Maintaining and troubleshooting cleaning devices can often feel overwhelming. Understanding the various elements that make up these machines is essential for efficient operation and repairs. A thorough knowledge of the internal structure can empower users to address issues proactively and ensure longevity in performance.

Each device consists of a multitude of essential components, each serving a unique purpose. Familiarity with these parts not only aids in identifying problems but also assists in performing routine maintenance. Recognizing the function of each segment can transform the way you interact with your equipment, making it a more user-friendly experience.

In this section, we will explore the intricate details of these systems, focusing on how each element interconnects to create effective functionality. By delving into the specifics, users can gain valuable insights that enhance both their understanding and ability to manage their cleaning tools efficiently.

Understanding Shop Vac Functionality

This section delves into the operational principles of a versatile cleaning device commonly employed for both wet and dry debris collection. By exploring its fundamental components and their interrelated functions, we can gain insight into how this equipment effectively manages various cleaning tasks.

Core Components

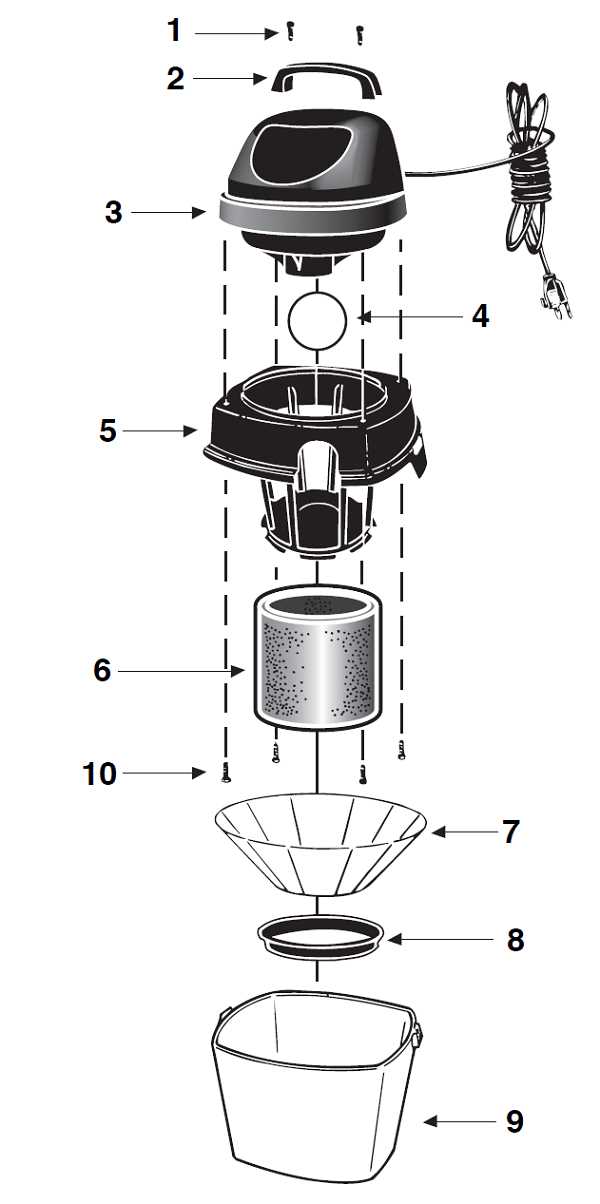

At the heart of this apparatus lies a powerful motor, responsible for generating the necessary suction. This motor drives an impeller that creates a pressure differential, allowing the device to draw in particles and liquids. Filters play a crucial role in trapping debris, ensuring that only clean air is expelled back into the environment. The construction typically includes a robust tank, which serves as a reservoir for collected materials.

Operational Mechanism

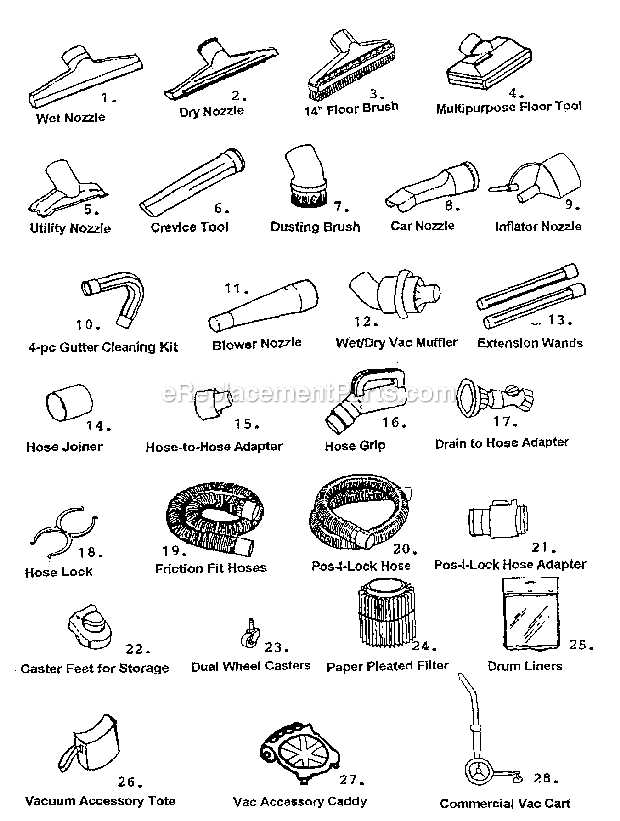

The operation begins with the activation of the motor, which initiates airflow through a network of hoses and attachments. Versatile nozzles enable users to tackle various surfaces, adapting to specific cleaning needs. This adaptability, combined with the efficient separation of solids and liquids, makes the device indispensable in both residential and commercial settings.

