In the realm of fluid management, efficiency and reliability are paramount. Grasping the intricate design and functionality of these devices is essential for optimal performance in various industrial applications. This section aims to explore the essential elements that contribute to the seamless operation of such mechanisms.

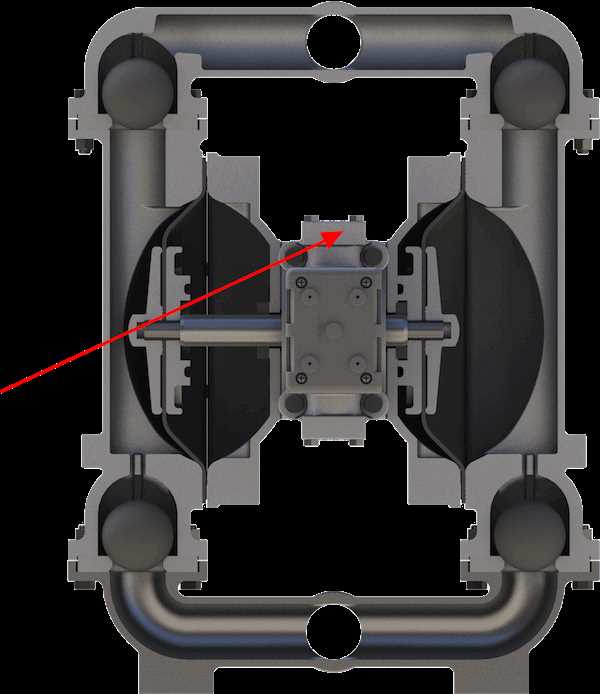

Components play a crucial role in determining how well these systems function. Each element is meticulously crafted to work in harmony, ensuring that the transfer of liquids occurs smoothly and effectively. By examining the relationship between these components, we can delve into the mechanics that drive their performance.

