In the world of timber processing, a thorough comprehension of the essential elements that comprise machinery is crucial for efficiency and effectiveness. Each section of these mechanical devices plays a specific role, contributing to their overall functionality and performance. Recognizing how these components interconnect can significantly enhance the operation and maintenance of such equipment.

From the power source to the cutting mechanism, the interplay of different units ensures that the task at hand is executed smoothly. A detailed analysis of each section not only aids in troubleshooting but also in optimizing usage. By delving into the intricate structure of these machines, users can gain insights that promote better handling and longer lifespan.

Whether one is a novice or an experienced user, familiarizing oneself with the various sections can lead to improved results and safer operation. The journey to mastering these tools begins with an exploration of their design and assembly, paving the way for more informed decisions in timber processing endeavors.

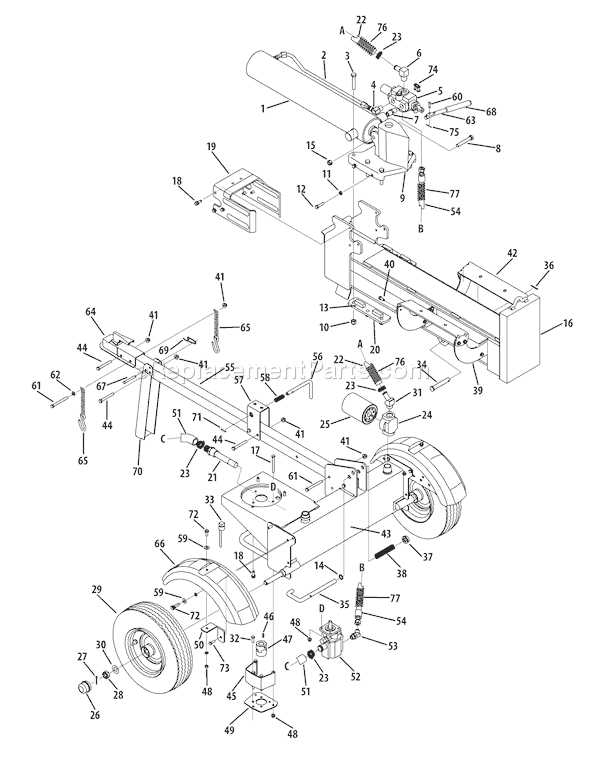

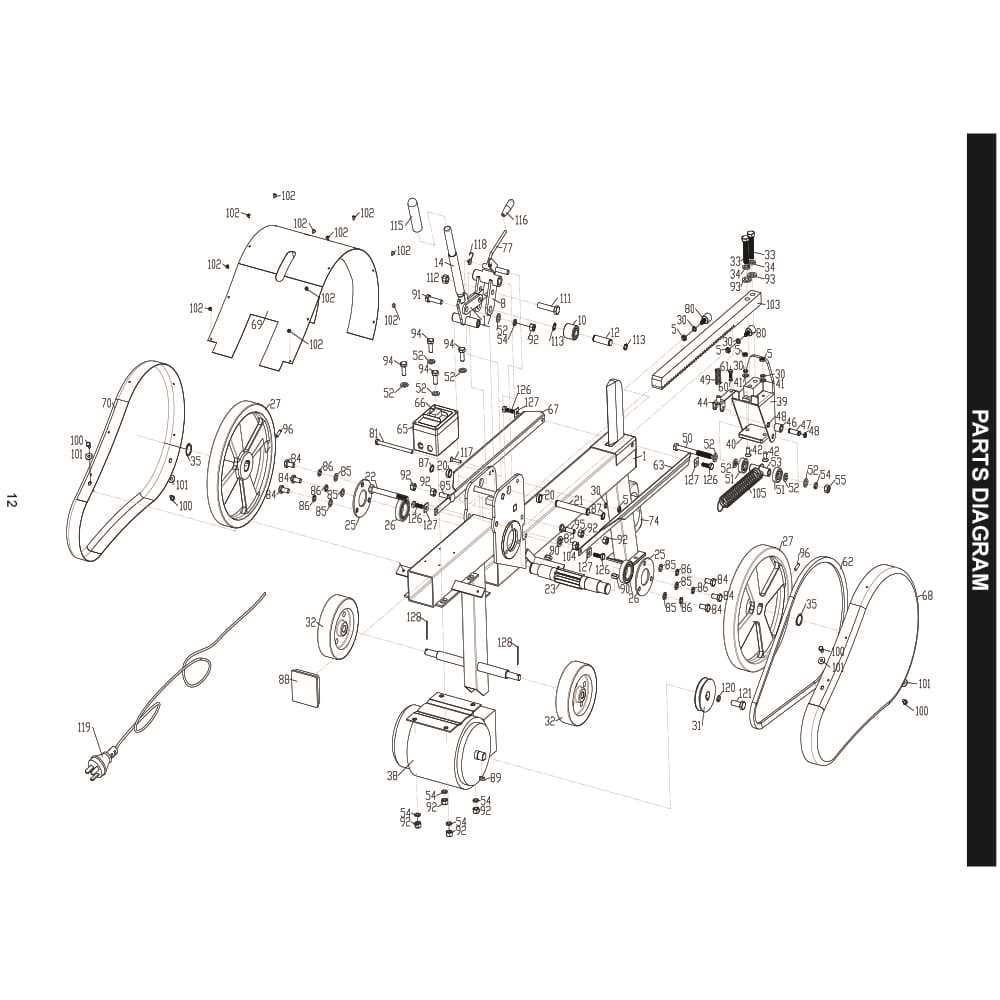

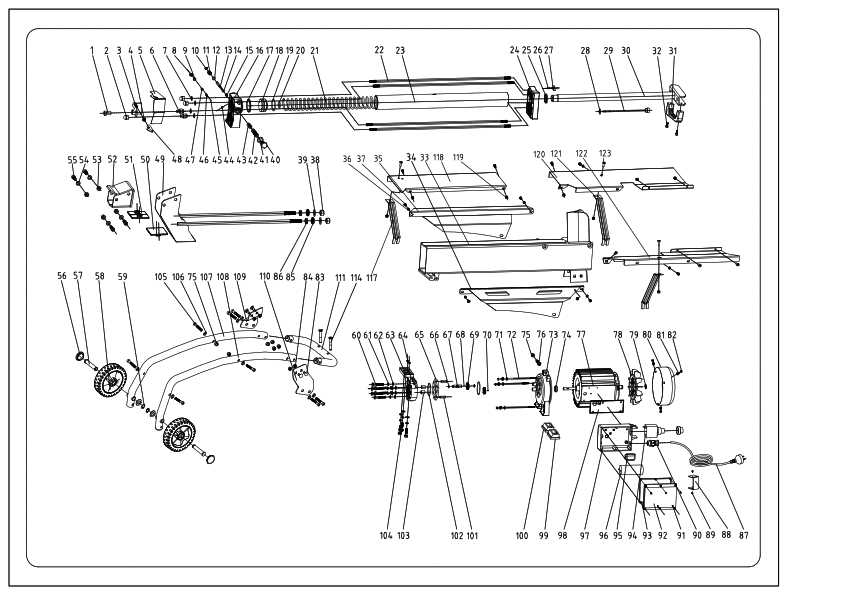

Understanding Wood Splitter Components

In the realm of log processing machinery, familiarity with individual elements is essential for optimal functionality and maintenance. Each component plays a crucial role in ensuring efficiency and effectiveness during operation. A comprehensive grasp of these elements can enhance user experience and extend the longevity of the equipment.

