The effective dismantling of sensitive materials relies on a sophisticated assembly of mechanisms working in harmony. Each element plays a crucial role in ensuring optimal functionality and security, making it essential to comprehend their interconnections.

Exploring these intricate mechanisms not only enhances user experience but also promotes informed decision-making regarding maintenance and upgrades. Familiarity with the various functionalities can ultimately lead to improved efficiency and longevity.

In this section, we will delve into the individual elements that comprise this crucial device. By understanding how each segment operates, users can better appreciate the complexity and importance of these systems in safeguarding information.

Understanding Paper Shredder Components

To effectively grasp the functionality of document-destroying machines, it’s essential to explore their individual elements. Each component plays a crucial role in ensuring the efficiency and reliability of the device, contributing to its overall performance and user experience.

The primary element responsible for the actual disintegration of materials is the cutting mechanism. This system is typically comprised of sharp blades designed to slice through sheets with precision. Complementing this is the motor, which provides the necessary power to drive the cutting mechanism, ensuring smooth operation during usage.

An integral feature of these devices is the feed system, which facilitates the introduction of documents into the machine. This system may include various designs, from manual feed slots to automatic feeds, enhancing convenience and efficiency for users. Additionally, safety features such as sensors help prevent mishaps, ensuring the device operates safely and effectively.

The collection bin serves as the final destination for the shredded material, allowing for easy disposal. Some models may offer transparent bins to monitor the fill level, while others include automatic shut-off mechanisms that activate when the container reaches capacity, preventing overflow.

Understanding these components provides insight into the overall design and functionality of document destruction machines, highlighting the importance of each element in achieving secure and efficient document disposal.

Common Types of Shredders Explained

In the realm of document destruction, various devices cater to distinct needs and preferences. Understanding the characteristics of these machines can help users select the right one for their specific requirements. From security levels to operational capacities, each type serves a unique purpose, making it essential to explore their features.

Cross-Cut Models

Cross-cut machines are designed to enhance security by transforming sheets into small confetti-like pieces. This level of destruction is ideal for sensitive information, ensuring that data cannot be reconstructed easily. The design often allows for a higher capacity, making these units suitable for both personal and office use.

Strip-Cut Models

Strip-cut variants operate differently, cutting documents into long, narrow strips. While they are generally faster and more affordable, the security they provide is lower compared to their cross-cut counterparts. These are typically best for non-sensitive materials or for users who require less stringent privacy measures.

