When it comes to maintaining outdoor spaces, having a comprehensive grasp of the various elements that make up a lawn machine is essential. Each component plays a crucial role in ensuring optimal performance and longevity, contributing to a well-manicured garden or yard. Knowledge of these features can empower users to make informed decisions during maintenance and repairs.

Exploring the intricacies of these mechanical parts can unveil insights that enhance the functionality of your equipment. By delving into the relationships between different elements, one can appreciate how they work together harmoniously to deliver superior results. Whether it’s understanding the engine’s role or the significance of the cutting mechanism, each aspect contributes to the ultimate efficiency of the machine.

For anyone looking to enhance their gardening experience, familiarizing oneself with these essential pieces is invaluable. This knowledge not only aids in troubleshooting issues but also fosters a deeper connection with the tools that facilitate outdoor beauty and upkeep.

Understanding the Yth18542 Model

This section delves into the intricacies of a specific machinery model that plays a vital role in various applications. By examining its components and functionalities, we can appreciate the engineering and design that contribute to its efficiency and reliability. Understanding these elements is crucial for effective maintenance and optimal performance.

Key Features and Benefits

The model is characterized by its robust construction and user-friendly interface. Each element is meticulously designed to enhance overall functionality, ensuring seamless operation. The advantages of this design extend to improved productivity and reduced downtime, making it a valuable asset in its field.

