The efficiency of cooling solutions relies on a variety of essential elements working in unison. In this section, we will explore the core elements that contribute to maintaining a refreshing environment in even the hottest conditions. This guide is designed to provide clear and practical insights into how these systems function, ensuring that each element plays its role in delivering optimal performance.

Familiarizing yourself with the key elements of any cooling system is critical for both maintenance and potential upgrades. Here, you will find a detailed breakdown of the most important elements, enabling a better understanding of how they interact. Whether you’re seeking to replace a specific element or improve overall functionality, this guide covers it all with clarity.

By exploring each component in detail, you’ll gain valuable knowledge that helps extend the lifespan of your equipment while enhancing its efficiency. Let’s dive into the specifics to ensure that you’re fully equipped with the knowledge necessary to keep your cooling solution performing at its best.

Understanding the System Components

To fully grasp how this cooling system operates, it’s essential to explore the various elements that contribute to its efficiency. Each component plays a critical role in ensuring optimal performance, from the circulation of air to the management of water flow. These elements work together seamlessly, providing a reliable cooling experience in a range of environments.

The system features a robust structure, built to withstand different conditions, while internal mechanisms ensure that air and water interact effectively. Understanding the function of each part will help users maintain and troubleshoot their cooling system effectively, ensuring long-lasting operation.

Airflow Management: One of the key aspects is how air moves through the unit. This is controlled by a fan mechanism designed to maximize the flow of cool air. Ensuring this part functions correctly is crucial for the overall efficiency of the system.

Water Circulation: The cooling process relies on proper water distribution. An integrated pump ensures that water flows consistently, providing the necessary moisture for effective temperature control. Regular checks of this component can prevent common issues such as clogging or reduced flow.

Cooling Pads: The core of the cooling process lies within the pads. These elements

Key elements for optimal cooling performance

Achieving the best cooling efficiency depends on various crucial factors that work together to enhance airflow and temperature reduction. These components must be correctly maintained and adjusted to ensure consistent and effective cooling across different environments.

Airflow management

Proper control of airflow is essential to maximizing cooling efficiency. This involves ensuring that air moves freely through the system, with minimal obstruction, allowing for uniform distribution of cool air across the area. Regular cleaning and adjustments of ventilation paths help maintain steady air circulation.

Water distribution

An evenly spread water supply plays a significant role in the cooling process. The system should maintain a consistent flow to ensure the cooling surfaces remain fully hydrated. Monitoring water levels and ensuring no blockages can prevent interruptions in the cooling cycle, preserving optimal performance.

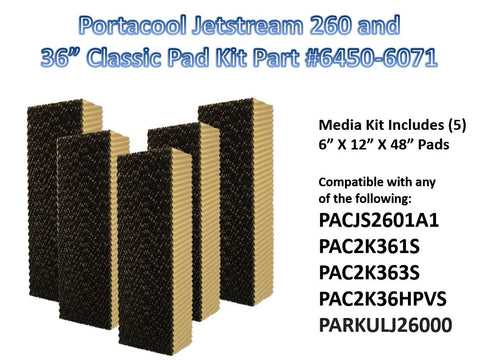

Identifying Essential Replacement Parts for Portacool

Understanding which components are critical for the operation of your cooling system ensures optimal performance and longevity. When maintaining these units, it is important to recognize which elements may require frequent replacement due to wear and tear or environmental factors. Regular inspection and proactive maintenance can prevent costly downtime and ensure continuous operation.

Key mechanical and functional elements often subjected to heavy use should be monitored closely. These include elements that influence airflow, moisture control, and temperature regulation. By identifying and addressing potential issues early, users can maintain efficiency and avoid unexpected breakdowns.

Guide to the most commonly needed replacements

Over time, various components of cooling systems require replacement to maintain optimal performance. Understanding which elements are most frequently subject to wear and tear can help users identify and address issues efficiently. This section highlights the most common items that may need to be swapped out and offers tips on selecting the correct alternatives.