Essential Components of a Shop Vac

Understanding the key elements of this versatile cleaning device is crucial for optimal performance and maintenance. Each component plays a vital role in ensuring effective operation and efficiency.

- Motor: The powerhouse that drives the unit, providing suction and airflow.

- Filter: Captures dust and debris, preventing them from escaping back into the environment.

- Hose: The conduit through which dirt and liquid are transported to the container.

- Collection Tank: The reservoir where debris is collected, available in various capacities.

- Wheels: Enhance mobility, allowing easy transport across different surfaces.

Each of these components contributes to the overall functionality, making them essential for effective cleaning tasks.

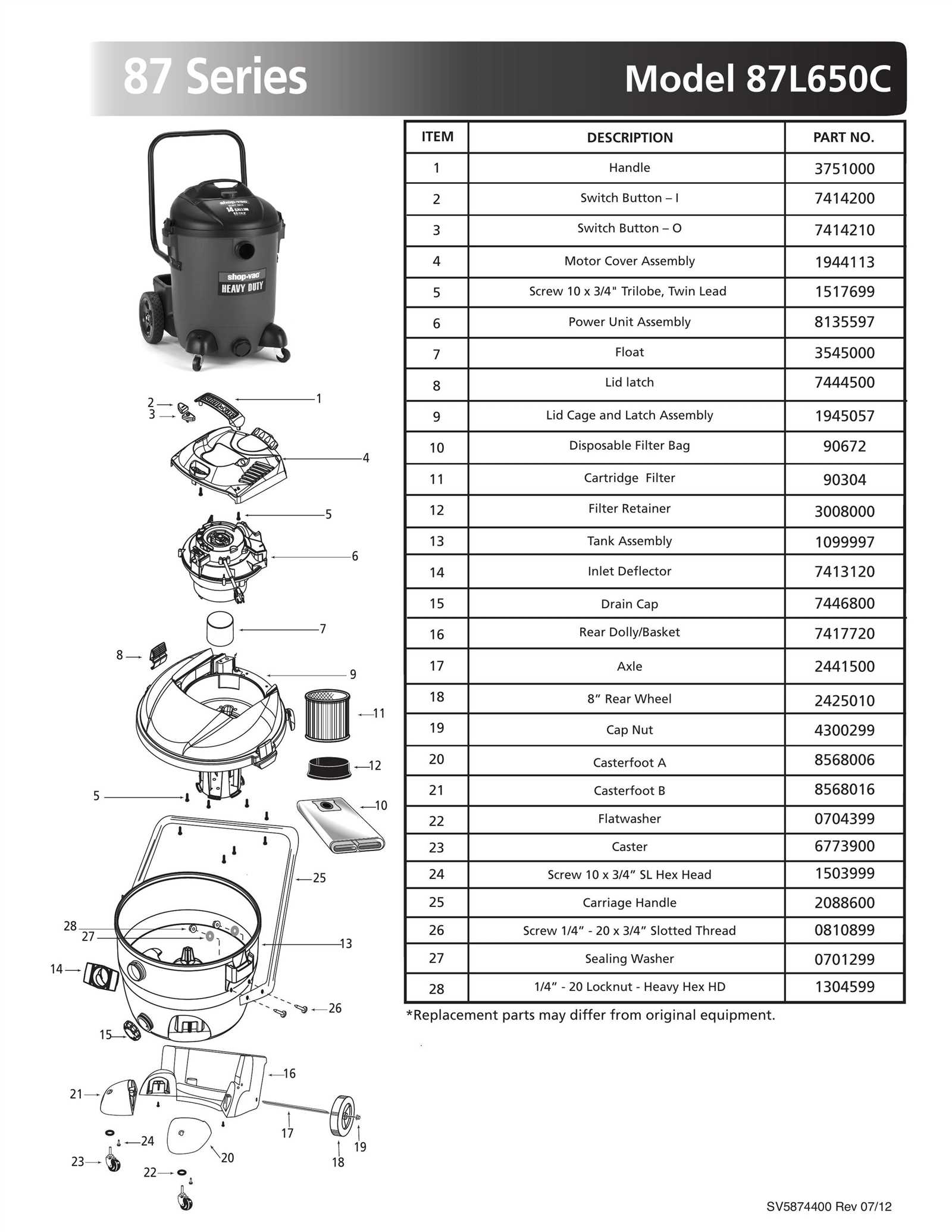

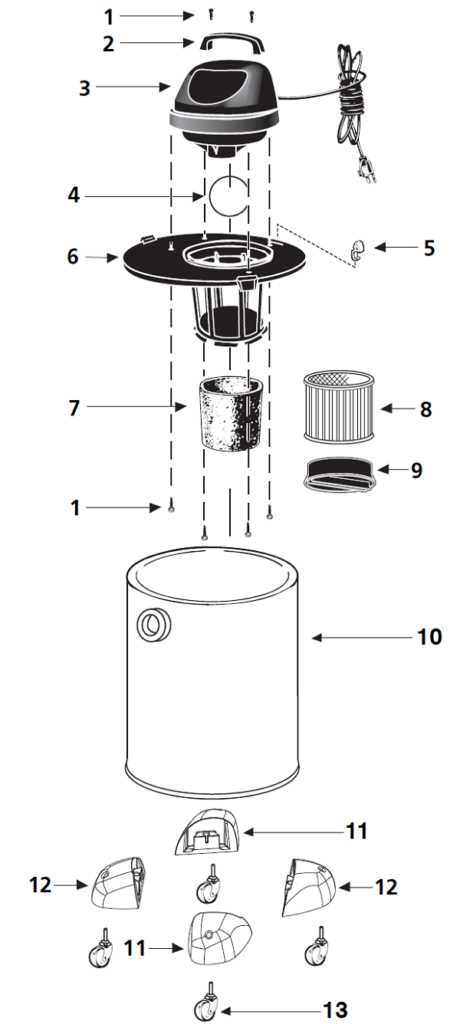

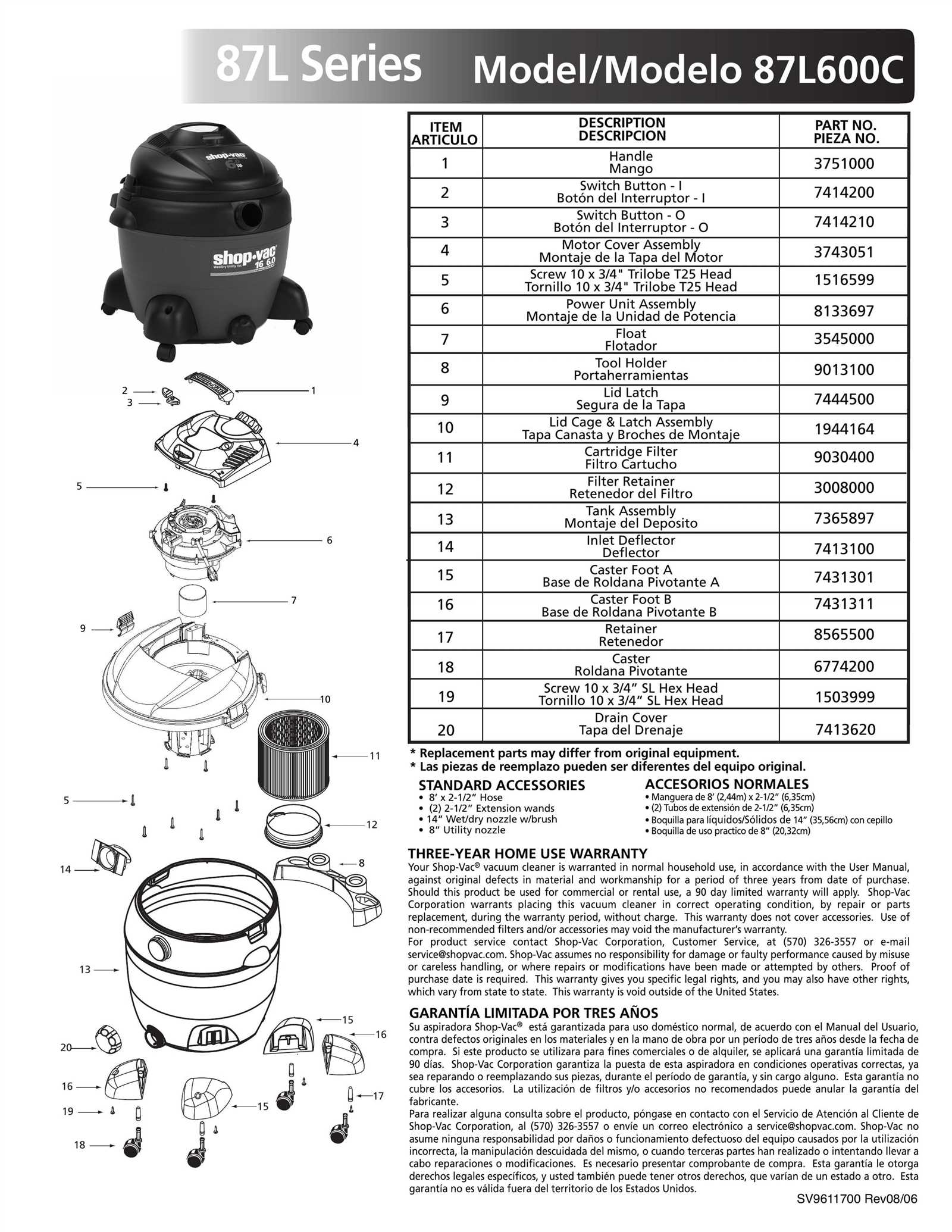

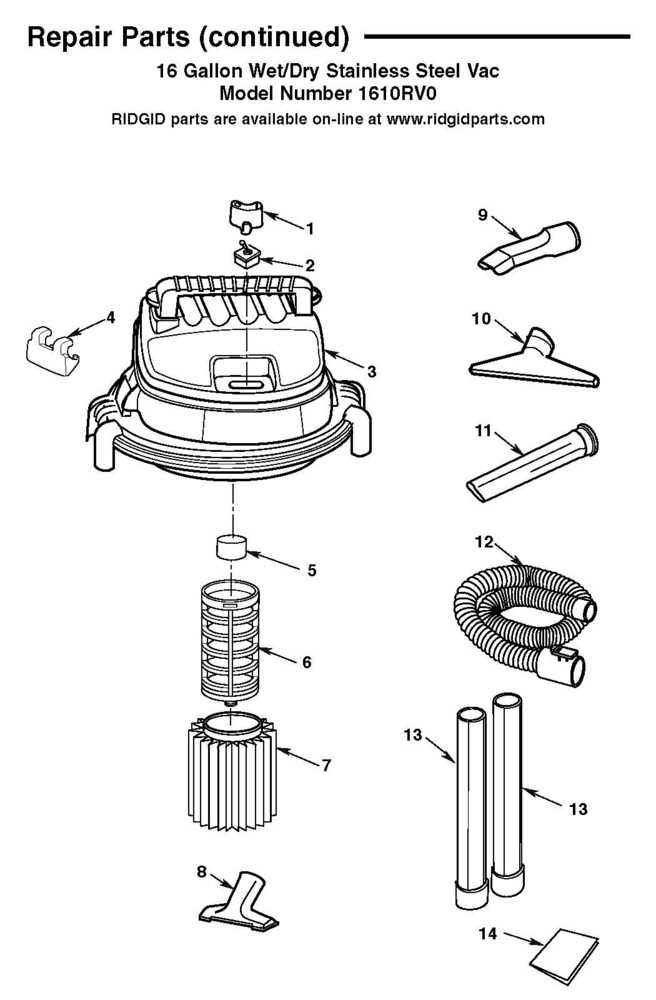

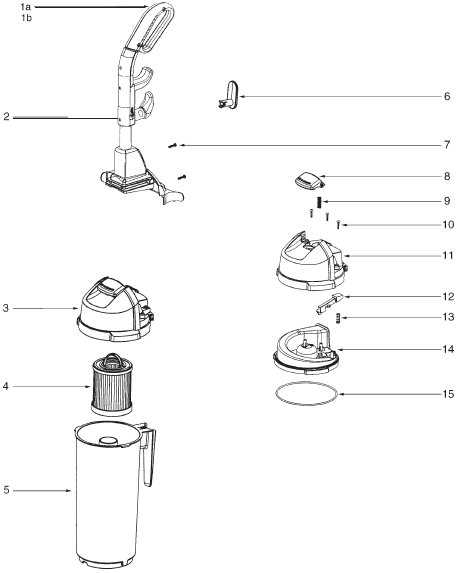

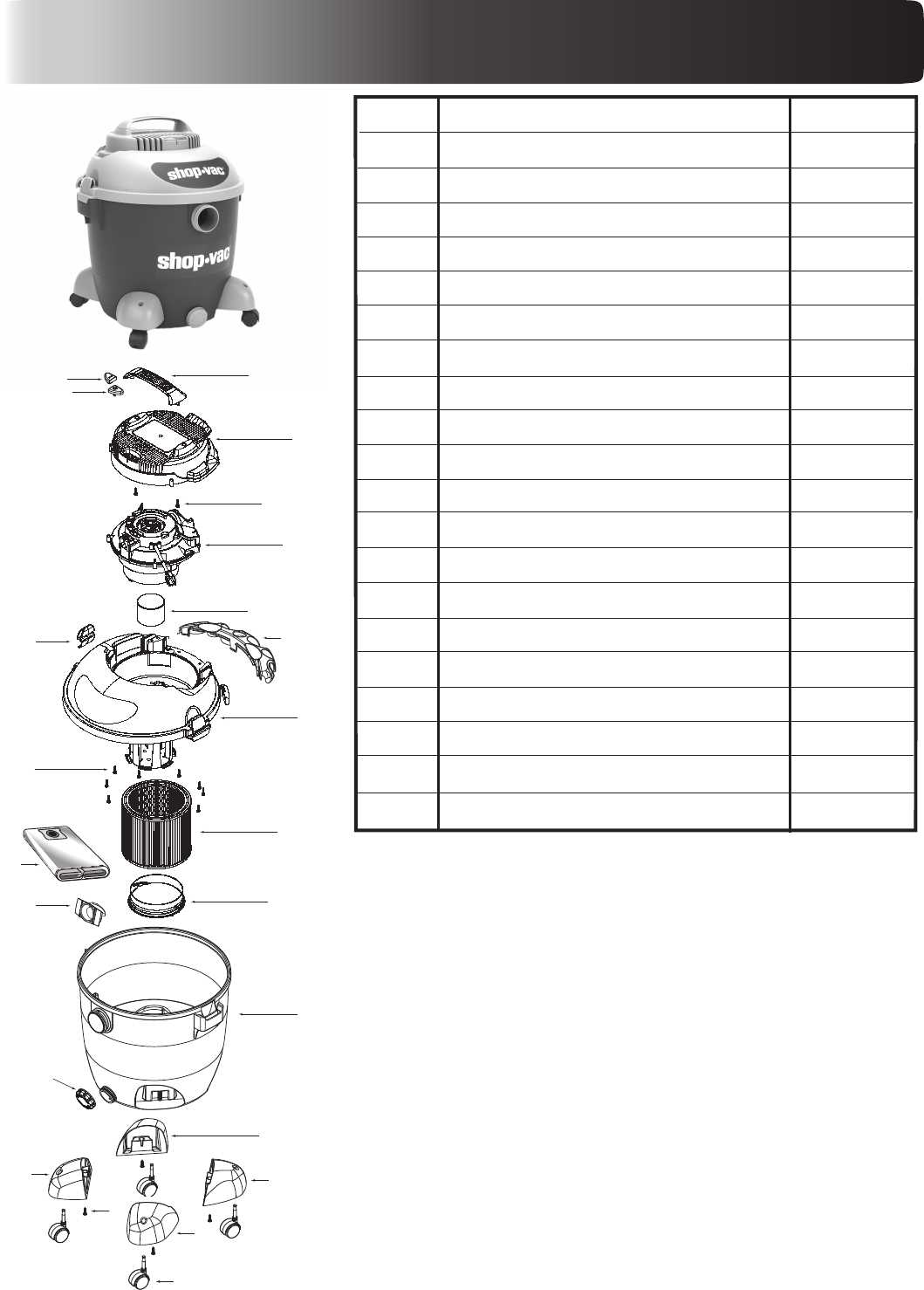

