In the realm of agricultural machinery, the efficiency and performance of various implements hinge on a comprehensive understanding of their individual components. This section delves into the intricate elements that play crucial roles in the functionality and durability of these tools. By examining the various sections, one can gain insights into their interconnections and the overall mechanics at play.

Each segment of these implements serves a distinct purpose, contributing to the seamless operation of the machinery. From the robust structures that provide support to the intricate mechanisms that facilitate movement, every element is designed with precision. Understanding these components not only enhances operational efficiency but also aids in maintenance and repair efforts.

Moreover, grasping the arrangement and relationship between these parts empowers users to make informed decisions regarding upgrades and replacements. As technology evolves, staying abreast of these developments is essential for maximizing productivity in the field. This exploration will guide you through the key elements that define the effectiveness of agricultural equipment.

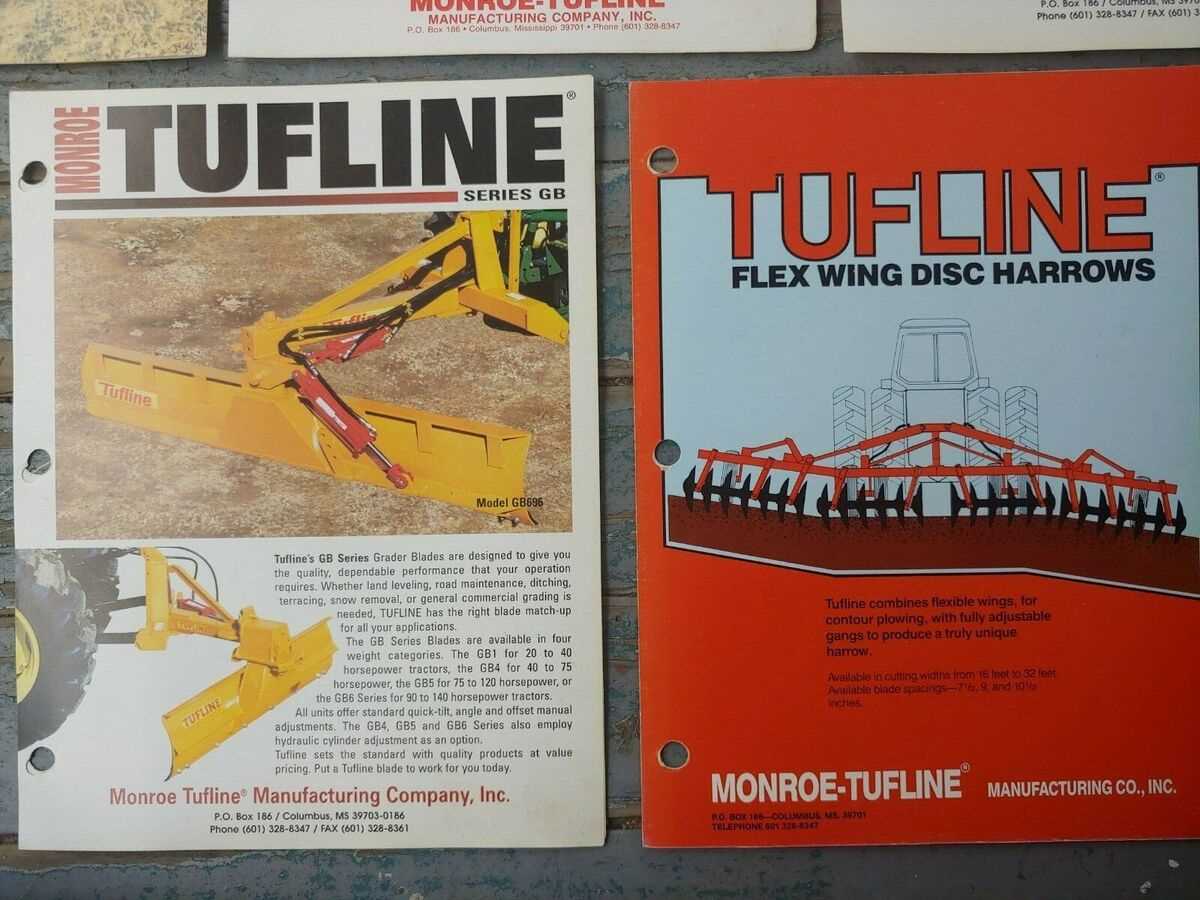

Tufline Disc Overview

This section provides a comprehensive look at a crucial piece of agricultural equipment designed for soil cultivation. Understanding its components and functionality is essential for optimizing performance and achieving effective results in land preparation.

Engineered for durability and efficiency, this machinery facilitates various farming tasks, making it an indispensable tool for modern agriculture. Each element plays a significant role in enhancing soil structure and promoting healthy crop growth.

