When it comes to maintaining and repairing outdoor machinery, having a clear visual representation of each component can be invaluable. This approach not only aids in identifying parts but also simplifies the troubleshooting process, ensuring that users can quickly find what they need. A comprehensive guide helps in recognizing the intricate details that make up your equipment.

In the world of landscaping and gardening tools, familiarity with various segments is essential for optimal performance. By breaking down the elements, users can enhance their knowledge and proficiency in handling repairs and replacements. This understanding leads to more efficient maintenance routines, ultimately extending the lifespan of the equipment.

Furthermore, grasping the layout of individual components empowers users to make informed decisions regarding upgrades or replacements. Having access to detailed illustrations serves as a handy reference, making it easier to navigate any issues that may arise. In this article, we delve into the specifics of the assembly, providing insights that will help you master your outdoor tools.

Poulan PP4218A Overview

This section provides a comprehensive look at a well-regarded tool designed for various outdoor tasks. Known for its reliability and efficiency, it has become a popular choice among enthusiasts and professionals alike.

The equipment features a range of specifications that cater to the needs of users, ensuring ease of operation and maintenance. Key attributes include:

- Powerful engine for effective cutting performance

- Lightweight design for maneuverability

- Durable construction for long-lasting use

- Ergonomic handle for comfortable grip

When considering this model, it is essential to understand its versatility. It excels in various applications, making it suitable for both small and large tasks:

- Tree trimming and pruning

- Yard clean-up and debris removal

- Firewood cutting for winter preparations

In summary, this tool represents an excellent investment for anyone looking to enhance their outdoor maintenance capabilities. Its robust features and user-friendly design make it an ideal choice for a wide array of gardening and landscaping activities.

Key Components of the Chainsaw

A chainsaw is a powerful tool designed for cutting through wood with precision and efficiency. Understanding its essential parts can enhance both safety and performance during operation. Each component plays a crucial role in the overall functionality and reliability of the device.

Core Parts Overview

The main elements of a chainsaw include the engine, cutting chain, guide bar, and safety features. Each of these components contributes to the machine’s ability to perform various tasks effectively.

Detailed Component Table

| Component | Description |

|---|---|

| Engine | Drives the chainsaw and powers the cutting chain. |

| Cutting Chain | Consists of sharp teeth designed for slicing through wood. |

| Guide Bar | Provides a track for the cutting chain to move around. |

| Safety Features | Includes chain brake and throttle lock to prevent accidents. |