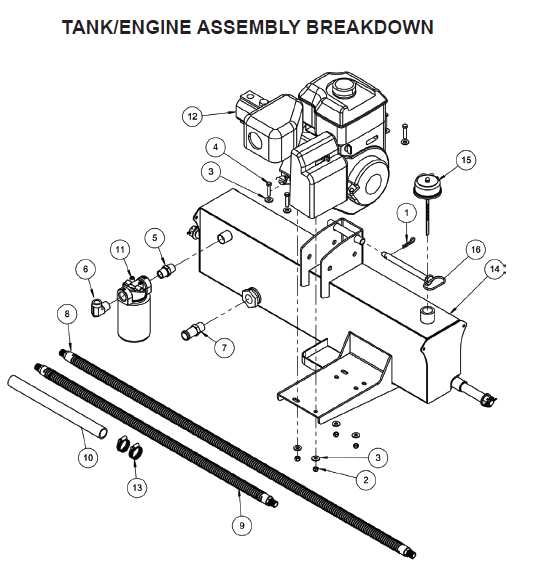

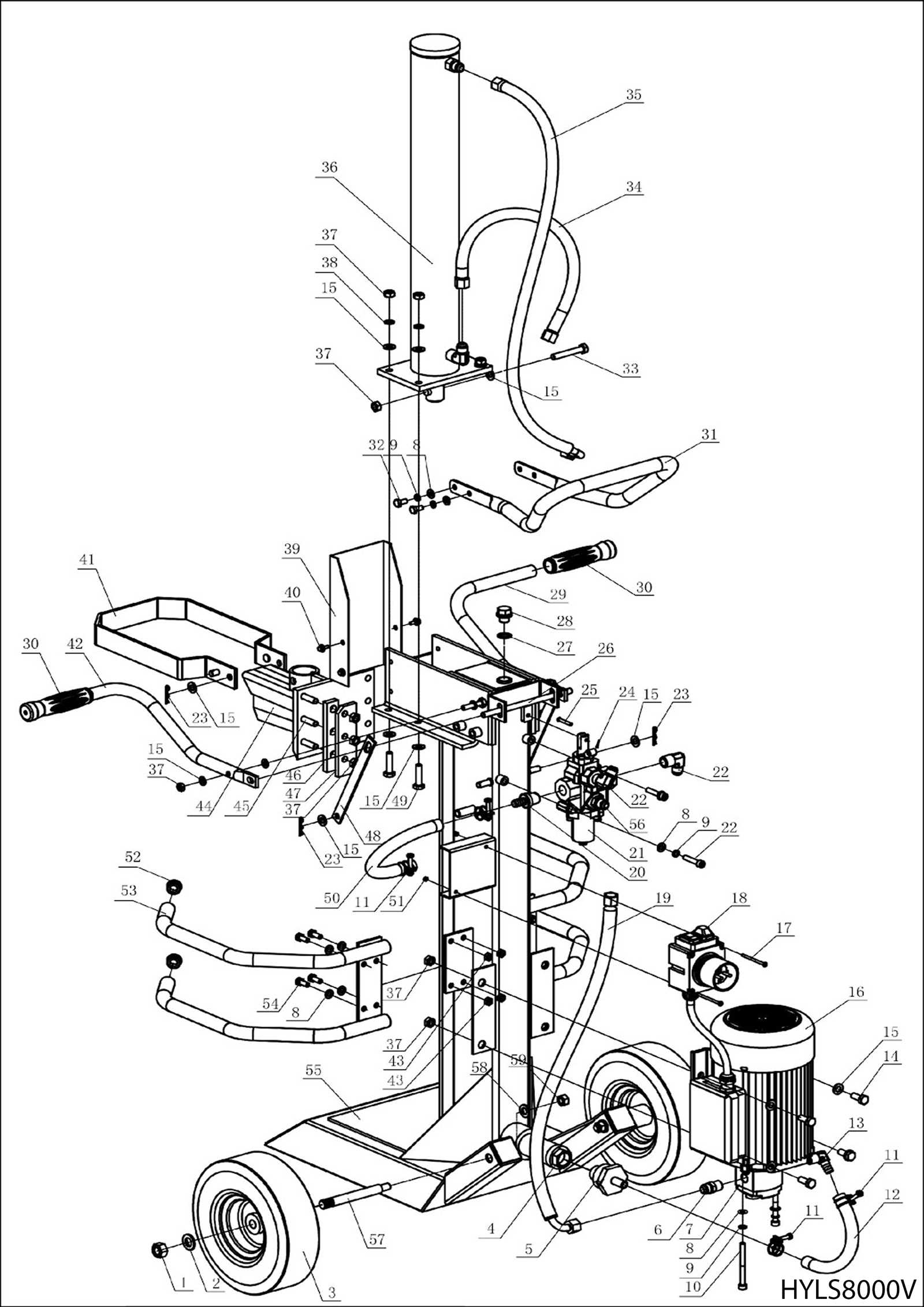

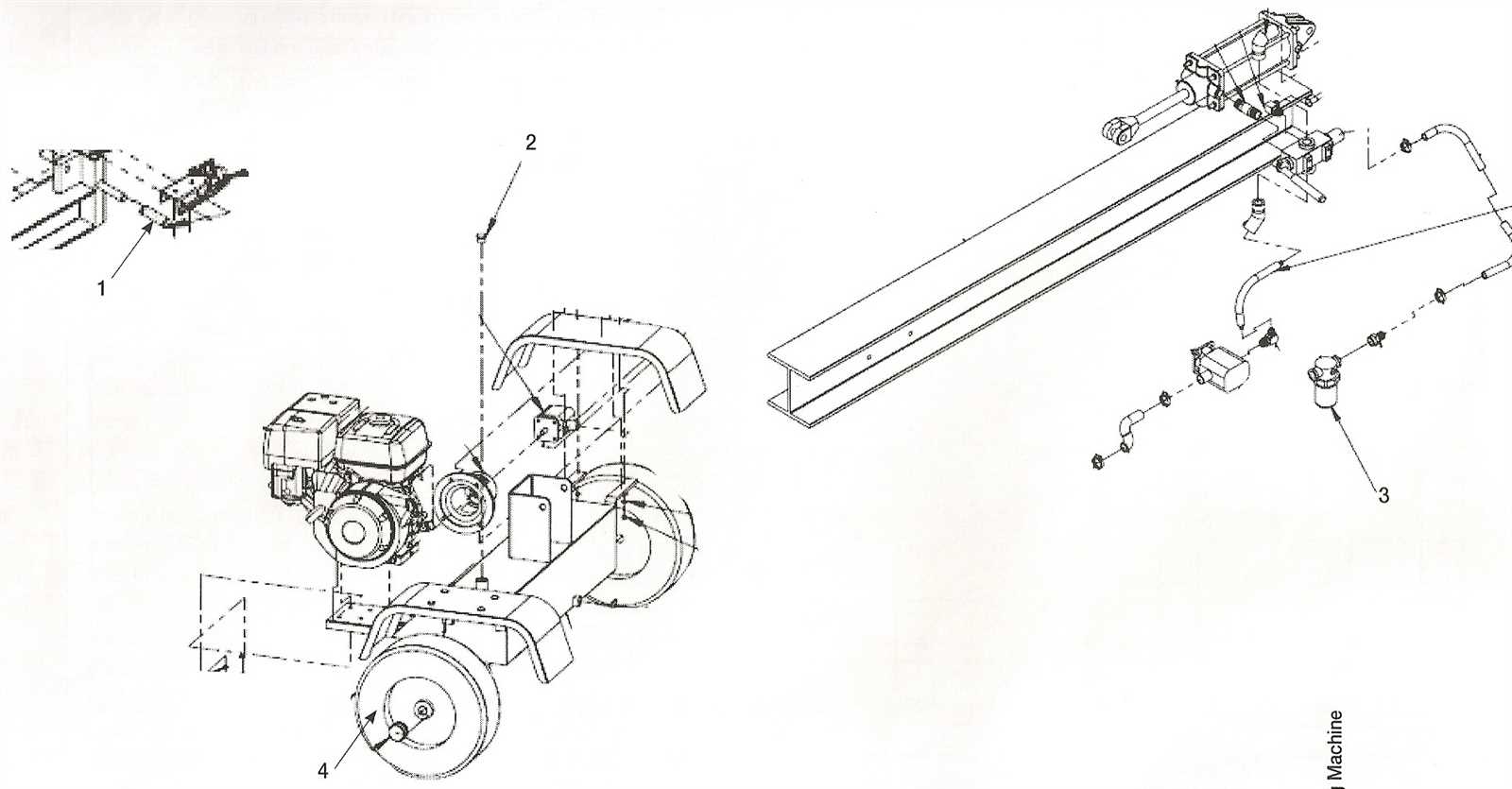

The key components of this machinery can be categorized into several groups, including the driving mechanism, cutting mechanism, and support structure. Each group serves specific functions that contribute to the overall performance and reliability of the system.

| Component | Description |

|---|---|

| Engine | Provides the necessary power to operate the equipment. |

| Hydraulic Pump | Converts mechanical energy into hydraulic energy to facilitate movement. |

| Cylinder | Acts as the force generator that drives the cutting action. |

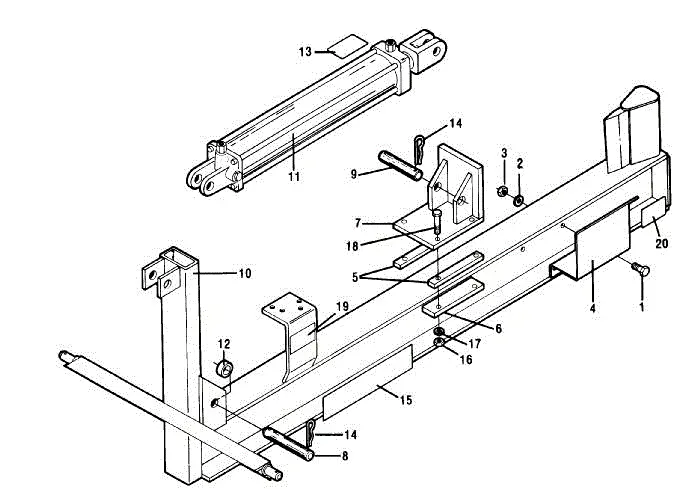

| Wedge | Serves as the primary tool for dividing the material into smaller sections. |

| Frame | Supports all components, ensuring stability and durability during operation. |

Understanding these key components helps users troubleshoot issues, perform regular maintenance, and operate their machinery more effectively. Each part is interdependent, working in harmony to achieve the desired results in log processing.

Key Parts of a Wood Splitter

Understanding the essential components of a log processing machine is crucial for effective operation and maintenance. Each element plays a significant role in ensuring the device functions smoothly and efficiently. By familiarizing yourself with these key components, you can enhance your productivity and ensure the longevity of your equipment.

