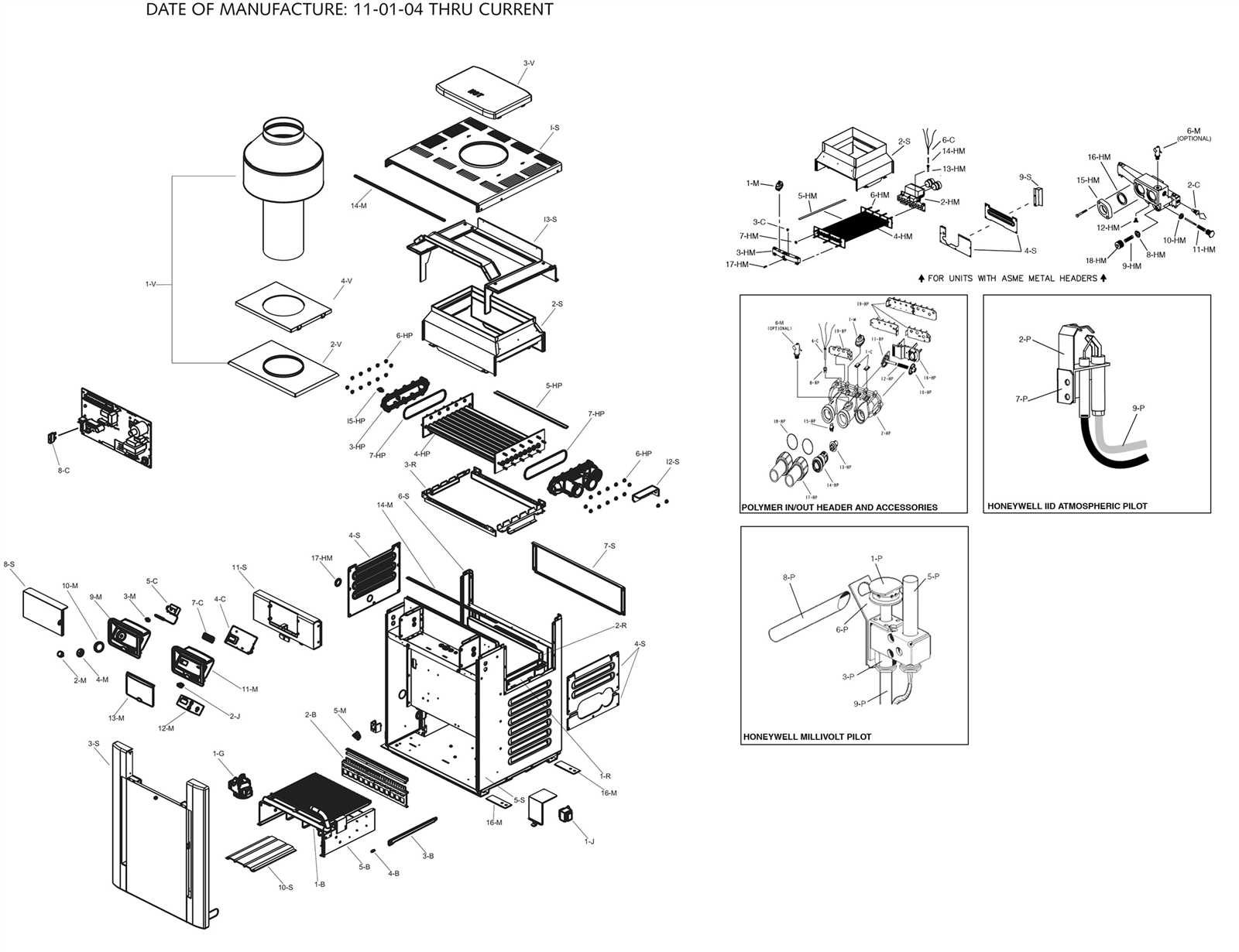

Understanding how different elements within a heating system work together is essential for maintaining its efficiency and reliability. A clear view of the various interconnected components helps in identifying potential issues and ensuring the proper functioning of the unit.