Maintenance and Troubleshooting

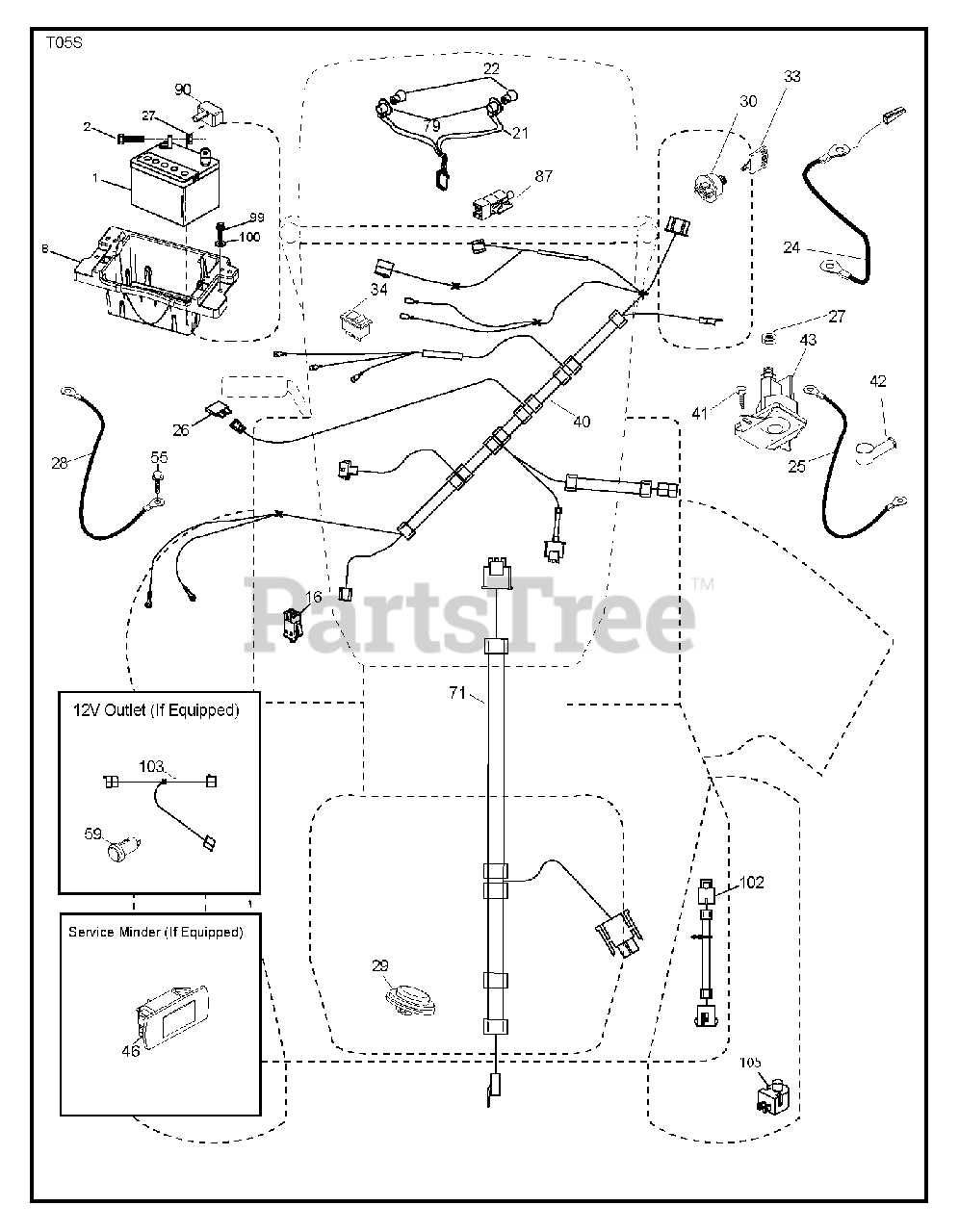

Key Components of the Yth18542

The intricate design of this machinery consists of various essential elements that work in harmony to ensure optimal performance. Each component plays a pivotal role in enhancing functionality and reliability, contributing to the overall efficiency of the system.

Engine: The heart of the machine, the engine delivers power and drives the entire operation. Its robust construction ensures longevity and high performance under various conditions.

Transmission: This vital element transfers power from the engine to the wheels, allowing for smooth acceleration and deceleration. An effective transmission system optimizes fuel efficiency and enhances maneuverability.

Chassis: The chassis provides structural integrity and supports all other components. Its design is crucial for stability, safety, and ease of handling.

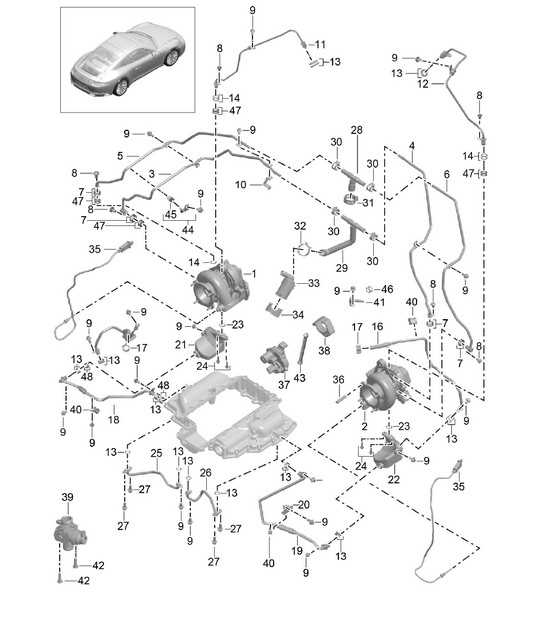

Hydraulic System: This system enables precise control of various functions, such as lifting and lowering attachments. It enhances the machine’s versatility and efficiency in various applications.