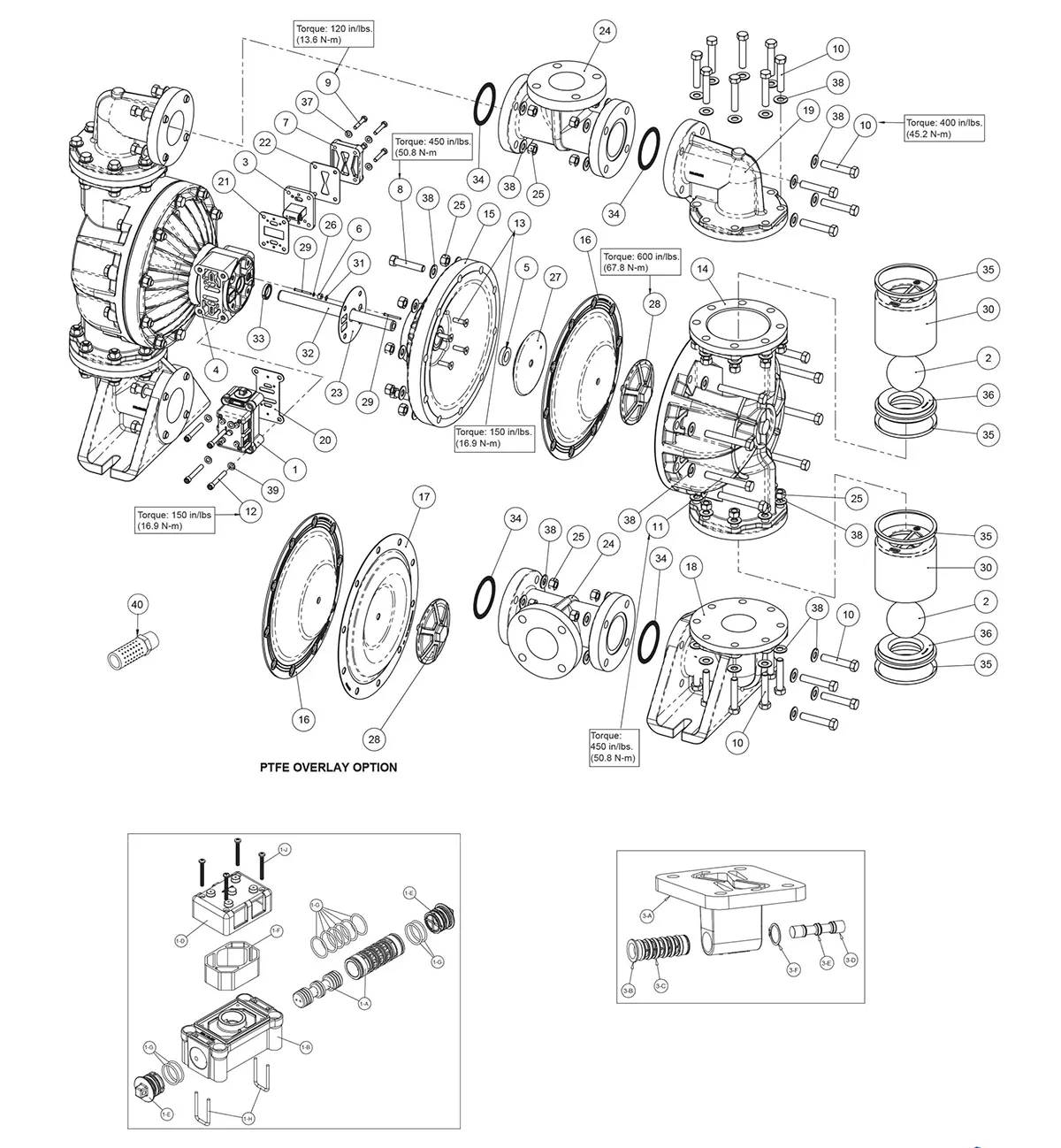

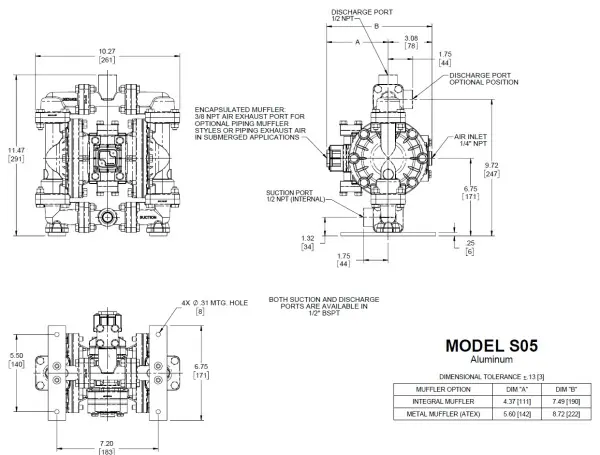

Furthermore, understanding the layout of these systems allows for better maintenance and troubleshooting. Recognizing the ultimate configuration can help users pinpoint issues swiftly, ensuring minimal downtime and enhanced productivity. Whether for repair or optimization, a clear grasp of these layouts is invaluable.

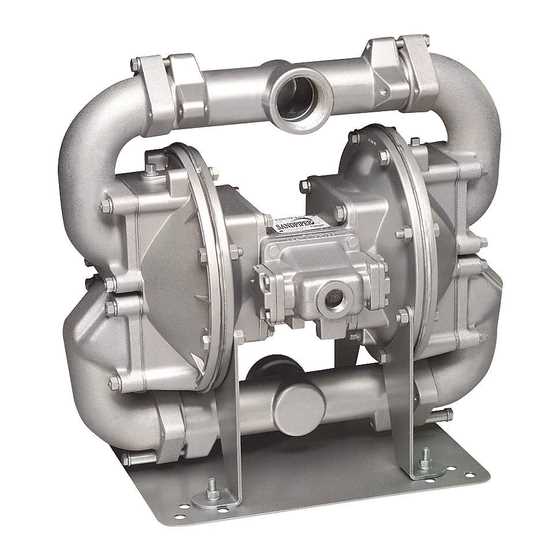

Understanding Sandpiper Pump Components

Gaining insight into the various elements that make up these mechanical devices is crucial for effective operation and maintenance. Each component plays a pivotal role in ensuring optimal performance and longevity.

- Housing: The outer shell that provides protection and structural integrity.

- Diaphragm: A flexible barrier that facilitates fluid movement.

- Valves: Essential for controlling flow direction and preventing backflow.

- Connecting Rods: Transfer motion between the driving mechanism and the diaphragm.

- Seals: Prevent leaks and maintain pressure within the system.

Each of these components contributes to the ultimate functionality of the device, making understanding their roles critical for anyone involved in maintenance or troubleshooting.