Each section of the system is meticulously designed to perform specific tasks. Whether it’s the control mechanisms or the piping network, knowing the arrangement of these sections aids in troubleshooting and ensures the smooth operation of the entire setup.

In addition, the ability to locate key elements quickly can save time during maintenance, reducing downtime and preventing more serious problems from occurring. Proper knowledge of the internal structure can significantly improve the longevity of the system.

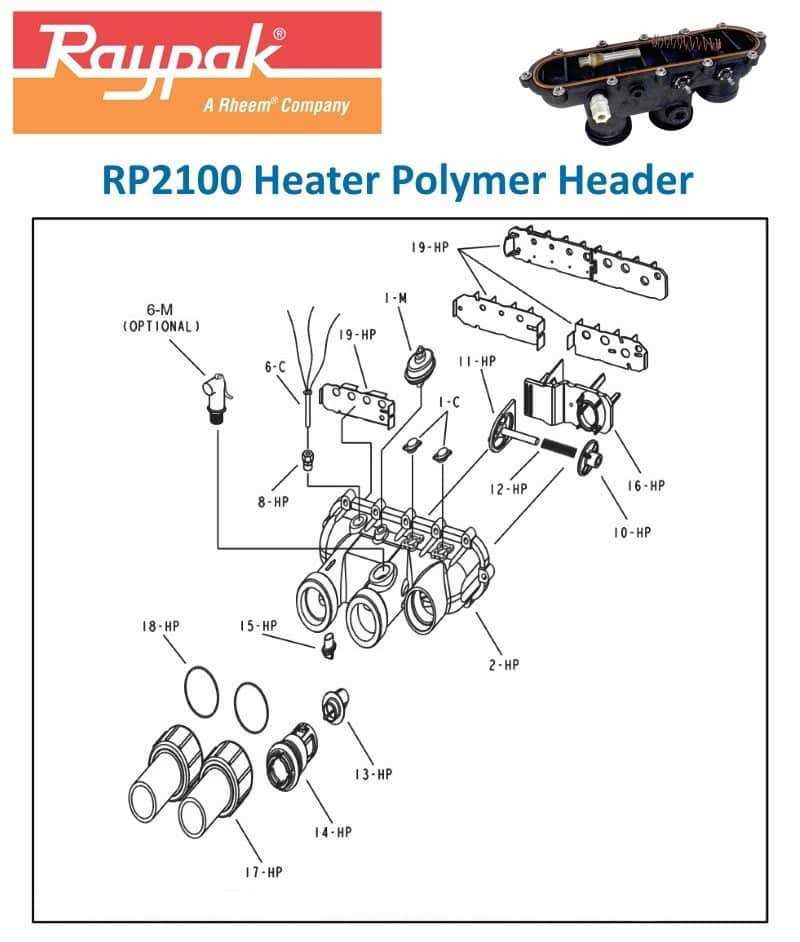

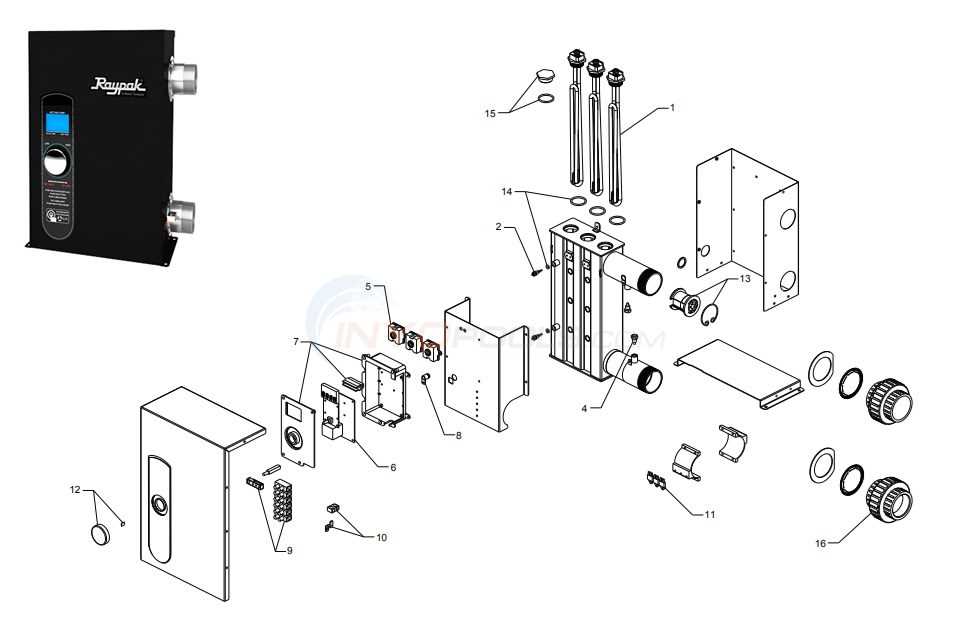

Overview of Raypak Components

This section provides a detailed exploration of the essential elements that make up the heating and water systems, ensuring efficient operation and performance. Each piece plays a crucial role in maintaining functionality and delivering the expected outcomes, whether in residential or commercial setups.

Key Elements

The following are the primary elements found in these systems:

| Component | Description |

|---|---|

| Heat Exchanger | Transfers heat between the fuel source and the water, enabling consistent temperature regulation. |

| Control Module | Ensures proper monitoring and adjustment of settings to maintain operational efficiency. |

| Burner Assembly | Responsible for igniting the fuel and generating heat, crucial for the overall system’s functionality. |

Maintenance Considerations

Regular inspection and servicing of these components

Key Features of Raypak Heaters

These heating systems are known for their reliability and efficiency, making them a popular choice in various settings. They are designed to meet high standards of performance, ensuring consistent and powerful heating for pools and spas.

- Energy Efficiency: The advanced technology used in these heaters allows for optimal fuel consumption, helping to reduce energy costs while maintaining effective heat output.

- Durable Construction: Built with high-quality materials, these systems are designed to withstand harsh weather conditions and extended use without losing efficiency.

- Simple Maintenance: Easy-to-access components and user-friendly designs ensure that upkeep and servicing can be done quickly, reducing downtime.

- Advanced Controls: Modern interfaces allow precise temperature management, ensuring comfort and flexibility for the user

