In the realm of agricultural machinery, having a clear understanding of various components is essential for effective maintenance and repairs. This section aims to provide insights into the intricate assembly of a specific model, focusing on its essential parts and their functions. Recognizing how each element interacts within the whole system can significantly enhance operational efficiency.

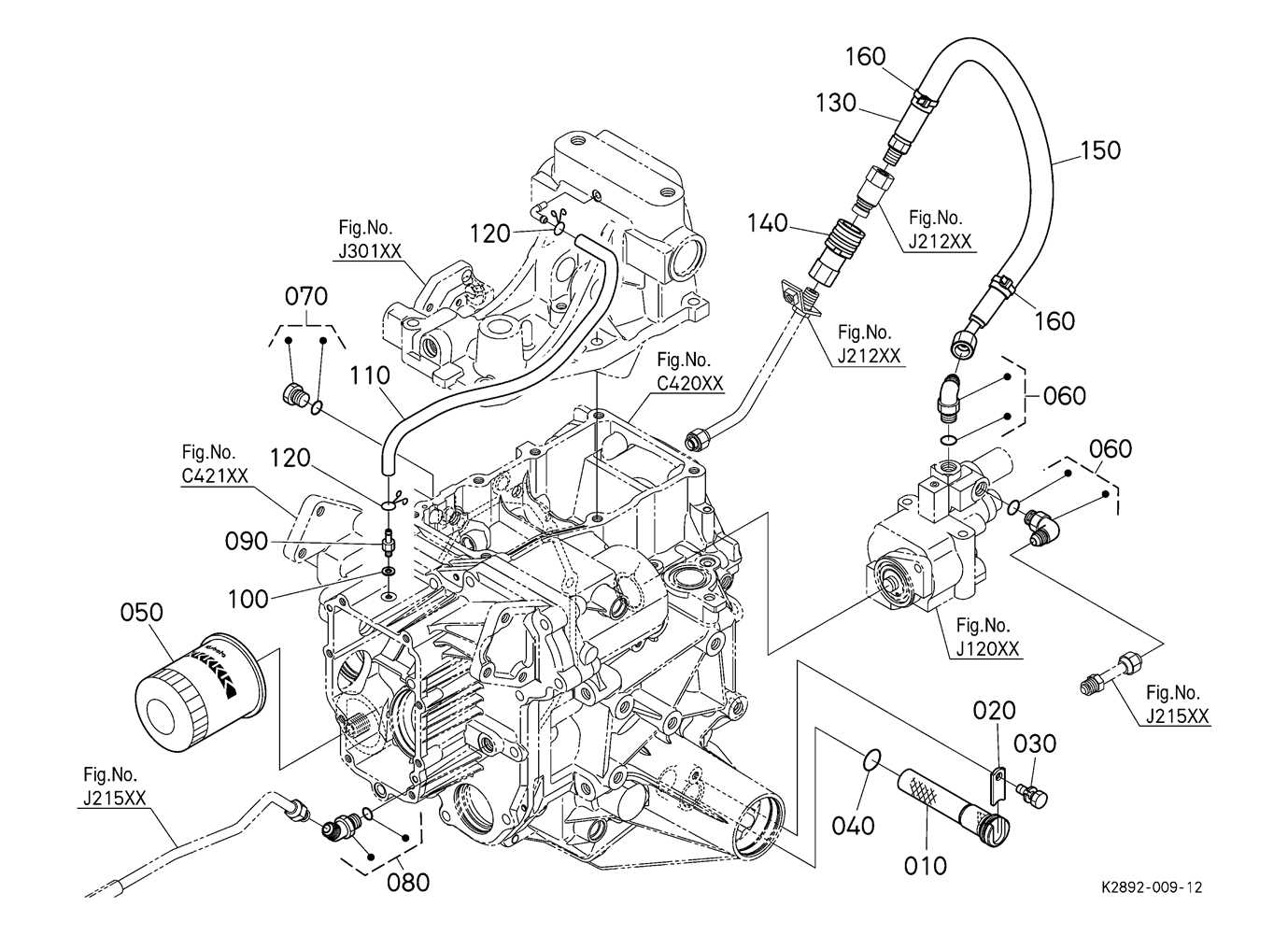

Detailed visual representations play a crucial role in comprehending the layout and arrangement of these essential elements. By examining these illustrations, users can easily identify individual components, facilitating quicker troubleshooting and informed decision-making during repairs. Such knowledge is invaluable for both novice operators and experienced professionals alike.