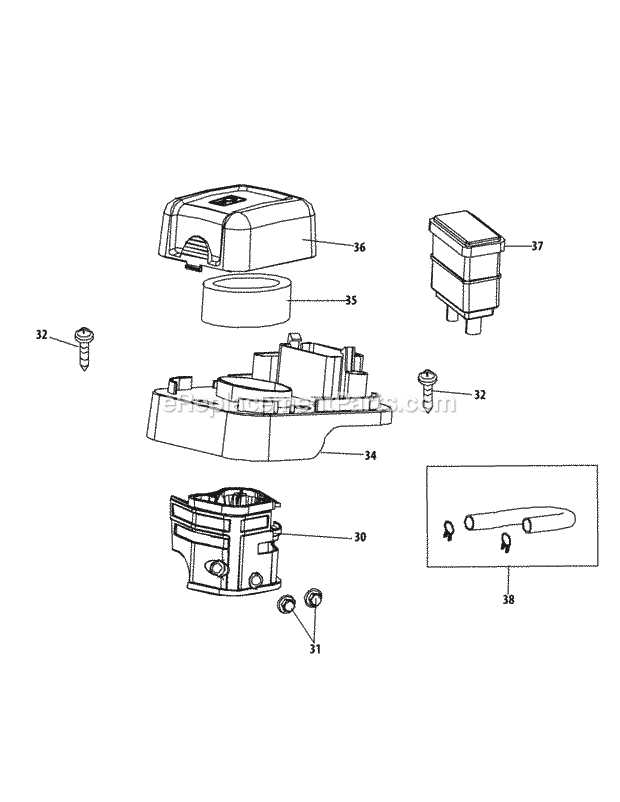

Engine: The powerhouse of the machinery, it provides the necessary force to drive the entire system. A robust engine ensures that the task is completed swiftly and with minimal effort.