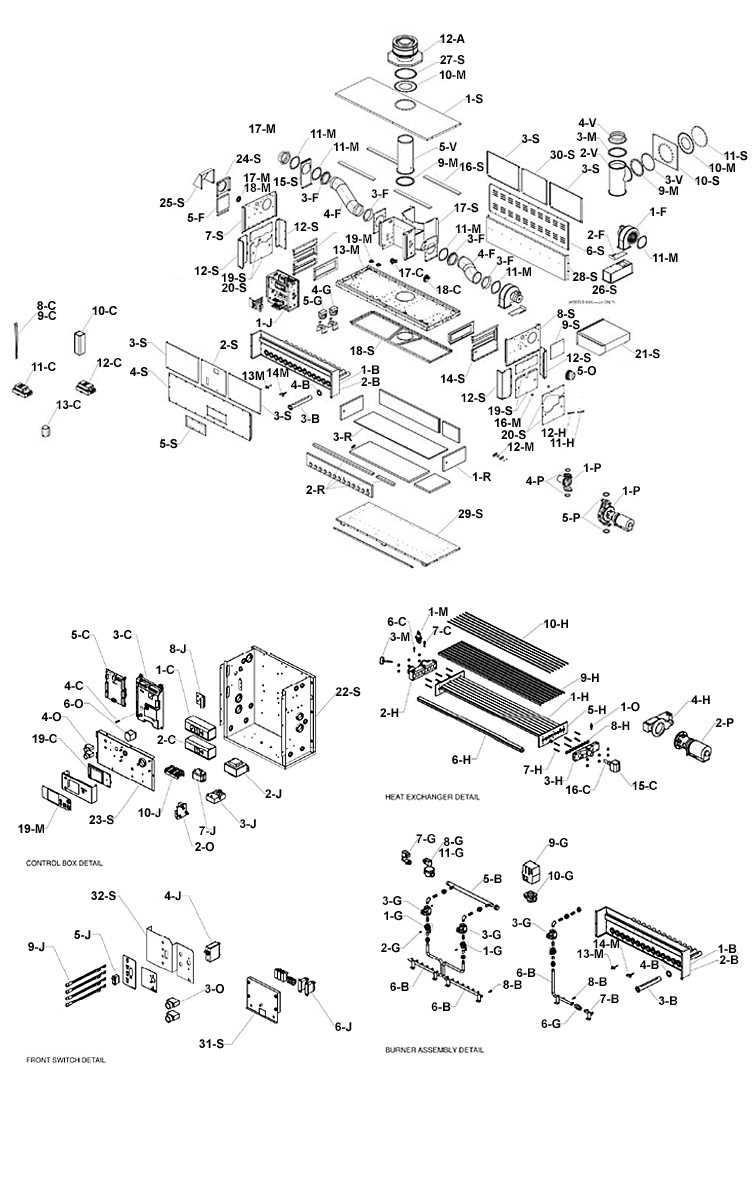

Understanding the Function of Heat Exchangers

Heat exchangers play a crucial role in many systems by transferring thermal energy between fluids, ensuring efficient temperature regulation. These components are designed to maintain a balance between two mediums, allowing energy to flow from one to another without direct contact. This process is fundamental to the performance of heating and cooling systems, as it helps optimize energy usage.

Basic Operation of Heat Exchangers

The operation of a heat exchanger relies on the movement of fluid through separate channels. As one fluid heats up or cools down, it passes that energy to the other medium, which moves in the opposite direction. Efficiency is achieved when there is a significant temperature difference between the fluids, allowing for maximum energy transfer. Different designs, such as plate or tube configurations, help accommodate various system requirements.