Moreover, familiarizing oneself with the configuration of these machines promotes better maintenance practices. Regular upkeep not only prolongs the lifespan of the equipment but also ensures optimal performance in various tasks. A thorough understanding of each part’s role empowers users to perform necessary adjustments and replacements confidently.

Understanding the various elements of a compact utility vehicle is essential for maintaining its performance and longevity. Each component plays a critical role in the overall functionality, and having a clear grasp of these parts can assist in troubleshooting and repairs.

Key Elements of the Vehicle

Familiarity with the primary sections of the machinery enhances efficiency in operations. Below are crucial components to be aware of:

- Engine assembly: The heart of the machinery, responsible for power generation.

- Transmission: A vital part that transfers power from the engine to the wheels.

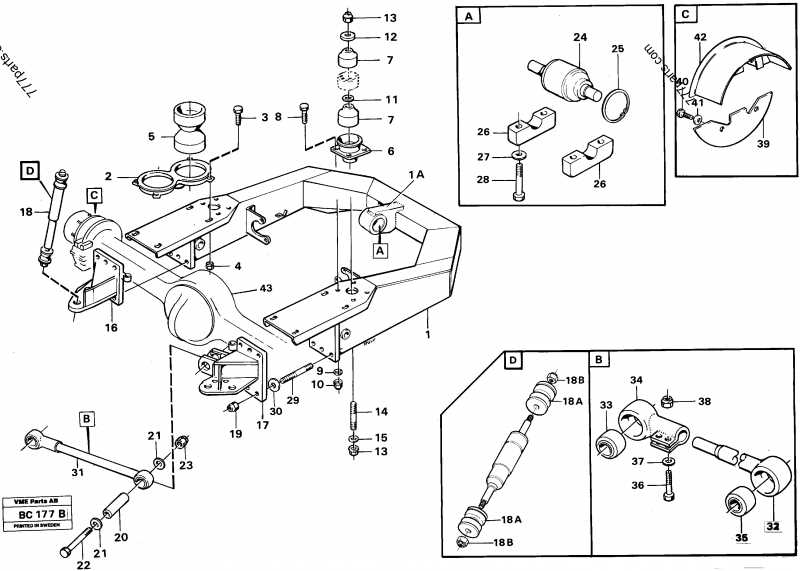

- Hydraulic system: Essential for lifting and operating attachments.

- Chassis: The framework that supports all other components.

- Electrical system: Manages power supply and control functions.

Importance of Component Identification

Recognizing each section contributes to effective maintenance strategies. Here are the benefits:

- Streamlined repairs: Knowing where each part is located can expedite troubleshooting.

- Improved safety: Understanding critical components can help prevent accidents.

- Enhanced performance: Regular checks can ensure that all parts function optimally.

Importance of Accurate Parts Identification

Proper identification of components is crucial in maintaining the functionality and longevity of machinery. Understanding the specifics of each element allows for effective repairs and replacements, minimizing downtime and enhancing performance.

When dealing with mechanical systems, precision is key. The following points highlight the significance of accurate identification:

- Enhanced Efficiency: Knowing the exact specifications of each component leads to quicker repairs, ensuring that machinery operates at optimal levels.

- Cost Savings: Accurate identification helps prevent unnecessary purchases and reduces the likelihood of errors during the repair process, ultimately saving money.

- Safety Assurance: Misidentifying components can lead to improper installations, which may pose safety risks to operators and equipment.

- Optimal Performance: Ensuring that the correct components are used guarantees that machinery functions as intended, avoiding performance issues.

In summary, meticulous identification of mechanical elements is essential for effective maintenance and operation. It not only promotes efficiency and safety but also contributes to the overall reliability of the system.

