In the realm of outdoor machinery, comprehending the intricacies of various elements is crucial for effective maintenance and repair. This knowledge not only enhances the lifespan of your tools but also ensures optimal performance during usage. A detailed breakdown of the machinery’s components allows users to identify issues promptly and address them with confidence.

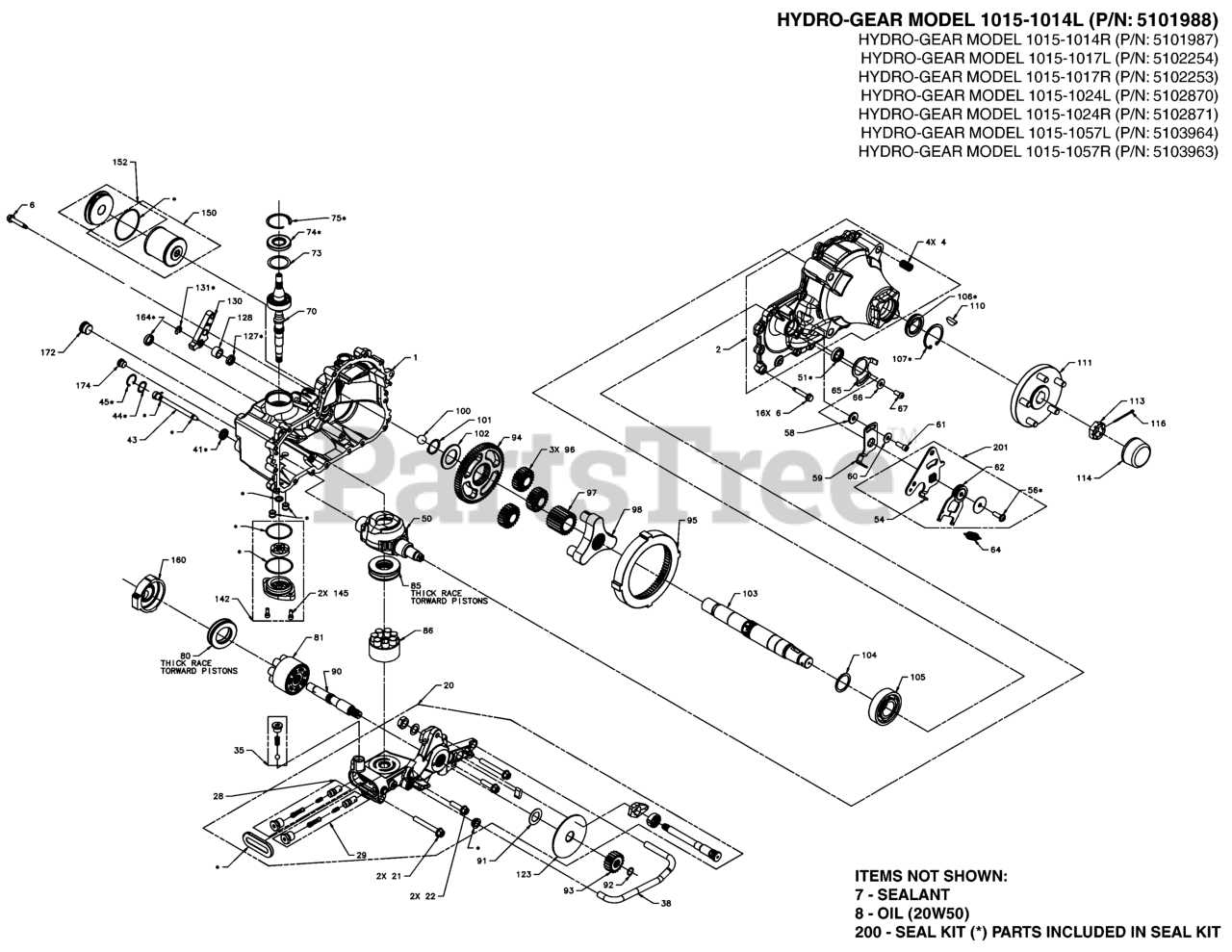

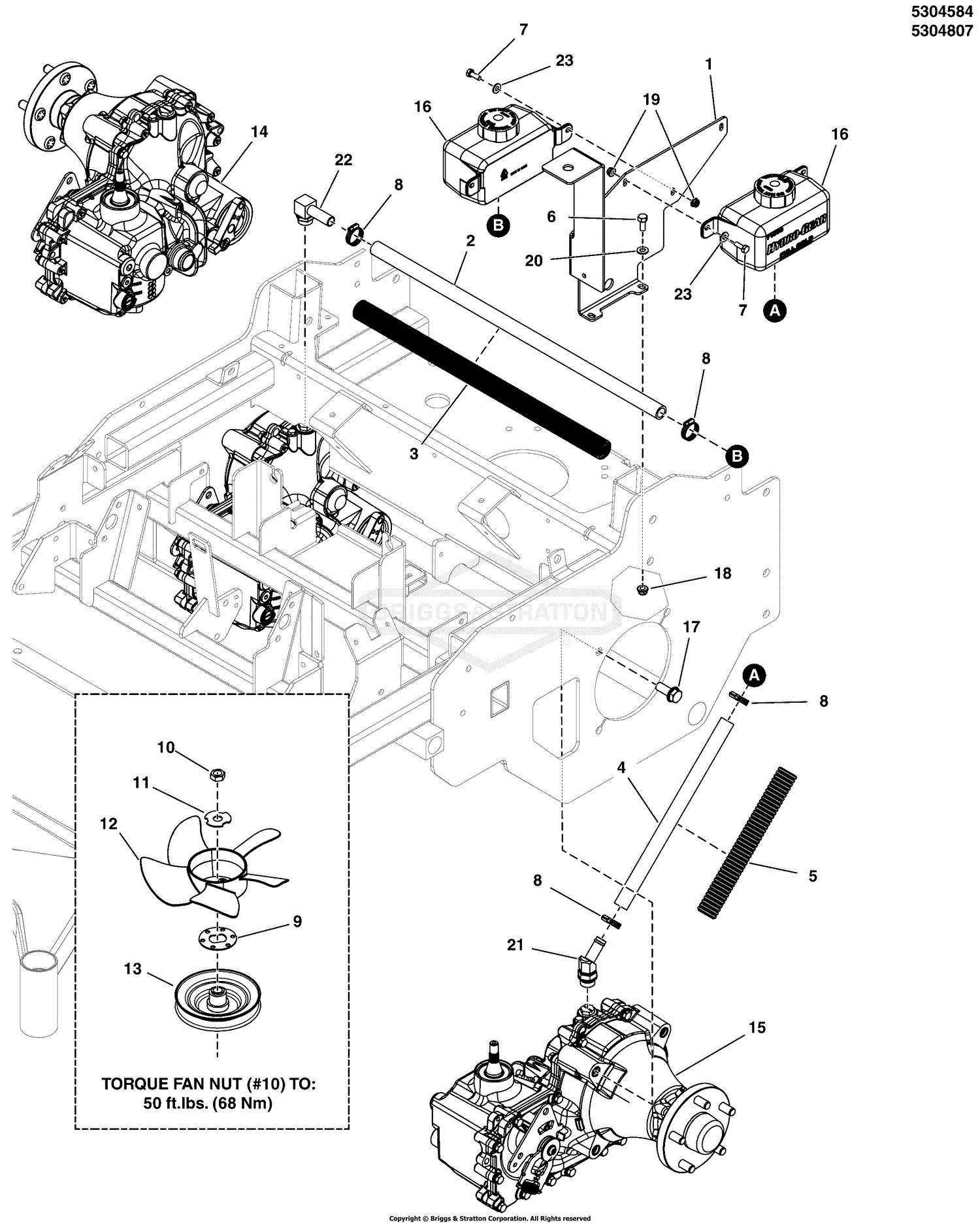

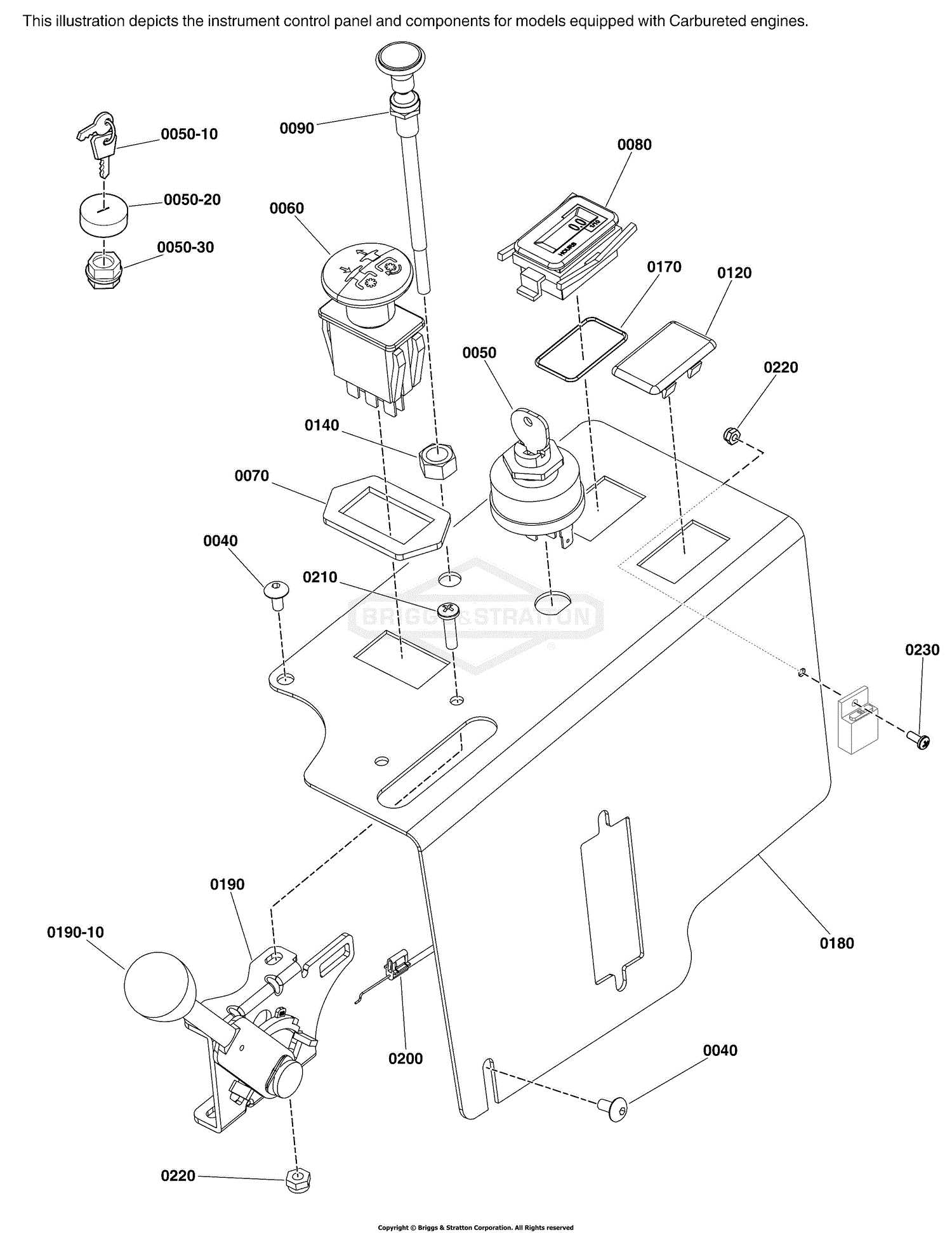

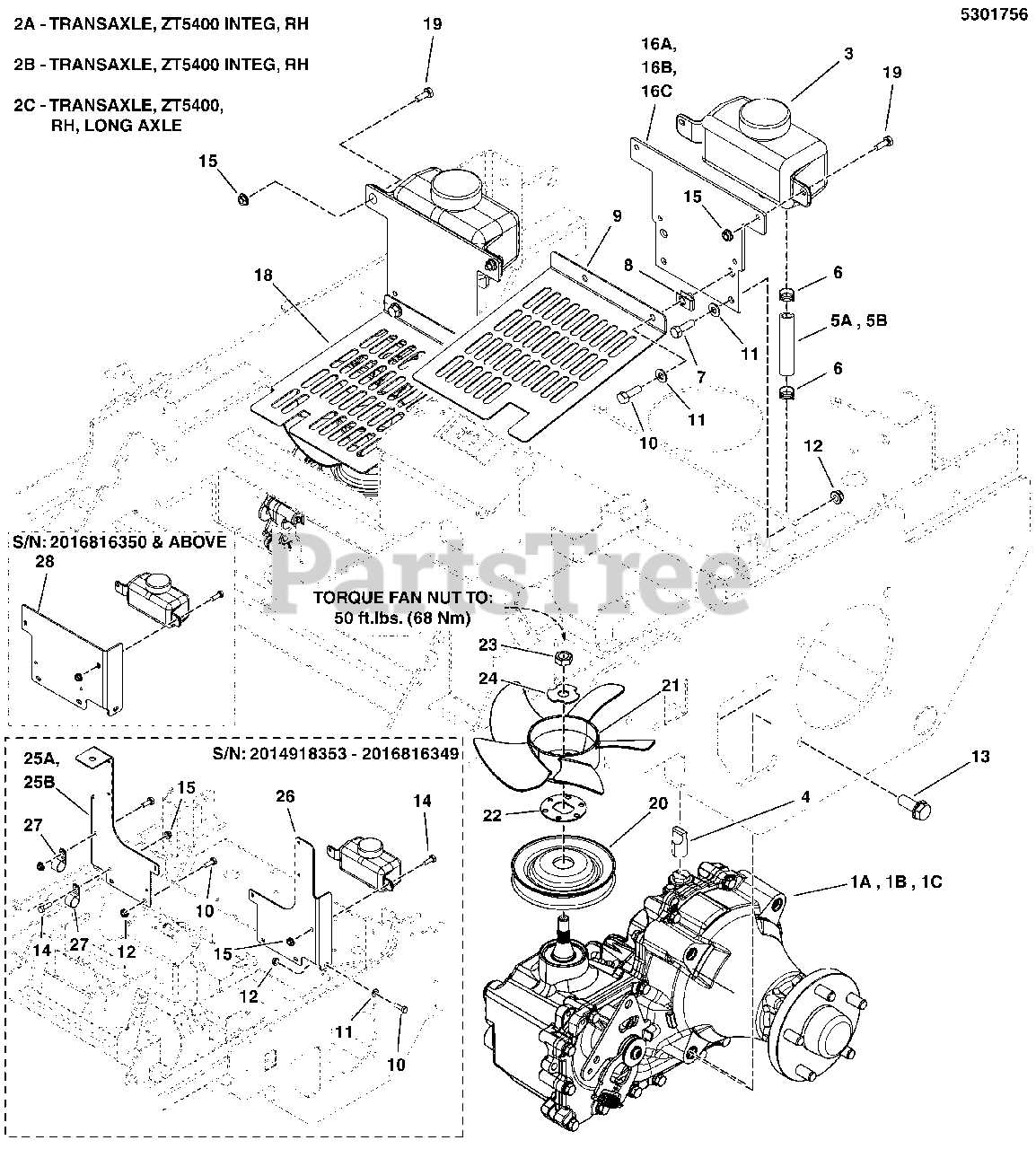

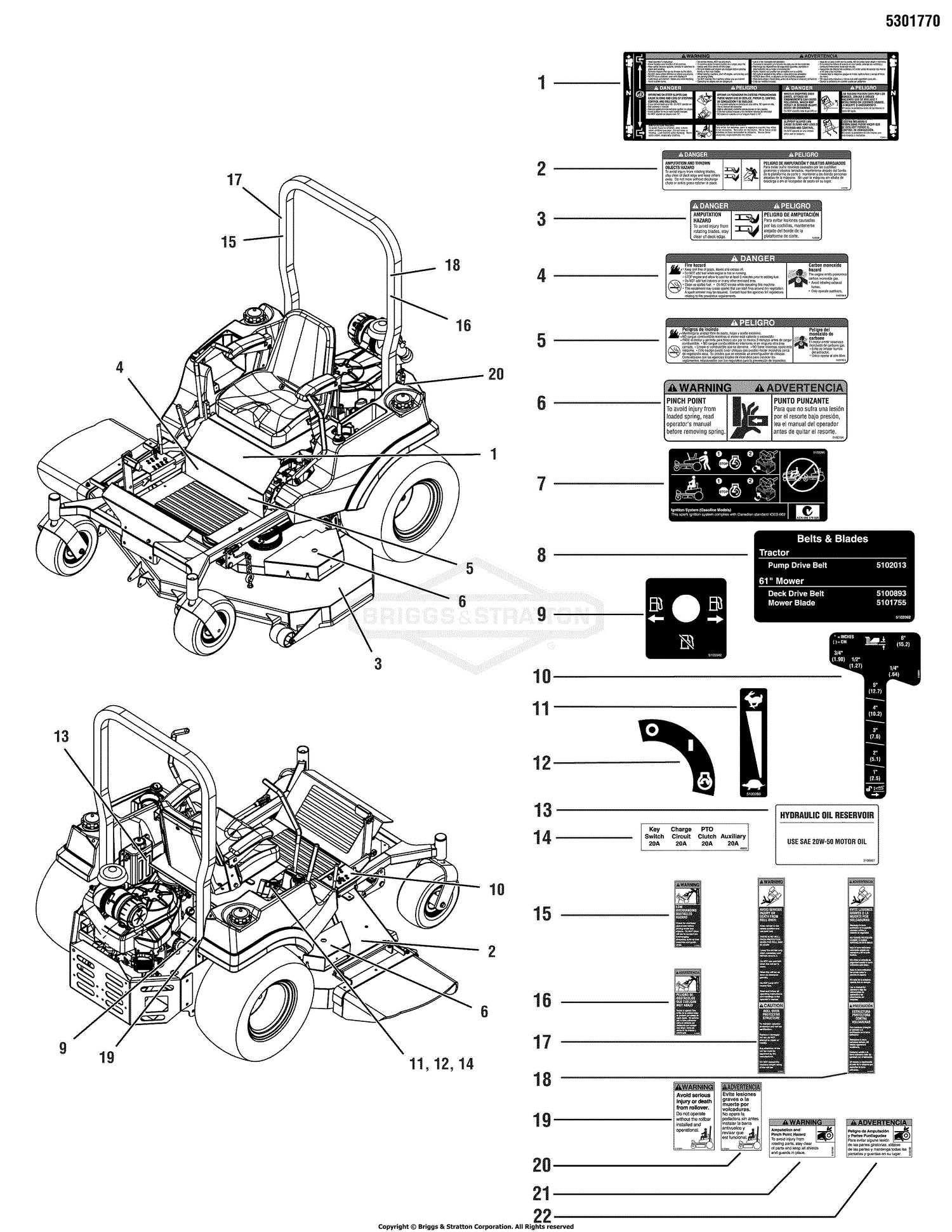

Visual aids play a significant role in this learning process, providing clear representations that simplify complex structures. By examining these illustrations, one can easily locate specific parts and understand how they interconnect within the entire system. This understanding is invaluable, particularly when it comes to troubleshooting and making informed decisions regarding repairs.

Furthermore, being familiar with each component fosters a deeper appreciation for the machinery itself. As users become more adept at recognizing individual elements, they are empowered to undertake maintenance tasks independently, ultimately saving time and resources. In this guide, we delve into the essential components and their functionalities, equipping you with the knowledge needed to keep your equipment in peak condition.