Types and Applications

There are

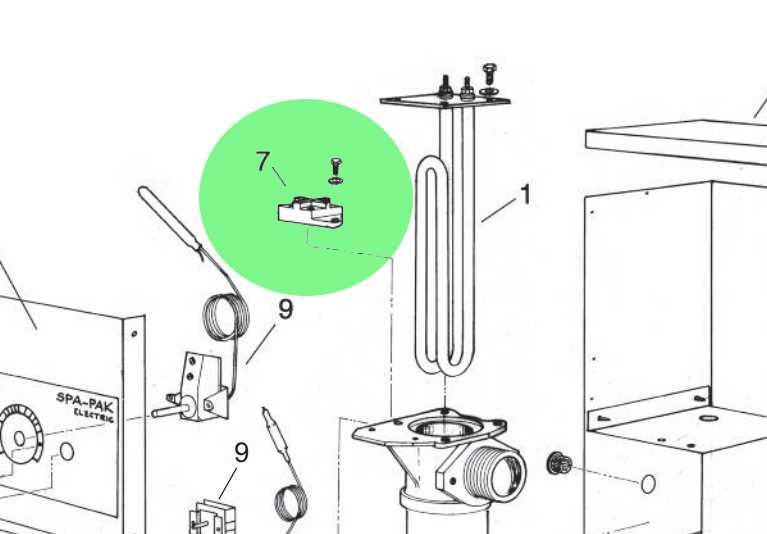

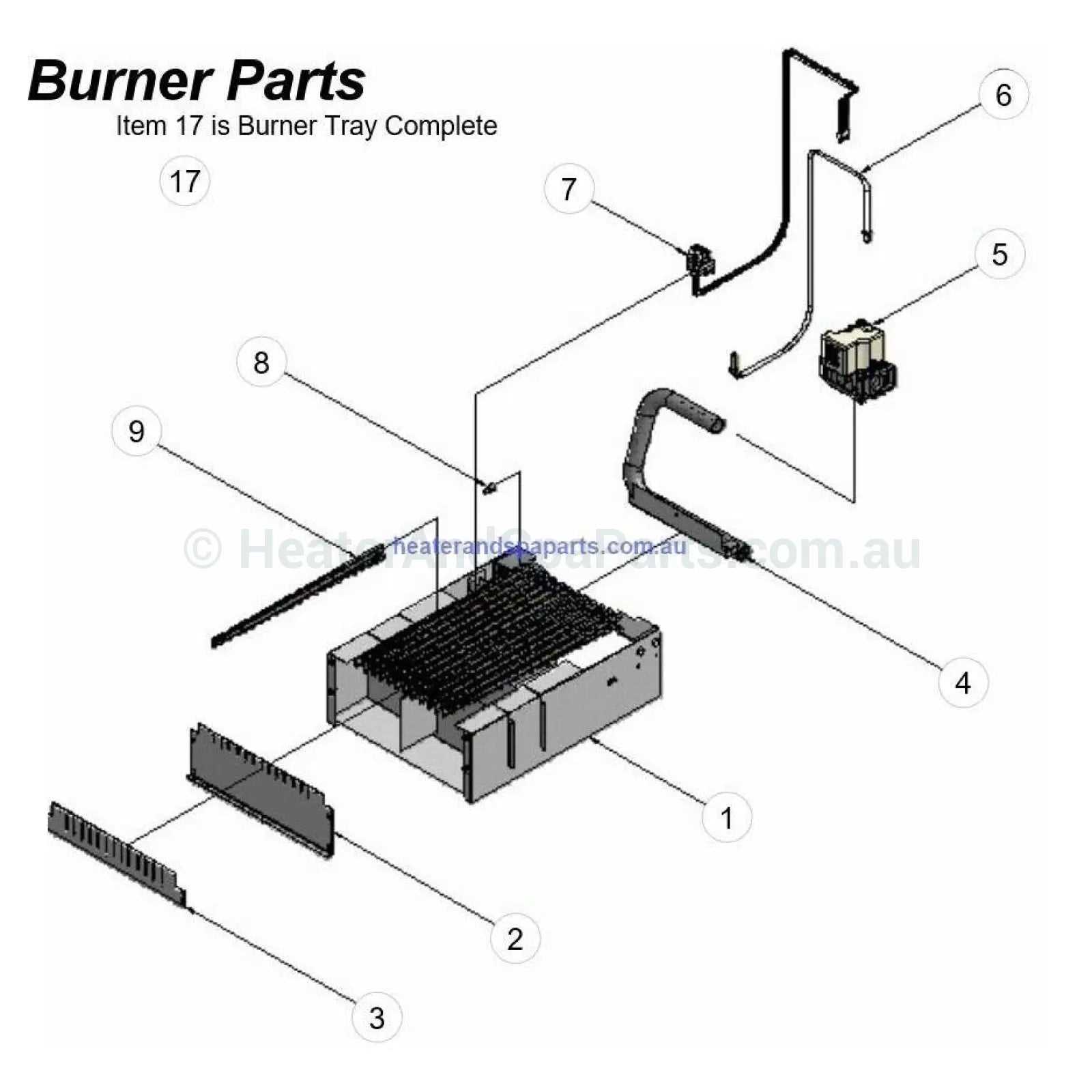

Burner System and Its Maintenance

The burner system plays a crucial role in ensuring efficient operation. Regular maintenance is essential to guarantee that the system functions properly, avoiding common issues such as blockages, improper combustion, or wear of key components. Keeping the burner clean and functional helps in maintaining optimal performance and extends the lifespan of the entire system.

Key Components of the Burner System

The burner assembly is made up of several critical parts, including the igniter, burner tubes, and flame sensor. Each of these elements works together to produce consistent heat output. Regular checks on these parts help in identifying potential problems before they escalate.

