In the realm of craftsmanship and repair, the effectiveness of a sturdy holding mechanism is paramount. This tool plays a crucial role in securely gripping materials, enabling artisans and hobbyists alike to execute precision tasks. By delving into the intricate elements that comprise this essential apparatus, one can gain a deeper appreciation for its functionality and design.

The construction of this device involves various integral elements, each serving a specific purpose to enhance usability. From the robust frame that provides stability to the intricate clamping mechanism that ensures a firm grasp, understanding these components is vital for both maintenance and effective operation. An overview of these parts reveals how they work in unison to facilitate seamless engagement with different materials.

By familiarizing oneself with the distinct elements of this holding tool, users can better navigate their usage, troubleshoot issues, and even customize their setup for specialized tasks. This knowledge empowers both seasoned professionals and enthusiastic newcomers, fostering a more efficient and enjoyable crafting experience. Explore the individual features that contribute to the overall performance of this indispensable instrument.

Understanding the Bench Vise Components

Every tool designed for clamping has its own set of essential elements that contribute to its functionality and efficiency. Familiarity with these components enhances the user’s ability to operate the tool effectively, ensuring precision and stability during various tasks. In this section, we will explore the critical components that make up this indispensable tool.

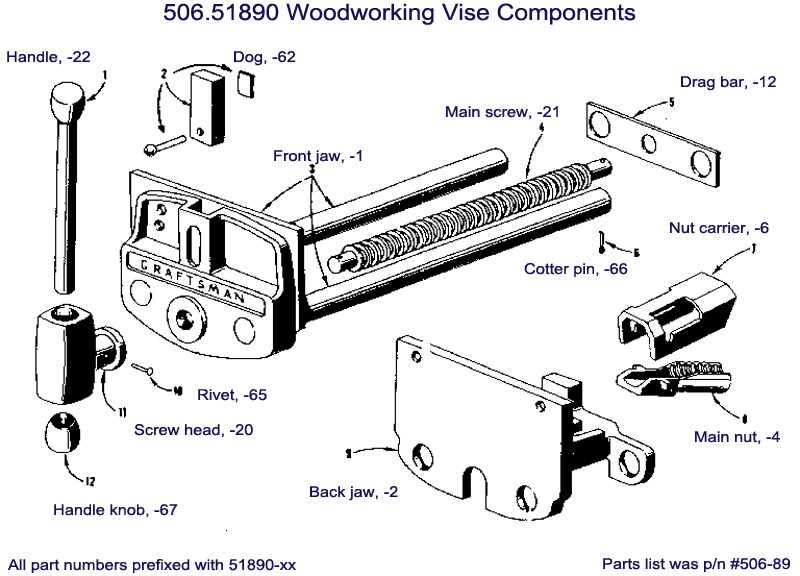

Frame: The main structure serves as the foundation, providing stability and support for all other elements. A robust frame is crucial for maintaining alignment and durability over time.

Jaws: These gripping surfaces are vital for holding objects securely. Often made from durable materials, the jaws can be smooth or serrated, depending on the application, ensuring a firm grasp without damaging the workpiece.

Screw Mechanism: This component enables the user to adjust the spacing between the jaws. A well-designed screw system allows for smooth operation, making it easy to secure and release items as needed.

Handle: An important feature for user control, the handle is used to tighten or loosen the jaws. Its ergonomic design can significantly enhance comfort during prolonged use.

Base: The stable bottom section provides mounting options, ensuring that the entire assembly remains anchored in place. A heavy and well-constructed base helps prevent unwanted movement while working.

Understanding these components allows users to appreciate the tool’s design and functionality better, leading to improved performance and safety in various applications.