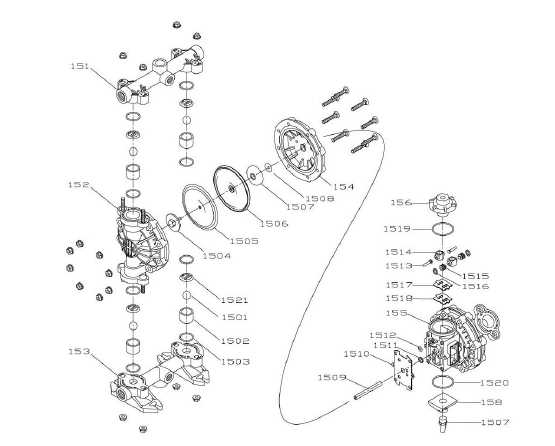

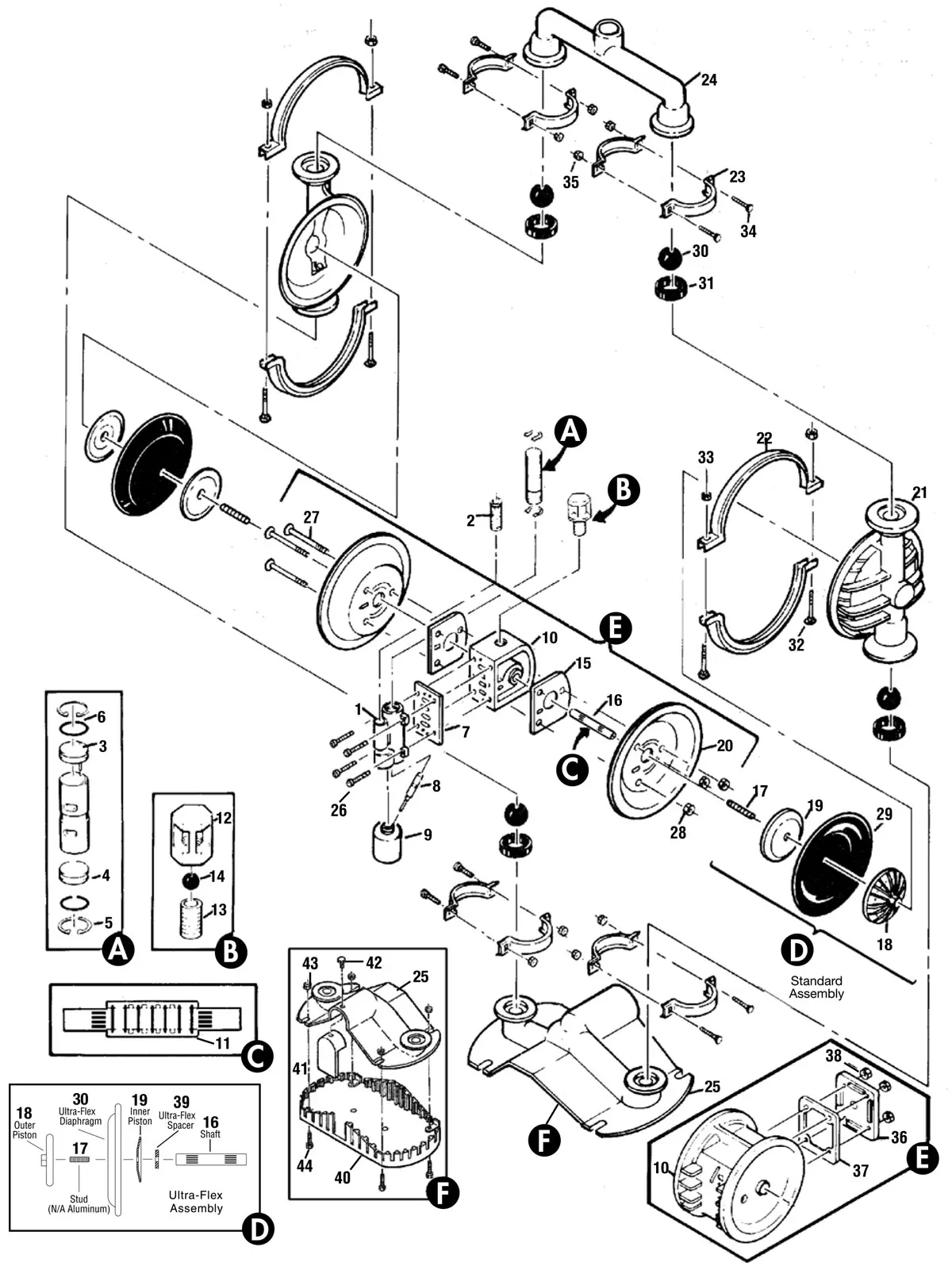

Detailed Parts Breakdown

This section provides an in-depth examination of the individual components that contribute to the overall functionality of the device. Understanding each element’s role enhances the ability to troubleshoot issues, perform maintenance, and ensure optimal performance. By familiarizing oneself with the various pieces, users can make informed decisions regarding repairs or replacements.