Component Maintenance Action Frequency Igniter Identifying Control Panel Elements

Understanding the various components of the control interface is essential for efficient operation and maintenance. Each element plays a vital role in ensuring optimal performance and user experience.

- Display Screen: This area presents vital information regarding system status and settings.

- Buttons: These controls allow users to navigate through options and modify settings.

- Indicators: Light signals provide immediate feedback about the system’s operational state.

- Temperature Controls: Adjustments can be made here to manage the desired output temperature.

- Safety Features: Elements designed to prevent malfunctions or hazardous situations are crucial for safe usage.

Familiarizing oneself with these components enhances the ability to troubleshoot and operate the system effectively.

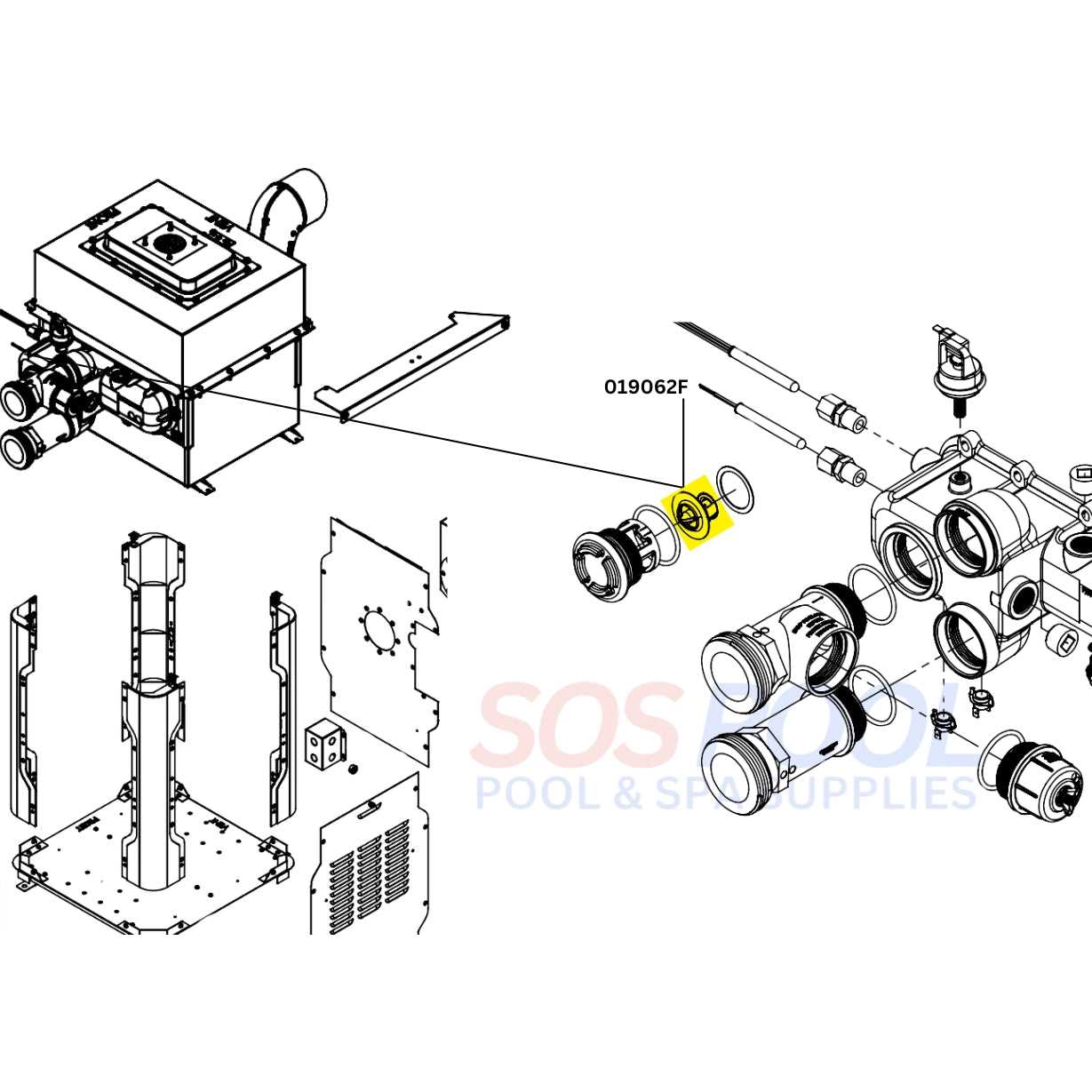

Pumps and Circulation Systems Explained

Efficient movement of fluids is essential in various applications, especially in heating and cooling setups. Understanding the mechanisms behind these systems is crucial for maintaining optimal performance and longevity. This section will delve into the fundamental components involved in the circulation of liquids, highlighting their roles and importance in overall functionality.

Pumps serve as the heart of circulation systems, responsible for moving fluids through pipes and equipment. They come in various types, each designed for specific tasks, ensuring the effective transfer of liquids from one point to another. By converting mechanical energy into hydraulic energy, pumps facilitate the necessary flow rates to meet system demands.

Additionally, circulation systems encompass a network of pipes, valves, and fittings that work together to distribute fluids efficiently. These systems are designed to maintain a consistent flow, prevent stagnation, and ensure even temperature distribution. Understanding the design and operation of these systems allows for better troubleshooting and optimization, enhancing performance and energy efficiency.

Replacing Valves and Connectors

Maintaining proper functionality in your system often requires the timely replacement of certain components. Valves and connectors play a crucial role in ensuring seamless operation and efficiency. Understanding the process involved in replacing these parts can prevent potential issues and enhance the overall performance of your equipment.

Identifying the Components

Before beginning the replacement process, it’s essential to identify the specific valves and connectors that need attention. This involves checking for signs of wear, leaks, or damage. Regular inspections can help determine when a replacement is necessary, ensuring that your system continues to operate optimally.

