Understanding how different elements work together in heating systems is essential for ensuring their efficient operation. Each element has its own role in maintaining the functionality and safety of the entire mechanism. These systems rely on several key components that interact seamlessly to generate and distribute warmth.

In this guide, we will examine the structure and function of crucial elements, exploring how they fit into the overall mechanism. By understanding the relationships between these elements, it becomes easier to diagnose issues and ensure proper maintenance.

Proper configuration of these components is crucial for reliable performance. Whether you are maintaining or repairing, knowing the layout and the purpose of each element is fundamental for achieving optimal results.

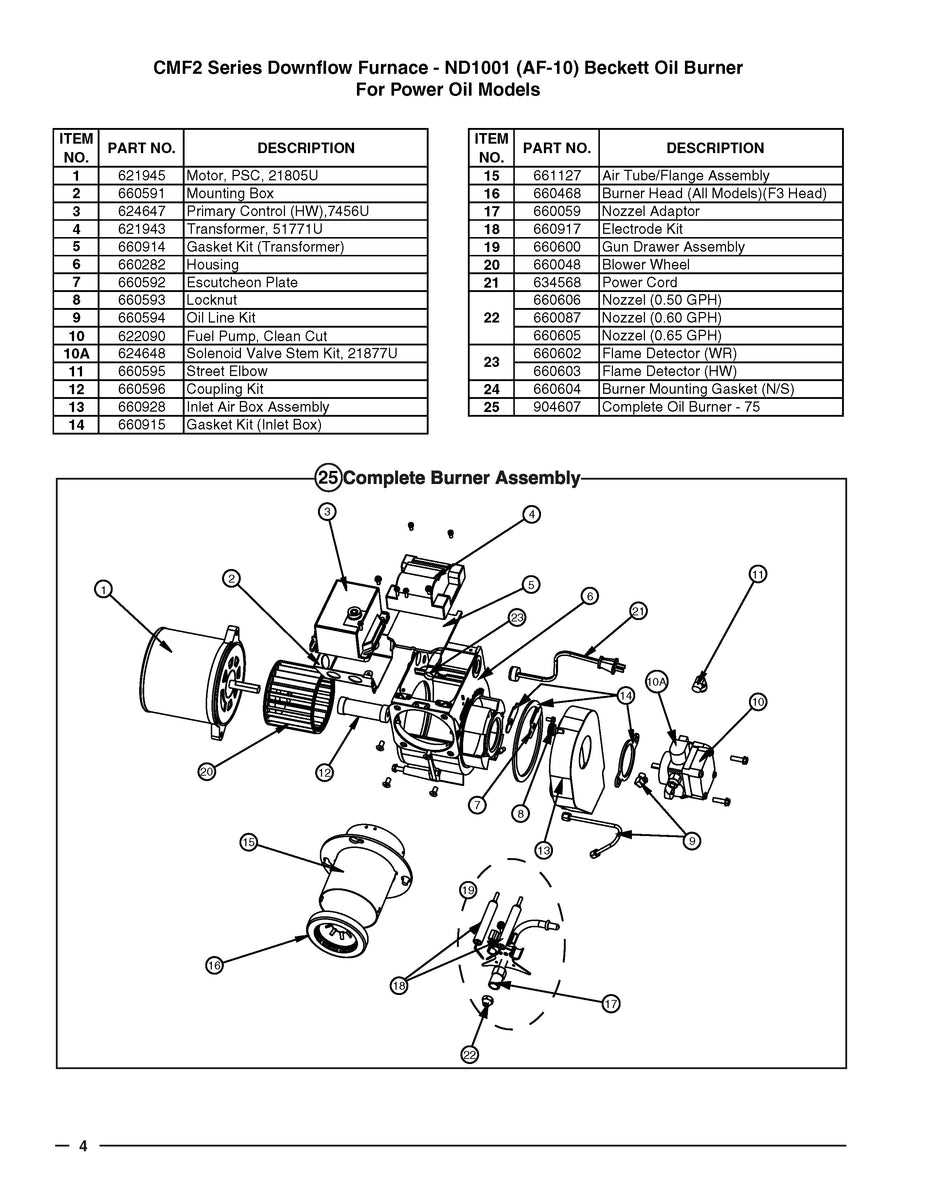

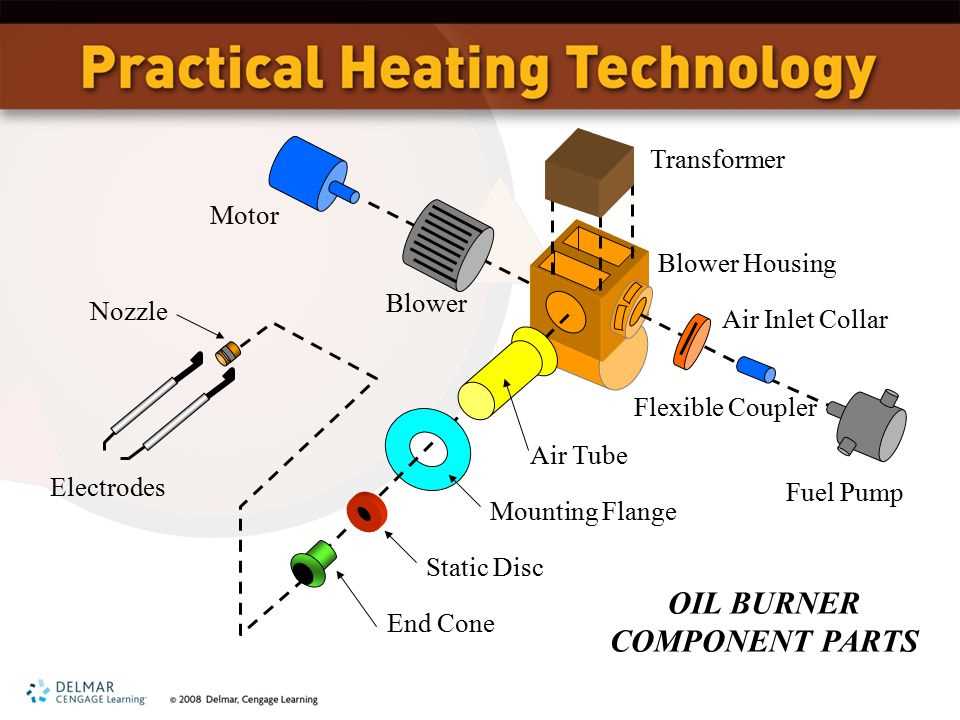

Oil Burner Parts Diagram

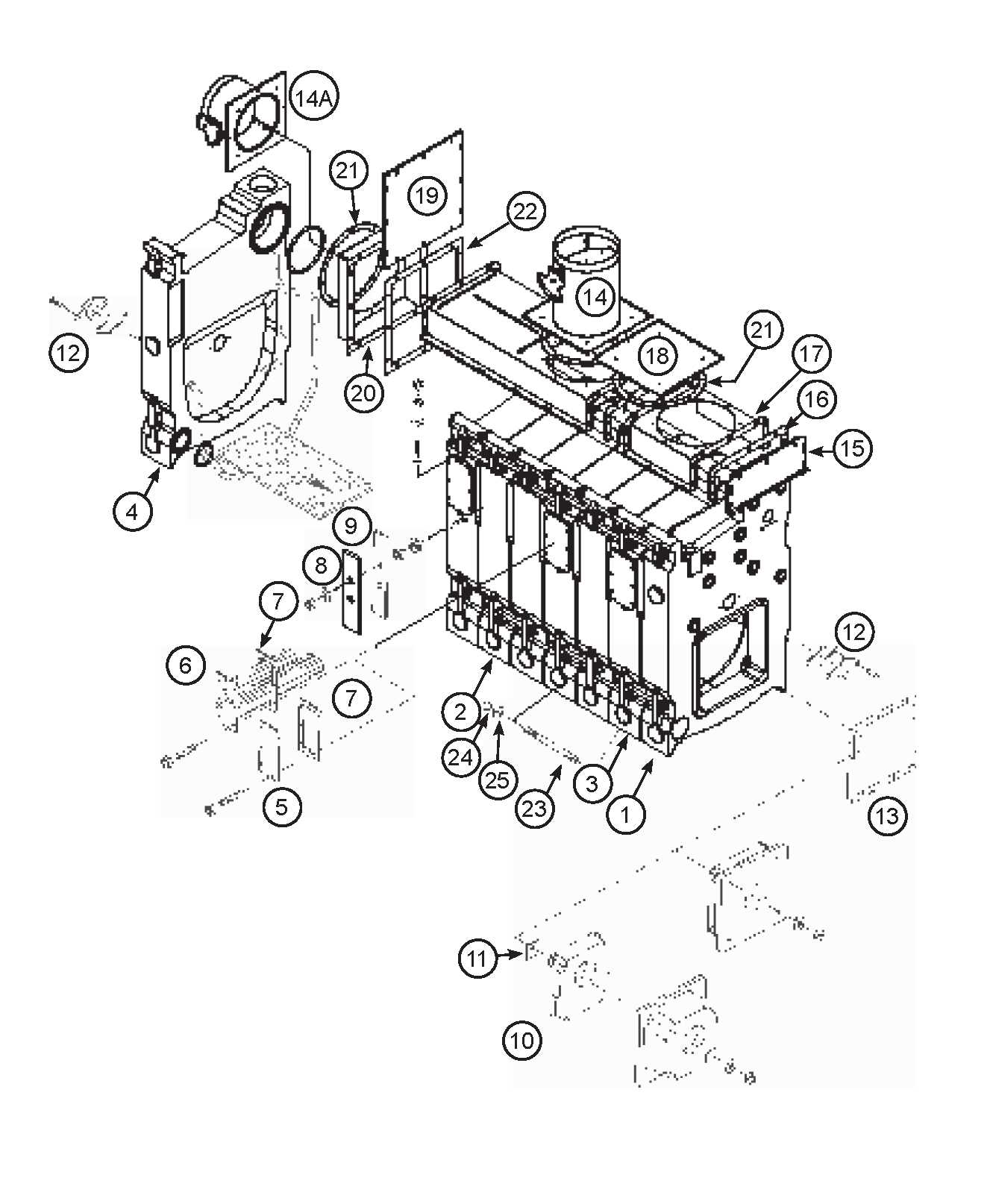

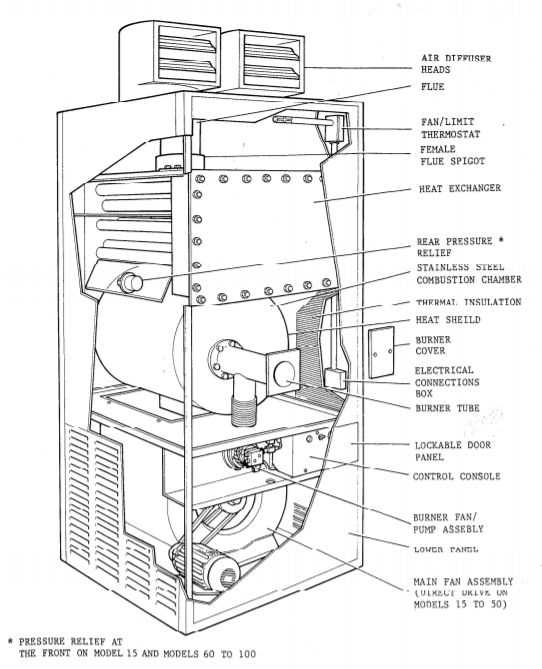

Understanding the internal mechanisms of a heating device is essential for efficient operation and maintenance. The layout of the system shows how different elements work together to ensure optimal functionality. Each component has a specific role, contributing to the overall performance and safety of the system.

Below is a breakdown of key components and their respective functions:

- Fuel delivery mechanism: This part ensures a consistent supply of fuel, regulating flow to maintain efficiency.

- Ignition element: Responsible for initiating the heating process, this component sets off the combustion that powers the entire system.

- Control system: Manages and monitors temperature, ensuring that the device operates within safe limits.

- Airflow regulator: Adjusts the intake of air, which is crucial for proper combustion and system performance.

