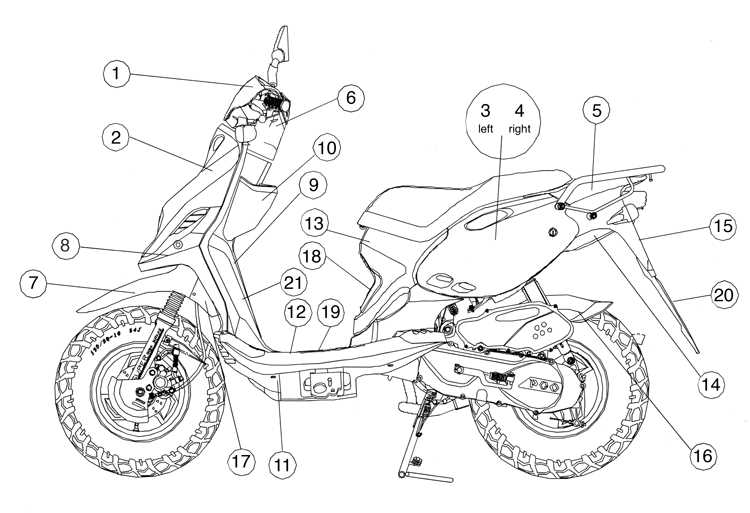

Understanding the detailed layout of various elements within your scooter is essential for both maintenance and enhancement. This breakdown will provide clarity on how each individual element connects and operates, ensuring a seamless riding experience.

For enthusiasts and mechanics alike, having a clear overview of the internal setup allows for more precise adjustments and effective troubleshooting. Delving into the structural map of these elements can help in identifying potential issues, ultimately extending the life of your vehicle.

Whether you are a beginner or a seasoned rider, knowledge of the internal mechanics of your two-wheeler is a valuable asset. This guide will walk you through the arrangement of crucial elements, making it easier to perform repairs and upgrades with confidence.

Essential Components Overview

Understanding the key elements of a two-wheeler’s system can significantly enhance maintenance and optimization. This section provides a structured look into the primary units, emphasizing their roles and interactions within the overall framework.

Primary Functional Units

- Engine Assembly: The heart of the system, responsible for converting fuel into mechanical power, driving the entire motion process.

- Transmission Mechanism: Facilitates smooth gear changes, adapting the engine’s output to various speed and torque requirements.

- Suspension Setup: Maintains ride comfort and stability by absorbing shocks from uneven surfaces and reducing vibrations.

Supportive Elements

- Brake System: Ensures controlled deceleration and stopping power, essential for safe handling.

- Electrical Components: Includes wiring, ignition modules, and other circuits that manage power distribution and signal transmission.