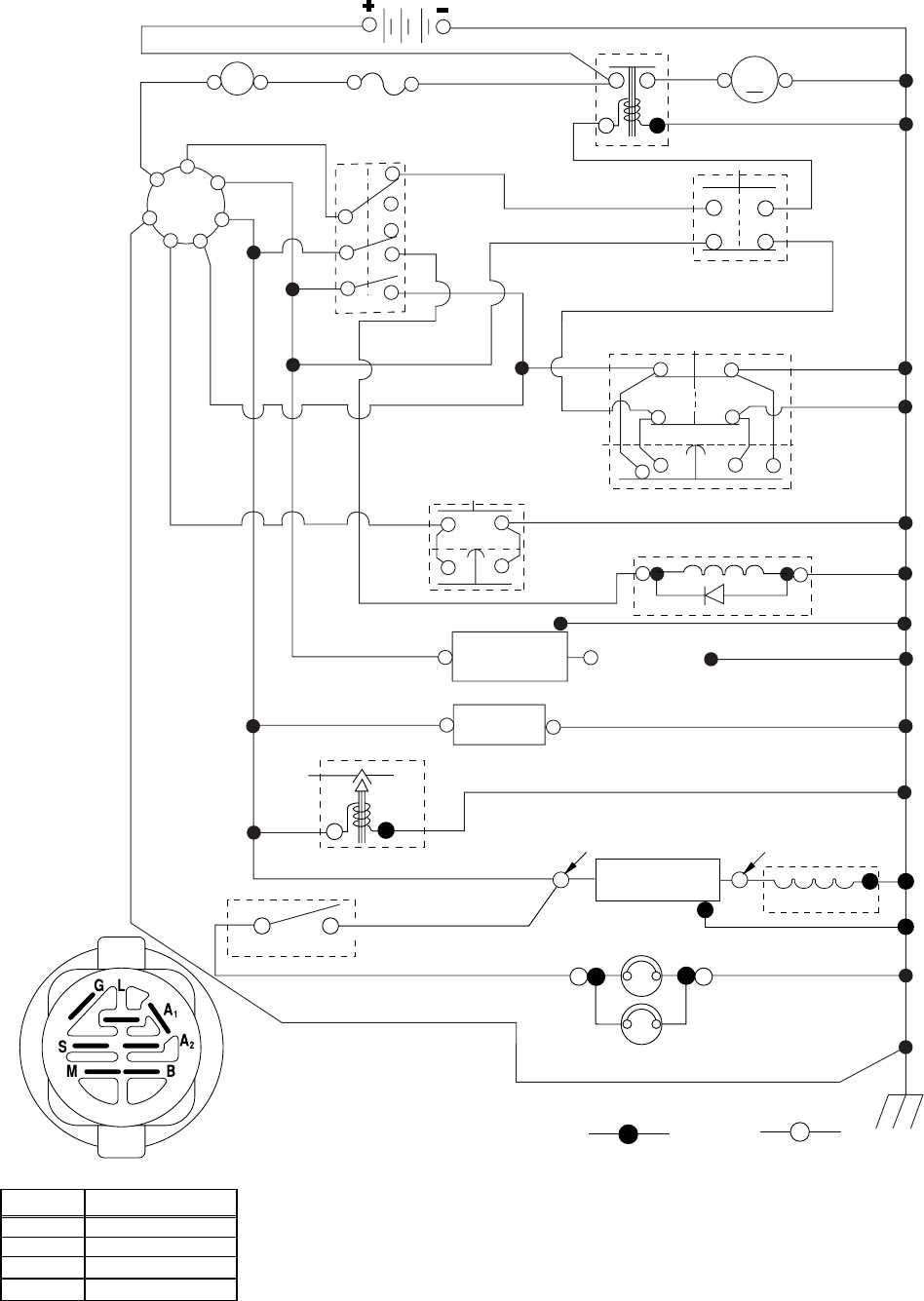

Electrical System: The electrical components manage everything from ignition to lighting, ensuring the machine operates seamlessly and safely.

Understanding these key elements allows users to appreciate the complexity and efficiency of the equipment, enabling informed maintenance and operation decisions.