Key Features of BX23S Parts

This section highlights the essential characteristics of components designed for compact utility tractors, focusing on their functionality and advantages. Understanding these features can enhance the user’s experience and maintenance efficiency.

One notable attribute is the robust construction that ensures durability under various operating conditions. These elements are engineered to withstand significant stress, contributing to the overall longevity of the machinery.

Additionally, the design of these components emphasizes compatibility with a range of attachments and implements, allowing for versatile usage. This flexibility enables operators to customize their equipment according to specific tasks, maximizing productivity.

Furthermore, ease of installation is a critical feature, facilitating quick replacements and minimizing downtime. This user-friendly approach simplifies maintenance procedures, ensuring that the equipment remains operational with minimal disruption.

Lastly, many of these components incorporate innovative technology that enhances performance and efficiency. Advanced engineering solutions contribute to improved functionality, making tasks easier and more efficient for the user.

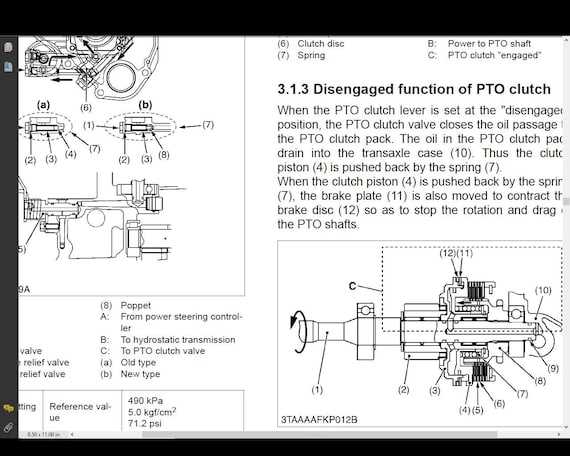

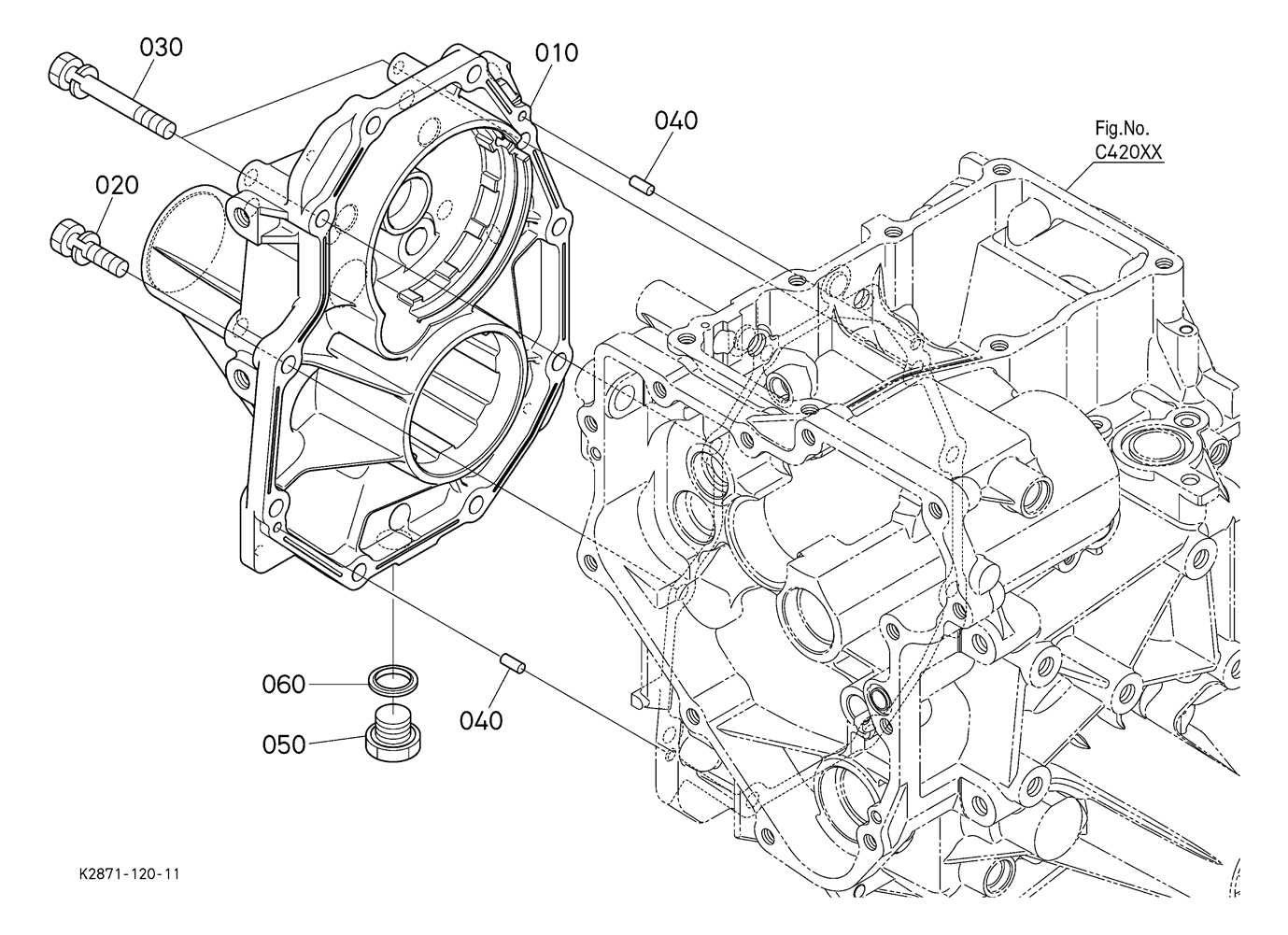

How to Read the Parts Diagram

Understanding the visual representation of components is essential for effective maintenance and repairs of machinery. These illustrations provide a detailed overview of various elements and their interconnections, allowing users to identify specific items and their functionalities.

To effectively interpret the illustrations, begin by familiarizing yourself with the overall layout. Typically, the components are organized systematically, often categorized by sections such as engine, transmission, and hydraulic systems. Pay close attention to the labeling, which often includes part numbers and descriptions that help clarify each element’s role.

| Component | Description | Part Number |

|---|---|---|

| Engine Block | Main housing for the engine components | 001A-1234 |