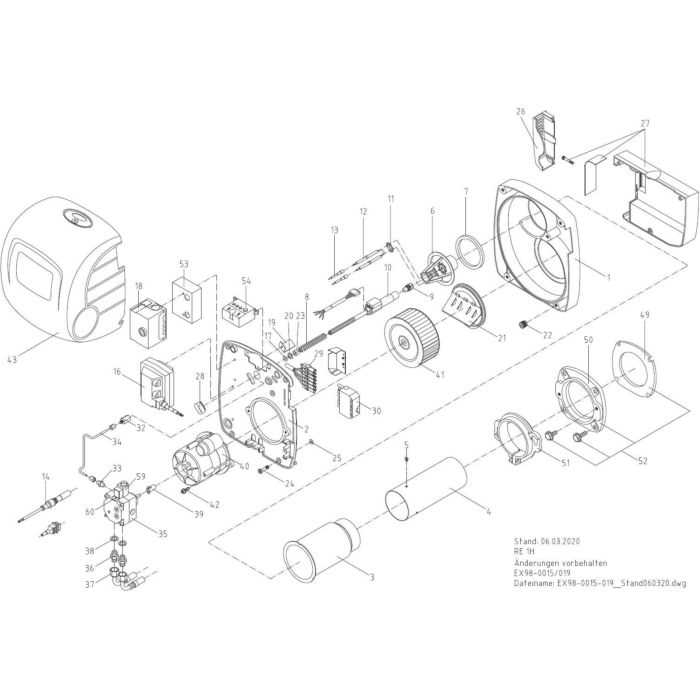

Key Components of an Oil Burner

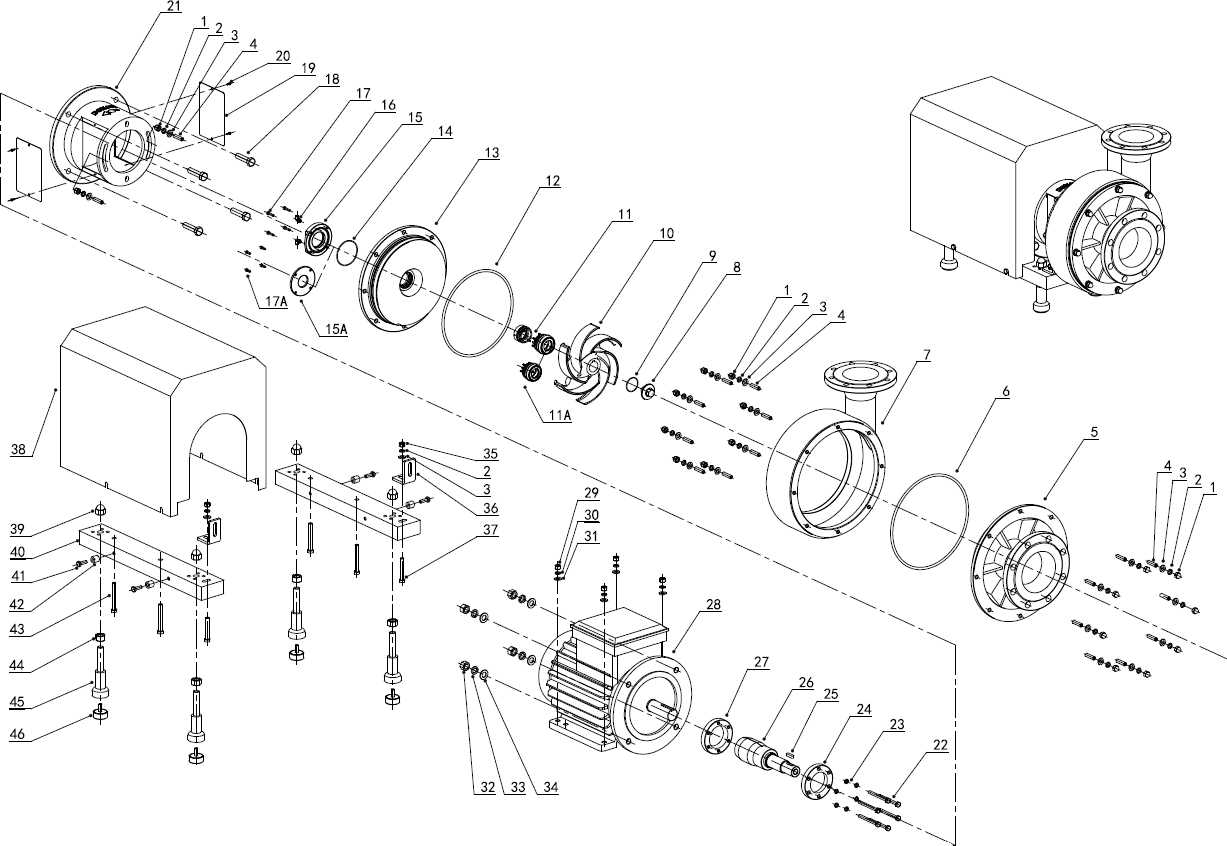

The mechanism responsible for generating heat through combustion relies on a carefully designed set of interconnected elements. Each component within this system plays a vital role in ensuring a consistent and efficient energy conversion process. The intricate nature of these elements contributes to the smooth functioning of the entire assembly, allowing for precise control of fuel and airflow.

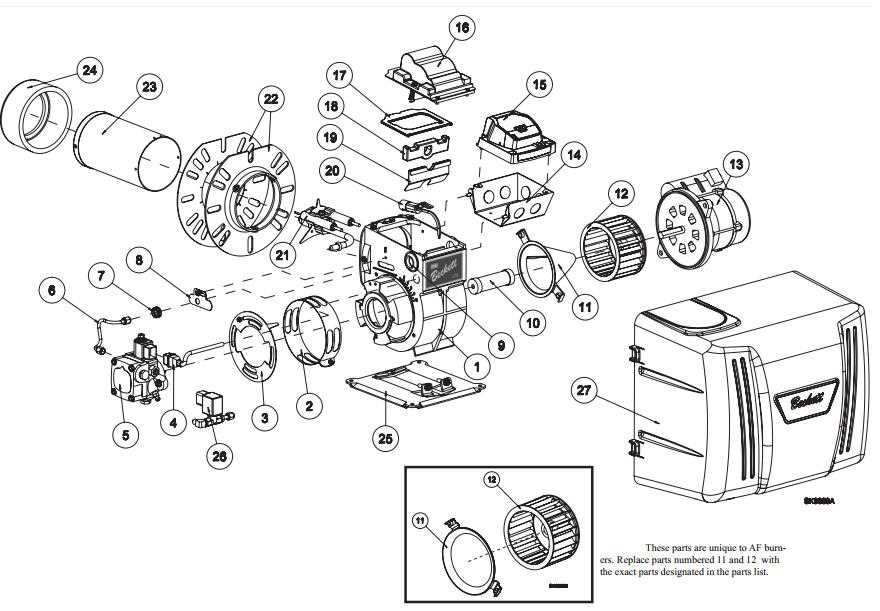

Ignition System

The ignition system serves as the starting point, initiating the combustion process. By providing the necessary spark, this component ensures that the fuel is ignited properly, allowing the entire system to begin converting energy. A reliable ignition setup is essential for stable operation and consistent heat output.

Fuel Delivery Mechanism

The fuel delivery mechanism is responsible for precisely regulating the flow of fuel into the combustion chamber. This system maintains the balance between fuel and air, optimizing the efficiency of the entire process. Any disruption or malfunction in this component can significantly impact the overall performance and reliability of the heating system.

How Oil Burners Work Efficiently

Efficient energy systems operate through a precise combination of heat management and fuel processing. These systems are designed to maximize thermal output while minimizing waste, ensuring that the fuel is utilized to its fullest potential. The goal is to deliver a steady supply of warmth, even under demanding conditions, with minimal energy loss.

Key factors that contribute to efficiency include proper air-fuel mixture control and optimized combustion techniques. Maintaining a balance between fuel input and heat output ensures that the system runs smoothly without excessive energy consumption or environmental impact. Regular maintenance of the unit also plays a significant role in sustaining this efficiency over time.

By carefully adjusting operational parameters, the entire heating mechanism can achieve a high-performance level. This results in consistent warmth and reduced fuel costs, making the system an ideal choice for long-term use in both residential and industrial applications.

Understanding the Fuel Delivery System

The fuel delivery system plays a crucial role in ensuring that the energy source is properly supplied to the equipment for efficient combustion. Its primary function involves guiding the energy source from the storage unit to the main combustion chamber, ensuring the right amount and pressure for optimal performance.

