Maintaining a robust agricultural machine requires a deep understanding of its individual elements. A comprehensive overview of these components can significantly enhance your ability to troubleshoot and ensure optimal performance. By familiarizing yourself with the intricate relationships between the various parts, you can make informed decisions during repairs or upgrades.

Each section of a tractor plays a vital role in its overall functionality, contributing to tasks such as power generation, steering, and transport. Grasping the layout and function of these segments not only aids in effective maintenance but also empowers operators to optimize their equipment for different agricultural needs. Detailed visual representations serve as invaluable tools in this learning process.

Exploring the assembly of a machine can unveil insights into its design and engineering, highlighting how various components interact to achieve specific tasks. Whether you are a seasoned operator or a newcomer, understanding these intricacies is essential for maximizing the potential of your machinery.

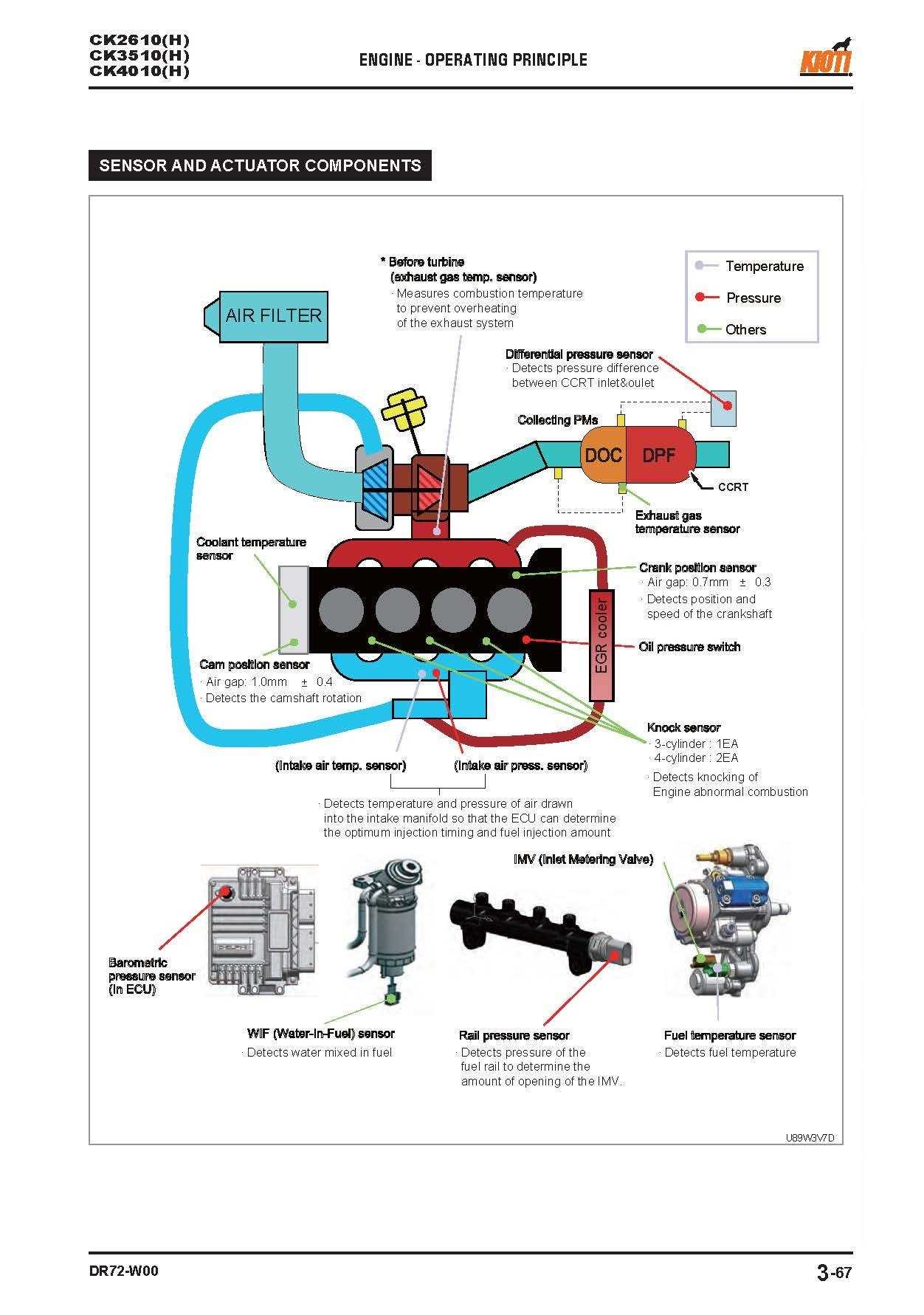

The effective functioning of any machinery relies heavily on its fundamental elements. Understanding these essential components provides valuable insights into the overall performance and reliability of the equipment. Each part plays a crucial role in ensuring seamless operation, and familiarity with them can enhance maintenance and troubleshooting efforts.

