In the realm of mechanical engineering, the intricate relationship between various elements plays a crucial role in ensuring the functionality and efficiency of devices. A comprehensive overview of these components allows users to grasp their interconnections and operational significance. This section delves into the essential features and configurations that contribute to the seamless performance of machinery.

Exploring the Fundamentals reveals how each element serves a specific purpose while collectively enhancing the overall mechanism. By examining these characteristics, one can appreciate the sophistication involved in the design and assembly of such systems. The synergy of these elements exemplifies the innovation inherent in mechanical engineering.

Furthermore, a detailed examination of these configurations can aid in maintenance and troubleshooting processes. Understanding how each piece interacts within the broader system empowers users to make informed decisions and ensure longevity. As we navigate through this topic, the focus will remain on clarity and insight into the essential functions that drive mechanical systems forward.

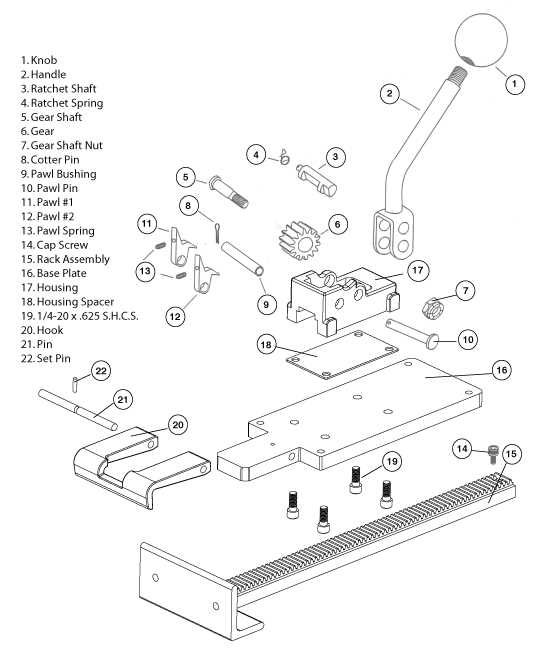

Understanding Ratchet Mechanisms

The intricacies of a specific mechanical system are foundational in various applications, providing efficiency and control in movement. This system operates based on a clever design that allows motion in one direction while preventing it in the opposite direction. Such mechanisms are vital in tools and machines, ensuring safety and reliability in their function.

At the core of this technology lies a few essential components that work together harmoniously:

- Driving element: This part provides the initial force to initiate movement.

- Engagement feature: This element allows the mechanism to catch and hold in place when movement occurs.

- Release mechanism: This feature facilitates the return motion or adjustment, enabling flexibility in use.

Applications of this system can be observed in everyday tools, such as:

- Hand tools that require adjustable torque settings.

- Automotive devices for precise tightening and loosening.

- Heavy machinery that needs controlled movement under load.

Understanding the functionality and design of this mechanical innovation reveals its significance in engineering, enhancing the performance of various devices. Mastery of these systems can lead to improved designs and greater efficiency in manufacturing processes.

Types of Ratchet Tools Available

Various tools designed for mechanical applications are essential for both professionals and DIY enthusiasts. These implements come in multiple forms, each serving unique purposes while enhancing efficiency in tasks that involve tightening and loosening fasteners.

Common Categories

- Socket Wrenches: These are versatile tools equipped with interchangeable sockets, allowing users to work on different sizes of fasteners.

- Torque Wrenches: Engineered to apply a specific torque to fasteners, these tools are crucial in ensuring that components are secured to the manufacturer’s specifications.

- Adjustable Wrenches: Featuring a movable jaw, adjustable wrenches can accommodate a range of fastener sizes, making them convenient for various tasks.

Specialized Tools

- Impact Wrenches: These power-driven tools deliver high torque output, making them ideal for heavy-duty applications, such as automotive repair.

- Flex Head Wrenches: With a pivoting head, these tools provide enhanced access to tight spaces, allowing for greater maneuverability.

- Ratcheting Screwdrivers: Designed for ease of use, these screwdrivers allow users to drive screws quickly without having to reposition the tool after each turn.