Key Components

There are several elements that often experience the most stress and are prone to needing replacements. Regular maintenance and timely intervention can extend the lifespan of your unit. Below is a list of the most frequently addressed areas.

- Cooling pads: One of the first elements to show signs of aging, these should be replaced regularly to maintain effectiveness.

- Pumps: Responsible for water circulation, a malfunctioning pump can severely impact performance and should be monitored for any issues.

- Fans: As the driving force behind air movement, fans are essential for efficient operation and may require attention due to motor wear or debris buildup.

Replacement Frequency

Different components have varying lifespans, and knowing when to replace them can help avoid unexpected breakdowns. Regular inspections and understanding the usage patterns of your system are key factors in determining the need for replacements.

- Inspect cooling pads every few months, replacing them at least once per

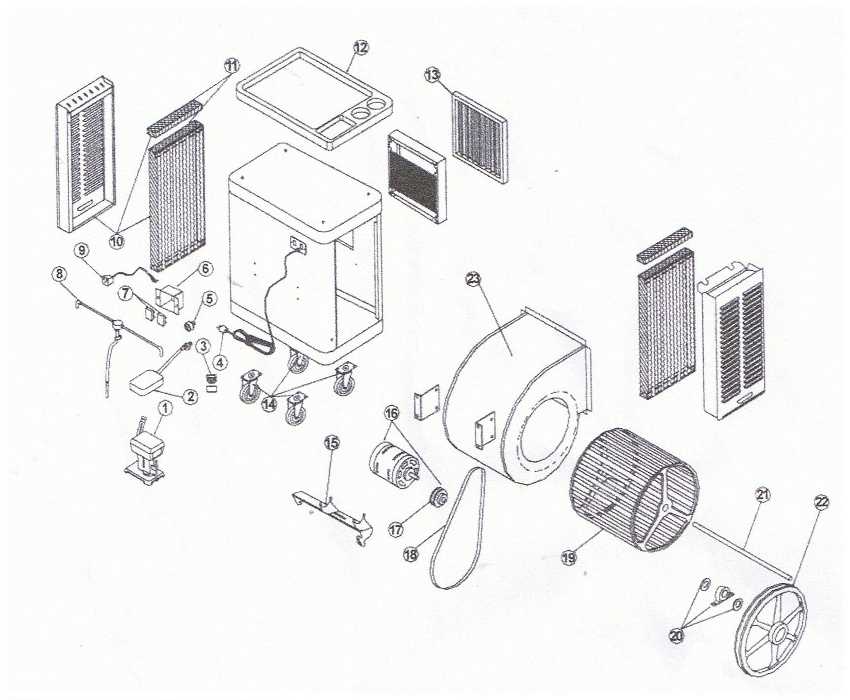

How to Read a Cooling Unit Component Blueprint

Understanding the layout of a cooling unit’s schematic is essential for identifying and locating individual elements. These visual guides provide a clear representation of how different components are arranged and connected, helping you to navigate the assembly or disassembly process more efficiently.

Key Symbols and Labels

The blueprint includes various symbols and labels that represent different elements. Each part is typically numbered or assigned a unique identifier, making it easier to cross-reference with a corresponding list or key. By familiarizing yourself with these symbols, you’ll be able to identify the necessary components quickly.

Locating Elements

When analyzing the schematic, pay attention to the arrangement of elements in relation to each other. This organization mirrors the actual structure, so understanding this layout will help you visualize the system’s construction and the position of each component. Study the flow of connections between different sections to understand how the system operates as a whole.

Symbol Description Function Circle Represents a specific component Identifies the location of a key element in the unit Step-by-step instructions for interpreting diagrams

Understanding visual representations of components can greatly enhance your ability to troubleshoot and maintain equipment. This section will guide you through the process of decoding these visual aids effectively, ensuring you can locate and identify each element with confidence.