Replacement Procedure

Follow these steps for an effective replacement of valves and connectors:

Step Description 1 Turn off the system and ensure that all pressure is released. 2 Disconnect the affected valves and connectors carefully. 3 Install the new components, ensuring proper alignment and secure fittings. 4 Check for leaks by testing the system at low pressure before full operation. Troubleshooting Common Raypak Parts Issues

Identifying and resolving typical issues with heating equipment components is crucial for maintaining optimal performance and longevity. By understanding common malfunctions and their symptoms, users can take appropriate actions to mitigate problems effectively.

1. Overheating Issues: If the system experiences excessive heat, it may be due to a malfunctioning thermostat or a blocked filter. Ensure that the temperature settings are appropriate and that all vents are clear. Regular maintenance can prevent overheating by promoting proper airflow.

2. Inconsistent Heating: Fluctuating temperatures can indicate a faulty ignition system or issues with the heating element. Check for any loose connections or damaged wiring. It is advisable to inspect the ignition components regularly to ensure reliability.

3. No Heat Production: A complete lack of heating may stem from a broken switch or power supply problems. Confirm that the unit is receiving adequate power and that all switches are functioning correctly. If power issues persist, consult a professional for assistance.

4. Unusual Noises: Odd sounds from the unit can suggest air trapped within the system or debris in the fan. Bleeding the system to remove air and inspecting the fan for obstructions can resolve this issue. Routine checks can help catch these problems early.

5. Water Leaks: Any signs of water leakage may indicate a failing seal or connection. Inspect hoses and fittings for wear or damage. Regularly replacing worn parts can prevent leaks from occurring and protect the surrounding area from water damage.

How to Source Genuine Raypak Parts

Finding authentic components for your heating equipment is crucial for optimal performance and longevity. Here are some strategies to ensure you acquire high-quality replacements.

Research Authorized Dealers

- Visit the manufacturer’s official website for a list of certified suppliers.

- Contact customer service for recommendations on reliable retailers.

Utilize Online Marketplaces

- Look for listings that specifically mention authenticity guarantees.

- Read customer reviews to assess seller reliability.

- Compare prices across various platforms for the best deals.