Main Components of the System

This system consists of several key elements that work together to ensure smooth and regulated fuel flow. A pump is typically responsible for transporting the fuel, while valves control the pressure and direction of the flow. Other mechanisms handle safety protocols, ensuring the process is stable and secure.

Ensuring Efficiency and Reliability

For the system to perform efficiently, each component must function in harmony. Regular maintenance and monitoring of these elements are

Electric and Ignition Parts Overview

The intricate network of electrical components and ignition elements is crucial for ensuring reliable functionality in heating systems. These elements work together to provide the necessary energy and control to activate and maintain efficient combustion processes. Understanding their role and interaction is key to proper system maintenance and operation.

Main Electrical Elements

Key electrical elements include switches, controllers, and relays. These devices regulate power flow and ensure precise timing for system activation. Proper alignment and condition of these components are essential for stable performance.

Ignition Components

The ignition system includes a variety of devices such as electrodes, transformers, and sensors. These elements are responsible for generating the initial spark and monitoring conditions to sustain ignition. Proper configuration and upkeep of these components are vital for safe and effective operation.

Maintaining Oil Burner Safety Systems

Ensuring the reliability of heating systems is crucial for efficient operation and the well-being of occupants. Regular maintenance of safety mechanisms is essential to prevent potential hazards. This section outlines key practices for upholding these protective measures, ensuring that heating equipment functions safely and effectively.

Here are some important steps to consider:

- Regular Inspections: Conduct routine checks to identify any wear and tear in safety devices. Look for signs of damage or malfunction.

- Testing Alarms: Ensure that smoke and carbon monoxide detectors are operational. Replace batteries as needed and test alarms monthly.

- Clearing Ventilation: Keep exhaust and intake pathways unobstructed. Blocked vents can lead to dangerous buildup of gases.

- Professional Servicing: Schedule annual inspections with certified technicians to perform comprehensive evaluations of all safety features.

- Emergency Protocols: Develop and communicate emergency response procedures to all household members to ensure prompt action in case of a safety event.

By implementing these practices, users can significantly reduce risks associated with heating systems and ensure a safe living environment.

Exploring Combustion Chamber Design

The configuration of the combustion area is crucial for achieving efficient energy production. This space is where the fuel interacts with air, leading to a chemical reaction that generates heat. A well-thought-out design not only enhances combustion efficiency but also minimizes emissions, ensuring a cleaner output.

Key elements of the combustion chamber include its shape, size, and materials. The geometry affects how well the fuel mixes with air, influencing the overall combustion process. Additionally, choosing appropriate materials can enhance durability and resistance to high temperatures, further optimizing performance. Understanding these components is essential for improving efficiency and reliability in heating systems.

Common Issues with Oil Burners

Many heating systems can encounter various challenges that affect their performance and efficiency. Understanding these potential problems is crucial for maintaining a reliable heating solution. Regular inspections and maintenance can help identify these issues early and prevent further complications.

Fuel Supply Problems

One frequent issue arises from interruptions in the flow of fuel. This can result from clogged filters, low fuel levels, or improper tank connections. Addressing these concerns promptly is essential to ensure a consistent and uninterrupted supply.

Ignition Failures

Another common challenge is ignition failure, where the system struggles to start or fails to stay lit. This could be due to faulty ignitors, electrical issues, or even dirty components. Regular cleaning and testing of ignition components can enhance reliability and performance.

Upgrading and Replacing Oil Burner Parts

Enhancing the efficiency and reliability of heating systems is essential for optimal performance. Regular updates and substitutions can significantly improve functionality, leading to energy savings and prolonged equipment life. Understanding the components involved and the processes for replacing them is vital for maintaining an effective heating solution.

When considering enhancements or replacements, the following aspects should be evaluated:

- Component Quality: Choose high-quality alternatives that ensure durability and effectiveness.

- Compatibility: Verify that new components are suitable for your existing setup to prevent operational issues.

- Installation: Proper installation is crucial; consider professional assistance if unsure about the process.

- Maintenance: Regular upkeep can extend the lifespan of all system elements, ensuring continued efficiency.

Additionally, monitoring performance and addressing any anomalies promptly can prevent more extensive problems. Investing in quality replacements not only enhances system operation but also contributes to overall safety and comfort.