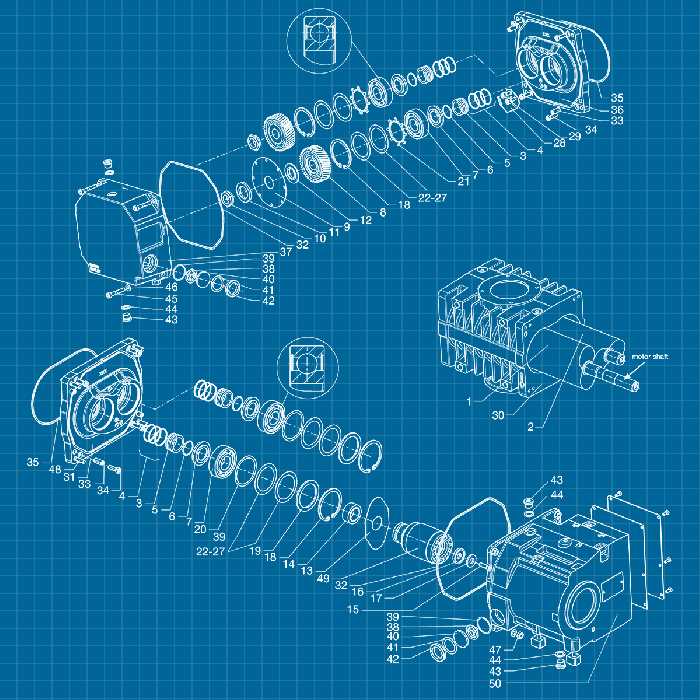

In the realm of machinery and engineering, having a clear overview of the components involved is crucial for effective maintenance and repair. An assembly blueprint serves as a vital tool, providing a visual representation of how various elements fit together. This facilitates not only understanding but also troubleshooting potential issues that may arise during operation.

When delving into the specifics, one can appreciate the intricate relationships between individual components. Each piece plays a pivotal role in the overall functionality, and recognizing this interconnectedness can enhance one’s ability to diagnose problems efficiently. Moreover, a well-structured visual reference aids in the identification of wear and tear, enabling timely interventions and prolonging the life of the equipment.

Ultimately, the knowledge of the assembly layout empowers technicians and enthusiasts alike, fostering a deeper comprehension of the machine’s inner workings. Whether for routine maintenance or complex repairs, having access to a comprehensive illustration of the system is an invaluable asset that ensures operational excellence.