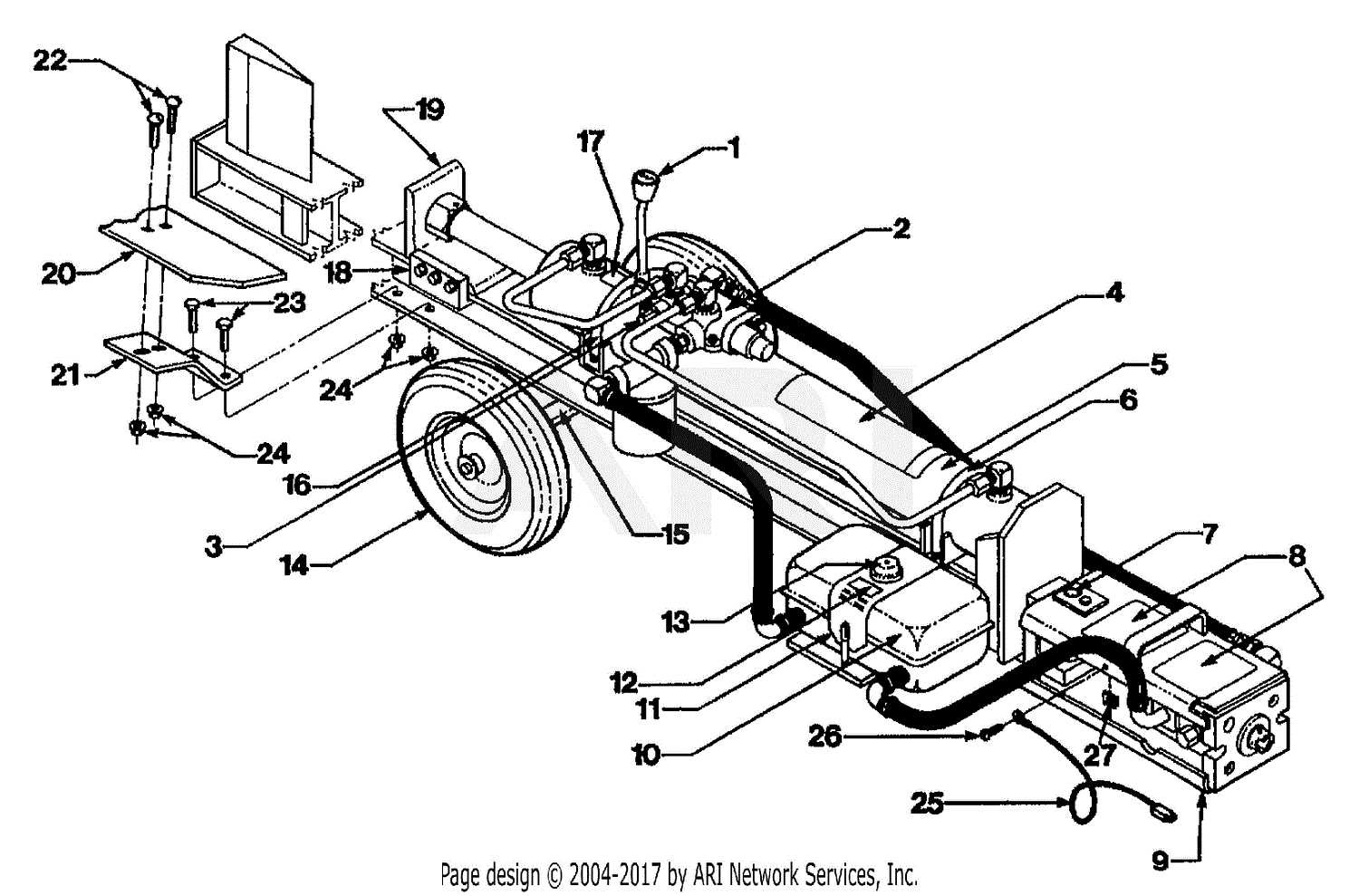

Hydraulic System: This system is vital for generating the pressure needed to perform the splitting action. It consists of a pump, hoses, and cylinders that work together to deliver optimal performance.

Splitter Wedge: This crucial component is responsible for the actual division of logs. Its design allows it to penetrate the wood effectively, making the splitting process efficient.

Frame: The structural backbone of the machine, providing stability and support. A well-constructed frame ensures durability and can withstand the rigors of heavy use.

Controls: These are essential for operating the machinery safely and effectively. They allow the user to manage speed, direction, and other critical functions with ease.

Safety Features: Equipped with various mechanisms to protect the user, these include shields, emergency stops, and other devices designed to minimize risk during operation.

By gaining a deeper understanding of these fundamental elements, operators can optimize their techniques and ensure the equipment remains in excellent condition for years to come.