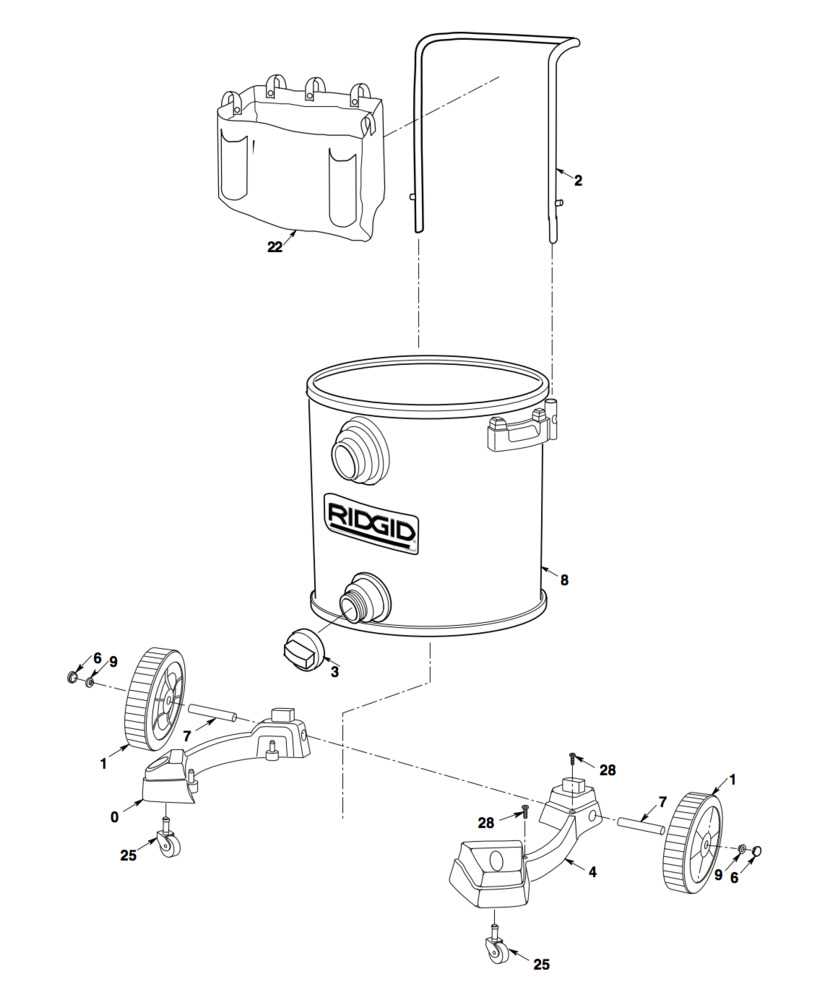

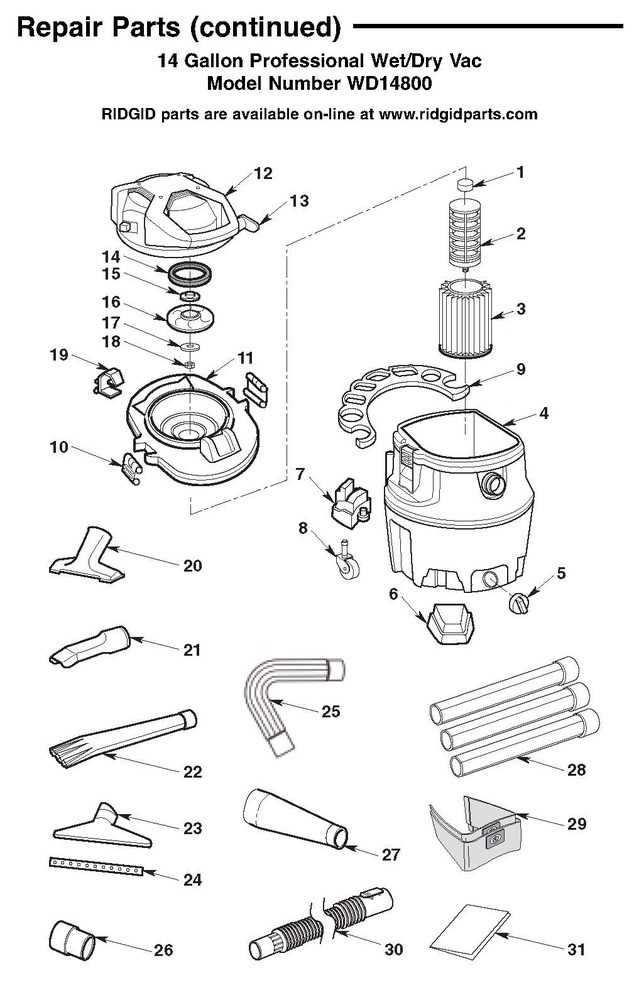

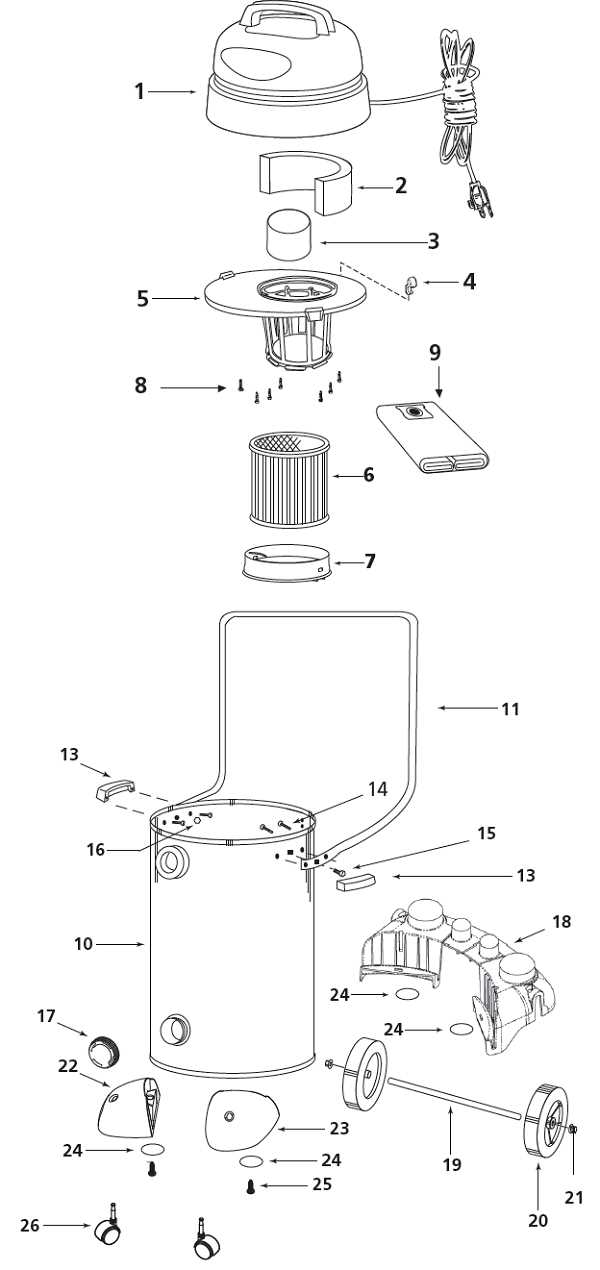

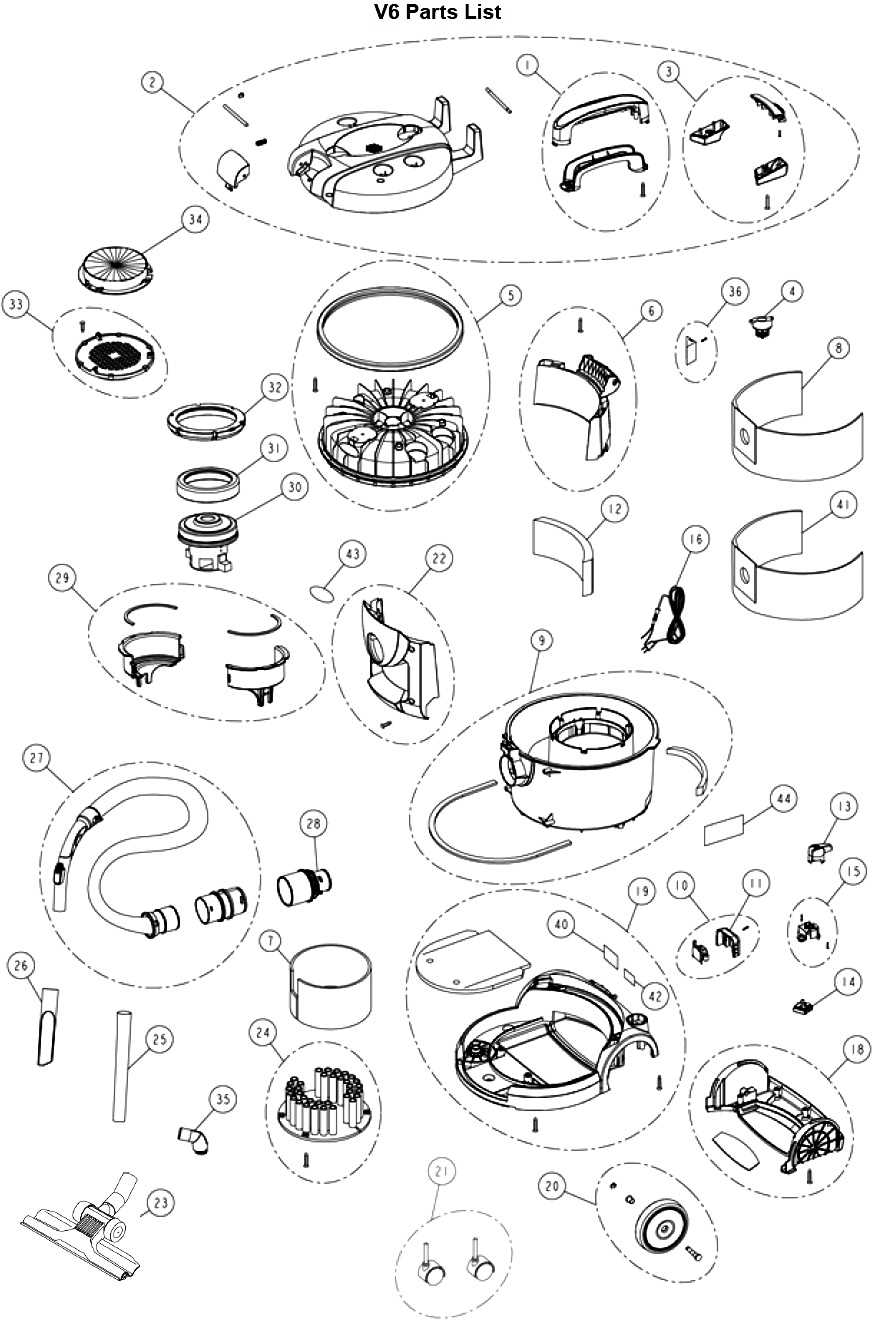

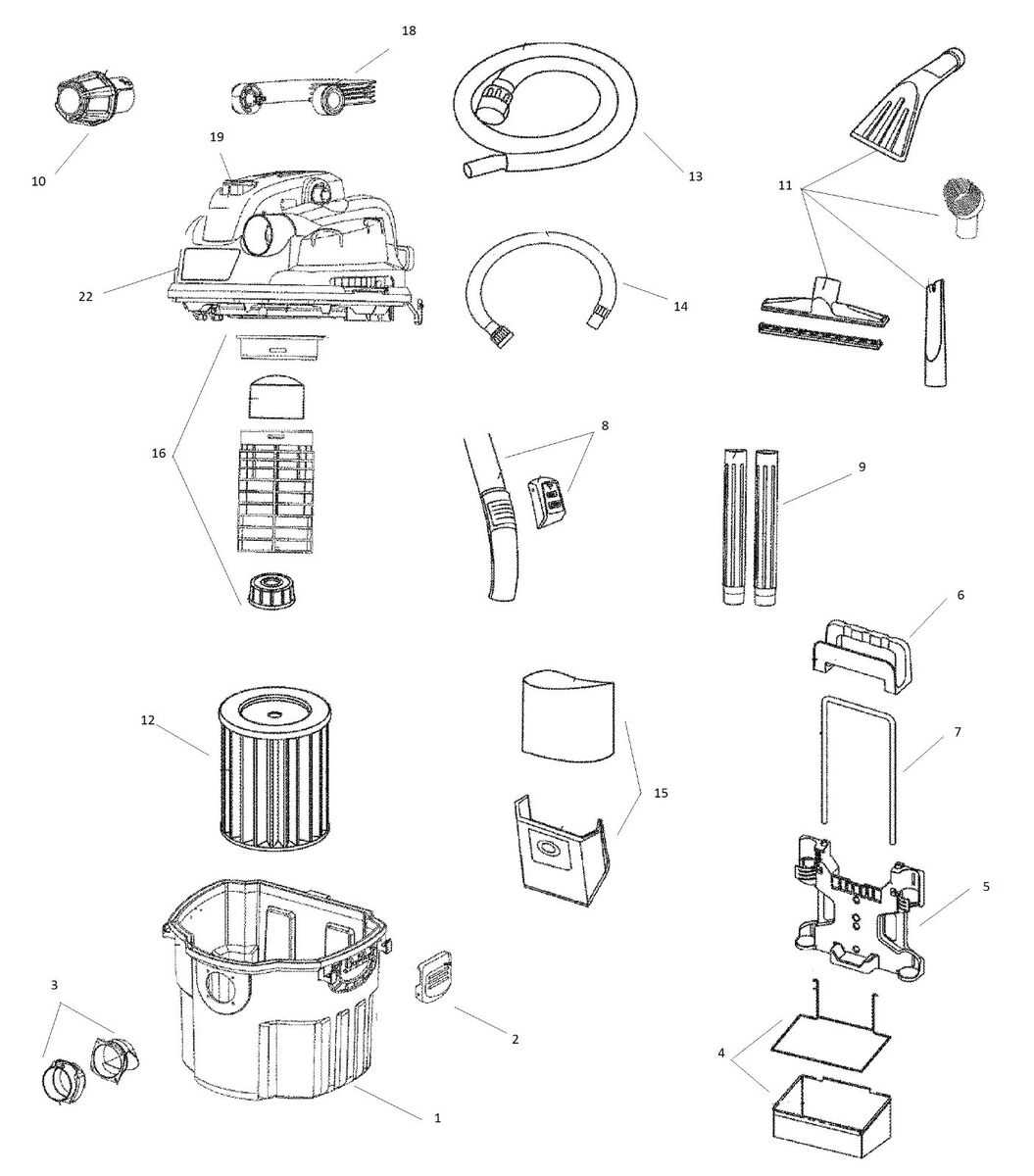

How to Read Parts Diagrams

Understanding the visual representations of components is essential for effective maintenance and repair. These illustrations provide critical insights into the structure and functionality of various elements, helping users to identify, locate, and replace parts efficiently.

