In the realm of construction machinery, having a comprehensive grasp of the essential elements that contribute to efficient operation is crucial. This knowledge not only enhances maintenance practices but also extends the lifespan of the equipment. A detailed examination of various components ensures that operators can troubleshoot issues effectively and perform repairs with confidence.

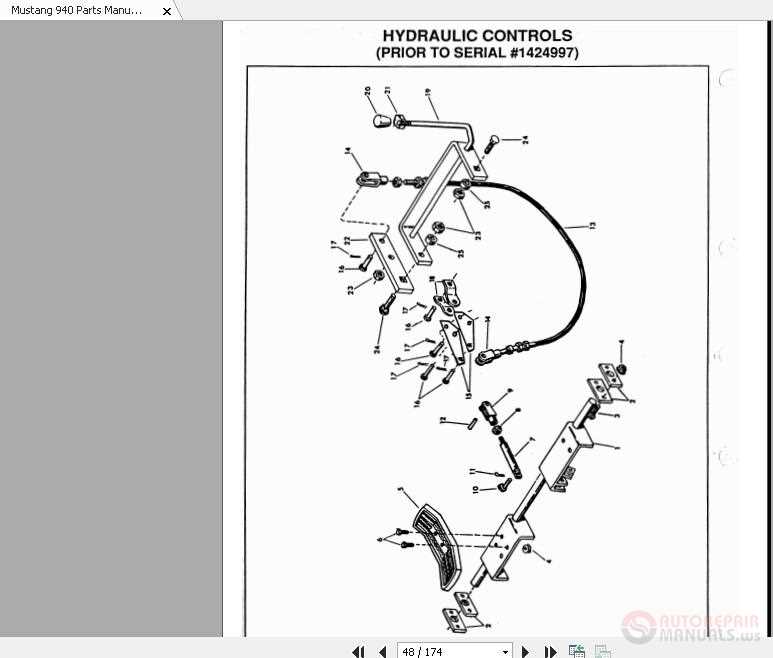

Familiarity with the intricate layout of these machines allows users to identify each component’s role within the overall system. Whether it’s for routine maintenance or unexpected repairs, recognizing how different parts interact can significantly improve workflow and productivity on job sites. A visual representation can serve as a vital reference, simplifying the process of locating and understanding each element’s function.

By delving into the specific features and configurations of these compact loaders, operators can empower themselves with the insights needed for optimal performance. This exploration not only aids in preventative maintenance but also prepares users for any challenges that may arise during operation, ensuring that they are equipped to keep their machinery running smoothly.

Understanding Mustang Skid Steer Components

Grasping the essential elements of a compact construction machine is crucial for optimal performance and maintenance. Each component plays a vital role in ensuring the functionality and efficiency of the equipment. Familiarity with these elements aids operators and technicians in troubleshooting and enhancing the machine’s capabilities.

- Frame: The structural backbone that provides support and stability.

- Engine: The powerhouse that drives all operations, generating the necessary energy.

- Hydraulic System: A crucial mechanism that facilitates movement and power transfer.