| Fuel Injector | Delivers fuel into the combustion chamber | 002B-5678 |

| Hydraulic Pump | Transfers fluid to power the hydraulic system | 003C-9101 |

By breaking down each section and examining the details, one can easily navigate through the intricate layout. This approach not only simplifies the process of locating specific items but also enhances the efficiency of repairs and maintenance.

Common Issues and Solutions

When operating compact machinery, users often encounter various challenges that can affect performance and efficiency. Recognizing these common issues is crucial for ensuring smooth operation and prolonging the life of the equipment. This section outlines typical problems that may arise and provides effective solutions to address them.

| Issue | Description | Solution |

|---|---|---|

| Engine Starting Problems | Difficulty in starting the engine may result from fuel supply issues or battery failure. | Check fuel levels and replace the battery if necessary. Ensure all connections are secure. |

| Overheating | Excessive heat can be caused by low coolant levels or a malfunctioning radiator. | Regularly check coolant levels and inspect the radiator for blockages. Clean or replace as needed. |

| Hydraulic Issues | Poor hydraulic performance can occur due to low fluid levels or leaks in the system. | Inspect the hydraulic fluid reservoir and replenish as necessary. Look for leaks and repair them promptly. |

| Steering Difficulties | Difficulty in steering may indicate issues with the steering linkage or low hydraulic fluid. | Check the hydraulic fluid levels and inspect the steering components for wear or damage. |

| Unusual Noises | Strange sounds during operation can signal mechanical problems or loose components. | Conduct a thorough inspection of moving parts and tighten any loose bolts. Replace worn components as necessary. |

Where to Find Replacement Parts

When it comes to maintaining machinery, locating high-quality replacement components is crucial for ensuring optimal performance and longevity. There are various avenues to explore when searching for these essential items, each offering different benefits and options for buyers.