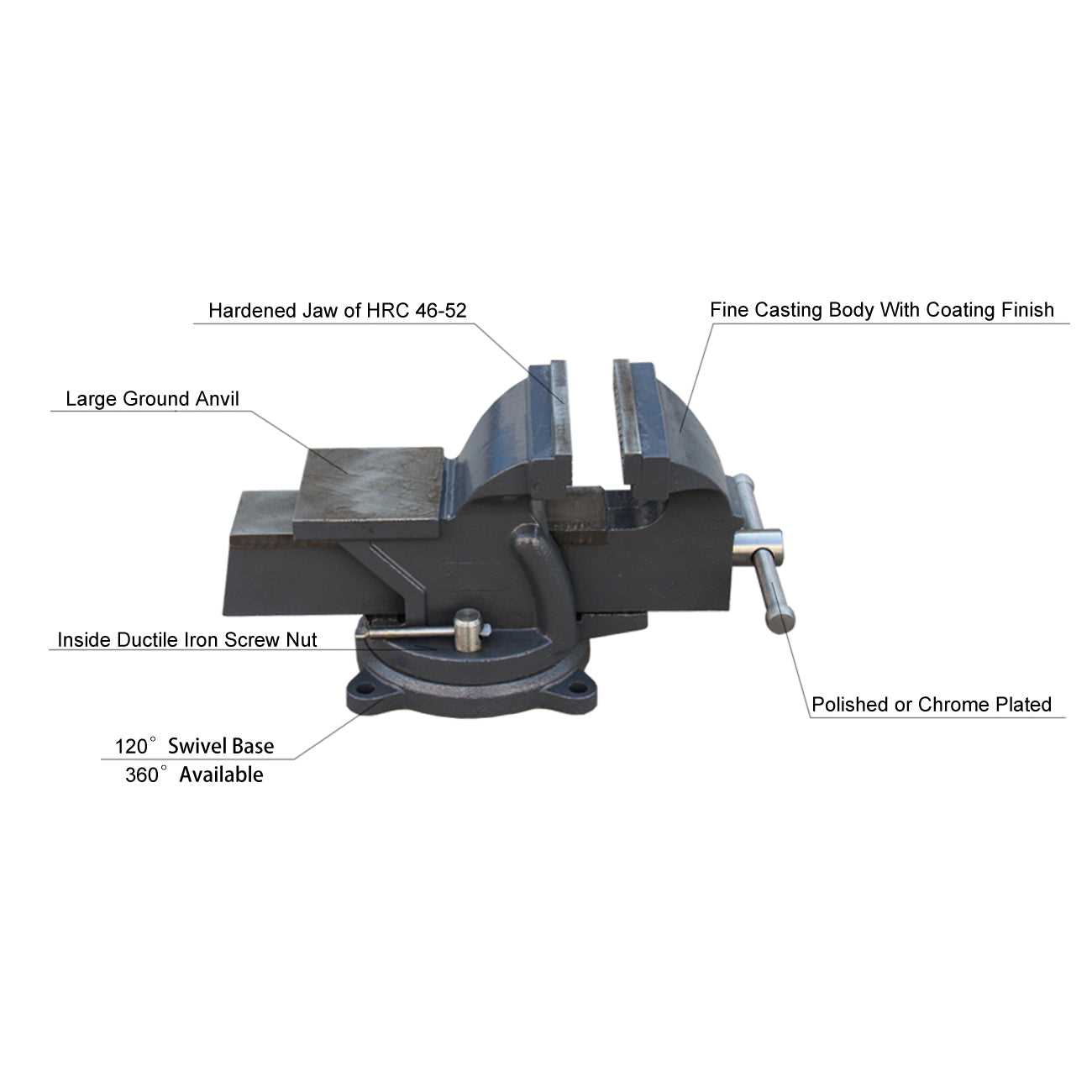

Key Elements of a Bench Vise

This section explores the essential components that contribute to the functionality and efficiency of a clamping tool. Understanding these elements can enhance your grasp of its mechanics and improve your usage experience.

Main Components

The primary features include the jaws, the screw mechanism, and the base. Each part plays a crucial role in securing materials and ensuring stability during work.

| Component | Function |

|---|---|

| Jaws | Grip and hold the workpiece securely. |

| Screw Mechanism | Adjusts the jaws to accommodate different sizes. |

| Base | Provides stability and can be mounted for better support. |

Add-on Features

Additional functionalities, such as swivel bases and quick-release mechanisms, enhance versatility and ease of use, making the tool more adaptable for various tasks.

