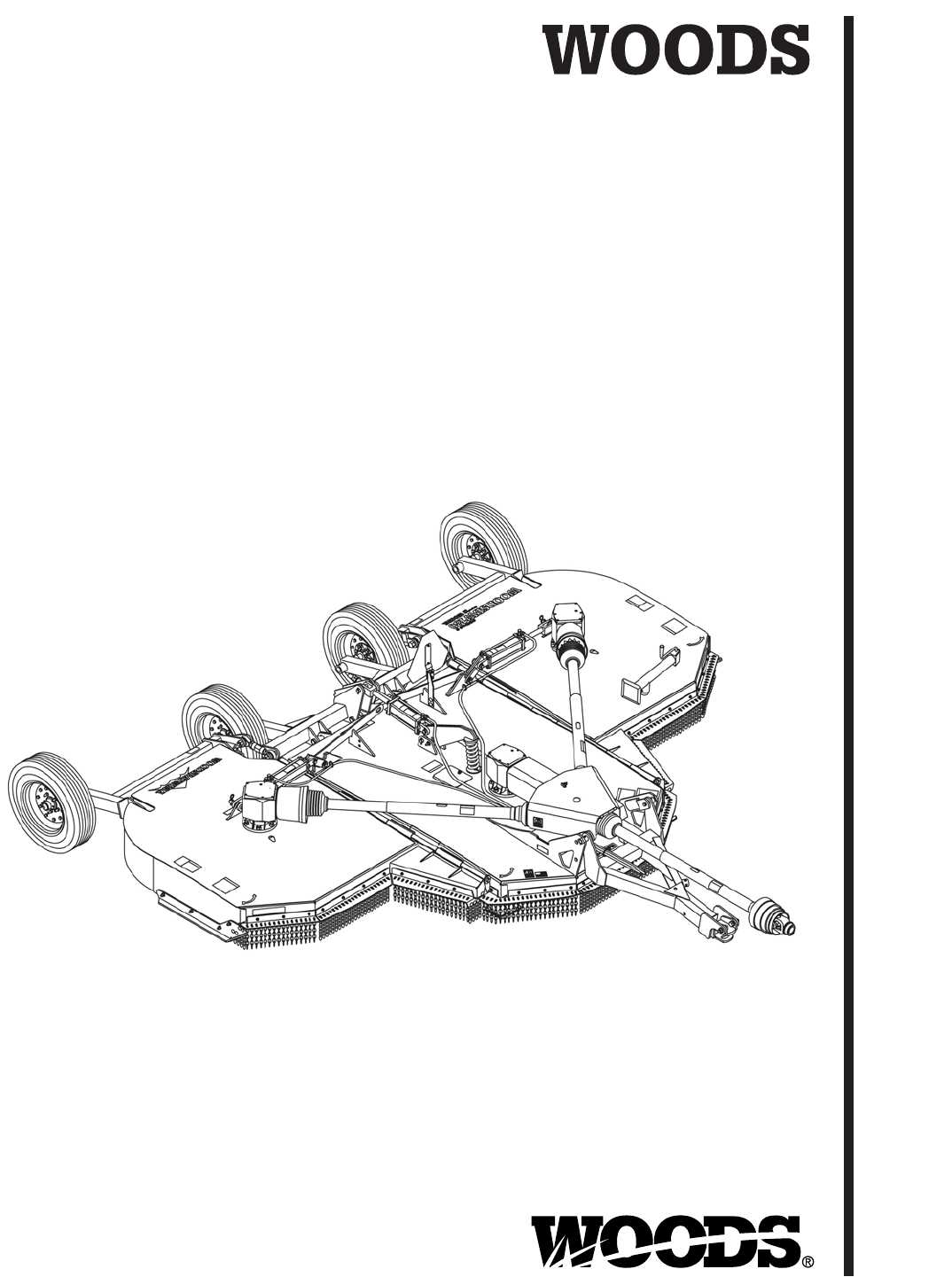

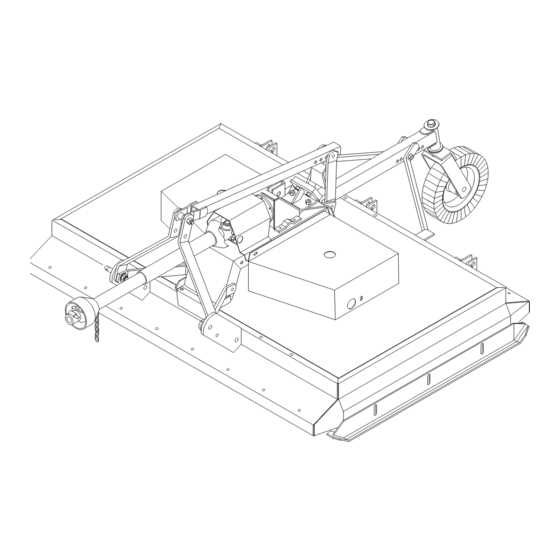

Understanding Woods Batwing Mower Components

This section delves into the essential elements of a specific type of agricultural equipment designed for efficient grass and vegetation management. Each component plays a critical role in the overall functionality, contributing to the machine’s effectiveness in various terrains and conditions.