- Exhaust Structure: Manages the expulsion of gases, enhancing e

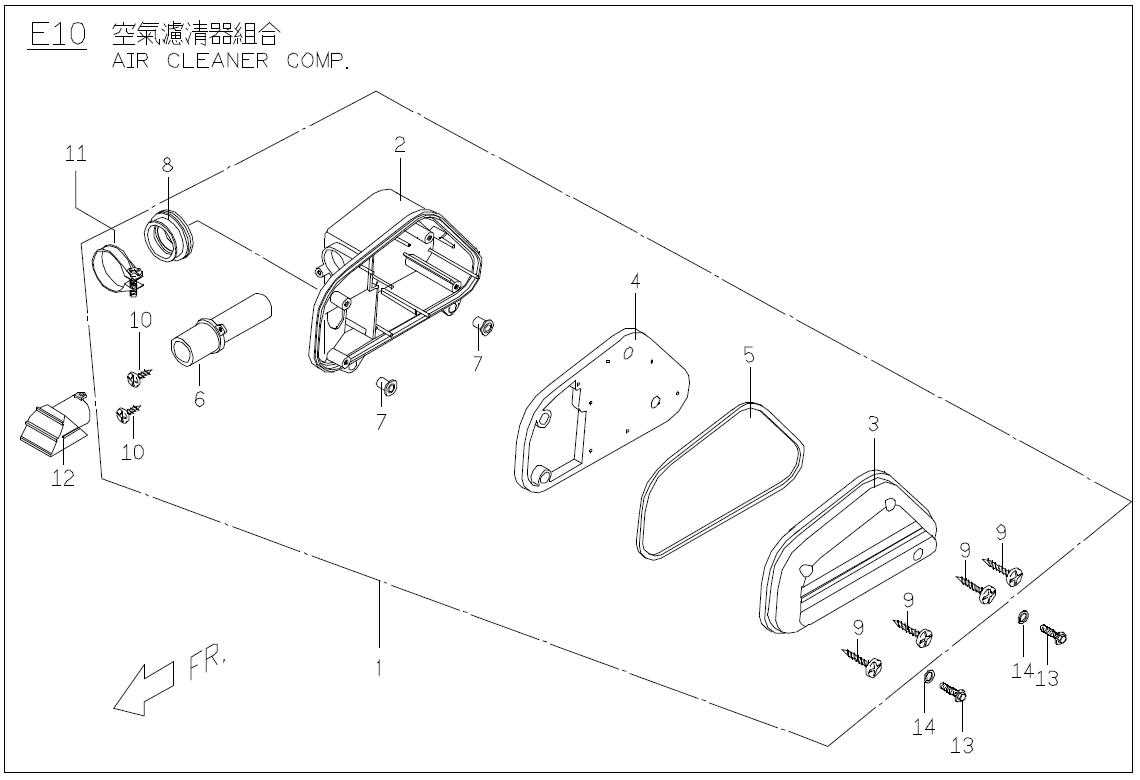

Exploring Engine Elements

The inner workings of a motor assembly consist of numerous interconnected components, each playing a crucial role in its performance. Understanding these elements can help in maintaining and enhancing overall functionality, ensuring optimal efficiency.

Piston and Cylinder: The piston moves within the cylinder, creating the necessary force for power generation. This movement is fundamental to the conversion of energy within the system.

Crankshaft and Camshaft: The crankshaft transforms linear motion into rotational force, while the camshaft synchronizes the engine’s valves, controlling the flow of air and fuel.

Carburetor or Injector System: The fuel delivery setup, whether it’s a carburetor or an injector, precisely mixes fuel and air, directly impacting the engine’s power and efficiency.

Key Engine Parts Explained

The internal components of a motorized system play a crucial role in its overall functionality and performance. Understanding these elements can help in maintaining and enhancing the efficiency of the machine. By examining each core element, we can gain insights into how they contribute to the smooth operation and power delivery of the unit.

Cylinder: Often regarded as the powerhouse, this component is where the magic of combustion occurs, converting fuel into mechanical energy. Its size and configuration directly impact the force generated by the motor.

Piston: This moving piece is essential for transmitting force created by the combustion process to the rest of the mechanism. The up-and-down motion of this part drives the crankshaft, setting the entire system in motion.

Crankshaft: Acting as the bridge between the combustion process and mechanical output, this rotating shaft converts linear energy from the piston into a rotational force. Its smooth operation is vital for the seamless power transfer throughout the system.

Spark Plug: Responsible for igniting the air-fuel mixture, this small yet critical element ensures that the energy conversion process initiat

Analyzing the Electrical System

Understanding the electrical configuration of a vehicle is crucial for both maintenance and upgrades. This section provides an overview of the system’s layout, highlighting key components and their roles in ensuring smooth operation.

Key Elements and Connections: The electrical setup relies on a network of wires and connections that distribute power to various modules. Each component, from the ignition to the lighting, plays a vital role in the overall performance. Proper knowledge of these elements is essential for diagnosing issues and performing adjustments.

Common Troubleshooting Techniques: Regular inspection of the connections and voltage levels can help identify potential issues before they lead to more significant problems. By monitoring these aspects, users can maintain optimal functionality and address any irregularities promptly.

Main Wiring Components Breakdown

The core elements of the electrical system play a crucial role in ensuring reliable connections and power distribution throughout the setup. Each component has its unique function, contributing to the overall efficiency of the network.

- Connectors: These essential links are responsible for joining wires and cables, enabling the smooth flow of electrical signals across different parts of the system.

- Fuses: Acting as safety devices, fuses protect the circuitry from overloads by breaking the connection when excessive current is detected.

- Relays: Relays are control units that operate by opening or closing circuits in response to an electrical signal, allowing for precise management of power flow.