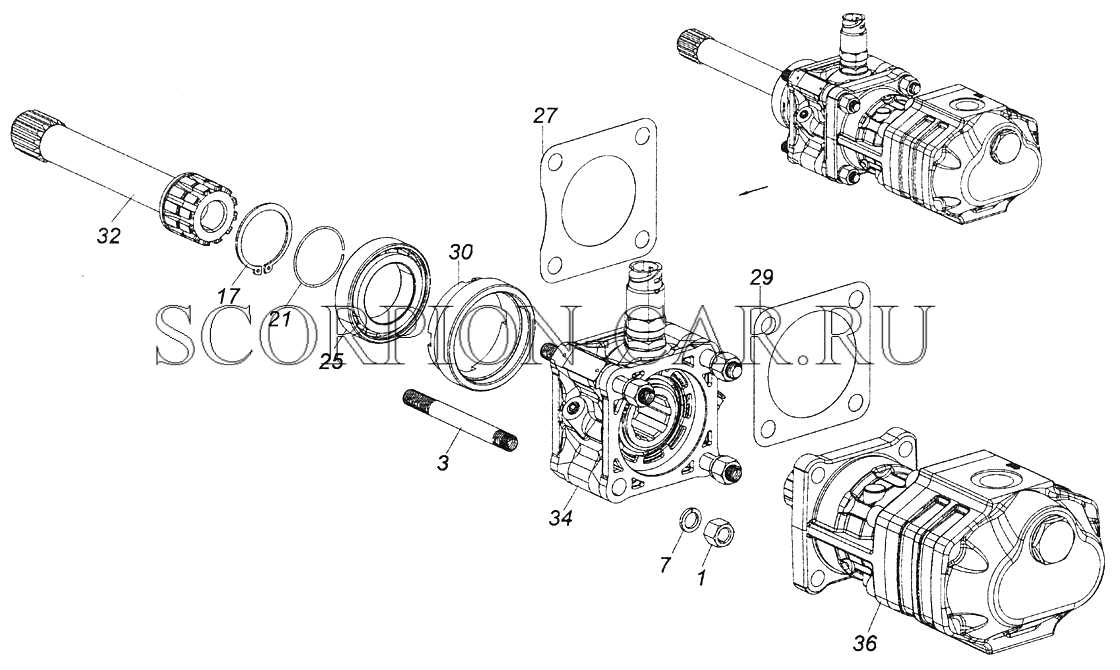

Understanding Comet ZWD 4040 Components

Gaining insight into the individual elements of a complex machinery system is essential for effective maintenance and troubleshooting. Each component plays a crucial role in ensuring optimal performance and reliability. By exploring the various parts, one can better appreciate how they interact and contribute to the overall functionality of the equipment.

Key Elements: The essential components include the drive mechanisms, control systems, and support structures. Understanding the purpose of each part allows for informed decision-making when addressing issues or performing upgrades.

Interconnectivity: Recognizing how these elements are interconnected is vital. For example, a malfunction in the control unit can lead to operational failures in the drive mechanisms, highlighting the importance of a holistic view when assessing performance.

Maintenance Practices: Regular inspection and maintenance of these individual parts can extend the lifespan of the entire system. Familiarity with the structure enables users to identify potential problems early and implement solutions efficiently.

Upgrades and Modifications: As technology evolves, understanding the foundational components allows for seamless integration of new features or enhancements. This adaptability is key to maintaining competitiveness and improving operational efficiency.

Importance of Parts Diagrams

Understanding the layout and components of a system is crucial for effective maintenance and repair. Visual representations serve as essential tools, enabling users to identify individual elements quickly and understand how they interact with one another. This clarity can significantly enhance the efficiency of troubleshooting and assembly processes.

Facilitating Repair and Maintenance

Accurate illustrations provide a roadmap for technicians, allowing them to pinpoint specific areas requiring attention. By having a clear view of the arrangement and connection of various components, repair work becomes more streamlined and precise. This reduces the likelihood of errors and minimizes downtime, ultimately saving both time and resources.

Enhancing User Knowledge

Diagrams also serve an educational purpose. They empower users to familiarize themselves with their equipment, promoting a deeper understanding of how each piece functions. This knowledge can lead to better care and informed decisions regarding upgrades or replacements, fostering a culture of proactive maintenance.

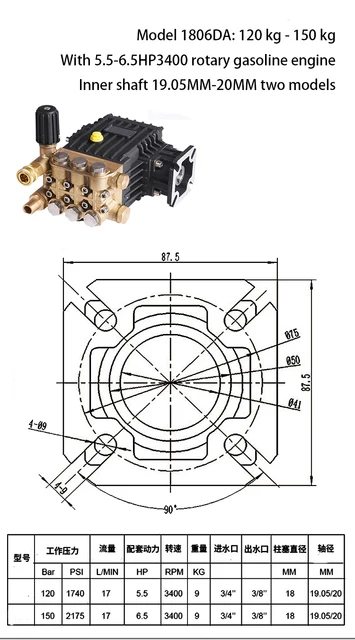

Key Features of the Comet ZWD 4040

This innovative machine stands out in its category due to a combination of advanced technology and user-friendly design. It excels in performance, efficiency, and versatility, making it suitable for a wide range of applications.

Robust Build Quality: Engineered with durable materials, this device is designed to withstand rigorous usage. Its sturdy construction ensures longevity, providing a reliable solution for both commercial and personal tasks.

Enhanced Performance: Equipped with a powerful engine, it delivers impressive results quickly and efficiently. The high output reduces operational time, allowing users to accomplish more in less time.