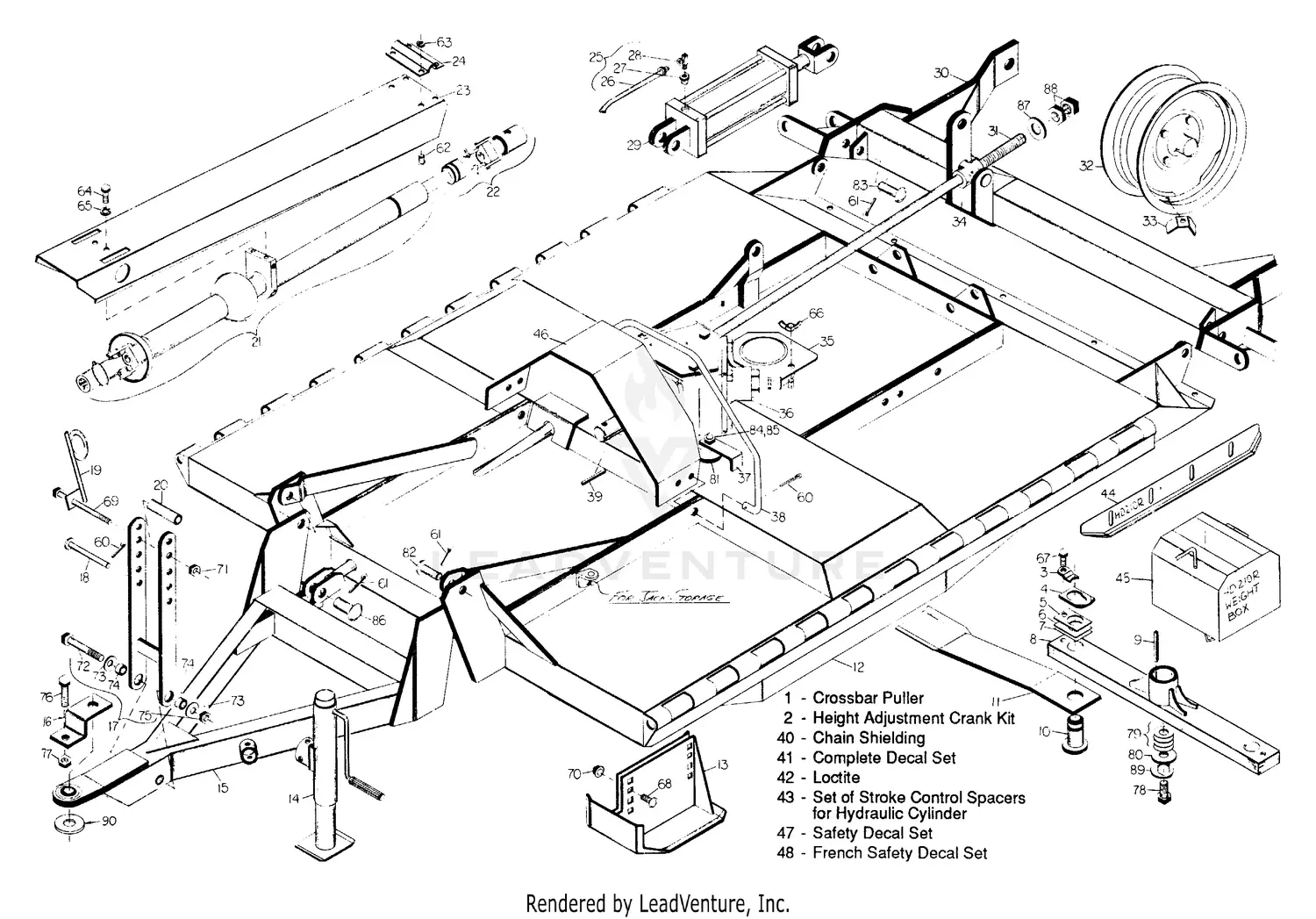

The primary structure serves as the foundation, supporting various mechanisms that enable the equipment to operate smoothly. Key features include cutting blades, which are engineered to handle dense growth, ensuring a clean cut. Additionally, the drive system facilitates the transmission of power from the engine to the cutting elements, optimizing performance.

Other important elements encompass the control mechanisms, which allow operators to adjust settings for different mowing heights and conditions. The safety features integrated into the design protect users during operation, highlighting the importance of user-friendly design in agricultural machinery.

Understanding the various components and their functions is essential for maintenance and effective use. Familiarity with these elements can enhance the longevity of the equipment and ensure optimal performance in the field.

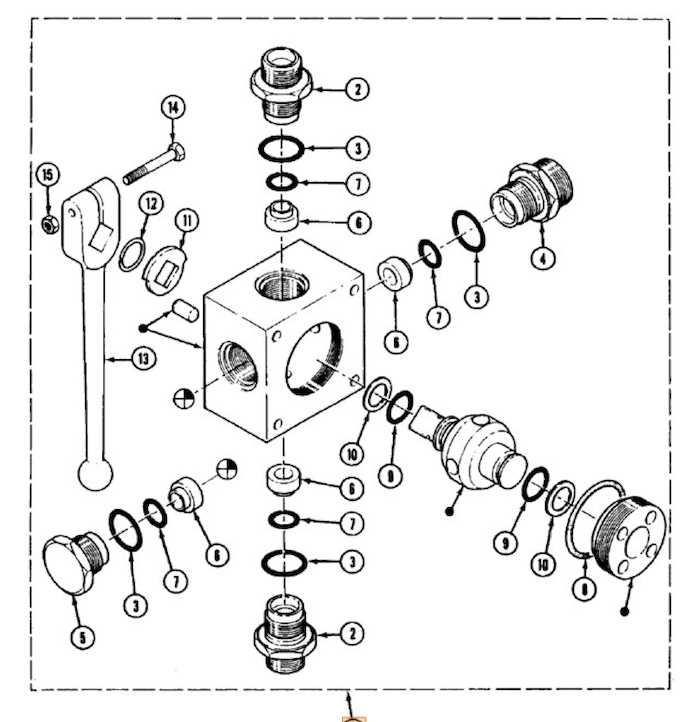

Importance of Accurate Parts Diagrams

Understanding the intricacies of equipment maintenance relies heavily on precise visual representations. These illustrations serve as essential guides for users, providing clarity on the various components and their arrangements within a machine. When each element is clearly depicted, it enhances the user’s ability to perform repairs and replacements effectively.

Accuracy in these visuals is crucial, as it directly impacts the efficiency of maintenance tasks. Users can quickly identify the necessary components and their specific locations, reducing the likelihood of errors during service. This can lead to significant time savings and minimize the frustration often associated with mechanical issues.

Moreover, accurate illustrations contribute to a deeper understanding of the machinery. Users become familiar with how different parts interact, fostering better decision-making when it comes to troubleshooting and upgrades. In essence, reliable visual aids not only simplify maintenance but also empower users to optimize their equipment’s performance.