Authorized Dealers and Retailers

One of the most reliable sources for obtaining necessary components is through authorized dealers. These establishments typically offer a comprehensive selection of items that meet the manufacturer’s standards, ensuring compatibility and quality. Furthermore, they often provide knowledgeable staff who can assist with inquiries and help identify the right components for specific needs.

Online Marketplaces and Forums

The internet has transformed the way individuals source components, providing access to numerous online marketplaces. Websites specializing in equipment and machinery often feature extensive catalogs, allowing users to compare prices and availability easily. Additionally, engaging with online forums dedicated to machinery enthusiasts can yield valuable insights and recommendations for trustworthy sellers and alternative options.

Maintaining Your Kubota BX23S

Regular upkeep is essential for the longevity and performance of your machinery. Implementing a consistent maintenance routine can prevent unexpected breakdowns and enhance efficiency. Understanding key components and their functions allows for more effective care, ensuring that the equipment operates smoothly throughout its lifespan.

Essential Maintenance Tasks

To keep your machine in optimal condition, prioritize routine tasks such as checking fluid levels, inspecting filters, and examining belts and hoses. Lubrication of moving parts is crucial; it reduces friction and minimizes wear over time. Always refer to the owner’s manual for specific maintenance intervals to adhere to the recommended schedules.

Signs of Wear and Tear

Awareness of common indicators of deterioration can prevent more severe issues. Unusual noises, decreased performance, or fluid leaks are signs that attention is needed. Regularly monitoring these symptoms can help you address minor problems before they escalate into major repairs. Taking proactive steps ensures that your equipment remains reliable and effective.

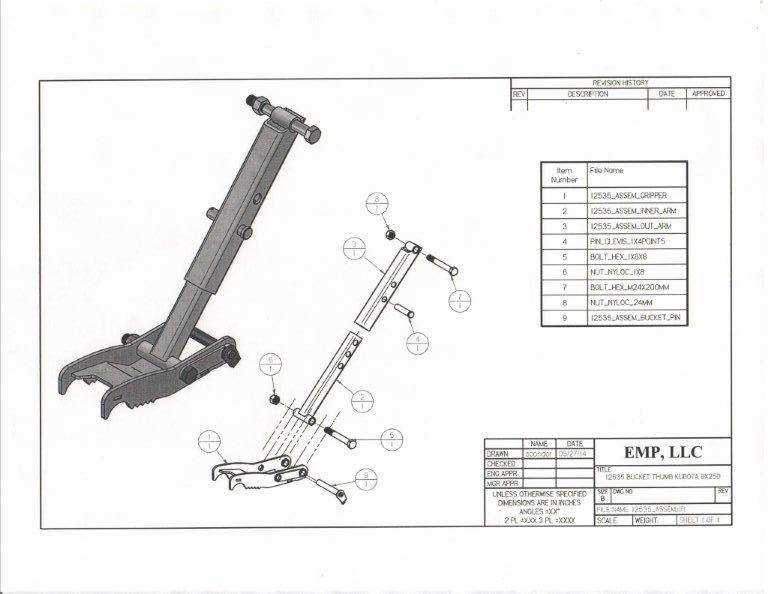

Upgrades and Accessories for Performance

Enhancing the functionality and efficiency of your machinery can significantly improve its overall performance. Investing in various upgrades and accessories not only boosts productivity but also extends the lifespan of the equipment. Below are some key modifications and add-ons that can elevate your operational capabilities.

Performance Enhancements

- Advanced Tires: Upgrading to specialized tires can provide better traction and stability, especially in challenging terrains.

- High-Performance Engine Parts: Installing components that increase horsepower and torque can enhance overall power and efficiency.

- Enhanced Hydraulics: Improved hydraulic systems can increase lifting capacity and response time, making tasks quicker and easier.

Useful Accessories

- Attachment Kits: Different attachments such as loaders, backhoes, and snowplows can make the equipment versatile for various tasks.

- Protective Gear: Accessories like guards and shields can help protect critical components from wear and tear.

- Storage Solutions: Organizing tools and parts with storage compartments can streamline workflows and improve efficiency.

By implementing these upgrades and utilizing helpful accessories, operators can achieve optimal performance and durability from their equipment, ensuring it meets the demands of any project.