In the realm of machinery, a comprehensive understanding of how various elements interact is essential for effective maintenance and repair. Knowing the configuration of each component allows users to troubleshoot issues with precision and confidence.

This guide delves into the intricate relationships between different parts, offering insights into their arrangement and functionality. By familiarizing yourself with this layout, you equip yourself with the knowledge necessary to ensure optimal performance.

Whether you are a seasoned technician or a curious enthusiast, grasping these concepts can significantly enhance your problem-solving capabilities. Embrace the challenge of understanding the ultimate composition of your equipment for a more efficient experience.

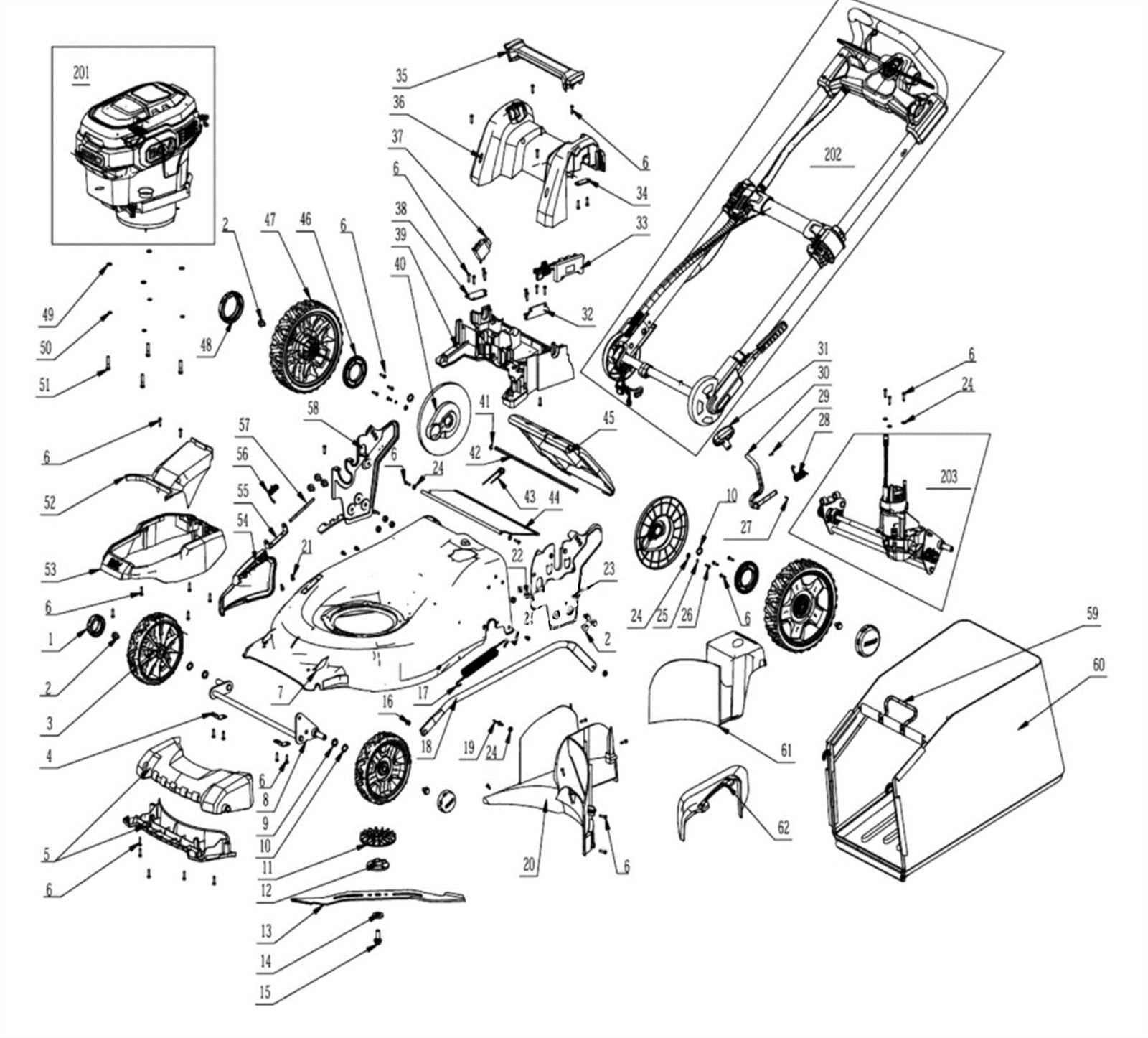

Understanding Hrr216vka Components

This section delves into the essential elements of the model, highlighting their roles and interconnections. A comprehensive understanding of these components is vital for effective maintenance and optimal performance. Each part contributes uniquely to the overall functionality, ensuring seamless operation.