Key Features of Batwing Mowers

These versatile implements are designed for extensive coverage and efficient operation in various terrains. They are particularly valued for their ability to manage larger areas with ease, providing an effective solution for landscape maintenance and agricultural tasks.

Enhanced Maneuverability

One of the standout characteristics of these implements is their exceptional maneuverability. This feature is crucial for navigating tight spaces and uneven ground. Key aspects include:

- Articulated design allowing for sharper turns.

- Adjustable wings for optimal cutting angles.

- Compact profile for improved handling in restricted areas.

Robust Construction

Durability is a primary concern when selecting equipment for heavy-duty tasks. The following attributes contribute to the longevity and reliability of these machines:

- High-quality materials that withstand harsh conditions.

- Reinforced components designed to handle rigorous usage.

- Corrosion-resistant finishes to enhance lifespan.

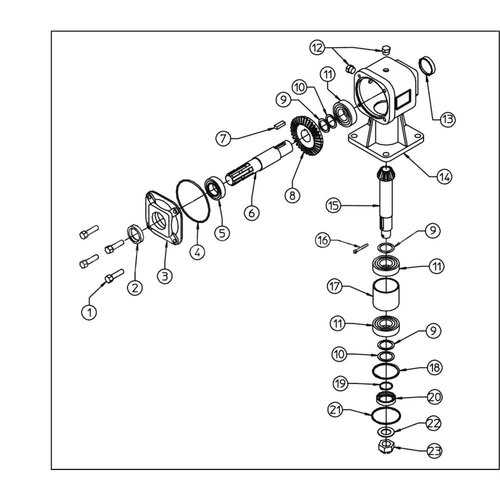

Identifying Essential Replacement Parts

Understanding the key components of your equipment is crucial for maintaining optimal performance. Recognizing when specific elements require attention can significantly enhance the longevity and efficiency of the machinery. This section focuses on the identification of vital elements that may need to be replaced periodically to ensure smooth operation.

Commonly Replaced Components

Frequent wear and tear can affect several critical components. Familiarity with these elements will aid in timely replacements and prevent unnecessary downtime.

| Component | Description | Function |

|---|---|---|

| Cutter Blades | Sharp metal blades that cut through vegetation. | Essential for effective cutting and performance. |

| Belts | Rubber strips that transfer power from the engine to the blades. | Ensure smooth operation of cutting mechanisms. |

| Gearbox | Enclosure containing gears for power transmission. | Regulates the speed and torque delivered to the blades. |

Tips for Replacement

When considering replacements, always opt for high-quality components. Regular inspections and understanding the signs of wear can help you make informed decisions, ensuring that your machinery operates at its best.

Common Issues with Mower Components

In the operation of agricultural machinery, various components may encounter challenges that affect overall performance. Recognizing these issues is crucial for ensuring efficient functionality and minimizing downtime. The following are some typical problems associated with different components of such equipment.

Frequent Problems

Several factors can contribute to malfunctions in the machinery. These include wear and tear, environmental conditions, and inadequate maintenance practices. Understanding these aspects helps in addressing the root causes effectively.

Maintenance Recommendations

Regular inspection and maintenance can prevent many common issues. Operators are advised to adhere to a systematic schedule for checks, ensuring that all components function as intended.

| Component | Common Issue | Recommended Action |

|---|---|---|

| Blades | Dullness or Damage | Sharpen or Replace |

| Hydraulic System | Leakage | Check Seals and Hoses |

| Gearbox | Overheating | Inspect for Proper Lubrication |

| Wheels | Wear and Tear | Inspect Tread and Pressure |

| Frame | Cracks or Damage | Evaluate Structural Integrity |

Maintenance Tips for Batwing Mowers

Regular upkeep is essential for ensuring optimal performance and longevity of your mowing equipment. Proper care not only enhances efficiency but also minimizes the likelihood of unexpected breakdowns. Here are some key practices to follow for effective maintenance.