- Wiring Harness: The harness organizes and secures multiple wires, guiding them through the structure while minimizing interference and wear.

- Grounding Points: These critical spots ensure that excess electrical charge safely dissipates, reducing the risk of electrical faults.

Understanding these components is key to maintaining a

Inspecting the Suspension Layout

Understanding the configuration of a vehicle’s suspension is crucial for maintaining its performance and stability. By carefully analyzing the arrangement of the components, one can ensure that each element works harmoniously to provide a smooth ride. A systematic approach to examining these elements can reveal signs of wear or misalignment, helping to address issues before they escalate.

Begin by visually checking the primary components for any visible damage or irregularities. Look for signs of corrosion, cracks, or bent parts, which might indicate the need for immediate attention. Pay close attention to the connecting joints and pivot points, as these areas often experience the most stress during use.

It’s essential to assess the integrity of the shock absorbers and springs, ensuring they compress and rebound as expected. Any inconsistencies in their movement could point to potential problems with damping or load distribution. Regularly inspecting these elements helps maintain the vehicle’s balance and handling, providing a safer driving experience.

Critical Suspension Parts Details

The stability and performance of any two-wheeled vehicle largely depend on specific components designed to manage movement and absorb shocks. Understanding the essential elements that contribute to a smooth ride is crucial for maintaining both control and safety on the road.

Shock Absorbers: These devices play a vital role in minimizing the impact from uneven terrain, enhancing the rider’s comfort and ensuring precise handling. Effective dampening reduces the strain on other components, extending their lifespan.

Spring Mechanism: This crucial element works in tandem with the shock absorbers to control the rebound and compression during movement. It aids in maintaining the proper alignment of the wheels, providing consistent traction and stability.

Linkage System: This interconnected framework supports the entire suspension setup by transferring forces evenly across the structure. It plays a significant part in reducing vibrations and distributing load efficiently, enhancing the overall durability of the system.

Evaluating the Exhaust Setup

Understanding the configuration of the exhaust system is crucial for enhancing performance and longevity. Analyzing its layout and how the individual components interact can lead to improved efficiency and smoother operation.

Components and Their Roles

The exhaust system comprises several elements that work together to manage emissions and optimize engine output. It’s essential to recognize each part’s function to ensure they contribute to overall efficiency.

Component Function Exhaust Pipe Channels the gases away from the engine to reduce backpressure. Muffler Dampens the noise produced by the escaping gases, creating a quieter ride. Catalytic Converter Converts harmful pollutants into less toxic emissions before release into the atmosphere. Inspection and Maintenance Tips

Regular inspe

Understanding Exhaust Components

The exhaust system plays a crucial role in the overall performance and efficiency of a motorized vehicle. It is responsible for directing harmful gases away from the engine and reducing noise produced during operation. A well-designed assembly not only enhances engine performance but also contributes to a cleaner environment by minimizing emissions.

Key Elements of the Exhaust Assembly

Several essential elements make up the exhaust assembly. These components work together to ensure effective gas expulsion while maintaining optimal engine function. The primary parts include the manifold, which collects exhaust gases from the engine; the catalytic converter, which reduces harmful emissions; and the muffler, which dampens sound. Each part serves a distinct purpose, and their arrangement is vital for efficiency.

Importance of Maintenance

Regular maintenance of the exhaust assembly is crucial for maintaining performance and longevity. Inspecting for leaks and corrosion can prevent more significant issues down the line. Keeping the system in good condition not only enhances the vehicle’s efficiency but also promotes environmental responsibility by ensuring that emissions are adequately managed.