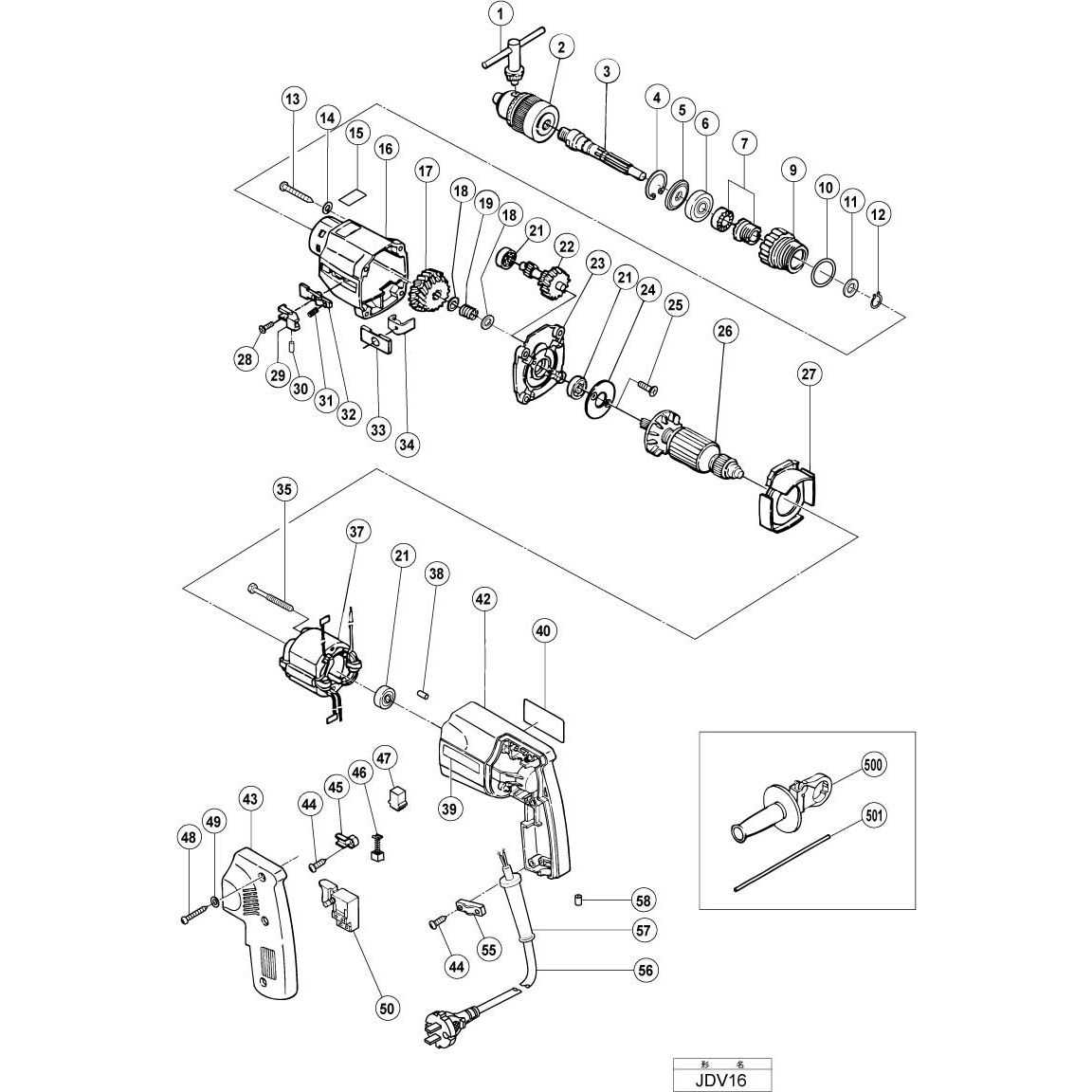

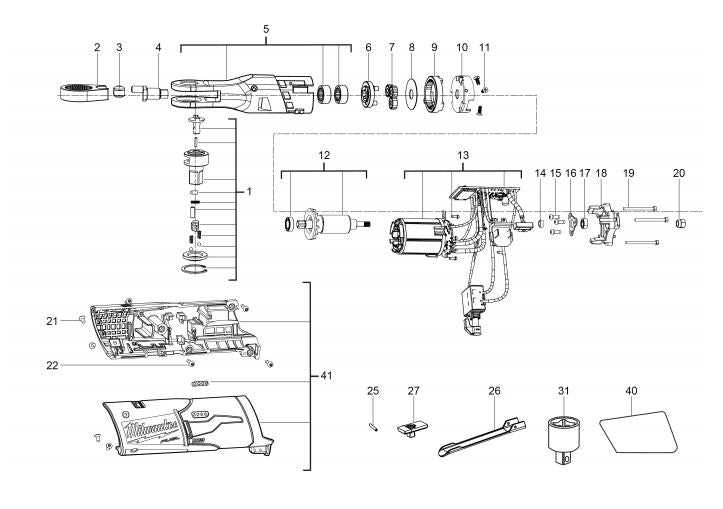

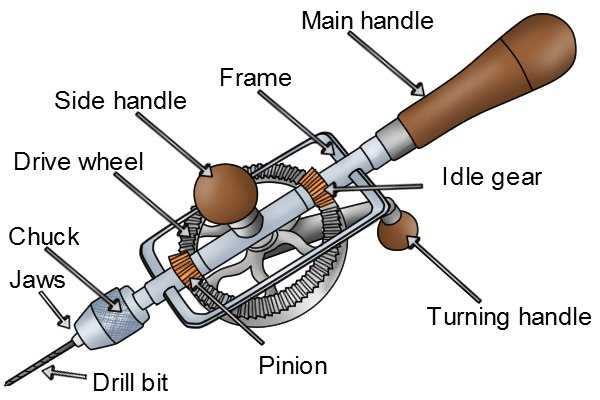

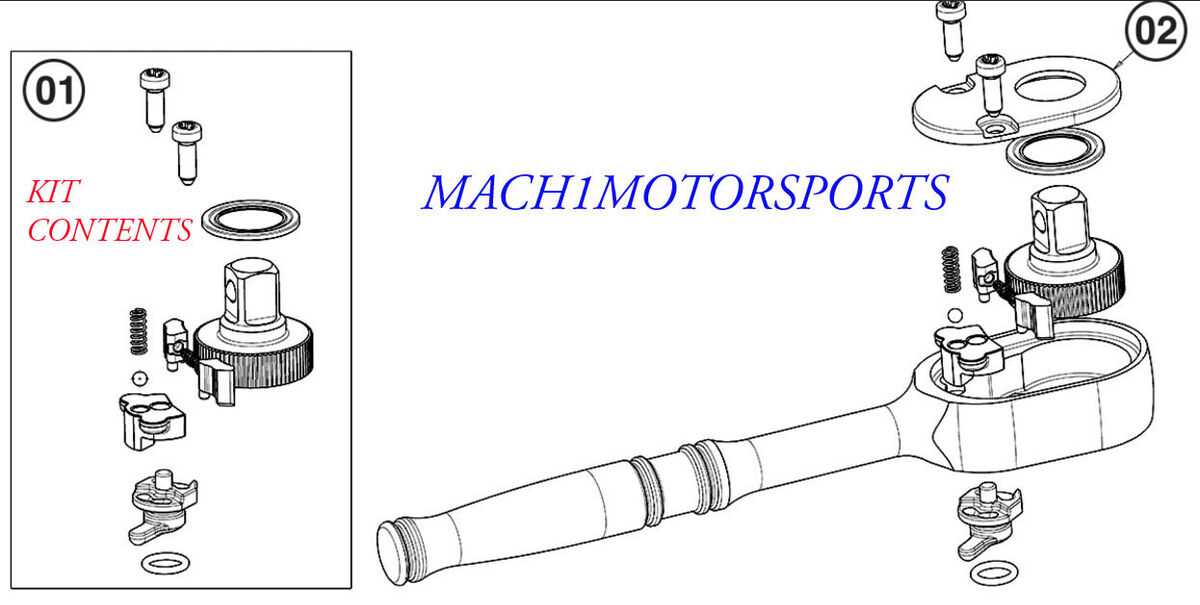

Key Components of Ratchet Systems

The functionality of mechanical systems relying on incremental movement hinges on several essential elements. Each component plays a crucial role in ensuring smooth operation and efficiency. Understanding these fundamental aspects is vital for grasping how such mechanisms perform their intended tasks.

One of the primary elements is the mechanism that enables unidirectional movement, allowing the assembly to progress in one direction while preventing reverse motion. This feature is vital for applications requiring secure and consistent operation.

Additionally, the engagement element, which facilitates the interaction between moving parts, is essential for achieving effective performance. This component ensures that the mechanism can lock in place, providing stability and support during operation.