1. Familiarize Yourself with the Symbols

Begin by examining the various symbols and icons used within the illustration. Each shape or line may represent a different function or part of the system. Take notes on any unfamiliar symbols, and refer to a legend if one is provided, as this will clarify their meanings.

2. Trace the Flow of Information

Next, follow the connections and pathways depicted in the representation. Pay close attention to how each component is linked, as this can reveal how the system operates as a whole. Understanding the flow can also help you identify potential areas of concern or maintenance needs.

Maintenance Tips for Portacool Equipment

Proper upkeep is essential to ensure the long-term functionality and efficiency of cooling units. Regular attention to critical components and following recommended practices can help to avoid unnecessary wear and costly repairs.

Cleaning the Filters

One of the most important maintenance tasks is to keep the filters free from debris. Dust and particles can accumulate quickly, reducing airflow and causing strain on the system. To maintain peak performance, it is advisable to clean or replace the filters regularly.

Inspecting Water Levels

Maintaining an adequate water supply is crucial for optimal cooling performance. Periodically check the water levels and ensure that the tank is filled to the required capacity. In addition, inspect for any leaks or blockages in the water supply line to prevent issues that could affect the cooling system’s efficiency.

Keep your cooling unit running smoothly

Maintaining optimal performance of your cooling system is essential for ensuring a comfortable environment. Regular upkeep not only prolongs the life of your equipment but also enhances its efficiency. By following a few simple practices, you can keep your unit functioning at its best throughout the hot months.

Essential Maintenance Practices

- Regular Cleaning: Dust and debris can accumulate in the unit, obstructing airflow. Make it a habit to clean the exterior and interior components regularly.

- Inspect Filters: Air filters play a crucial role in the efficiency of your system. Check them monthly and replace or clean them as necessary to ensure optimal airflow.

- Check Water Levels: Ensure that the water reservoir is filled to the appropriate level. Insufficient water can lead to inefficient cooling and potential damage.

Troubleshooting Common Issues

- Unit Not Cooling: If your system isn’t providing adequate cooling, check for blockages in the airflow paths and ensure the water supply is sufficient.

- Noisy Operation: Unusual sounds may indicate loose components or debris within the unit. Inspect the internal parts and tighten any loose connections.

- Frequent Shutdowns: If the system shuts off unexpectedly, it may be overheating. Ensure that air intake is unobstructed and that the filters are clean.

Choosing the Right Parts for Your Portacool

Selecting the appropriate components for your cooling system is essential to ensure optimal performance and longevity. Understanding the various elements involved allows you to make informed decisions that enhance efficiency and reliability. Whether you are upgrading existing equipment or replacing worn-out elements, it is crucial to consider compatibility, quality, and functionality.

Begin by evaluating the specifications of your cooling unit, including airflow capacity and power requirements. This assessment will help you identify which elements are necessary for maintaining the desired cooling performance. Always opt for high-quality replacements to avoid future malfunctions and ensure that your system runs smoothly.

Additionally, consider the environment in which your unit will operate. Factors such as humidity and temperature can affect the performance of different components, making it vital to choose those that are suited to your specific needs. Proper maintenance and timely replacements will not only prolong the life of your cooling equipment but also contribute to overall energy efficiency.

Factors to consider when ordering replacements

When seeking new components for your cooling equipment, it’s crucial to evaluate several key aspects to ensure optimal performance and compatibility. Making informed decisions can enhance efficiency and prolong the lifespan of your system.

Compatibility

- Verify that the selected components match the specifications of your existing system.

- Check model numbers and compatibility information to avoid any mismatches.

- Consult the manufacturer’s guidelines to ensure proper fit and function.

Quality and Warranty

- Opt for high-quality replacements to ensure reliability and durability.

- Inquire about warranties and return policies to protect your investment.

- Read reviews or seek recommendations to gauge the reputation of the supplier.

By taking these factors into account, you can make more informed choices when acquiring new components for your cooling system.