Regular maintenance and awareness of the individual elements contribute to the longevity of this equipment. Familiarizing oneself with its construction ensures better handling and maximizes productivity during farming operations.

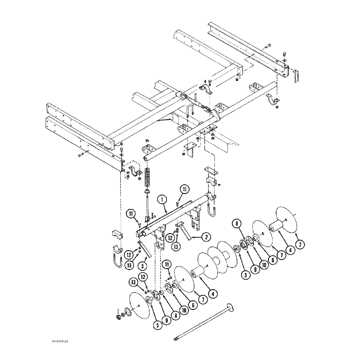

Key Components of Tufline Discs

Understanding the essential elements of agricultural equipment is crucial for optimizing performance and longevity. Each component plays a specific role, contributing to the overall functionality and efficiency of the machinery. Here, we explore the vital elements that make up these tools, highlighting their importance in agricultural operations.

| Component | Description |

|---|---|

| Frame | The structural backbone that supports all other elements, ensuring stability during use. |

| Blades | Cutting edges designed to penetrate the soil, enhancing tillage effectiveness. |

| Hitch | A connection point for attaching the implement to a tractor, allowing for seamless operation. |

| Wheel Assembly | Facilitates movement and ensures proper depth control while working the soil. |

| Adjustable Settings | Features that allow operators to modify depth and angle, tailoring performance to specific tasks. |

By familiarizing oneself with these key elements, operators can ensure they make informed decisions about maintenance and usage, ultimately leading to improved productivity and reduced downtime.

Understanding Disc Assembly Process

The process of assembling cutting-edge agricultural components involves a meticulous approach to ensure optimal performance and durability. Each phase is crucial, as it contributes to the overall functionality of the equipment, ultimately enhancing efficiency in the field. Mastery of this assembly process can lead to improved outcomes for users.

Key Components and Their Functions

Each element plays a specific role within the assembly, working together harmoniously. For instance, the outer ring serves as a protective layer, while the inner mechanism provides stability and precision. Understanding these roles is essential for proper maintenance and troubleshooting, which can prevent costly downtime.

Assembly Techniques

Various techniques are employed during the construction phase to ensure that every unit is robust and reliable. Alignment is critical; improper positioning can lead to inefficiencies. Fastening methods also vary, with some components requiring specialized tools for secure attachment. Mastering these techniques can greatly influence the longevity and effectiveness of the assembled units.

Importance of Regular Maintenance

Consistent upkeep of agricultural equipment is essential for ensuring optimal performance and longevity. Neglecting routine care can lead to diminished efficiency, increased downtime, and ultimately higher costs. By prioritizing maintenance, operators can enhance productivity and safeguard their investment.

Enhancing Performance

Regular maintenance helps to identify and rectify potential issues before they escalate into significant problems. This proactive approach not only boosts the overall functionality of machinery but also ensures that it operates at peak capacity.

Cost Efficiency

Investing time in maintenance can lead to substantial savings over time. By preventing major repairs and extending the lifespan of equipment, operators can minimize operational expenses and maximize their returns.

Troubleshooting Common Issues

When working with agricultural machinery, it is essential to identify and resolve frequent problems to ensure optimal performance. Understanding potential malfunctions can help users maintain efficiency and prolong the lifespan of their equipment.

Common Problems and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| Inconsistent cutting | Worn components | Inspect and replace worn parts. |

| Excessive vibration | Improper alignment | Check and realign machinery. |

| Poor soil penetration | Incorrect weight distribution | Adjust weight settings for balance. |

Maintenance Tips

Regular inspections and proper upkeep are crucial for preventing issues. Clean all components, lubricate moving parts, and ensure fasteners are secure to maintain peak functionality.