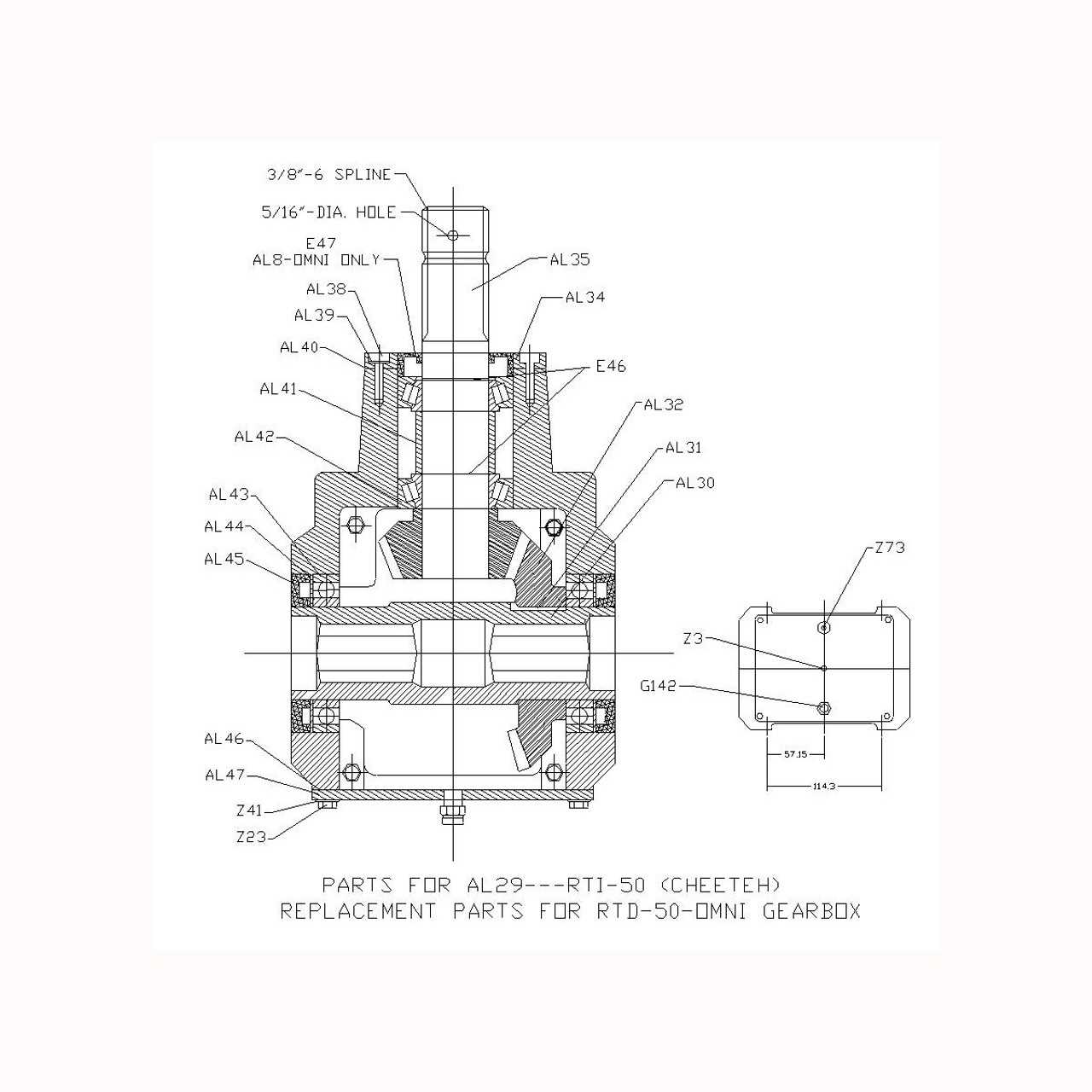

Reviewing the Transmission System

The transmission mechanism plays a vital role in ensuring efficient power transfer and overall performance in scooters. Understanding its components and functionality is essential for optimal operation and maintenance.

This section focuses on the key elements of the transmission system, highlighting their significance and interconnections. The primary components include:

- Variator: This adjusts the gear ratio based on speed and throttle input.

- Belt: Serves as the link between the engine and variator, transmitting power effectively.

- Clutch: Engages and disengages the engine from the transmission system, allowing for smooth acceleration.

- Gear Set: Defines the overall ratio and impact on performance and efficiency.

Each component contributes to the smooth operation of the vehicle, influencing acceleration, top speed, and responsiveness. Regular inspections and maintenance of these parts can significantly enhance the longevity and reliability of the entire transmission system.

In summary, a well-functioning transmission mechanism is crucial for achieving optimal performance. Familiarity with its components and their roles can empower users to make informed decisions regarding maintenance and repairs.