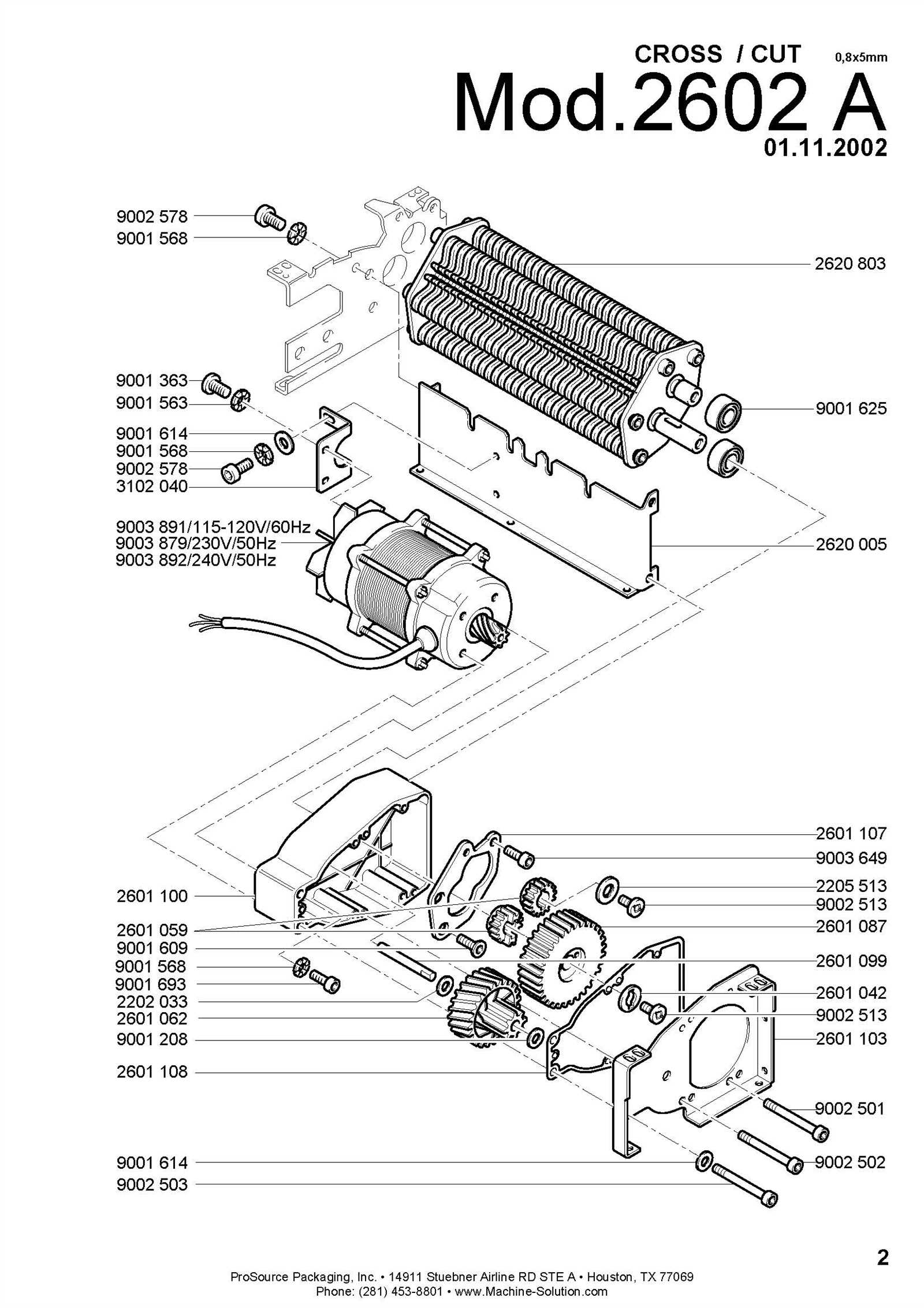

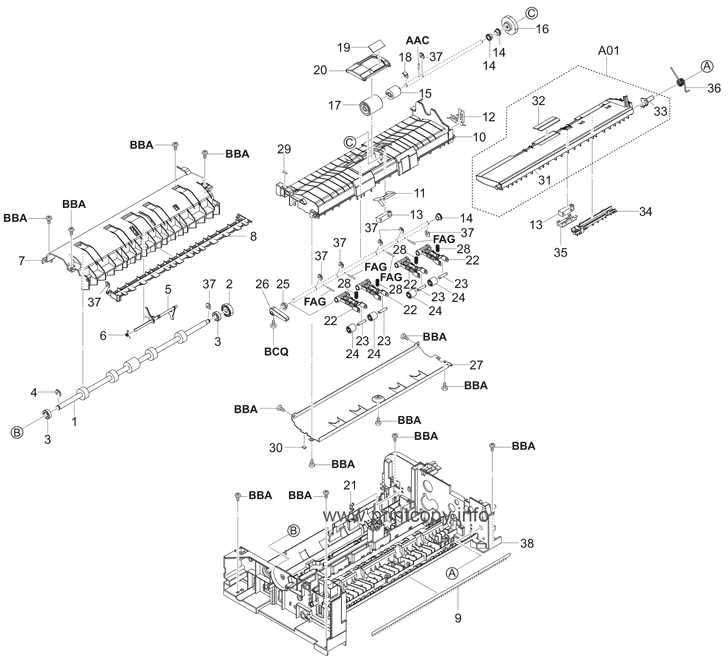

Key Parts of a Shredder Machine

Understanding the essential components of a cutting device is crucial for effective operation and maintenance. Each element plays a significant role in ensuring efficiency and longevity, contributing to the overall functionality of the machine. Familiarity with these elements enhances user experience and troubleshooting skills.

Cutting Mechanism: This is the core of the machine, where the actual slicing occurs. Typically made of hardened steel, it is designed to handle various materials with precision, providing clean and effective results.