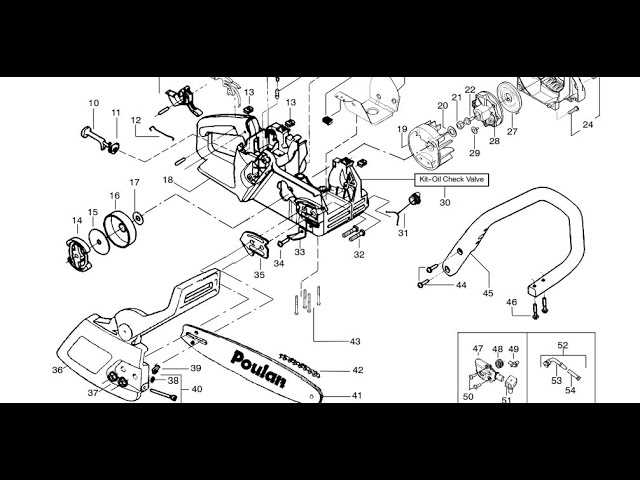

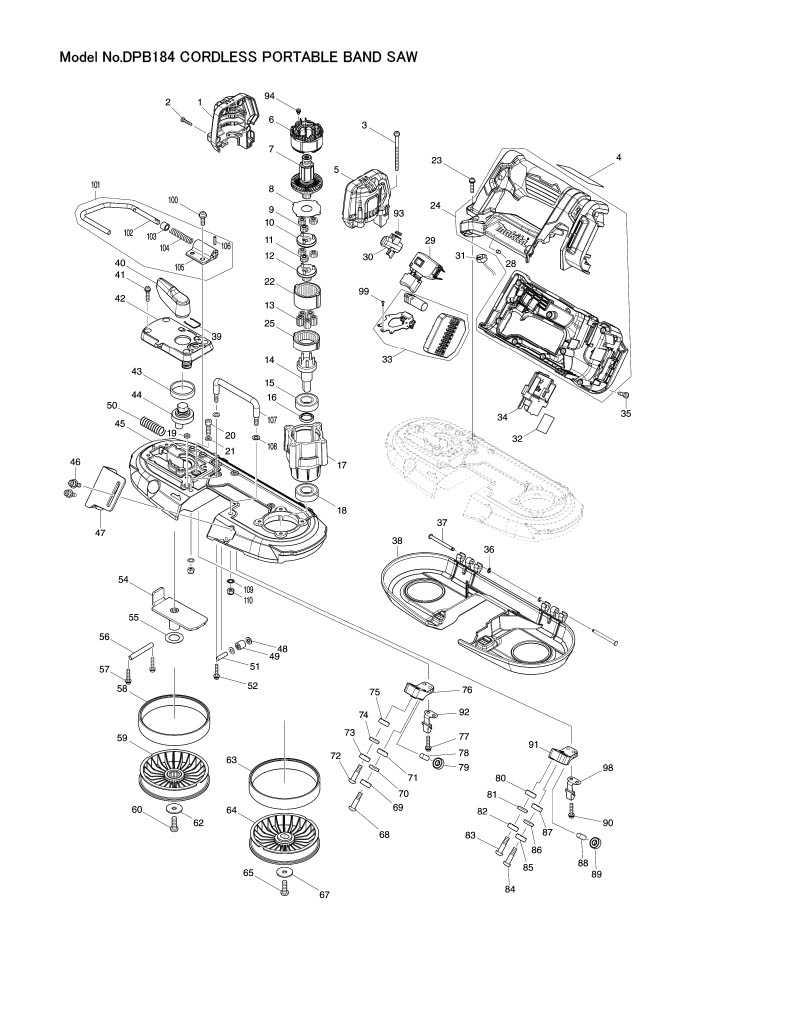

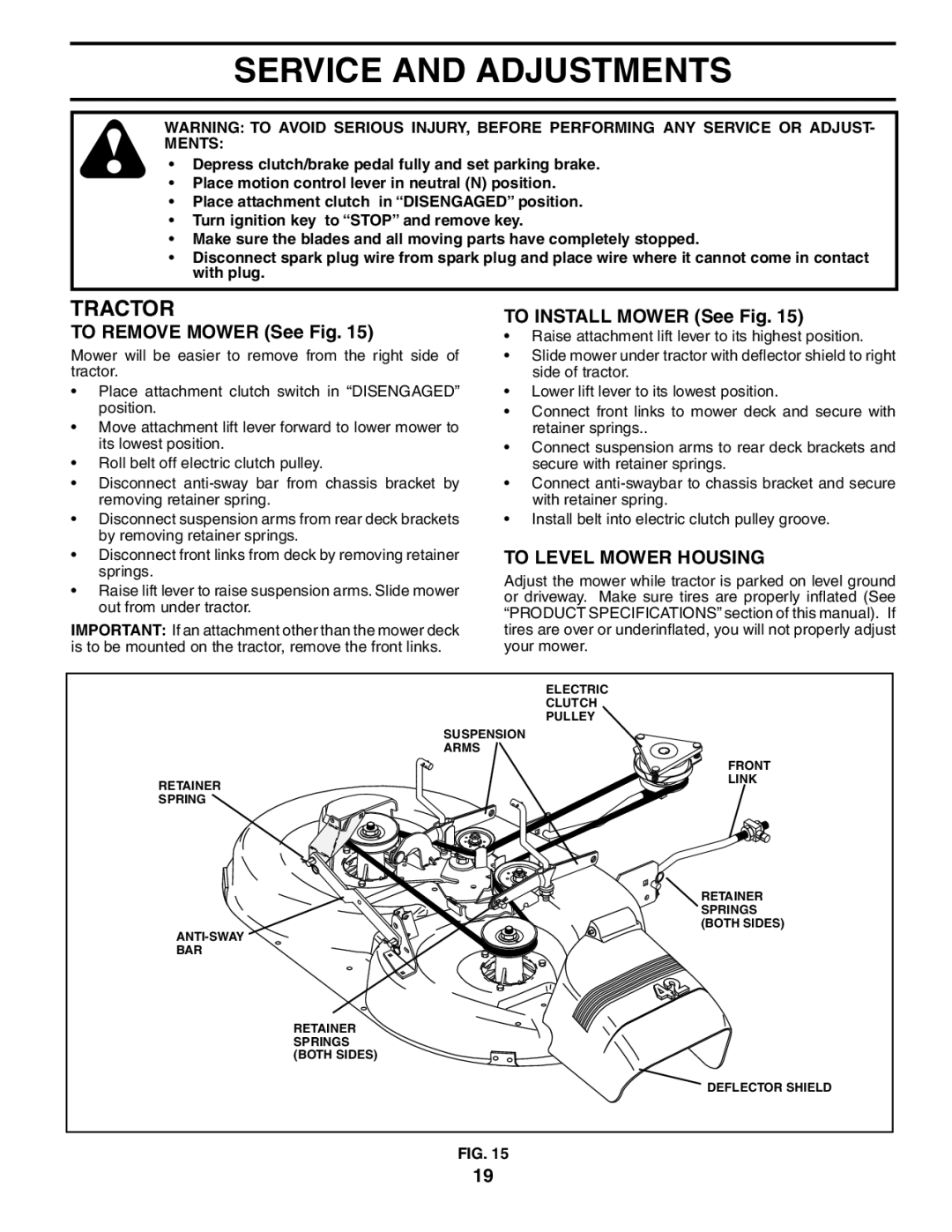

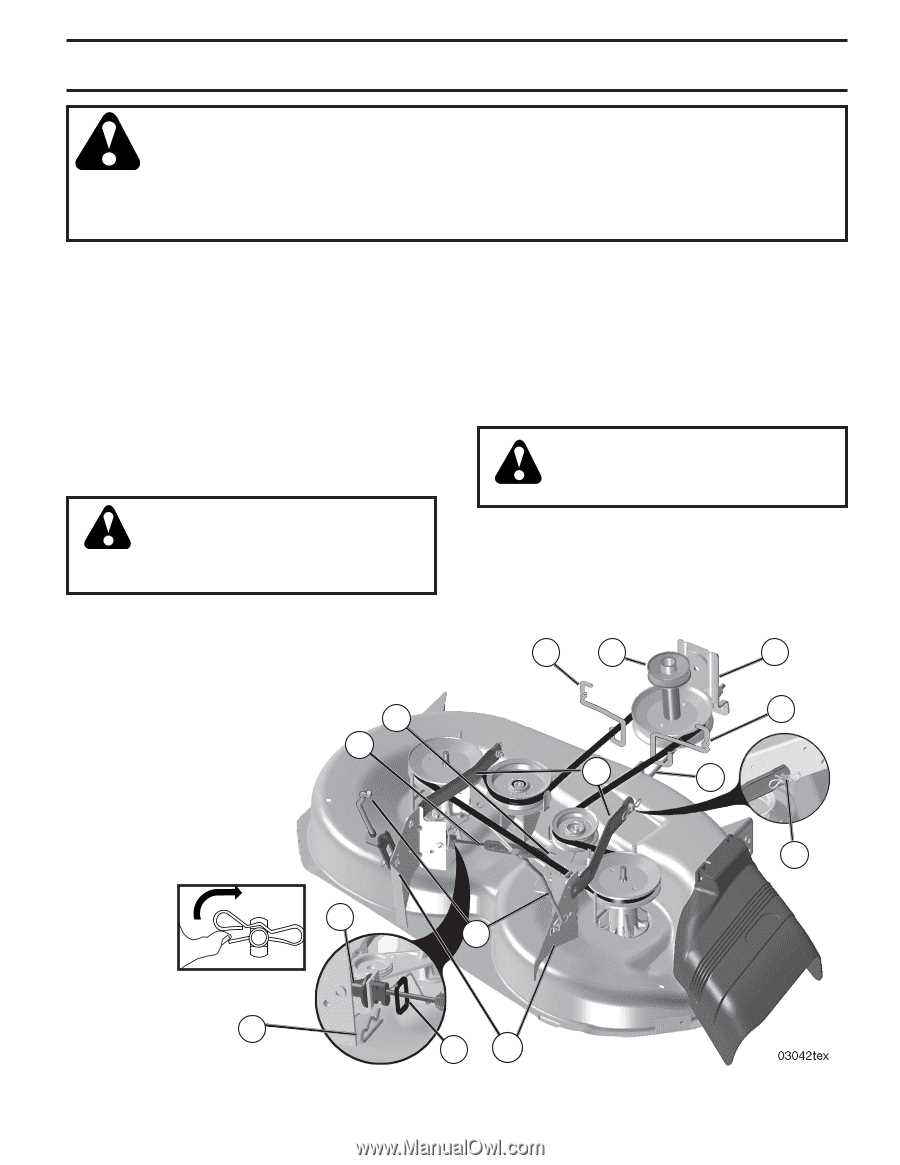

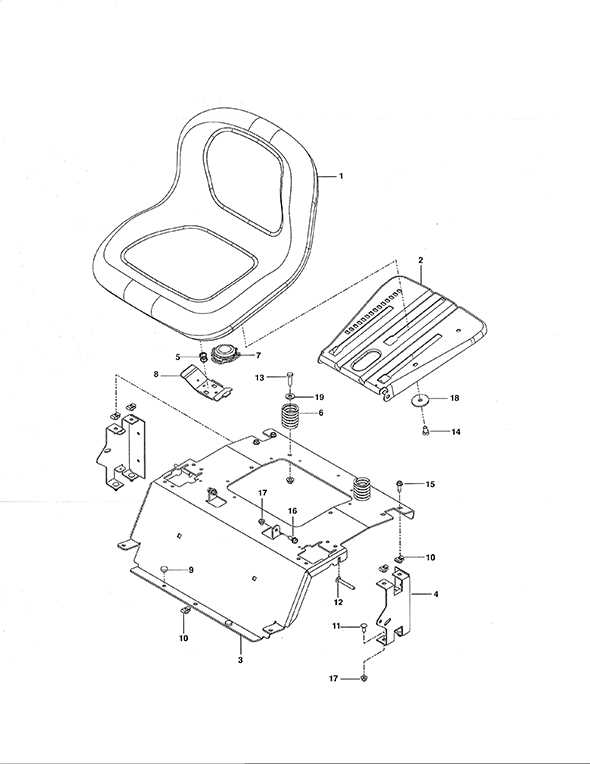

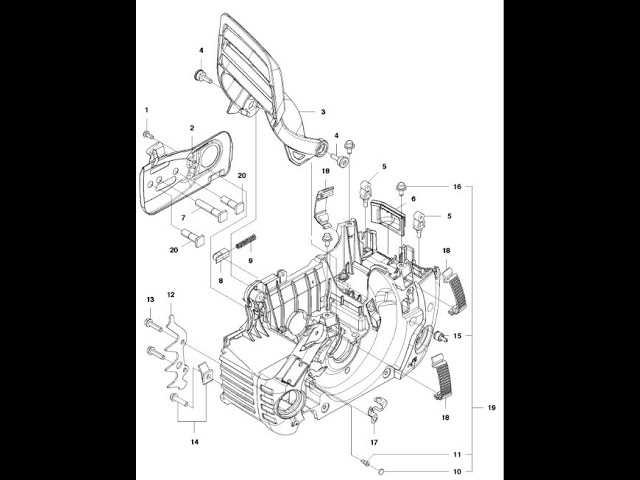

Importance of Parts Diagrams

Understanding the layout and components of machinery or equipment is crucial for effective maintenance and repair. Visual representations serve as essential tools for technicians and users alike, enabling them to grasp the intricate relationships between different elements. This clarity enhances efficiency and accuracy in various tasks, from troubleshooting to routine servicing.

Benefits of Visual Representations

- Enhanced Understanding: Clear visuals allow individuals to quickly identify parts and their functions.

- Streamlined Repairs: Technicians can easily locate components, reducing time spent on fixes.

- Reduced Errors: Accurate visuals minimize the risk of misidentifying or misplacing elements during assembly or disassembly.

Applications in Maintenance

- Facilitates training for new staff, ensuring they become proficient more quickly.

- Assists in inventory management by providing a reference for necessary components.

- Improves communication among team members by standardizing references to specific elements.

How to Read a Parts Diagram

Understanding the visual representation of components is crucial for effective assembly and maintenance. This guide will provide insights into interpreting these illustrations, ensuring clarity and efficiency in identifying various elements.