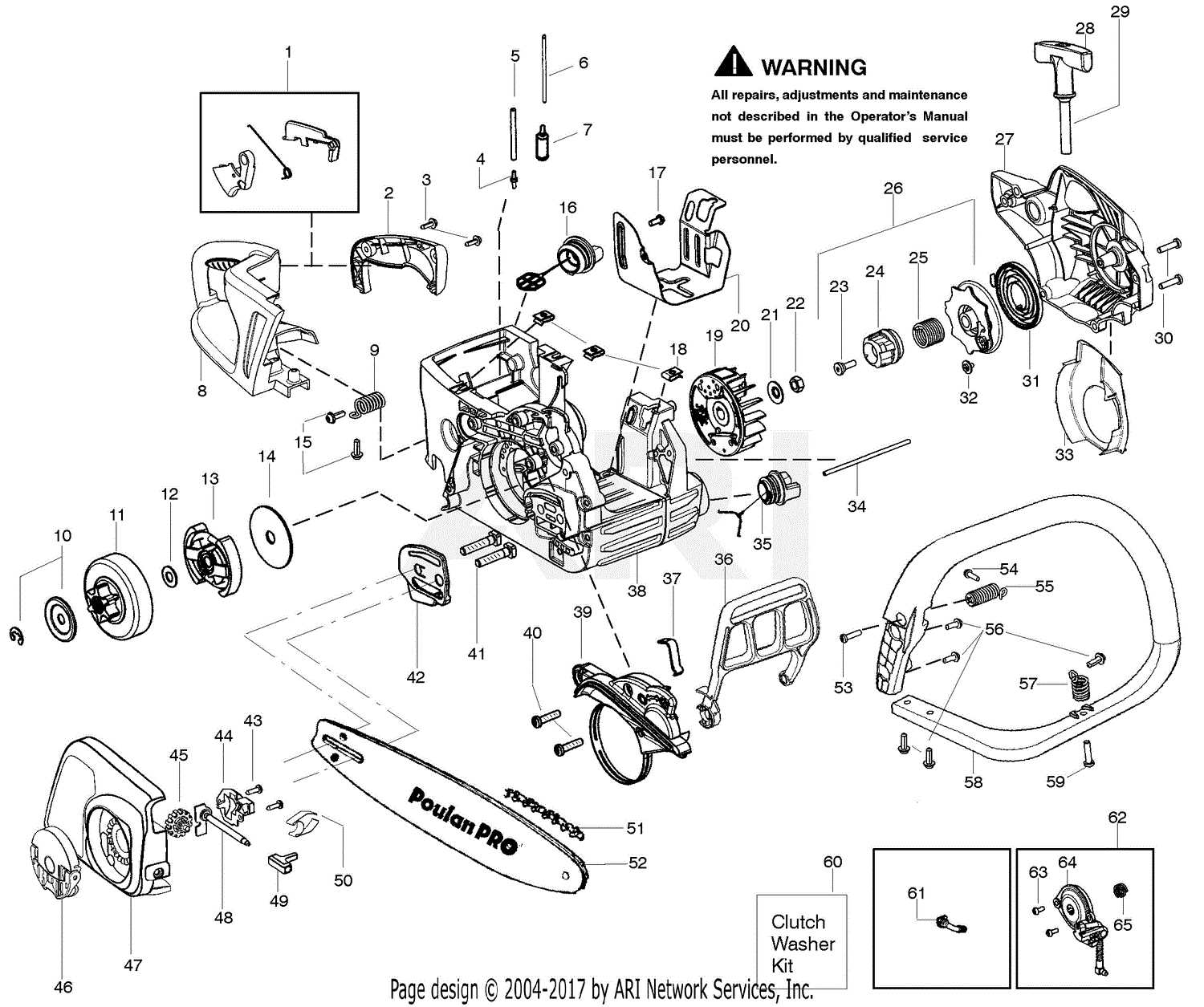

Understanding the Parts Diagram

Grasping the layout of a machine’s components is essential for effective maintenance and repair. Such illustrations serve as valuable tools, offering a visual representation of individual elements and their interconnections. This knowledge enables users to identify, troubleshoot, and replace faulty items with ease.

Benefits of Visual References

Utilizing a visual reference simplifies complex assemblies. By breaking down the overall structure into identifiable segments, users can quickly locate specific parts. Familiarity with these images enhances one’s ability to understand how different elements work together, facilitating smoother repairs and replacements.

Navigating the Illustration

Each component is typically labeled with a unique identifier, allowing for straightforward communication regarding replacements or inquiries. Understanding these labels is crucial for obtaining the correct items when needed. Overall, mastering the visual guide not only boosts confidence but also empowers users to tackle maintenance tasks effectively.

Common Issues and Solutions

In any mechanical device, users often encounter specific challenges that can hinder performance. Understanding these common problems and their respective remedies is essential for maintaining efficiency and prolonging the lifespan of the equipment.

1. Difficulty Starting: Many users report issues with ignition. This may stem from a faulty spark plug or an empty fuel tank. Regular maintenance, such as replacing the spark plug and ensuring proper fuel levels, can mitigate this issue.

2. Poor Cutting Performance: When the cutting efficiency declines, it may indicate dull blades or improper tension. Sharpening the blades and adjusting tension according to the manufacturer’s specifications can restore optimal functionality.

3. Excessive Vibration: Unusual vibrations can signify loose components or imbalanced parts. Tightening screws and ensuring proper assembly are effective solutions to this problem.

4. Fuel Leaks: Leaks can arise from damaged hoses or fittings. Inspecting and replacing these parts promptly can prevent further damage and maintain safety.

5. Overheating: If the machine overheats, it may be due to a clogged air filter or insufficient lubrication. Regularly cleaning or replacing the air filter and checking oil levels can help keep the device running cool.

Maintenance Tips for Longevity

Ensuring the durability and performance of outdoor equipment requires regular care and attention. By following a systematic maintenance routine, you can significantly extend the lifespan of your tools and enhance their efficiency. This section provides practical tips to keep your machinery running smoothly for years to come.