Key Components Overview

The assembly consists of several critical elements, including the housing, seals, and valves. Each component serves a specific purpose, from containing fluid to regulating flow. Knowing the materials used in construction can also inform users about durability and potential wear over time.

Maintenance Considerations

Functionality of Each Component

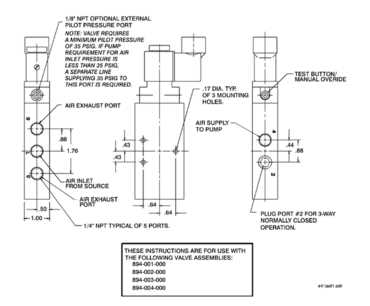

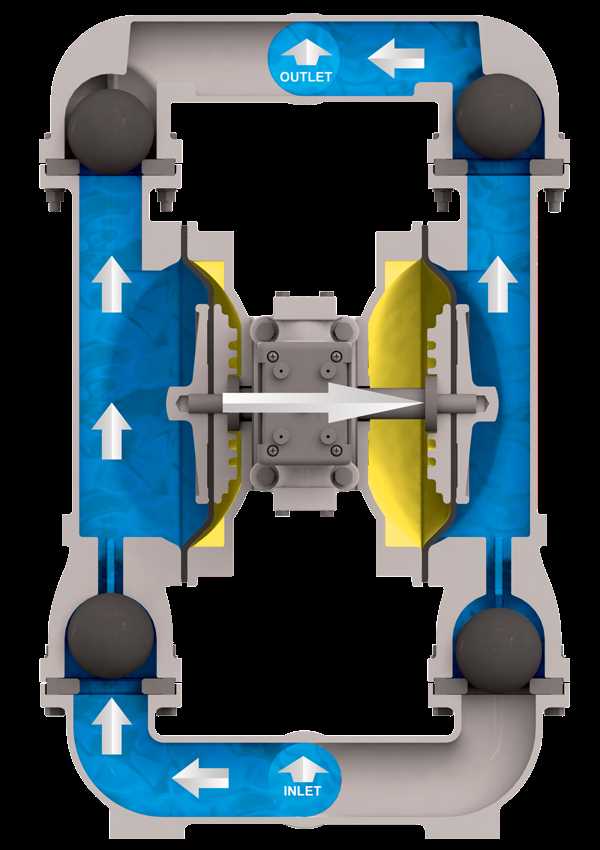

Understanding the roles of various elements within a fluid transfer mechanism is essential for optimal performance and maintenance. Each piece serves a specific purpose, contributing to the overall efficiency and reliability of the system.

The intake assembly is designed to facilitate the entry of liquid, ensuring a smooth flow into the mechanism. It works in conjunction with the body to maintain pressure and direct the fluid effectively. Seals and gaskets play a critical role in preventing leaks, ensuring that all liquids remain contained and that the system operates under the correct pressure conditions.

Within the operational core, the actuator converts energy into motion, driving the mechanism’s action. This component is crucial for initiating the flow and maintaining the desired rate. Additionally, the discharge section is responsible for releasing the fluid into the intended outlet, ensuring that the transfer is completed efficiently.

Moreover, the control elements, including valves and regulators, manage the flow rate and pressure, providing precise adjustments to meet varying operational demands. These components enhance the system’s adaptability, making it suitable for different applications.

Finally, monitoring instruments provide vital feedback, allowing operators to track performance and identify potential issues before they escalate. This proactive approach is essential for ensuring longevity and reliability in any fluid handling system.

Maintenance Tips for Longevity

Ensuring the durability of equipment requires regular upkeep and attention to detail. By following essential care practices, users can significantly enhance the lifespan and performance of their machinery.

Regular Inspection

- Conduct visual checks for wear and tear.

- Listen for unusual noises during operation.

- Monitor performance metrics to identify inconsistencies.

Proper Cleaning

- Remove debris and contaminants after each use.

- Use suitable cleaning agents to avoid damage.

- Ensure all components are thoroughly dried before reassembly.

Common Issues and Solutions

In the realm of fluid transfer systems, various challenges can arise that impact performance and efficiency. Understanding these common difficulties and their respective remedies is crucial for optimal functionality and longevity.

Leaks are a frequent issue, often caused by worn seals or improper fittings. To address this, regularly inspect components and replace any damaged seals to ensure a tight connection.

Noisy Operation can indicate air entrapment or misalignment. Checking for air pockets and realigning parts can significantly reduce unwanted sounds.

Reduced Flow Rate may stem from clogs or restrictions within the system. Clearing blockages and ensuring unobstructed pathways will help restore the desired flow.

Overheating can occur due to excessive friction or inadequate cooling. Ensuring proper lubrication and monitoring operational temperatures can mitigate this risk.