Feed Entry: This area allows users to introduce items into the device. Its design often includes safety features to prevent jams and ensure smooth operation, minimizing the risk of accidents during use.

Motor: The power source that drives the cutting mechanism. A robust motor ensures consistent performance and durability, allowing the device to operate seamlessly even under heavy workloads.

Collection Bin: This component collects the shredded material, facilitating easy disposal. Designed for convenience, it often includes features such as indicators to signal when it needs emptying.

Control Panel: The interface for users, where settings can be adjusted. It typically includes buttons for power, speed control, and other operational modes, providing flexibility based on the user’s needs.

Safety Features: These elements are designed to protect users and the machine itself. Common safety measures include automatic shut-off systems and reverse functions to prevent jams, ensuring safe and efficient operation.

Functionality of Cutting Mechanisms

The cutting systems employed in various devices serve a crucial role in ensuring efficient destruction of materials. Their design and operation influence the effectiveness and speed of the process, which can vary based on intended use and target material characteristics.

Types of Cutting Mechanisms

Different mechanisms provide unique benefits tailored to specific tasks. Understanding these variations can help in selecting the most suitable option for various needs.

| Type | Functionality | Advantages |

|---|---|---|

| Rotary Blades | Continuous rotation for uniform cutting | High speed and efficiency |

| Cross-Cut Blades | Diagonal cutting for finer results | Increased security and smaller pieces |

| Strip-Cut Blades | Straight cuts into long strips | Simplicity and faster operation |

Impact on Performance

The design of these mechanisms directly impacts the ultimate efficiency and safety of the operation. Selecting the right system enhances the overall user experience and ensures optimal results in material handling.

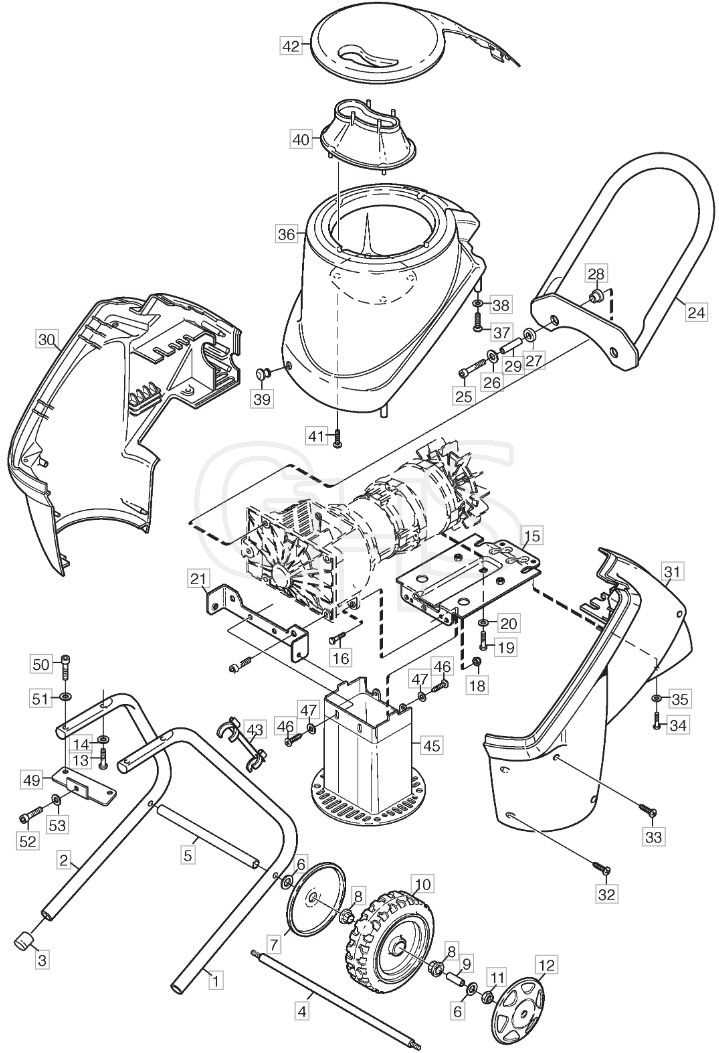

Importance of Waste Collection Bins

Effective waste management is crucial for maintaining a clean and safe environment. Properly designed receptacles play a significant role in ensuring that discarded materials are collected efficiently, preventing littering and promoting recycling efforts.