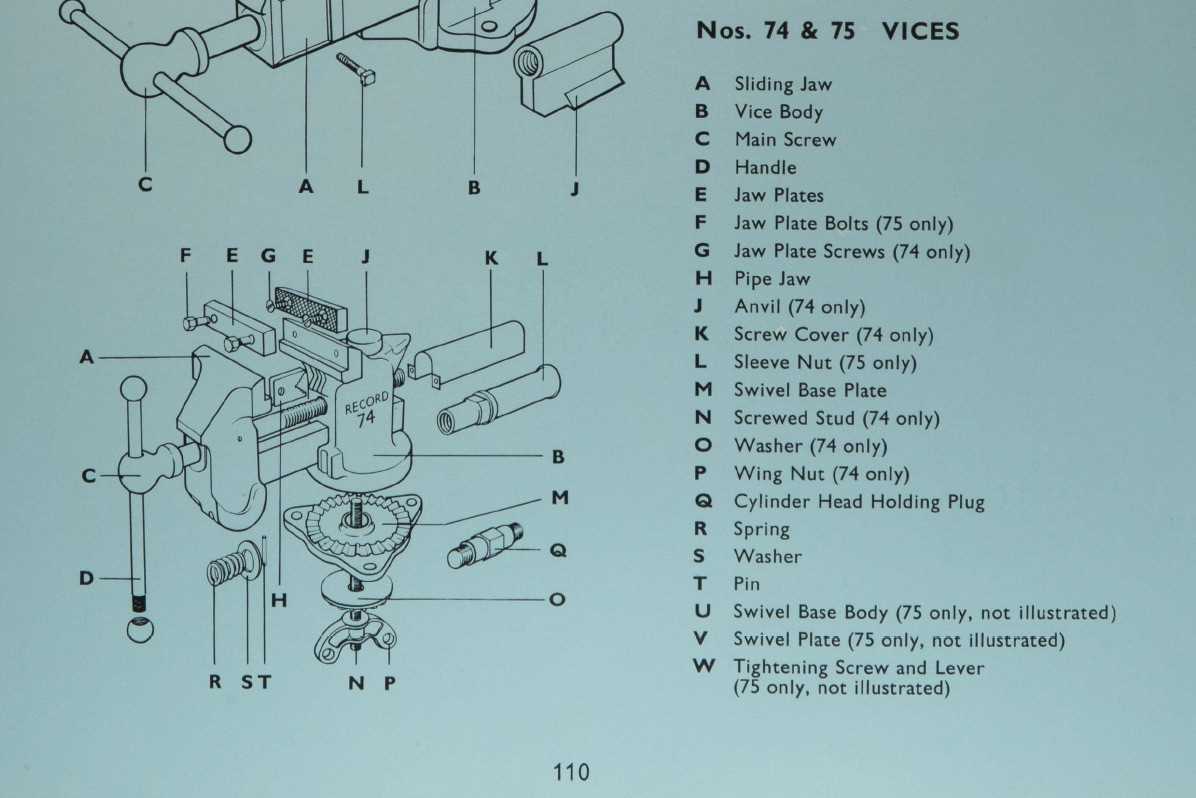

Types of Bench Vises Explained

Understanding the various kinds of clamping tools available can significantly enhance your work efficiency and precision. Each type serves a distinct purpose, tailored for specific tasks and materials. This section will delve into the characteristics and applications of different models, allowing you to choose the right one for your needs.

Standard Clamping Tools

These are the most commonly used tools, designed for general purposes such as woodworking and metalworking. They feature a straightforward design, providing a stable grip on items without complex adjustments. Ideal for everyday tasks, they are favored for their ease of use and versatility.

Specialized Holding Devices

For more intricate projects, specialized tools are essential. These models come with unique features that cater to specific materials or processes, such as rotating bases or adjustable jaws. They are invaluable in industries requiring high precision and tailored applications, making them a must-have for professionals.