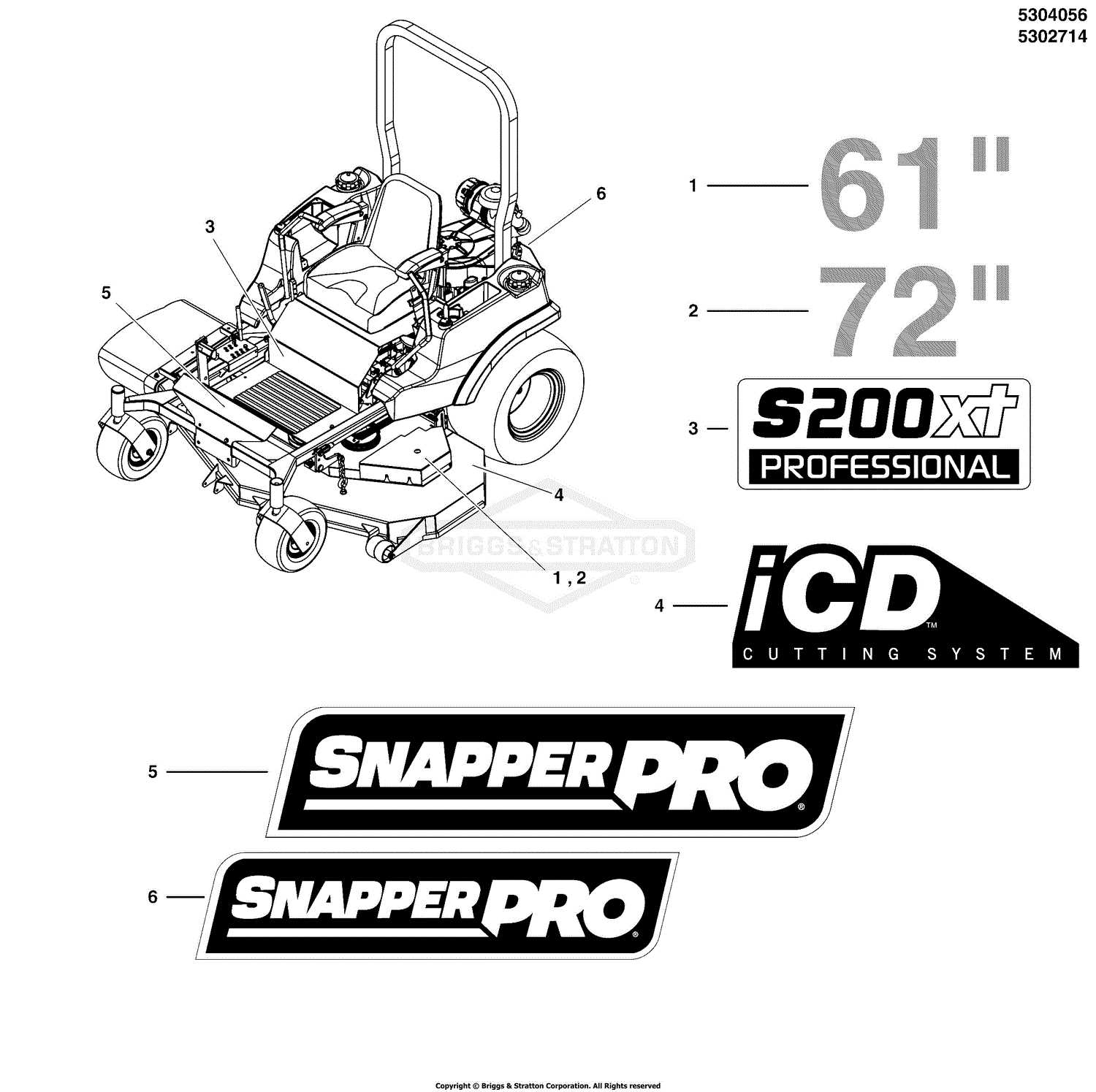

Understanding Snapper Pro S200XT Components

Grasping the intricacies of lawn care machinery is essential for optimal performance and maintenance. Each element plays a vital role in ensuring the overall functionality of the equipment. By familiarizing oneself with the various components, operators can enhance their understanding and troubleshoot any potential issues effectively.