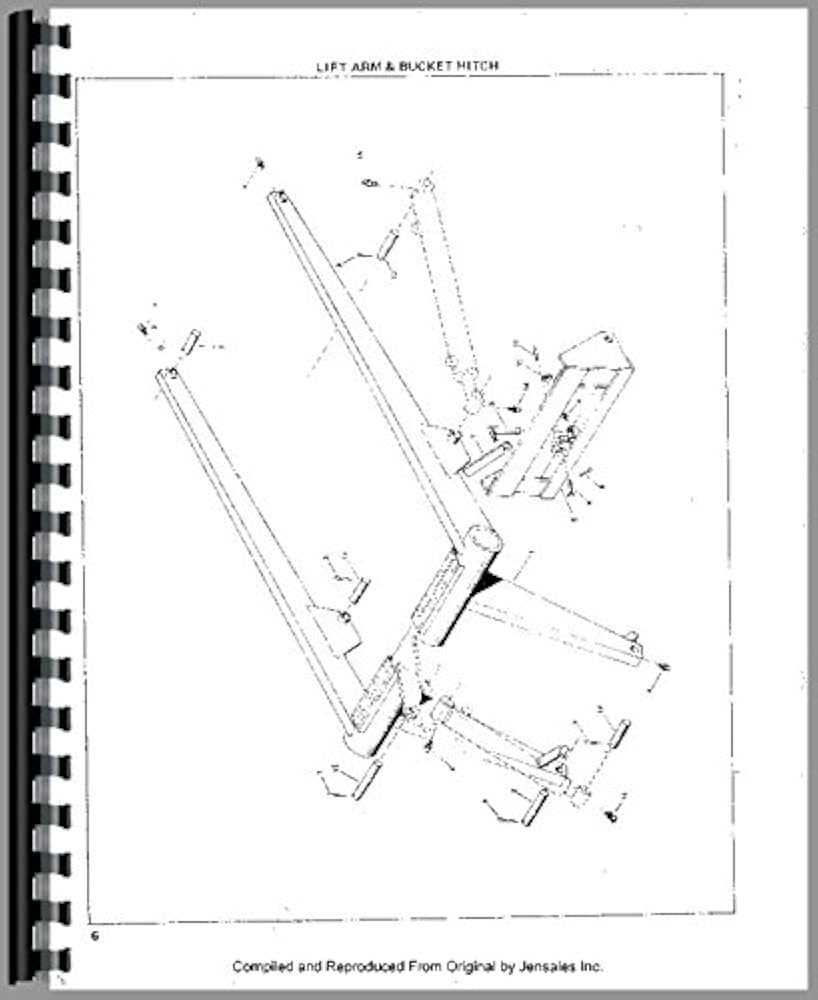

- Lift Arms: These components are responsible for raising and lowering attachments with precision.

- Attachments: Various tools that can be connected for specific tasks, enhancing versatility.

Understanding how these elements interact is fundamental for maximizing performance. Regular inspections and maintenance ensure longevity and reliability, minimizing downtime and repair costs.

- Check the engine regularly for optimal performance.

- Inspect hydraulic fluid levels and connections.

- Ensure lift arms are functioning smoothly.

- Evaluate attachment compatibility for specific jobs.

By prioritizing knowledge of these components, operators can ensure their equipment runs efficiently, meeting the demands of various projects with ease.

Importance of Accurate Parts Diagrams

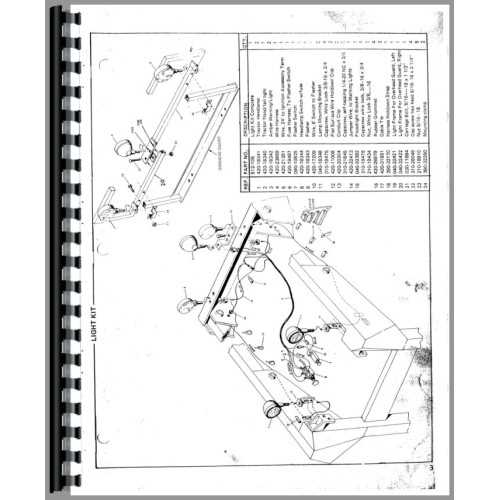

Clear and precise illustrations of components play a crucial role in maintenance and repair activities. These visual guides not only enhance understanding but also streamline the process of identifying necessary items for servicing machinery. Accurate representations significantly reduce the risk of errors and improve efficiency during repairs.

Benefits of Detailed Visuals

- Enhanced Clarity: Detailed images provide a clear overview, making it easier to recognize various elements and their functions.

- Time-Saving: Quick identification of components helps technicians work more efficiently, reducing downtime.

- Reduced Mistakes: Accurate visuals minimize the likelihood of selecting incorrect items, which can lead to costly errors.

Impact on Maintenance Practices

- Informed Decisions: With a comprehensive understanding of the machinery layout, operators can make better choices regarding repairs and replacements.

- Streamlined Processes: A well-structured visual guide enables smoother workflows during maintenance tasks.

- Training Aid: These illustrations serve as effective tools for educating new staff, ensuring they grasp essential information quickly.

In summary, well-crafted visuals are indispensable in the realm of machinery upkeep, ensuring a more efficient and error-free approach to maintenance and repair tasks.

Common Parts and Their Functions

Understanding the key components of heavy machinery is essential for optimal performance and maintenance. Each element plays a vital role in ensuring the machine operates smoothly and efficiently, contributing to its overall functionality.

Major Components

The following table outlines some of the essential elements found in this type of equipment, along with their primary functions:

| Component | Function |

|---|---|

| Engine | Powers the machine, providing the necessary energy for movement and operation. |

| Hydraulic System | Facilitates the lifting and lowering of attachments, enhancing versatility and efficiency. |

| Transmission | Transfers power from the engine to the wheels, ensuring smooth acceleration and maneuverability. |

| Frame | Provides structural integrity and support for all components, ensuring durability under heavy loads. |

Additional Elements

Other notable components also contribute to the effectiveness of the machine:

| Component | Function |

|---|---|

| Cooling System | Regulates the engine temperature, preventing overheating and ensuring efficient operation. |

| Control Panel | Allows the operator to manage and monitor machine functions easily. |

| Wheels/Tires | Provide traction and stability on various surfaces, impacting maneuverability and performance. |

| Attachments | Enhance functionality, allowing the machine to perform a variety of tasks beyond basic movement. |

Maintenance Tips for Skid Steers

Proper upkeep of compact machinery is crucial for ensuring optimal performance and longevity. Regular maintenance not only enhances functionality but also helps in avoiding costly repairs down the line. Here are some essential tips to keep your equipment in top shape.