Key Elements to Consider

When examining these representations, pay attention to the labels, numbering, and symbols. Each aspect plays a significant role in conveying the relationships and functions of the components. Familiarizing yourself with these features will enhance your comprehension.

Steps for Effective Interpretation

| Step | Description |

|---|---|

| 1 | Begin by identifying the overall layout and orientation of the illustration. |

| 2 | Note the reference numbers that correspond to individual elements, allowing for easy lookup. |

| 3 | Pay close attention to any accompanying legends or notes that clarify specific details. |

| 4 | Utilize a systematic approach, checking each component against the list for accuracy. |

Common Issues with Yth18542 Parts

When dealing with mechanical components, it’s essential to recognize the frequent challenges that users encounter. Understanding these issues can help in ensuring better performance and longevity of the equipment. Here, we explore some prevalent problems associated with these specific elements.

| Issue | Description | Potential Solution |

|---|---|---|

| Wear and Tear | Over time, components can degrade due to friction and repeated use. | Regular inspections and timely replacements can mitigate this issue. |

| Improper Installation | Incorrect assembly can lead to malfunction or damage. | Follow manufacturer guidelines closely during installation. |

| Corrosion | Exposure to moisture can cause rust and deterioration. | Use protective coatings and store in dry environments. |

| Misalignment | Components may not align properly, causing inefficiencies. | Regularly check alignment and adjust as necessary. |

Addressing these common issues proactively can lead to improved functionality and reduced downtime, ensuring the machinery operates smoothly and effectively.

Where to Find Replacement Parts

Locating suitable components for your equipment can be essential for maintaining its functionality and longevity. Various resources are available to ensure you find the right items quickly and efficiently.

Online Retailers

Many online platforms offer a vast selection of components. Here are some popular options:

- Specialized websites that focus on machinery

- Major e-commerce sites with dedicated sections for equipment

- Manufacturer’s official websites for direct purchases

Local Suppliers

Exploring nearby stores can also yield beneficial results. Consider these options:

- Local hardware stores with specialized sections

- Authorized dealers with extensive inventories

- Salvage yards that may have used components available

Maintenance Tips for Longevity

Ensuring the durability of machinery requires consistent attention and care. By implementing simple practices, one can enhance performance and extend the lifespan of equipment. Regular checks and preventive measures play a crucial role in avoiding major issues down the line.

Routine Inspections

Conducting periodic evaluations is essential. Look for signs of wear and tear, and address any irregularities promptly to prevent further damage.

Proper Lubrication

Maintaining appropriate lubrication levels minimizes friction and helps components operate smoothly. Be sure to use the correct type of lubricant specified for your machinery.

| Maintenance Task | Frequency |

|---|---|

| Visual Inspection | Weekly |

| Lubrication Check | Monthly |

| Deep Cleaning | Quarterly |

| Professional Service | Annually |

Comparison with Other Models

Analyzing various machinery models reveals significant differences in design, functionality, and performance. This comparison offers insights into how distinct features contribute to user experience and operational efficiency. By examining similar systems, we can better understand the strengths and weaknesses that each model presents.

Key Differences

- Engine Performance: Variations in horsepower and torque can affect the overall output and suitability for specific tasks.

- Durability: The materials used in construction can lead to differences in lifespan and maintenance requirements.

- Fuel Efficiency: Some models are engineered for lower consumption, impacting long-term operational costs.

User Experience

- Ease of Use: Controls and interface designs vary, influencing how intuitively users can operate the machinery.

- Comfort Features: Some models offer enhanced ergonomics, reducing fatigue during extended use.

- Maintenance Access: Design choices can affect how easily users can perform routine checks and repairs.

Understanding these aspects not only aids in making informed purchasing decisions but also highlights the importance of choosing the right equipment for specific applications.

Resources for Further Information

For those seeking to deepen their understanding of machinery components and their configurations, numerous resources are available. These can enhance knowledge and facilitate effective troubleshooting and maintenance practices.

| Resource Type | Description | Link |

|---|---|---|

| Manufacturer Manuals | Official documentation providing detailed insights and specifications. | Visit Manufacturer Site |

| Online Forums | Communities where enthusiasts share experiences and solutions. | Join the Discussion |

| Video Tutorials | Step-by-step guides showcasing repairs and assembly techniques. | Watch Tutorials |

| Technical Blogs | Articles that explore common issues and innovative fixes. | Read More |