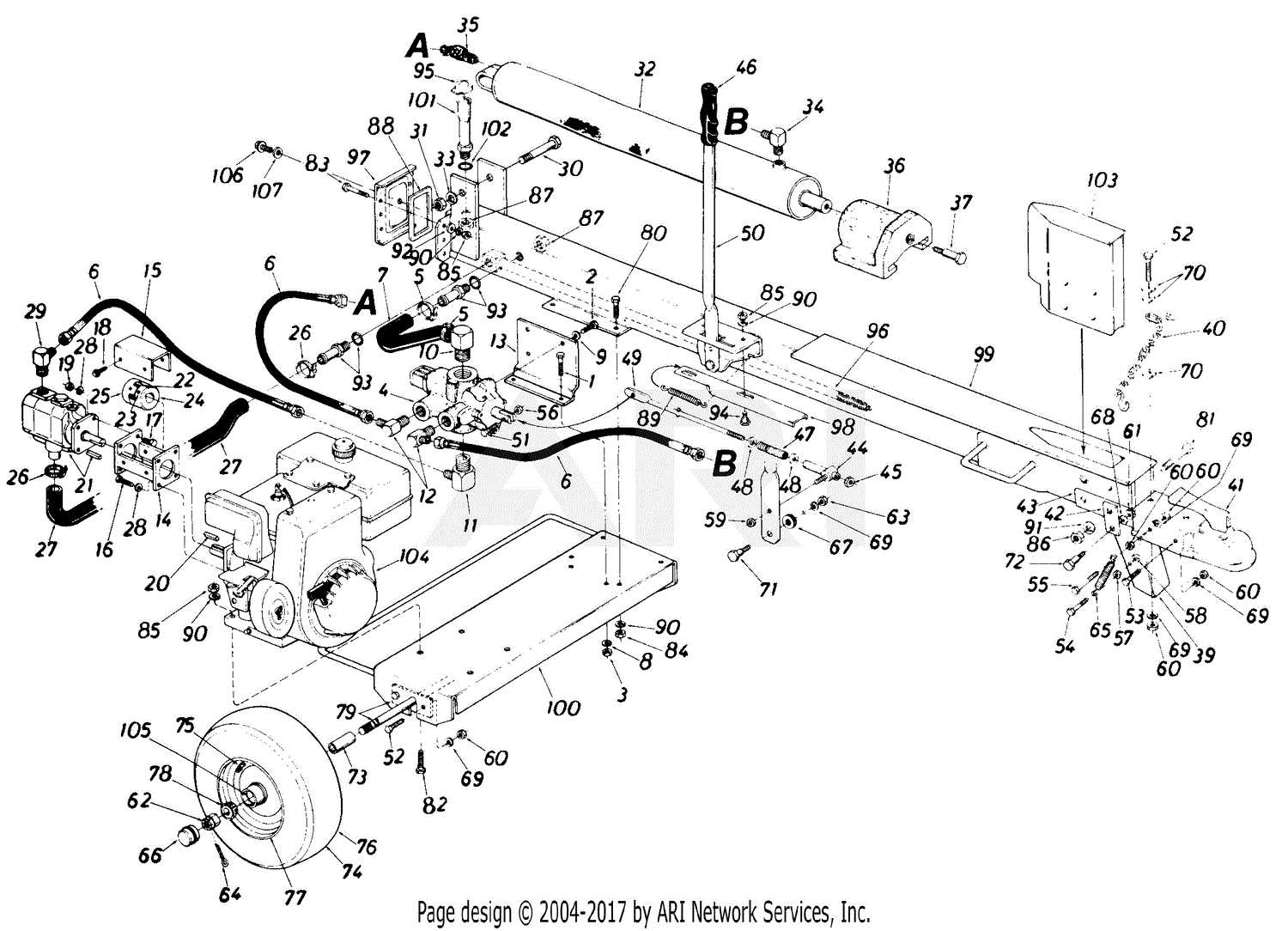

How the Hydraulic System Works

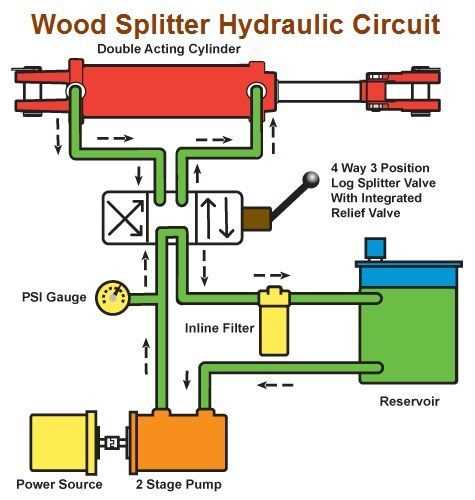

The hydraulic mechanism is a crucial component in many powerful machines, providing efficient force multiplication and precise control. By utilizing fluid under pressure, this system converts small inputs into significant outputs, enabling heavy-duty operations with minimal manual effort. Understanding its functionality can enhance both maintenance and operational efficiency.

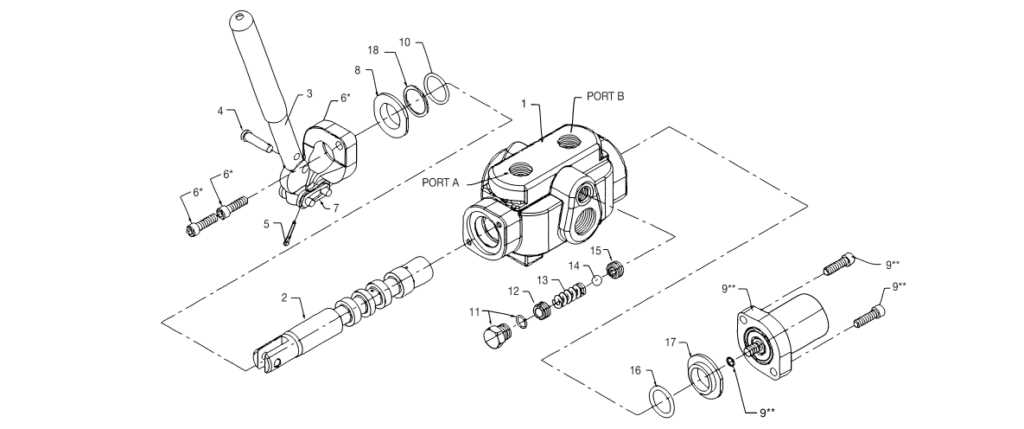

Key Components of the Hydraulic System

At the heart of this system are several essential elements. The pump generates hydraulic pressure, moving fluid through the network of hoses and valves. The cylinders are where the actual work occurs, converting hydraulic energy back into mechanical motion. Additionally, valves regulate the flow, allowing operators to control speed and direction with precision.

How Pressure is Generated

Pressure is created when the pump draws in fluid and forces it into the cylinders. The enclosed space in these components allows for an increase in pressure, which can be utilized to perform heavy tasks efficiently. When the operator activates the system, the fluid’s force is transmitted through the entire circuit, ensuring that the required action is executed smoothly and effectively.