The following table outlines key elements found in high-performance mowing machinery, including their functions and relevance to overall operation:

| Component | Function | Importance |

|---|---|---|

| Engine | Powers the machine, driving the blades. | Critical for performance and efficiency. |

| Deck | Houses the cutting blades and ensures even grass cutting. | Essential for achieving a clean cut. |

| Wheels | Provide mobility and stability during operation. | Important for maneuverability on various terrains. |

| Controls | Allow the operator to adjust speed and direction. | Key for user-friendly operation. |

| Fuel System | Supplies energy to the engine. | Necessary for consistent performance. |

Understanding these components empowers users to maintain their machinery effectively, ensuring longevity and reliability throughout its operational life.

Importance of Parts Diagrams

Understanding the layout and components of machinery is crucial for effective maintenance and repair. Visual representations serve as essential guides, enabling users to identify and access necessary elements efficiently. This knowledge not only streamlines the repair process but also enhances the longevity and performance of the equipment.

Enhanced Troubleshooting

Detailed illustrations facilitate quicker identification of issues, allowing technicians to pinpoint faults without extensive trial and error. This clarity reduces downtime and improves overall productivity, making repairs more manageable and less frustrating.

Efficient Ordering of Components

Accurate visual aids help in ensuring that the right elements are ordered when replacements are needed. This minimizes the risk of errors and speeds up the restoration process, ultimately leading to more reliable operation and reduced costs.

Key Features of Snapper Pro S200XT

The latest model in this line boasts an impressive array of characteristics that enhance performance and usability. Designed for efficiency, it caters to both professional landscapers and avid gardeners, making yard maintenance a more enjoyable experience.

Powerful Engine: At its core, the unit is equipped with a robust engine that delivers exceptional torque and speed, ensuring quick and effective mowing even in challenging conditions.

Durable Construction: Built with high-quality materials, this machine offers longevity and resilience. Its sturdy frame can withstand the rigors of frequent use while providing stability on uneven terrain.

Advanced Cutting Technology: Featuring a sophisticated cutting system, the model ensures a clean and precise cut. Adjustable cutting heights allow users to tailor their mowing experience based on grass type and desired finish.

User-Friendly Controls: Ergonomically designed controls make operation intuitive and straightforward, allowing users to navigate with ease and focus on the task at hand.

Enhanced Maneuverability: The compact design enables easy handling in tight spaces, making it ideal for both open lawns and intricate landscapes.

Comfort Features: Equipped with a cushioned seat and adjustable armrests, it ensures comfort during extended use, reducing fatigue and increasing productivity.

With these standout features, this model is engineered to meet the demands of users seeking efficiency and reliability in their outdoor tasks.

Common Replacement Parts Explained

Understanding essential components for lawn equipment maintenance is crucial for ensuring optimal performance. Various elements may require attention over time, and recognizing these can help users make informed decisions regarding upkeep and replacements.

Blades: These are vital for achieving a clean cut. Dull or damaged blades can lead to uneven trimming, making it necessary to replace them periodically for better results.

Air Filters: Clean air filters play a significant role in engine efficiency. Clogged filters restrict airflow, which can hinder performance and fuel economy. Regular checks and replacements can prevent engine strain.

Spark Plugs: These components ignite the fuel-air mixture in the engine. Worn or faulty spark plugs can cause starting issues or rough idling. Routine replacement can enhance starting performance and overall engine health.

Batteries: Powering the equipment, a reliable battery is essential. Over time, batteries can lose their ability to hold a charge. Replacing them when performance declines ensures uninterrupted operation.