Engine and Transmission

The heart of any machine is its power unit, which drives performance and efficiency. Coupled with a robust transmission system, these elements work together to deliver optimal torque and speed. Proper maintenance of these systems is vital for sustained operation.

Hydraulic System

A well-designed hydraulic mechanism is integral for enhancing the versatility of the equipment. It enables effective movement and control of various attachments, making it adaptable to a range of tasks. Regular checks can prevent leaks and ensure consistent pressure levels, maximizing functionality.

| Component | Description |

|---|---|

| Power Unit | Delivers energy for movement and operation. |

| Transmission | Facilitates power transfer between engine and wheels. |

| Hydraulic Mechanism | Enables controlled movement of attachments. |

| Chassis | Provides structural support and stability. |

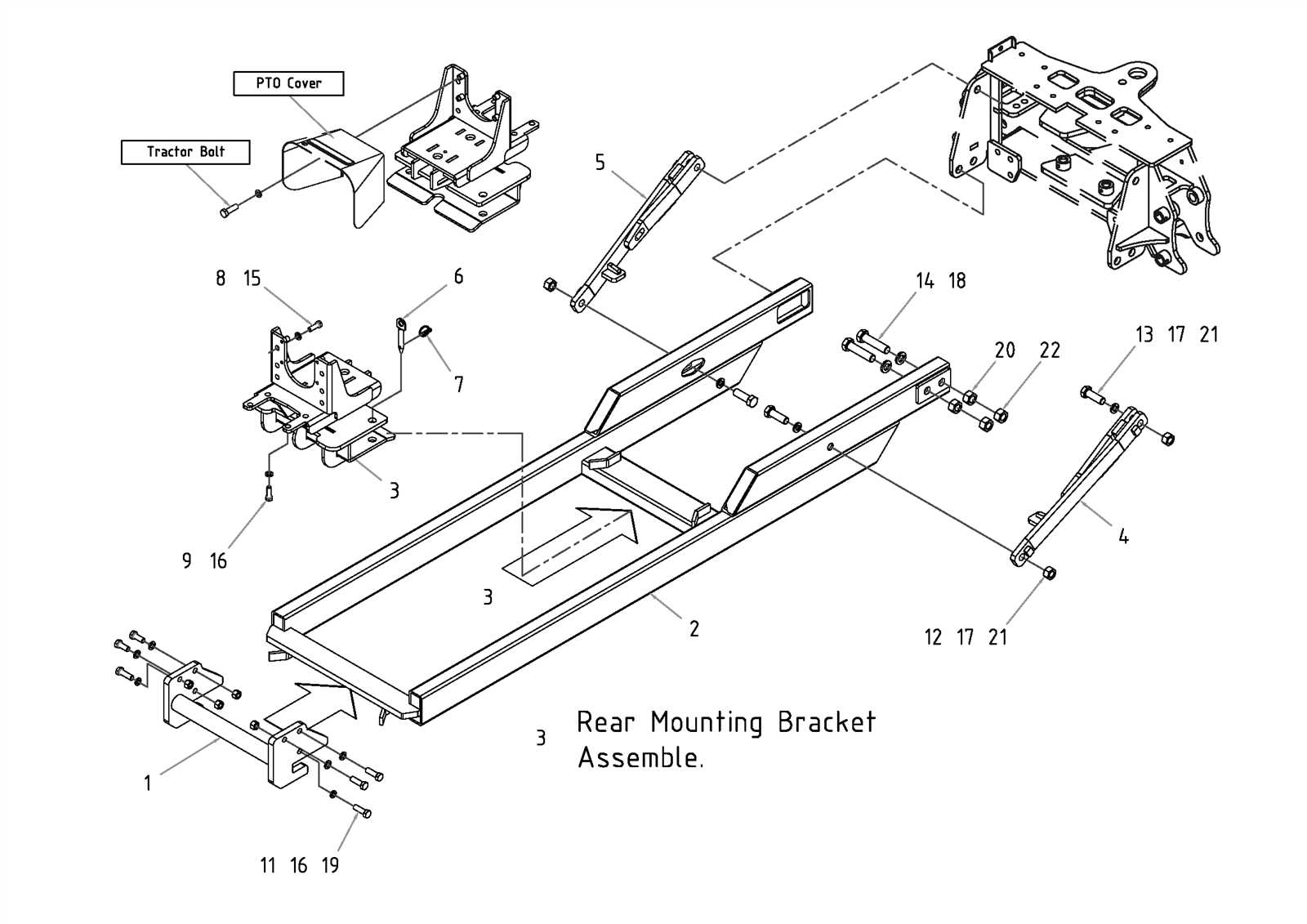

Understanding the Parts Layout

This section aims to provide a comprehensive overview of the arrangement and configuration of various components within a specific machinery model. Familiarizing oneself with the organization of these elements is crucial for effective maintenance and repair. By understanding the structure, users can easily identify and address any issues that may arise during operation.