Importance of Material Selection

The choice of materials in the design and manufacturing of tools is crucial for ensuring their functionality, durability, and overall performance. Selecting the right substances can significantly impact the effectiveness of the tool, influencing factors such as strength, resistance to wear, and stability under stress. Understanding the properties of various materials allows for better decision-making, leading to more reliable and efficient products.

Key Factors in Material Selection

When determining the appropriate materials, several key factors must be considered:

| Factor | Description |

|---|---|

| Strength | The ability to withstand applied forces without failing. |

| Durability | Resistance to wear and tear over time, ensuring longevity. |

| Cost | Economic feasibility of materials, balancing quality and budget. |

| Weight | Influence on portability and ease of use. |

Impact on Performance

Choosing the right material not only enhances the physical characteristics of tools but also contributes to their operational efficiency. The right material can reduce maintenance needs and extend the tool’s life, ultimately leading to improved performance and user satisfaction. As technology evolves, innovations in material science continue to offer new possibilities for enhancing tool effectiveness.

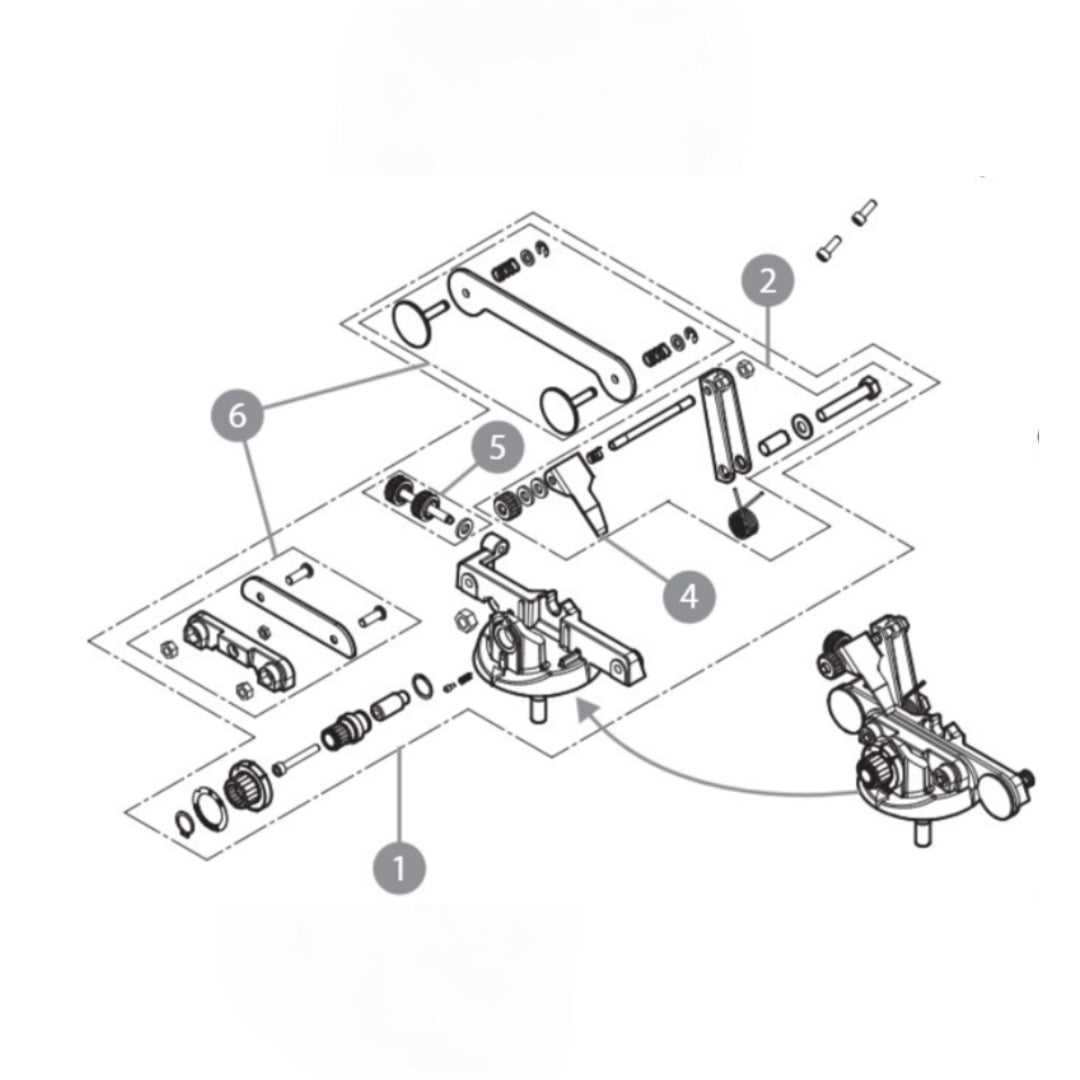

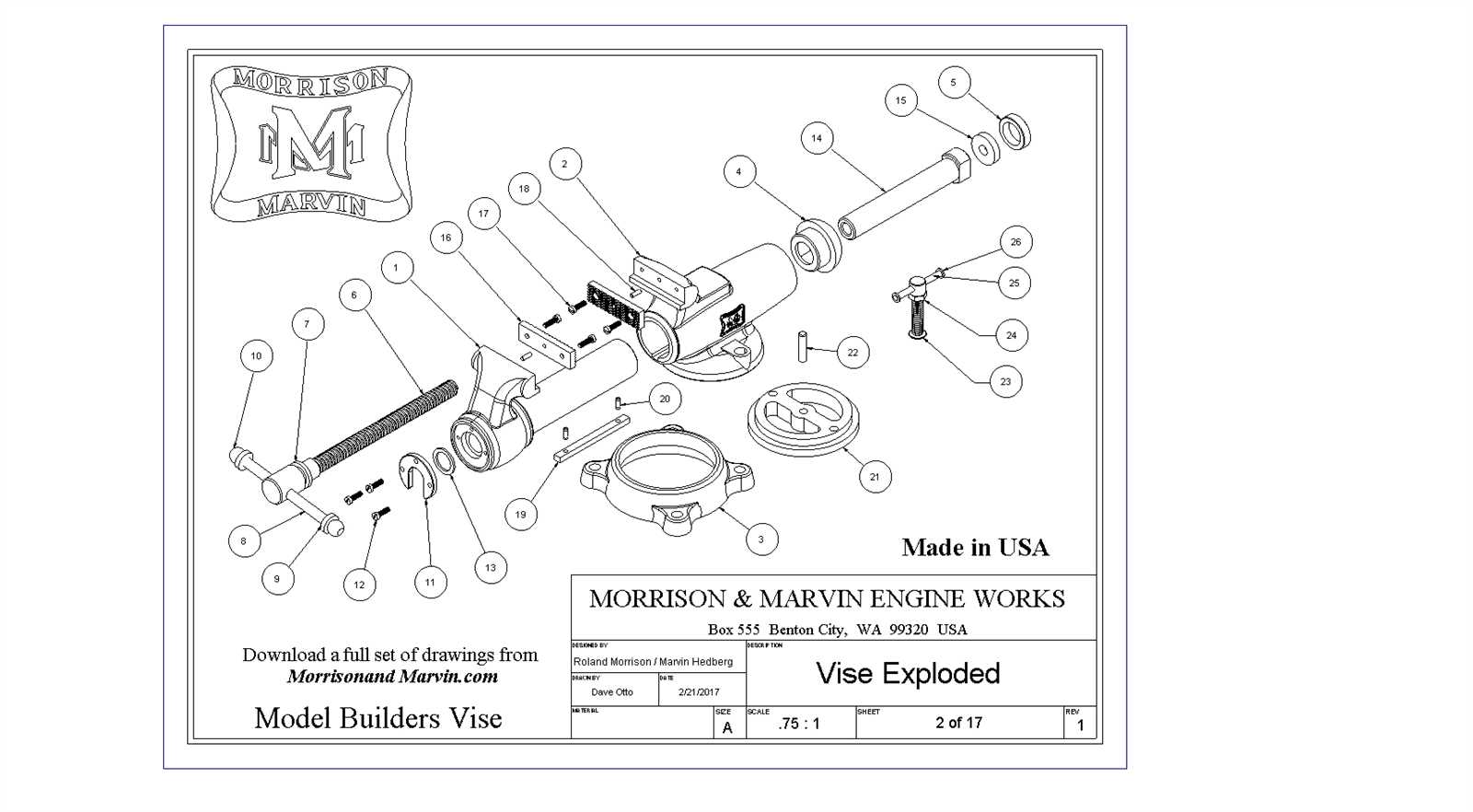

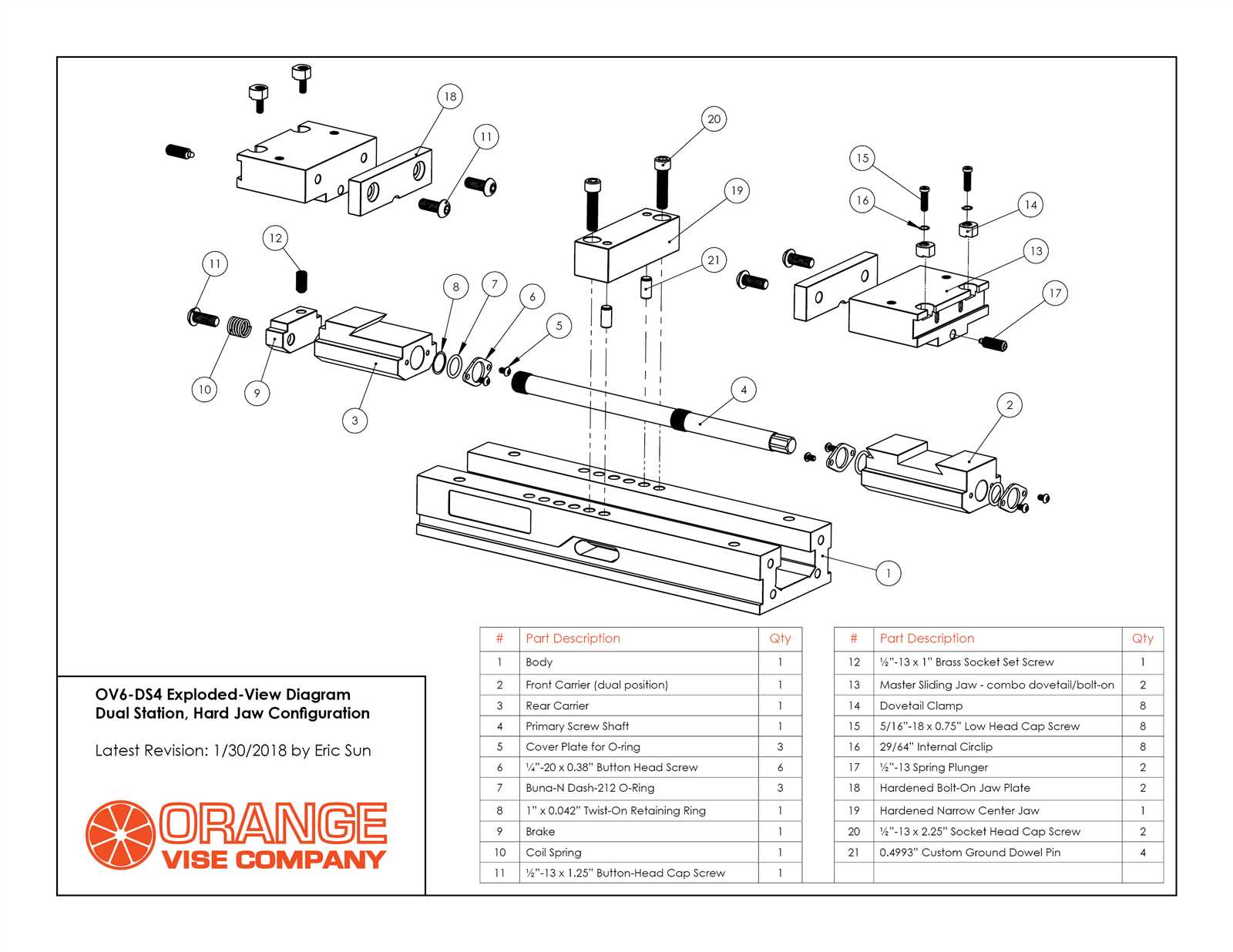

How to Read a Vise Diagram

Understanding the structure and functionality of mechanical tools can be simplified by analyzing detailed graphical representations. These diagrams provide a clear view of how various components work together, helping users identify key elements and their functions. By focusing on the layout and connections between individual sections, one can grasp the essential working principles of the tool, making it easier to assemble or repair.