Key Elements to Focus On

- Labels: Each component is often accompanied by a label indicating its name or reference number.

- Connections: Arrows or lines may show how different elements are linked or interact with one another.

- Grouping: Parts may be organized into sections that highlight their specific functions or areas within the overall system.

Steps to Interpret the Visual Guide

- Start by identifying the main sections of the illustration.

- Look for the key or legend that explains symbols and colors used.

- Follow the lines or arrows to understand how components relate to each other.

- Cross-reference the identified parts with the accompanying list for clarity.

By mastering these techniques, you can navigate component illustrations with confidence, ensuring accurate identification and successful repairs.

Common Issues and Solutions

Many users encounter various challenges with their cleaning machines, impacting performance and efficiency. Identifying these common problems is essential for effective troubleshooting and ensuring optimal operation.

One frequent issue is reduced suction power. This can often be traced back to clogged hoses or filters. Regularly inspecting and cleaning these components can restore functionality.

Another problem is the machine making unusual noises. This may indicate a foreign object obstructing the mechanism or worn-out parts. Thoroughly checking for blockages and examining components can help resolve this concern.

Additionally, leaks can occur in the system, affecting performance. Ensuring that all connections are tight and replacing any damaged seals will help maintain proper function.

Lastly, overheating can be a sign of overuse or blocked airflow. Allowing the unit to cool down and clearing any obstructions can prevent long-term damage.

Choosing the Right Replacement Parts

Selecting the appropriate components for your cleaning equipment is essential for maintaining its performance and longevity. Understanding the specific requirements of your model can significantly enhance efficiency and ensure that your device operates optimally.

When considering replacements, quality should be a top priority. Always opt for components from reputable manufacturers to avoid compatibility issues and to guarantee durability. Inferior products may lead to malfunctions or even damage your machinery.

Additionally, it’s crucial to refer to the manufacturer’s guidelines to identify the correct specifications needed for your unit. This includes examining dimensions, materials, and any unique features that may affect compatibility. By doing so, you ensure a seamless fit and reliable performance.

Lastly, consult customer reviews and expert recommendations when making your choice. Insights from others who have faced similar situations can provide valuable information about the best options available, helping you make an informed decision.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your cleaning device requires regular attention and care. By implementing a few simple practices, you can keep it running efficiently and avoid costly repairs. Below are some essential tips to enhance durability and performance.

- Regular Cleaning: After each use, clean the exterior and interior components to prevent dust and debris buildup.

- Inspect Filters: Check filters frequently for clogs. Replace or wash them as necessary to maintain optimal airflow.

- Monitor Hoses: Examine hoses for cracks or blockages. Clear any obstructions and replace damaged sections promptly.

- Check Seals: Ensure all seals are intact. Replace worn or damaged seals to prevent leaks.

- Store Properly: Keep the device in a dry, cool location to protect it from moisture and extreme temperatures.

- Follow Manufacturer Guidelines: Adhere to the care instructions provided by the manufacturer for specific maintenance procedures.

By integrating these practices into your routine, you can significantly enhance the performance and lifespan of your cleaning equipment.

Upgrading Your Shop Vac System

Enhancing your cleanup setup can significantly improve efficiency and performance. By selecting the right components and accessories, you can transform a basic system into a powerful tool tailored to your specific needs. Here are some key considerations for elevating your setup.

- Assess Your Needs: Determine the primary tasks you will perform. Will you be tackling large debris, fine dust, or liquids?

- Upgrade the Hose: A wider, more flexible hose can increase airflow and maneuverability, making it easier to access tight spaces.

- Consider Filtration: Investing in a high-efficiency filter can trap smaller particles, improving air quality and system longevity.

- Add Attachments: Various nozzles and brushes can enhance versatility, allowing for better performance on different surfaces.

Implementing these upgrades can lead to a more effective and enjoyable cleaning experience, ultimately saving time and effort in your projects.

Where to Find Parts Diagrams

Locating detailed illustrations of components is essential for maintenance and repairs. Here are some reliable sources to help you access these valuable resources:

- Manufacturer Websites: Most brands offer downloadable resources directly on their official sites.

- Retailer Platforms: Major online retailers often provide access to assembly visuals alongside product listings.

- User Manuals: Check the user guide that came with your device; they frequently contain diagrams.

- Repair Forums: Online communities can be a treasure trove of shared resources and expert advice.

- Third-Party Websites: Specialized sites focus on repair resources and may offer illustrations for a variety of models.

Utilizing these options can help you effectively troubleshoot and repair your equipment.