Importance of the Wedge Design

The configuration of the cutting element plays a crucial role in enhancing efficiency and effectiveness during the splitting process. A well-designed wedge not only facilitates a smoother operation but also significantly reduces the amount of force required to achieve optimal results. This design aspect is vital for both safety and performance.

Enhanced Efficiency

An effective wedge shape allows for better penetration into the material, minimizing resistance and enabling quicker separation. This efficiency is particularly important in high-demand scenarios where time and effort are critical factors.

Safety Considerations

A properly engineered wedge design contributes to safer operation by decreasing the likelihood of binding or jamming. This reduces the risk of accidents and ensures a more reliable experience for the user, ultimately promoting a safer work environment.

Safety Features in Wood Splitters

Ensuring user protection while operating machinery is paramount. Various mechanisms are incorporated to minimize risks and enhance security. Understanding these features helps users operate the equipment safely and effectively.

Modern machines are designed with multiple safety elements that address potential hazards. These include emergency stop buttons, protective guards, and mechanisms that prevent unintentional activation. Each component plays a crucial role in safeguarding the user during operation.

| Safety Feature | Description |

|---|---|

| Emergency Stop Button | A readily accessible button that halts operation immediately in case of an emergency. |

| Protective Guards | Barriers that shield the user from moving parts and flying debris. |

| Two-Hand Operation | Requires both hands to be used for activation, ensuring the user remains at a safe distance. |

| Safety Switch | Prevents the machine from starting if not properly set up or if safety guards are removed. |

By familiarizing oneself with these critical safety features, operators can significantly reduce the likelihood of accidents and injuries while utilizing their machinery effectively.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the life of any machinery. By following a few key practices, users can ensure optimal performance and durability over time.

- Regular Cleaning: Keep the equipment free from debris and dirt to prevent wear and tear.

- Lubrication: Apply appropriate lubricants to moving components to reduce friction and enhance efficiency.

- Inspection: Conduct routine checks for wear on essential elements and replace any damaged parts promptly.

- Storage: Store the machinery in a dry, sheltered location to protect it from the elements.

- Sharpening: Maintain cutting edges for maximum effectiveness and to reduce strain on the motor.

Implementing these strategies will ultimately contribute to a longer lifespan and better performance.

Choosing the Right Power Source

When selecting an appropriate energy source for your machinery, several factors must be considered to ensure optimal performance and efficiency. The right choice can significantly impact both the functionality and convenience of your equipment, making it crucial to evaluate the available options based on your specific needs and usage scenarios.

Types of Energy Sources

There are three primary categories of energy sources to consider:

- Electricity: Ideal for indoor use, offering consistent power without emissions.

- Gas: Provides portability and higher power output, suitable for outdoor tasks.

- Hydraulic: Known for high efficiency and strength, often used in heavy-duty applications.

Factors to Consider

When choosing an energy source, keep these considerations in mind:

- Location: Determine whether you will operate indoors or outdoors.

- Power Requirements: Assess the energy needs of your equipment for optimal performance.

- Portability: Consider how easily you can transport your machinery based on its energy source.

- Environmental Impact: Evaluate the emissions and noise levels associated with each option.

- Maintenance: Different energy sources require varying levels of upkeep and care.

By carefully weighing these factors, you can make an informed decision that enhances your overall experience and productivity.

Common Issues and Troubleshooting

When operating heavy machinery designed for cutting and processing timber, various challenges may arise. Understanding these potential problems can greatly enhance performance and longevity. This section outlines frequent difficulties encountered and offers practical solutions to ensure optimal functionality.

Performance Degradation

One common issue is a noticeable drop in efficiency. This may be due to dull cutting edges or misaligned components. Regular maintenance, including sharpening blades and checking alignment, can help restore effectiveness. Lubrication of moving parts is also crucial; insufficient grease can lead to increased friction and wear.

Hydraulic System Failures

Hydraulic systems are vital for power transmission. Leaks or low fluid levels can result in inadequate pressure, causing operational failures. Regularly inspect hoses and connections for wear. If a leak is detected, replacing the damaged components promptly is essential. Additionally, ensure that the hydraulic fluid is clean and at the correct level to maintain peak performance. Timely maintenance can prevent major breakdowns.

Upgrading Your Wood Splitter

Enhancing your machinery can significantly improve performance and efficiency. By focusing on specific components, you can achieve remarkable results, making tasks easier and faster.

- Assess the current functionality to identify areas for improvement.

- Consider upgrading the engine for increased power and speed.

- Replace dull blades with high-quality alternatives for cleaner cuts.

- Install a more efficient hydraulic system to enhance operation.

- Upgrade wheels for better maneuverability across various terrains.

Prioritizing these enhancements will ensure your equipment meets your ultimate needs.