Regular Cleaning

Keeping your equipment clean is essential for optimal performance. Here are some steps to follow:

- Remove debris and dirt after each use to prevent buildup.

- Use a soft brush or cloth to clean sensitive areas.

- Inspect air filters and clean or replace them as needed.

Routine Inspections

Conducting regular checks can help you catch potential issues before they escalate. Consider these practices:

- Examine all moving parts for wear and tear.

- Check fuel and oil levels frequently.

- Ensure bolts and screws are tightened and secure.

Implementing these maintenance strategies will not only improve the functionality of your equipment but also save you time and money on repairs in the long run.

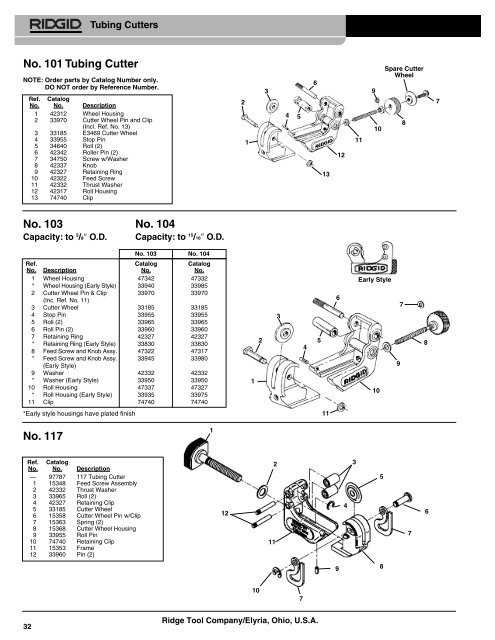

Where to Find Replacement Parts

Locating the necessary components for your equipment can be a straightforward process if you know where to look. Several reliable sources offer a wide selection of alternatives to ensure your machinery runs smoothly and efficiently. Understanding the various options available will help you make informed decisions when seeking replacements.

One of the best places to start is the official website of the manufacturer. Here, you can often find a dedicated section for components that are compatible with your model. Additionally, authorized dealers and local retailers frequently stock essential items and can provide valuable assistance in selecting the correct replacements.

Online marketplaces also present a vast array of choices, allowing you to compare prices and find the best deals. Websites that specialize in outdoor equipment often have user-friendly interfaces that make searching for specific items easier. Furthermore, community forums and social media groups can be excellent resources for recommendations and advice from fellow users who may have faced similar challenges.

Assembly and Disassembly Guide

Understanding the process of assembling and disassembling equipment is essential for maintenance and repair. This guide aims to provide clear instructions to ensure a smooth and efficient experience. By following these steps, users can avoid common pitfalls and extend the lifespan of their machinery.

To begin the assembly process, gather all necessary components and tools. Start by identifying the main parts and their corresponding connections. It is crucial to follow the correct sequence to avoid any damage. Ensure that all components are clean and free from debris before starting. Once ready, secure the main assembly and tighten connections as specified.

Disassembly requires careful attention to detail as well. Start by disconnecting power sources and removing any safety guards. Take note of how components fit together; taking pictures can be helpful for reference. Loosen screws and fasteners gradually to prevent any damage. Organize removed parts to simplify reassembly later. Following these steps will facilitate a straightforward process, whether you are putting together or taking apart your equipment.

Safety Precautions While Operating

Ensuring safety during operation is paramount to prevent accidents and injuries. By adhering to specific guidelines, users can create a secure environment while utilizing power tools or machinery. Awareness of potential hazards and preparation are key components in fostering a safe working atmosphere.

Always wear appropriate personal protective equipment, including safety goggles, gloves, and sturdy footwear. These items help shield against flying debris and provide additional grip and stability. Before starting, inspect the equipment thoroughly to ensure that all components are functioning correctly and securely attached.

Maintain a clean and organized workspace to minimize distractions and reduce the risk of tripping or slipping. Keep bystanders at a safe distance to avoid any accidental contact with moving parts. Additionally, familiarize yourself with the operating manual to understand the specific safety features and emergency protocols associated with the equipment.

Stay focused and avoid multitasking while operating machinery. Fatigue can impair judgment and reaction times, so take regular breaks if necessary. If you encounter any issues during operation, turn off the equipment and assess the situation before proceeding. Always prioritize safety to ensure an efficient and hazard-free experience.