Versatile Functionality: This model features multiple settings and attachments, enabling it to adapt to various tasks seamlessly. Whether for light-duty or heavy-duty applications, it offers the flexibility needed for any job.

User-Centric Design: With an intuitive interface and ergonomic controls, operating this machine is straightforward and comfortable. Users can easily navigate through its features, enhancing overall productivity.

Maintenance Friendly: Designed with accessibility in mind, routine maintenance is simplified, reducing downtime and extending the lifespan of the equipment. Easy access to key components ensures that upkeep is hassle-free.

Common Issues with Comet Parts

Understanding the frequent challenges encountered with components in certain machinery can enhance performance and longevity. Users often face various concerns that can hinder efficiency and lead to increased maintenance efforts.

One prevalent issue involves wear and tear due to prolonged usage, which may result in decreased functionality. Regular inspections are crucial to identify any signs of deterioration early. Another common problem is misalignment, which can cause excessive strain and lead to premature failure of elements.

Additionally, improper installation or lack of maintenance can lead to significant complications. Ensuring that all elements are correctly fitted and serviced can mitigate many of these issues. Finally, sourcing quality replacements is vital; inferior components may exacerbate existing problems or introduce new ones.

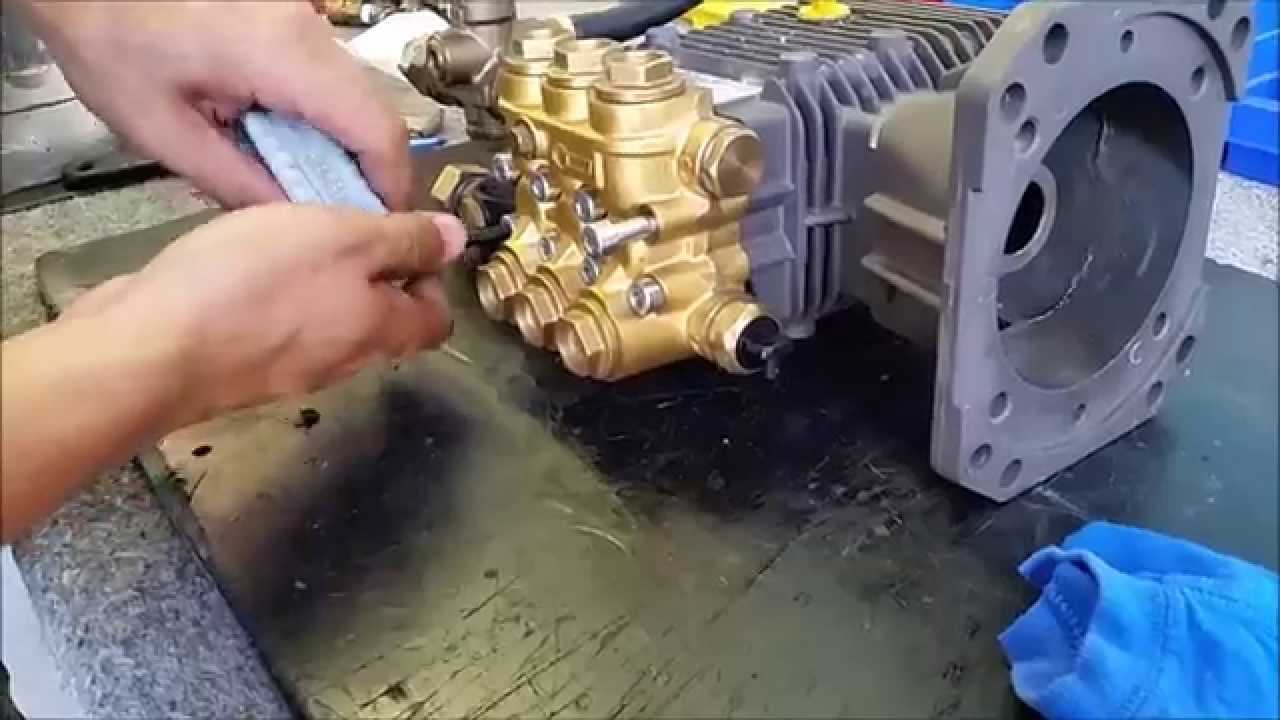

Step-by-Step Assembly Guide

This section provides a comprehensive approach to assembling your equipment efficiently and accurately. Following these instructions will ensure that each component is properly fitted, promoting optimal functionality and longevity of the machine.