The following table illustrates the key components, their functions, and their positions within the system:

| Component Name | Function | Location |

|---|---|---|

| Engine | Provides power for operation | Front section |

| Transmission | Transfers power to wheels | Under the chassis |

| Hydraulic System | Controls movement of implements | Near the rear |

| Electrical System | Manages electrical functions | Cab area |

| Cooling System | Regulates engine temperature | Adjacent to the engine |

Importance of Accurate Diagrams

Precise illustrations play a crucial role in various technical fields, ensuring clarity and efficiency during assembly, repair, or maintenance tasks. When visual representations are accurate, they provide a reliable reference that can significantly reduce errors and enhance productivity.

Benefits of Accurate Representations

- Enhanced Understanding: Clear visuals help users grasp complex structures and components quickly.

- Reduced Mistakes: When details are accurately depicted, the likelihood of making errors during installation or repairs diminishes.

- Time Efficiency: Users can complete tasks more swiftly with reliable references, saving both time and effort.

Impact on Maintenance and Repairs

- Facilitates Troubleshooting: Accurate visuals assist in identifying issues promptly, enabling faster resolution.

- Improves Training: New users benefit from precise illustrations, enhancing their learning experience and confidence.

- Streamlines Communication: Clear visuals serve as effective communication tools among team members, reducing misunderstandings.

Common Maintenance Procedures

Regular upkeep is essential for ensuring the longevity and efficiency of your machinery. Implementing consistent maintenance practices can prevent unexpected breakdowns and extend the operational lifespan of your equipment. Below are key procedures to incorporate into your routine servicing schedule.

Routine Inspections

Conducting frequent inspections is vital for identifying potential issues before they escalate. Consider the following tasks:

- Check fluid levels, including oil, coolant, and hydraulic fluids.

- Examine belts and hoses for signs of wear or damage.

- Inspect filters and replace them as needed to maintain optimal performance.

Cleaning and Lubrication

Keeping components clean and properly lubricated can significantly enhance performance. Follow these guidelines:

- Regularly clean air intake and exhaust systems to prevent blockages.

- Apply appropriate lubricants to moving parts to reduce friction and wear.

- Remove debris from around the engine and other critical areas to prevent overheating.

Identifying Replacement Parts Easily

Locating suitable components for your machinery can be a straightforward task when you have the right approach. Understanding the layout and functions of various elements is crucial for ensuring that replacements fit seamlessly and perform effectively. This section provides insights into simplifying the process of finding the correct components without the confusion of technical jargon.

Utilizing Visual Guides

Visual aids can significantly enhance your ability to identify necessary elements. Here are some strategies:

- Refer to labeled illustrations that show each component’s location and function.

- Compare your equipment with reference images to spot discrepancies or worn-out parts.

- Use color-coded charts to differentiate between various types of elements easily.

Leveraging Online Resources

The internet is a valuable tool for accessing information about component identification. Consider the following options:

- Visit forums and communities where enthusiasts share their experiences and solutions.

- Explore manufacturer websites for detailed specifications and compatibility lists.

- Utilize search engines to find specific guides or videos that demonstrate replacement procedures.

Benefits of Using Official Diagrams

Utilizing authorized schematics can greatly enhance the efficiency and effectiveness of maintenance and repair tasks. These documents provide clear and precise visual references, ensuring that users can accurately identify components and their interconnections. Relying on sanctioned illustrations helps in minimizing errors and streamlining the troubleshooting process, ultimately leading to better performance and longevity of the equipment.

Enhanced Accuracy

Official schematics are designed to meet industry standards, providing detailed and correct information about various elements. This accuracy is crucial for technicians and users alike, as it eliminates confusion and potential mistakes that could arise from using unofficial sources. By following these verified illustrations, users can be confident that they are addressing the right components in their operations.

Time Efficiency

Accessing reliable visual references can save significant time during repairs and maintenance. With well-organized layouts and annotations, these authorized documents enable users to quickly locate parts and understand their functions. This efficiency is especially beneficial in high-pressure situations where time is of the essence.

| Benefit | Description |

|---|---|

| Accuracy | Ensures correct identification of components. |

| Time Savings | Streamlines repair processes and reduces downtime. |

| Standard Compliance | Meets industry standards for safety and quality. |

Where to Find Authentic Resources

Accessing genuine materials and documentation is essential for anyone looking to maintain or repair their machinery effectively. With the right resources, users can ensure that they are utilizing quality components and following accurate guidelines for service and repairs. This section will outline various avenues to locate reliable information and authentic resources.

Official Manufacturer Websites

One of the most reliable sources for genuine information is the official website of the manufacturer. These sites often provide comprehensive manuals, specifications, and resources that are essential for understanding the equipment’s inner workings. Users can usually find downloadable PDFs or interactive resources that detail all necessary components and procedures.

Authorized Dealers and Service Centers

Visiting authorized dealers and service centers can be incredibly beneficial. These establishments not only sell genuine items but often offer expert advice and assistance. Technicians at these locations can provide insights on installation, maintenance, and troubleshooting, ensuring that users have access to accurate and helpful information.