Convenience is one of the primary benefits of having designated collection units. By providing accessible locations for disposal, individuals are more likely to discard their waste responsibly rather than leave it on the ground. This practice helps keep public spaces tidy and reduces the risk of pollution.

Moreover, organized waste collection contributes to better resource management. When materials are sorted and contained, it becomes easier to identify which items can be recycled or reused. This process not only conserves natural resources but also minimizes the environmental impact of waste.

Additionally, the presence of these units can foster a sense of community responsibility. When residents see that efforts are being made to maintain cleanliness, they are more inclined to participate in keeping their surroundings pristine. This collective action leads to a healthier and more sustainable living environment.

In summary, the implementation of dedicated disposal units is essential for encouraging responsible waste handling, promoting recycling, and nurturing a culture of environmental stewardship.

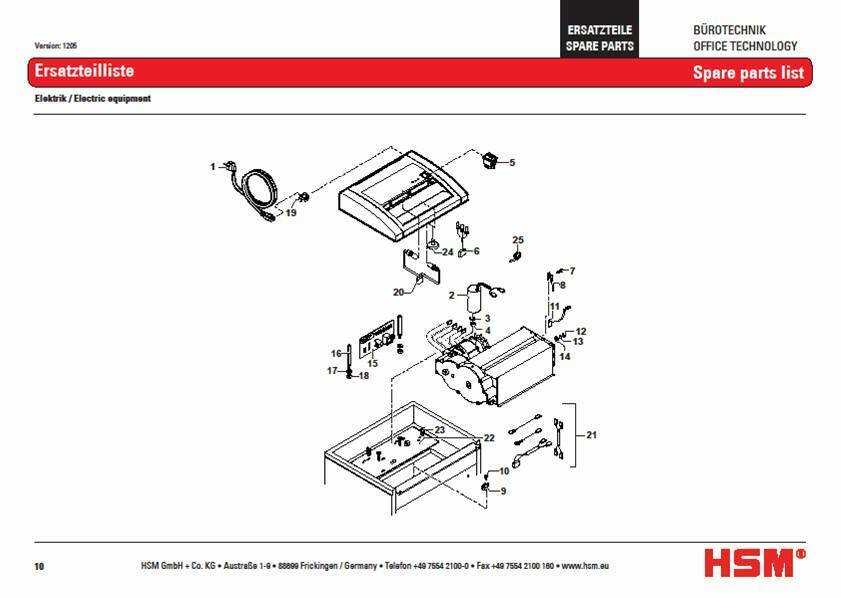

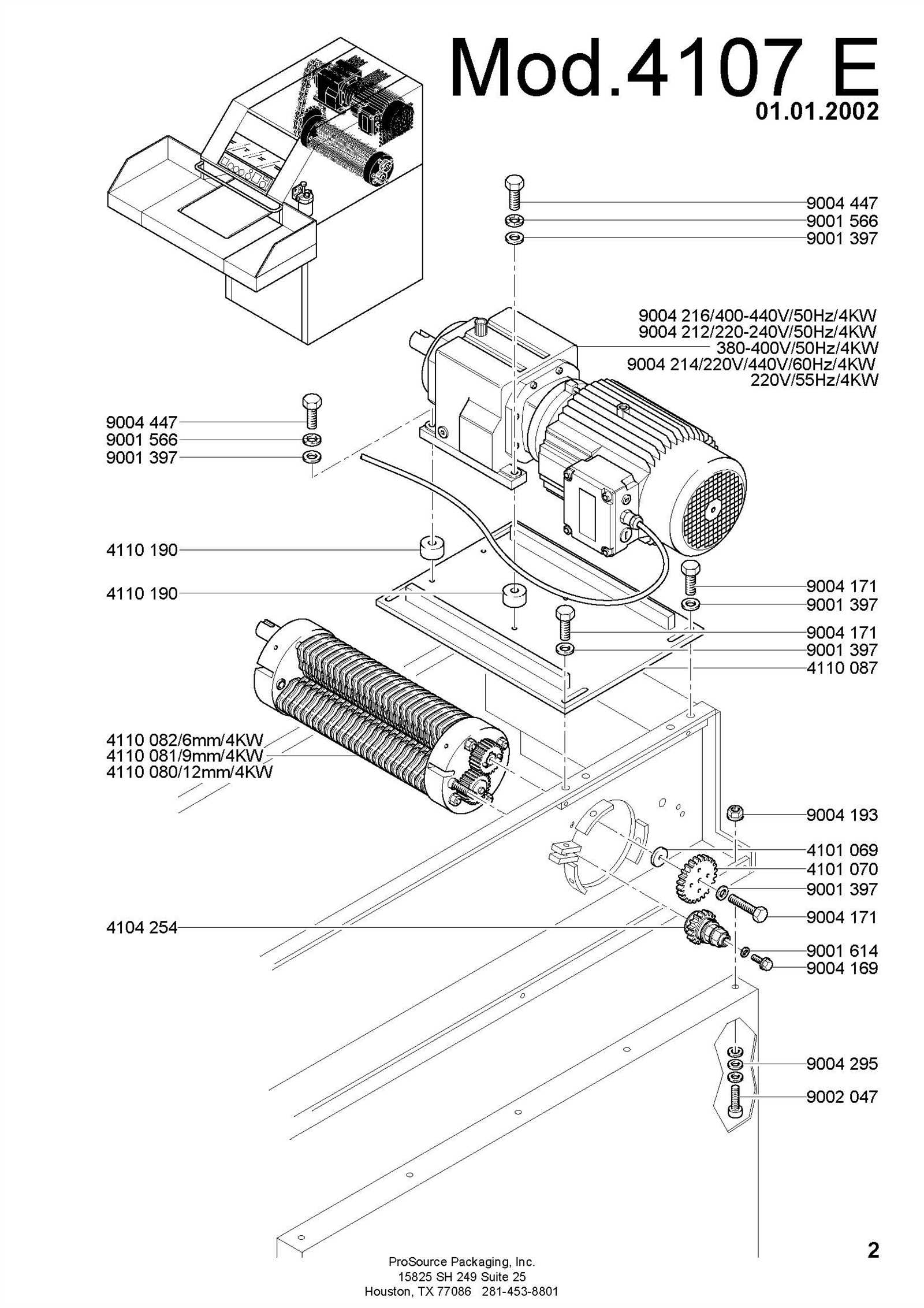

Motor Specifications and Performance

This section explores the key attributes and operational efficiency of the drive mechanism that powers the cutting mechanism. Understanding these specifications is essential for assessing performance and ensuring effective functionality in various applications.

Key Specifications

| Specification | Details |

|---|---|

| Power Rating | 200-300 Watts |

| Voltage | 120/240 Volts |

| Speed | 3000-5000 RPM |

| Torque | High Torque for Efficient Operation |

Performance Metrics

Evaluating the efficiency of the motor involves considering factors such as noise levels, heat generation, and durability. High-performance motors are designed to operate with minimal noise while maintaining a steady output, contributing to a reliable and user-friendly experience.

Safety Features in Shredder Design

Ensuring user safety is a paramount consideration in the design of modern document destruction devices. Manufacturers implement various innovative mechanisms to minimize risks during operation, providing peace of mind to users and protecting against accidents.

Automatic Shut-Off Mechanisms

One of the key safety features is the automatic shut-off mechanism. This function detects when foreign objects are introduced or when the device is overloaded, instantly halting operation to prevent potential damage and injuries. This proactive approach helps maintain a safe environment while extending the lifespan of the equipment.

User-Friendly Controls

Additionally, user-friendly controls play a vital role in safety. Many devices incorporate intuitive buttons and clear indicators, reducing the likelihood of user error. Safety locks are also common, ensuring that the machinery cannot be activated accidentally, especially in environments where children may be present.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life of any machinery. By following a few key practices, users can enhance performance and minimize the likelihood of malfunctions. Regular care not only boosts efficiency but also protects the investment made in these devices.