By proactively addressing these issues, users can maintain efficiency and extend the life of their equipment.

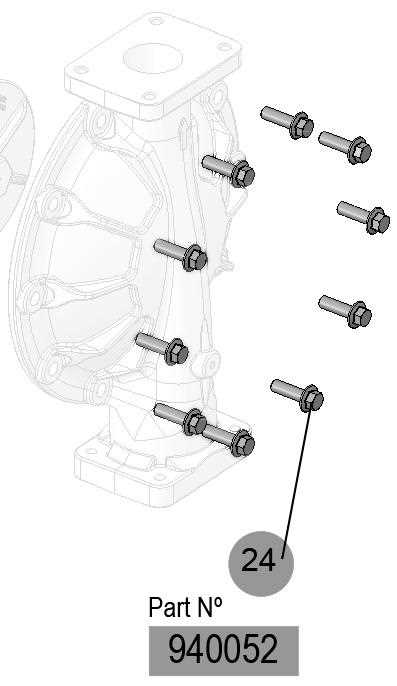

Choosing Quality Replacement Parts

When it comes to maintaining optimal performance in any equipment, selecting high-quality components is essential. The longevity and efficiency of machinery often depend on the reliability of the elements that replace the originals. Investing in superior alternatives can prevent frequent breakdowns and ensure smoother operations.

First and foremost, it’s crucial to consider the manufacturer’s recommendations. Adhering to these guidelines helps in finding compatible solutions that meet performance standards. Additionally, researching reputable suppliers can lead to discovering reliable options that guarantee durability.

Another significant aspect is to examine the materials used in the construction of the replacements. Components made from high-grade materials often withstand wear and tear better, ultimately saving costs in the long run. Furthermore, reading reviews and seeking feedback from other users can provide valuable insights into the quality of specific offerings.

Ultimately, taking the time to assess and choose well-crafted replacements can significantly enhance the overall functionality and lifespan of your equipment. Prioritize quality over cost to ensure a more effective and efficient operational experience.

Importance of Accurate Diagrams

Precision in visual representations is crucial for understanding complex mechanisms. These illustrations serve as vital tools, enabling users to grasp intricate details and relationships within systems. Without clear visuals, the risk of misunderstanding or miscommunication increases significantly.

Effective communication relies on the ability to convey information succinctly. Accurate illustrations reduce the likelihood of errors during assembly or maintenance, ultimately enhancing operational efficiency. Clarity in these visuals fosters confidence, allowing individuals to engage with technical aspects more effectively.

Furthermore, well-crafted representations can serve as educational resources. They facilitate learning by breaking down complicated processes into manageable components, making it easier for users to develop a comprehensive understanding. This, in turn, leads to informed decision-making and improved performance.

How to Read Pump Diagrams

Understanding technical illustrations is essential for effective maintenance and troubleshooting. These visual representations provide critical information about the components and their interrelations. Familiarity with these elements enhances comprehension and aids in efficient repairs.

Key Elements of Technical Illustrations

- Symbols: Recognize the various symbols that denote different elements.

- Labels: Pay attention to the labels that specify component names and functions.

- Connections: Observe lines indicating connections, flow directions, and interdependencies.

Steps to Interpret the Illustration

- Start by identifying the main components outlined in the visual.

- Follow the flow paths to understand the operational sequence.

- Cross-reference with any accompanying documentation for detailed explanations.

Resources for Further Learning

Expanding your knowledge on the intricacies of fluid transfer systems can significantly enhance your understanding and application of various components. Numerous resources are available to aid in deepening your comprehension and ensuring you stay informed about the latest technologies and methodologies.

Books and Manuals: Seek out specialized literature that covers the fundamentals and advanced concepts related to fluid handling mechanisms. Texts often provide in-depth analyses, practical examples, and detailed illustrations to facilitate learning.

Online Courses: Consider enrolling in digital learning platforms offering courses focused on mechanical systems and fluid dynamics. These courses often include interactive components, allowing for a hands-on approach to understanding complex topics.

Industry Websites: Explore reputable websites that provide insights, technical articles, and updates on new developments in the field. Subscribing to newsletters or blogs can keep you informed about trends and innovations.

Community Forums: Engage with fellow enthusiasts and professionals through online discussion boards. Sharing experiences and asking questions can lead to valuable knowledge exchange and networking opportunities.

Webinars and Workshops: Attend virtual seminars or in-person workshops conducted by experts. These events often cover practical applications and case studies, providing a rich learning environment.

By utilizing these diverse resources, you can build a robust foundation in the subject and stay current with advancements in technology.