Begin by organizing all components and tools required for the assembly process. Lay out the parts in a clear manner to facilitate easy access during assembly. Verify that you have everything you need, as this will minimize interruptions.

Start with the base unit. Securely attach the foundational elements using the designated fasteners. Ensure that each piece aligns perfectly before tightening, as misalignment can lead to operational issues later on.

Next, proceed to install the intermediate components. Carefully follow the sequence outlined in your reference guide. Pay close attention to orientation and positioning to avoid complications down the line. Each part should fit snugly without excessive force.

Once the midsection is complete, focus on the assembly of the final components. These typically include the operational features that enhance the device’s capabilities. Again, ensure everything is aligned and securely fastened.

Finally, conduct a thorough inspection of the assembled unit. Check for any loose screws or misaligned pieces. Once satisfied, proceed to the testing phase to confirm that all functionalities operate as intended. This final step is crucial to verify the integrity of your work.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a challenging yet essential task. Whether you’re looking to maintain functionality or enhance performance, knowing where to search is crucial. Here are some effective avenues to explore when seeking out replacements.

Online Resources

- Manufacturer’s Website: Start by visiting the official site of the original manufacturer. They often provide catalogs and options for ordering directly.

- E-commerce Platforms: Websites like Amazon, eBay, or specialized retailers frequently stock a variety of components. User reviews can help gauge quality.

- Dedicated Parts Stores: Online stores focused on specific types of machinery may have extensive selections and knowledgeable staff.

Local Outlets

- Authorized Dealers: Find local dealers who specialize in your equipment. They may offer genuine parts and expert advice.

- Repair Shops: Local repair services can be a valuable resource for both sourcing and installing components.

- Salvage Yards: Check salvage or recycling centers where you might discover used parts at reduced prices.

Maintenance Tips for Longevity

Ensuring the prolonged performance of your equipment requires a proactive approach to care and maintenance. By adhering to a systematic routine, you can significantly enhance efficiency and extend the lifespan of various components. Below are some essential strategies to keep in mind.

Regular Inspections

Conducting routine assessments is crucial for identifying potential issues before they escalate. Here are key areas to focus on:

- Check for signs of wear and tear on moving parts.

- Inspect electrical connections for any loose or corroded wiring.

- Examine fluid levels and look for leaks.

Proper Cleaning Techniques

Maintaining cleanliness is vital for optimal functionality. Follow these cleaning practices:

- Remove dust and debris from surfaces regularly.

- Use appropriate cleaning agents to avoid damage.

- Ensure ventilation areas are clear to promote airflow.

By incorporating these maintenance tips into your routine, you can help ensure that your equipment remains in peak condition for many years to come.

Comparing Models: ZWD 4040 vs. Others

This section explores the distinctions and similarities between a specific model and its competitors in the market. By examining key features, performance metrics, and user feedback, we aim to provide a comprehensive overview that assists potential buyers in making informed decisions.

When analyzing various options, it is essential to consider aspects such as durability, efficiency, and ease of use. The discussed model often stands out for its unique specifications, which may cater to specific needs better than alternatives. Understanding these nuances helps highlight why some users may prefer one model over another.

In terms of performance, comparisons can reveal strengths and weaknesses that are not immediately apparent. For instance, while one model may excel in speed, another might offer superior reliability. Evaluating these factors allows consumers to weigh their priorities effectively.

User experiences also play a crucial role in the evaluation process. Reviews and testimonials can shed light on long-term satisfaction, maintenance requirements, and overall value. This information can be invaluable when considering different models.

Ultimately, a thorough comparison empowers consumers to select the model that best aligns with their individual needs and preferences, ensuring they make a choice that provides the most benefit over time.