Finally, the housing or frame provides structural integrity, allowing for the secure arrangement of all elements. This casing not only protects the internal components but also contributes to the overall durability and reliability of the entire system.

How Ratchets Work in Practice

The mechanism in question plays a crucial role in various applications, allowing for efficient operation and ease of use. Its design enables movement in one direction while preventing backward motion, ensuring that tasks can be performed effectively without the risk of slippage.

When engaged, this mechanism facilitates a smooth, incremental movement, which is particularly beneficial in tightening or loosening fasteners. Users can apply force in a single direction, and the system will automatically lock in place, providing stability and control during operation.

In practical scenarios, this technology is invaluable in situations where precise adjustments are necessary. For example, in mechanical repair or construction, the ability to easily shift between actions without losing grip enhances overall productivity. The system’s reliability and functionality make it a preferred choice for both professionals and hobbyists alike.

Understanding the workings of this mechanism can greatly improve efficiency and safety. By mastering its use, individuals can tackle various tasks with confidence, making it an essential tool in many toolkits.

Maintenance Tips for Ratchet Parts

Proper upkeep of your mechanical tools ensures their longevity and optimal performance. Regular attention to the various components involved can prevent wear and enhance efficiency. Here are some essential practices to consider for maintaining your equipment.

Regular Cleaning

- Remove debris and dirt from all surfaces.

- Use a soft brush or cloth for detailed cleaning.

- Ensure that no foreign objects obstruct moving elements.

Lubrication Practices

- Apply a suitable lubricant to all moving components.

- Check for signs of rust or corrosion and address them promptly.

- Avoid over-lubrication, which can attract dirt.

By following these guidelines, you can significantly extend the life of your mechanical devices and maintain their functionality over time.

Common Issues with Ratchet Mechanisms

In mechanical systems that employ a locking mechanism, various challenges may arise during operation. These difficulties can lead to performance issues, affecting the overall functionality and reliability of the device. Understanding these common problems can assist users in troubleshooting and ensuring proper maintenance.

Wear and Tear

Frequent usage can lead to significant wear on the components involved in the locking mechanism. Over time, this can result in diminished effectiveness, causing slippage or failure to engage properly. Regular inspection and timely replacement of worn elements are crucial for maintaining optimal performance.

Alignment Problems

Misalignment of the mechanism’s components may occur due to improper installation or external forces. This misalignment can prevent the device from operating smoothly, leading to inefficiencies and potential damage. Ensuring correct alignment during installation and periodic checks can mitigate these issues.

Choosing the Right Ratchet for Tasks

Selecting the appropriate tool for various tasks is crucial for achieving optimal results. The right device can enhance efficiency and ensure that projects are completed safely and effectively. Understanding the features and specifications of different models is essential for making an informed choice.

When considering a suitable tool, it is important to evaluate the specific requirements of your task. Factors such as size, torque, and intended use play a significant role in the selection process. The following table outlines some key considerations when choosing a tool:

| Feature | Description |

|---|---|

| Size | Choose based on the space available and the nature of the task. |

| Torque Range | Ensure the tool can handle the required torque for your applications. |

| Material | Select a durable material that can withstand the conditions of use. |

| Mechanism | Consider whether a quick-release feature or a locking mechanism is needed. |

| Grip | Evaluate the comfort and ergonomics of the handle for prolonged use. |

By carefully assessing these attributes, you can make an educated decision that will enhance your overall efficiency and effectiveness in completing tasks.

Innovations in Ratchet Design

Recent advancements in mechanical engineering have led to remarkable improvements in the functionality and efficiency of torque mechanisms. These innovations have redefined the capabilities of tools that rely on such mechanisms, enhancing their usability and performance in various applications.

Enhanced Durability and Performance

One of the significant advancements is the development of materials that increase the longevity and effectiveness of these mechanisms. Key innovations include:

- Use of high-strength alloys to withstand greater loads.

- Advanced coatings that reduce friction and wear.

- Precision engineering techniques to improve the fit and operation of components.

Ergonomic and User-Friendly Designs

In addition to improved materials, the design of these mechanisms has also evolved to prioritize user comfort and efficiency. Innovations in this area include:

- Streamlined shapes that enhance grip and control.

- Adjustable settings for varied torque applications.

- Color-coded indicators for easy identification of settings.