Wheels and Tires: Proper mobility is essential for any lawn equipment. Worn wheels or tires can affect maneuverability and stability. Regular inspection and timely replacement contribute to smoother operation.

By keeping track of these key components, users can maintain their equipment effectively, ensuring it remains in top condition for every task.

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient maintenance and repairs. These illustrations provide a detailed overview of various elements and their interconnections, making it easier to identify what is needed for any project.

Here are some key steps to effectively interpret these visuals:

- Familiarize Yourself with Symbols: Each illustration often uses specific icons or notations. Take time to learn what these symbols represent to avoid confusion.

- Identify Sections: Many visuals are divided into distinct areas. Recognizing these sections helps in understanding how components are organized and related.

- Follow the Flow: Look for directional arrows or lines that indicate the assembly or functional flow. This can provide insights into how parts work together.

- Refer to the Legend: If available, check the accompanying legend or key. This often clarifies the meaning of various markings and enhances comprehension.

Utilizing these strategies can greatly improve your ability to decipher these technical illustrations, streamlining your repair processes and enhancing your overall efficiency.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended lifespan and optimal performance of your equipment. By following a few key practices, you can prevent unnecessary wear and enhance efficiency. Emphasizing maintenance not only saves time but also minimizes costs associated with repairs.

Routine Inspections

Conducting periodic checks is vital. Look for signs of wear and tear, such as frayed belts or loose connections. Addressing minor issues promptly can prevent them from escalating into significant problems.

Proper Cleaning and Storage

After each use, ensure that all components are cleaned thoroughly to remove debris and dirt. Store your equipment in a dry, sheltered place to protect it from environmental damage. Consistent cleaning and appropriate storage will significantly enhance its durability.

Where to Buy Replacement Parts

Finding suitable components for your equipment is essential for maintaining optimal performance. Various retailers offer a wide range of options, from authorized dealers to online marketplaces, ensuring you can easily access what you need.

Authorized distributors are often the best choice for guaranteed quality and compatibility. They typically stock a comprehensive selection and can provide expert advice. Additionally, reputable online platforms offer convenience and competitive pricing, making it easier to compare different products and reviews.

Local hardware stores may also carry essential items, catering to those who prefer immediate purchases without waiting for shipping. For rare or specialized components, consider checking specialty shops or manufacturer websites to ensure you get exactly what you require.

Lastly, online forums and community groups can be excellent resources for recommendations and tips on sourcing reliable components from trusted suppliers. Engaging with fellow enthusiasts often leads to valuable insights and potential deals.

Troubleshooting Common Issues

When operating outdoor machinery, encountering problems is a common experience. Understanding the frequent challenges and their solutions can enhance performance and prolong the life of your equipment. This section outlines typical issues that users may face and provides guidance on how to address them effectively.

Common Problems and Solutions

| Issue | Possible Cause | Recommended Solution |

|---|---|---|

| Engine won’t start | Empty fuel tank or stale fuel | Refill with fresh fuel |

| Uneven cutting | Dull blades or improper height adjustment | Sharpen blades and adjust cutting height |

| Overheating | Clogged air filter | Clean or replace air filter |

| Excessive vibration | Loose or damaged components | Tighten or replace affected parts |

Preventive Measures

To minimize the occurrence of these issues, regular maintenance is essential. Ensure that all components are checked periodically and any signs of wear are addressed promptly. Keeping the machinery clean and well-lubricated will also contribute to smoother operation and fewer complications.

Upgrades and Modifications Overview

This section explores the various enhancements and customizations that can significantly improve performance and functionality. Whether seeking to boost efficiency or tailor features to individual preferences, understanding the possibilities can lead to a more satisfying experience.

Performance Enhancements

Focusing on upgrades that enhance speed and reliability is crucial. Options may include optimizing the engine components, improving the fuel system, or incorporating advanced technology for better control.

Aesthetic Customizations

Beyond functionality, visual upgrades can make a considerable impact. Changing color schemes, adding decals, or upgrading wheels can create a unique look that reflects personal style.