Regular Cleaning

Consistent cleaning is crucial for preventing the buildup of debris and residue. Utilize a soft brush or cloth to remove any remnants that may accumulate in the internal components. This practice helps maintain optimal functionality and reduces wear on the equipment over time.

Lubrication and Inspection

Periodic lubrication of moving elements is vital for smooth operation. Use manufacturer-recommended lubricants to ensure compatibility and effectiveness. Additionally, routinely inspect the machinery for any signs of damage or wear, addressing issues promptly to avoid more significant problems in the future.

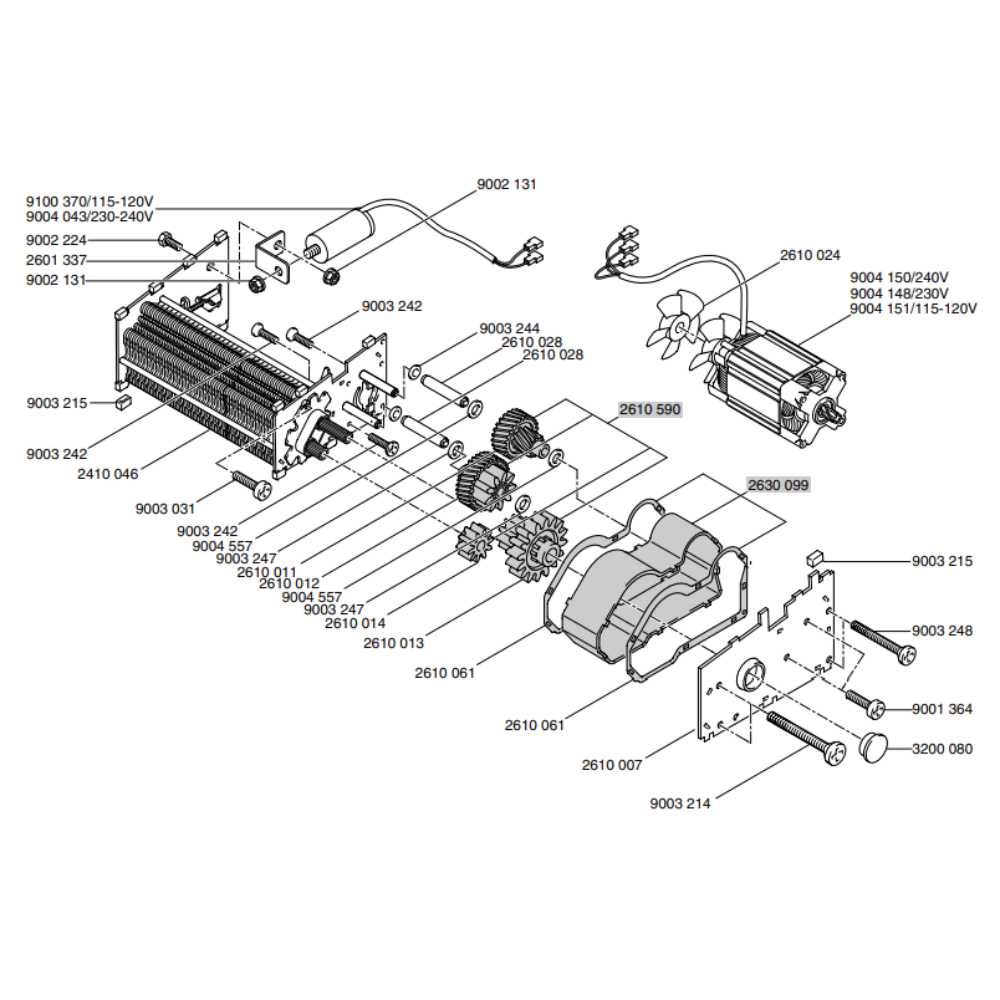

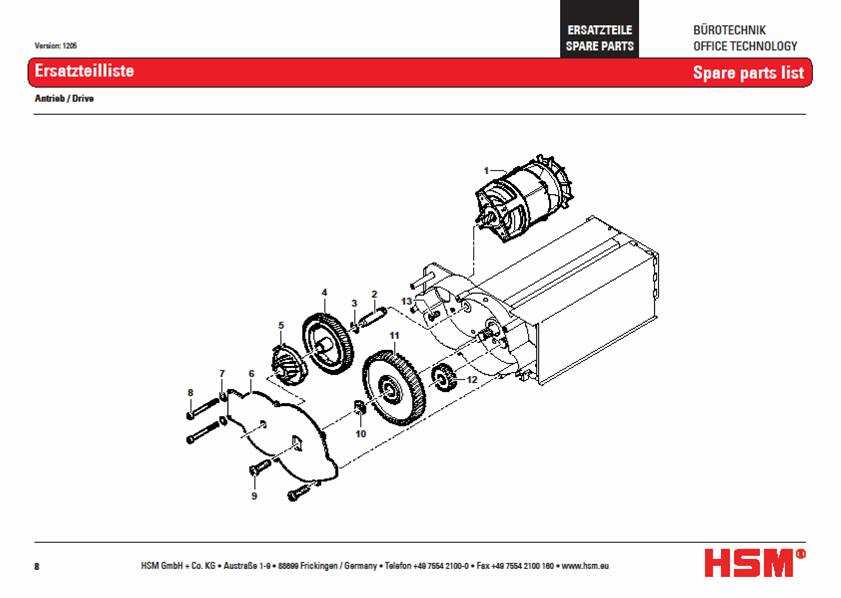

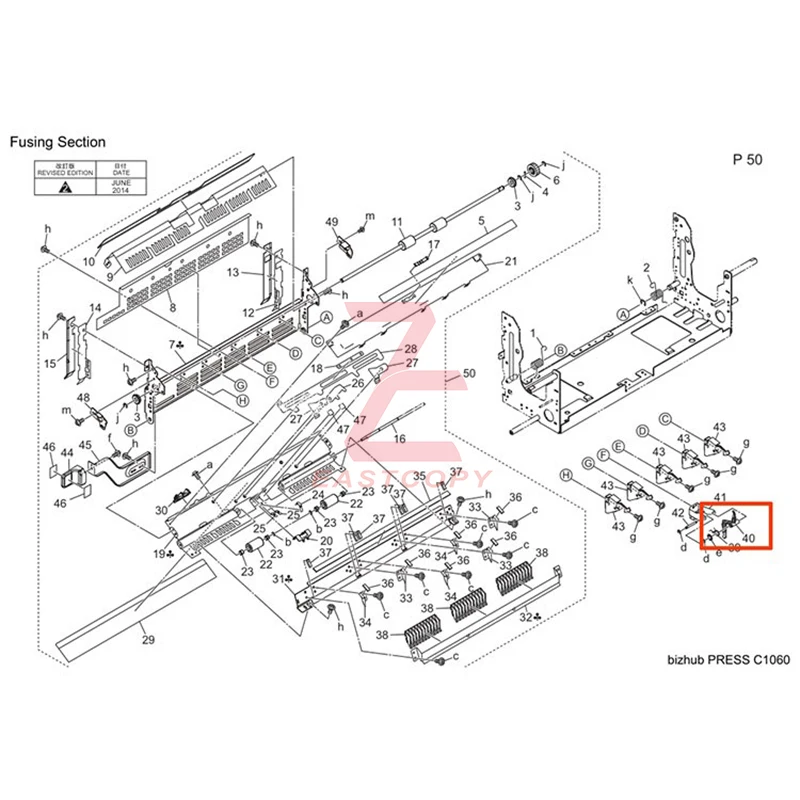

Identifying Replacement Parts Easily

Understanding the components of your device can streamline the process of finding suitable substitutes when needed. By familiarizing yourself with the various elements, you can quickly identify what requires replacement and seek out the correct options. This approach not only saves time but also ensures compatibility, enhancing overall efficiency.

Utilizing visual aids can significantly aid in this process. Diagrams or labeled images serve as valuable resources, allowing you to pinpoint the specific sections that may need attention. By comparing your findings with available models, you can make informed decisions about replacements, ensuring optimal performance.

Moreover, consulting user manuals or online resources dedicated to your device can provide insights into common issues and the corresponding solutions. Engaging with community forums may also reveal tips from other users who have navigated similar challenges, enriching your understanding and approach.