Key Symbols and Labels

Diagrams often use specific symbols and labels to represent various parts and mechanisms. These symbols help to quickly identify specific areas of interest, and the accompanying labels provide further clarification. Paying attention to these visual cues ensures efficient navigation through the illustration.

Understanding Component Interactions

Each part of the tool is designed to work in conjunction with others. The diagram typically highlights the points of interaction between these components. By following the lines or arrows indicating movement or con

Common Bench Vise Configurations

Understanding the various designs used in clamping tools is essential for selecting the right model for specific tasks. Different mechanisms and features cater to a range of applications, providing flexibility and precision during work. In this section, we will explore popular configurations and their unique benefits.

Stationary Models

These types are fixed in place and offer robust stability, making them ideal for heavy-duty applications where minimal movement is required. Their solid construction ensures a firm hold during demanding tasks, offering reliable performance when precision and strength are priorities.

Swivel Variants

For situations where versatility is important, rotating versions come into play. Their ability to turn provides enhanced maneuverability, allowing users to adjust the workpiece position without the need to constantly reposition the tool itself. This flexibility makes them particularly useful in environments where multi-angle access is crucial.

Maintenance Tips for Longevity

Proper care and attention to your tools can significantly extend their lifespan, ensuring they continue to perform effectively over time. Regular upkeep is essential to prevent wear and tear, allowing your equipment to remain in optimal condition for years of use.

Regular Cleaning

Keeping your tool free of dirt, dust, and debris is crucial. A simple routine of wiping down surfaces after use and occasionally applying lubrication to moving components will reduce friction and prevent corrosion. Make sure to check for any trapped particles that could cause damage during operation.

Inspection and Adjustments

Periodically inspect all mechanical elements to identify any signs of deterioration. Tighten any loose fasteners and ensure that all parts are aligned correctly. This proactive approach can help avoid potential issues that may arise from prolonged use and ensure smooth functionality.

Upgrades for Enhanced Performance

Improving the functionality of your tool setup can significantly increase efficiency and precision during various tasks. By making targeted enhancements, users can achieve smoother operation, greater durability, and versatility, allowing them to handle a wider range of applications with ease.

Material Enhancements

- Opt for high-strength alloys or treated metals to improve wear resistance and extend the longevity of your equipment.

- Consider corrosion-resistant coatings to protect against environmental factors and maintain optimal performance over time.

Functional Add-Ons

- Install quick-release mechanisms for faster adjustments and greater convenience during repetitive tasks.

- Add precision control handles to improve fine-tuning and ensure better control over intricate projects.

Choosing the Right Bench Vise

When selecting a tool for securing workpieces during various tasks, it’s essential to consider several key factors to ensure optimal performance and safety. Different tools are designed for specific applications, and choosing the right one will significantly impact both efficiency and longevity.

- Material Quality: Look for durable construction materials, such as steel or cast iron, that can handle heavy-duty tasks without deforming or wearing out quickly.

- Size and Capacity: Consider the jaw width and opening range to ensure the tool fits the dimensions of the materials you plan to work with.

- Mounting Options: Evaluate the installation methods, such as bolt-down or clamp-based systems, depending on your workspace setup and the portability requirements.

- Swivel and Rotation: Some models offer full rotation or pivoting features, which enhance versatility by allowing access to different angles during use.

- Additional Features: Integrated pipe grips, anvil surfaces, or quick-release mechanisms can add extra functionality, making the tool more versatile and convenient for a range of tasks.

By carefully evaluating these factors, you can choose the tool that best meets your needs, ensuring both durability and ease of use in various applications.