Regular Inspections

Conducting frequent checks can prevent unexpected breakdowns. Focus on the following areas:

- Fluid levels: Check oil, hydraulic fluid, and coolant regularly.

- Filters: Inspect and replace air and fuel filters as needed.

- Tires: Examine tread wear and maintain proper inflation.

Cleaning and Lubrication

Maintaining cleanliness and proper lubrication is vital for optimal performance:

- Wash the machine to remove dirt, mud, and debris.

- Lubricate moving parts according to the manufacturer’s schedule.

- Pay attention to hinges, pivot points, and chains to prevent wear.

By following these maintenance tips, you can significantly extend the lifespan of your equipment and ensure it operates efficiently. Regular attention to these details will pay off in the long run.

Identifying Replacement Parts Easily

Finding the right components for your machinery can be a challenging task, especially when you need to ensure compatibility and quality. A clear understanding of how to navigate catalogs and technical resources will streamline the replacement process significantly.

Start by examining the equipment’s manual. Most manuals contain valuable information about the specifications and recommended components. This resource can provide crucial details, including part numbers and descriptions, helping you pinpoint what you need.

Utilizing online resources can also enhance your search. Many manufacturers and suppliers offer detailed inventories, including images and specifications, making it easier to compare options. Look for websites that specialize in heavy machinery components for accurate information.

Another effective method is to connect with experts or forums. Engaging with fellow operators and professionals can yield insights into the most reliable components and tips for sourcing them. These platforms often share experiences that can lead to better purchasing decisions.

Finally, consider using visual aids. Diagrams or exploded views available in manuals and online can help you understand how different elements fit together, ensuring you choose the correct replacements with confidence.

Tools for Skid Steer Repairs

When it comes to maintaining and fixing compact machinery, having the right equipment is essential. A well-equipped workshop can significantly reduce downtime and enhance efficiency. Various tools are specifically designed to address the unique challenges posed by these versatile machines, ensuring that repairs are carried out smoothly and effectively.

Essential Tools for Maintenance

Regular upkeep requires a selection of fundamental instruments that aid in diagnosing and resolving issues. These tools help technicians inspect components and perform necessary replacements with precision.

| Tool Type | Description |

|---|---|

| Wrenches | Used for tightening or loosening fasteners, available in various sizes and types. |

| Sockets | Essential for reaching tight spots, often paired with ratchets for added leverage. |

| Torque Wrench | Ensures fasteners are tightened to the manufacturer’s specifications, preventing damage. |

| Diagnostic Tools | Electronic devices that help identify malfunctions and performance issues quickly. |

Specialized Repair Instruments

In addition to standard tools, specialized instruments are vital for specific tasks. These tools enhance the repair process, making it more efficient and reliable.

| Tool Type | Description |

|---|---|

| Hydraulic Jacks | Used for lifting machinery safely to access undercarriage components. |

| Pry Bars | Essential for removing stuck parts or aligning components during assembly. |

| Grease Gun | Facilitates the lubrication of moving parts, essential for smooth operation. |

| Cutting Tools | Needed for modifying or replacing damaged components, including saws and shears. |

Comparing Mustang Models and Parts

This section explores various machine variants and their components, highlighting differences and similarities that can influence performance and efficiency. Understanding these distinctions aids in selecting the right model for specific tasks, ensuring optimal operation and maintenance.

| Model | Engine Power | Weight Capacity | Key Features |

|---|---|---|---|

| Model A | 50 HP | 1,500 lbs | Compact design, enhanced maneuverability |

| Model B | 60 HP | 2,000 lbs | Improved stability, versatile attachments |

| Model C | 70 HP | 2,500 lbs | High lift capacity, robust construction |

Where to Find OEM Parts

Locating original equipment manufacturer components can significantly enhance the performance and longevity of your machinery. Whether you are looking to replace a worn item or upgrade an existing one, understanding where to source these genuine items is crucial. Here, we explore various avenues to help you procure high-quality OEM replacements with ease.

Authorized Dealers

One of the most reliable options for acquiring genuine components is through authorized dealers. These distributors are officially recognized by the manufacturer and maintain a stock of authentic items. By purchasing from these dealers, you ensure that the parts meet the necessary standards for compatibility and reliability.

Online Marketplaces

The internet offers a vast array of platforms for purchasing original components. Websites specializing in industrial equipment often feature a dedicated section for genuine items. When using these resources, it’s vital to verify the seller’s credibility and check for customer reviews to ensure the quality of the products.

In conclusion, securing authentic components involves exploring various channels, with authorized dealers and reputable online platforms being among the most effective. Always prioritize quality to maintain the efficiency of your machinery.