-

Routine Inspections: Frequently examine your machinery for any signs of wear and tear. Look for loose bolts, damaged blades, and other components that may require attention.

-

Cleaning: After each use, clean the equipment thoroughly to remove debris, grass clippings, and dirt. This helps prevent rust and other damage.

-

Lubrication: Regularly lubricate moving parts to reduce friction and wear. Refer to the manufacturer’s guidelines for recommended lubricants and application frequency.

-

Blade Maintenance: Keep blades sharp for efficient cutting. Dull blades can lead to poor performance and increased fuel consumption. Sharpen or replace blades as needed.

-

Fluid Checks: Regularly check and replace fluids such as oil and hydraulic fluid. Ensure that levels are adequate and that fluids are clean to promote proper function.

By following these maintenance tips, you can ensure that your equipment operates efficiently and effectively, providing reliable service for many seasons to come.

How to Source Genuine Parts

Acquiring authentic components is essential for maintaining the efficiency and longevity of your equipment. Ensuring that you obtain high-quality replacements can significantly impact the performance of your machinery. This section outlines effective strategies to secure genuine replacements and enhance your operational reliability.

One of the most reliable methods for sourcing authentic components is to establish connections with authorized dealers. These professionals can provide assurance regarding the quality and compatibility of the items. It’s advisable to consult the manufacturer’s website or customer service for a list of approved distributors in your area.

Additionally, attending trade shows and industry events can offer valuable opportunities to meet suppliers and learn more about available options. Engaging with representatives can also provide insights into new products and innovations.

| Source Type | Benefits | Considerations |

|---|---|---|

| Authorized Dealers | Guaranteed authenticity, expert advice | May be more expensive |

| Trade Shows | Direct access to suppliers, networking opportunities | Travel may be required |

| Online Marketplaces | Convenience, wide selection | Risk of counterfeit products |

| Manufacturer’s Website | Direct sourcing, assurance of quality | Limited availability in some regions |

By following these strategies, you can enhance the likelihood of acquiring genuine components, ultimately ensuring the effectiveness and durability of your equipment.

Comparing Aftermarket vs. OEM Parts

When it comes to maintaining equipment, understanding the differences between generic and original components is essential. Each option presents distinct advantages and challenges, making it crucial for users to weigh their choices carefully.

Benefits of Original Components

- Designed specifically for your equipment, ensuring optimal fit and performance.

- Manufactured by the same company, often leading to better reliability and longevity.

- Typically supported by warranties, providing peace of mind in case of defects.

Advantages of Generic Components

- Generally more affordable, making them an attractive option for budget-conscious consumers.

- Available from various suppliers, offering a wider selection and potential for better availability.

- Some aftermarket brands provide enhanced features or materials that can improve functionality.

In conclusion, the choice between original and generic components often depends on individual needs, preferences, and budget considerations. Evaluating the pros and cons of each type can lead to more informed decisions and better maintenance outcomes.

Resources for Mower Repair and Support

When it comes to maintaining and fixing your landscaping equipment, having access to the right resources is essential. Whether you’re seeking troubleshooting tips, instructional guides, or community support, there are numerous avenues to explore that can enhance your repair experience and ensure your machinery operates effectively.

Utilizing manuals, online forums, and video tutorials can significantly aid in understanding the mechanics of your equipment. Additionally, many manufacturers provide dedicated support websites that include valuable documentation and customer service contact information.

| Resource Type | Description | Examples |

|---|---|---|

| Owner’s Manuals | Detailed documents that provide instructions on operation, maintenance, and troubleshooting. | PDF downloads from manufacturer websites |

| Online Forums | Communities where users share experiences, solutions, and advice on repairs. | Specialized discussion boards and social media groups |

| Video Tutorials | Step-by-step guides available on platforms like YouTube that visually demonstrate repair processes. | Channels dedicated to equipment maintenance |

| Local Repair Shops | Professional services that offer repair and maintenance assistance. | Certified technicians in your area |

| Manufacturer Support | Direct assistance from the company that produces your equipment, including FAQs and troubleshooting guides. | Customer service hotlines and live chat options |