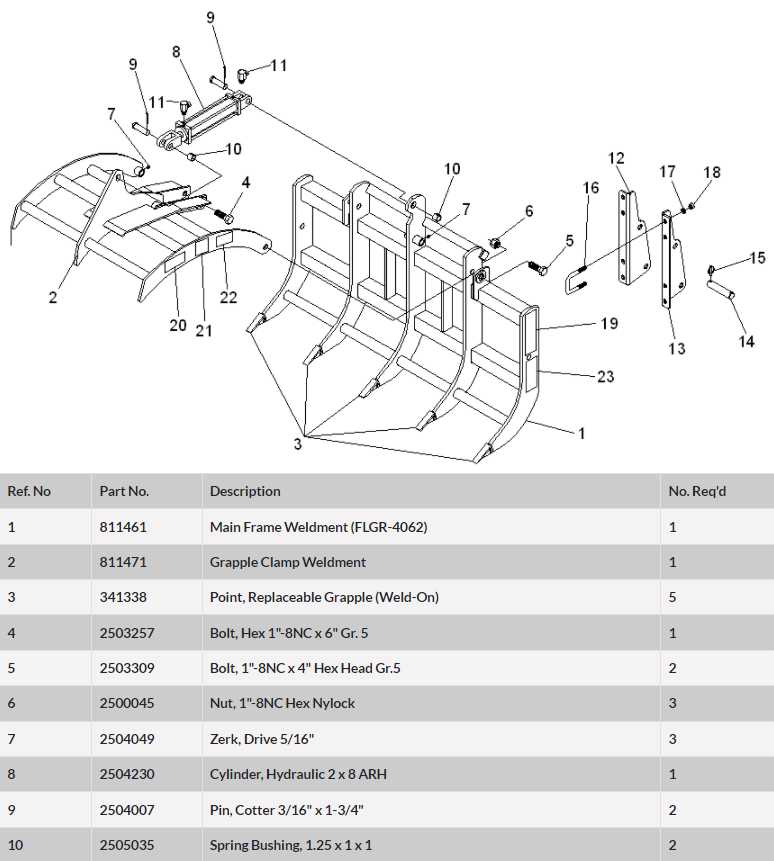

Replacement Parts Availability

Ensuring the functionality of agricultural equipment is paramount, and having access to necessary components is crucial for seamless operations. Availability of suitable replacements can significantly reduce downtime and enhance efficiency. Knowledge of where to procure these items can aid users in maintaining optimal performance.

Sources for Components

Several retailers and online platforms specialize in offering high-quality alternatives. Authorized distributors often provide original pieces, while aftermarket suppliers may present more cost-effective options. It’s advisable to research and compare to find the most suitable choice.

Importance of Quality

Investing in durable and reliable alternatives is essential for longevity. Choosing reputable sources ensures that the items meet industry standards, thereby minimizing the risk of failure. Quality should always take precedence over price when it comes to critical machinery components.

Benefits of Using Tufline Equipment

Utilizing high-quality agricultural machinery can significantly enhance productivity and efficiency on the field. This equipment is designed to meet the rigorous demands of farming, ensuring optimal performance and durability. By investing in such reliable tools, users can experience numerous advantages that contribute to better outcomes in their agricultural practices.

Enhanced Efficiency

One of the primary benefits is the increase in operational efficiency. The machinery is engineered to perform tasks swiftly and accurately, reducing the time required for fieldwork. With advanced features, farmers can cover larger areas in shorter periods, leading to improved overall productivity.

Durability and Reliability

Another significant advantage is the durability of the equipment. Built with high-quality materials, these tools withstand harsh conditions and prolonged use, minimizing downtime due to repairs. This reliability translates to consistent performance season after season, allowing farmers to focus on their crops rather than maintenance issues.

Moreover, the equipment’s design often incorporates user-friendly features, making operation easier and more intuitive. This not only enhances the user experience but also promotes safer working conditions, ultimately benefiting the entire farming operation.

Comparing Tufline with Competitors

This section explores the distinctions and advantages of a specific brand in relation to its rivals in the agricultural equipment market. By analyzing features, durability, and performance metrics, we aim to provide a comprehensive overview that aids in informed decision-making for potential buyers.

Performance and Durability

When evaluating performance, it’s essential to consider how well each product handles various soil types and conditions. The brand in question is recognized for its robust construction and reliability, often outperforming competitors in tough environments. Customers frequently report increased longevity and decreased maintenance needs, making it a preferred choice for many professionals in the field.

Cost-Effectiveness

Price points can vary significantly among brands, but value for money is crucial. While some competitors may offer lower initial prices, the total cost of ownership, including repairs and replacements, often favors the featured brand. Users tend to appreciate the balance of affordability and quality, resulting in a more economical investment over time.

Expert Tips for Optimal Use

Maximizing the efficiency of agricultural tools requires careful attention to detail and understanding of the equipment’s functionality. Whether you are tilling, cultivating, or preparing your soil, certain strategies can enhance performance and longevity.

Regular Maintenance: Schedule consistent check-ups to ensure that all components are in peak condition. Clean, lubricate, and replace worn parts to prevent costly breakdowns.

Proper Settings: Always adjust your equipment according to the specific soil type and crop requirements. This ensures optimal penetration and minimizes soil compaction.

Calibrate Depth: Regularly monitor and adjust the working depth for consistent results. This can significantly impact the effectiveness of soil preparation.

Monitor Performance: Keep an eye on how your equipment handles different conditions. Make necessary adjustments based on your observations to achieve the ultimate results.

Use Quality Accessories: Invest in high-quality attachments that complement your machinery. This can improve functionality and overall productivity.