Key Elements and Their Functions

In any mechanical system, specific components serve distinct purposes. Familiarizing yourself with these functions can enhance your ability to troubleshoot and repair. Here are some of the primary elements:

| Component | Function |

|---|---|

| Engine | Drives the overall mechanism, providing necessary power. |

| Blade | Responsible for cutting, ensuring precision and efficiency. |

| Chassis | Supports all other parts, offering stability and structure. |

| Control System | Manages operations and allows user input for desired settings. |

Maintaining Optimal Performance

To ensure longevity and reliability, regular inspection and maintenance of these components are crucial. Understanding how each part interacts allows for more effective diagnostics and repairs, ultimately enhancing the lifespan of the entire system.

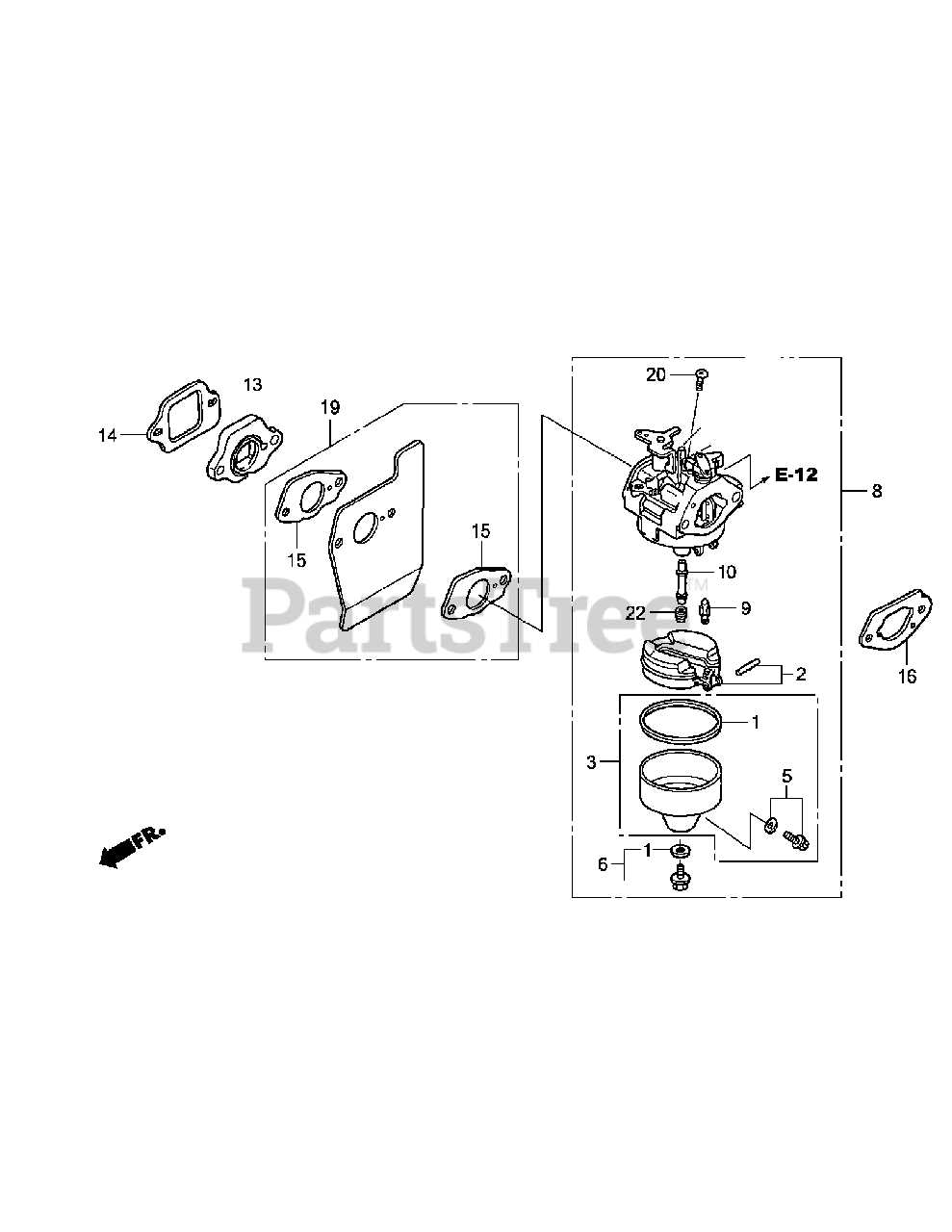

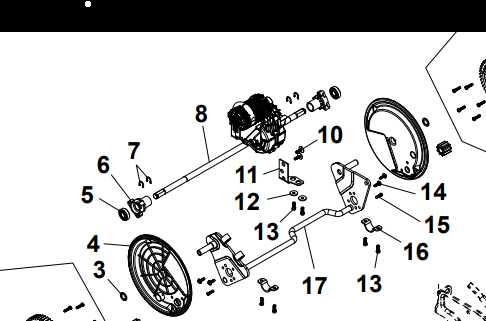

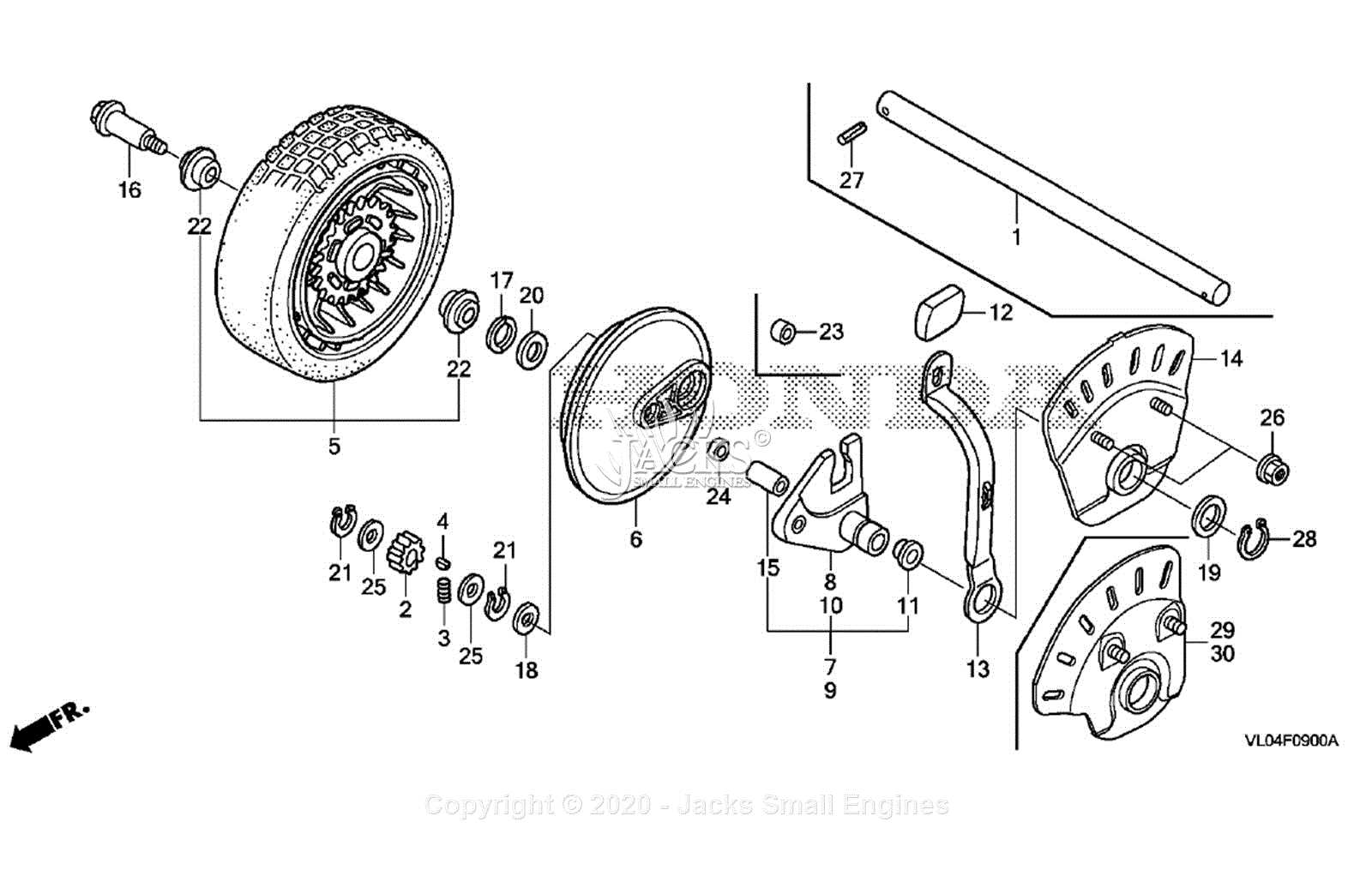

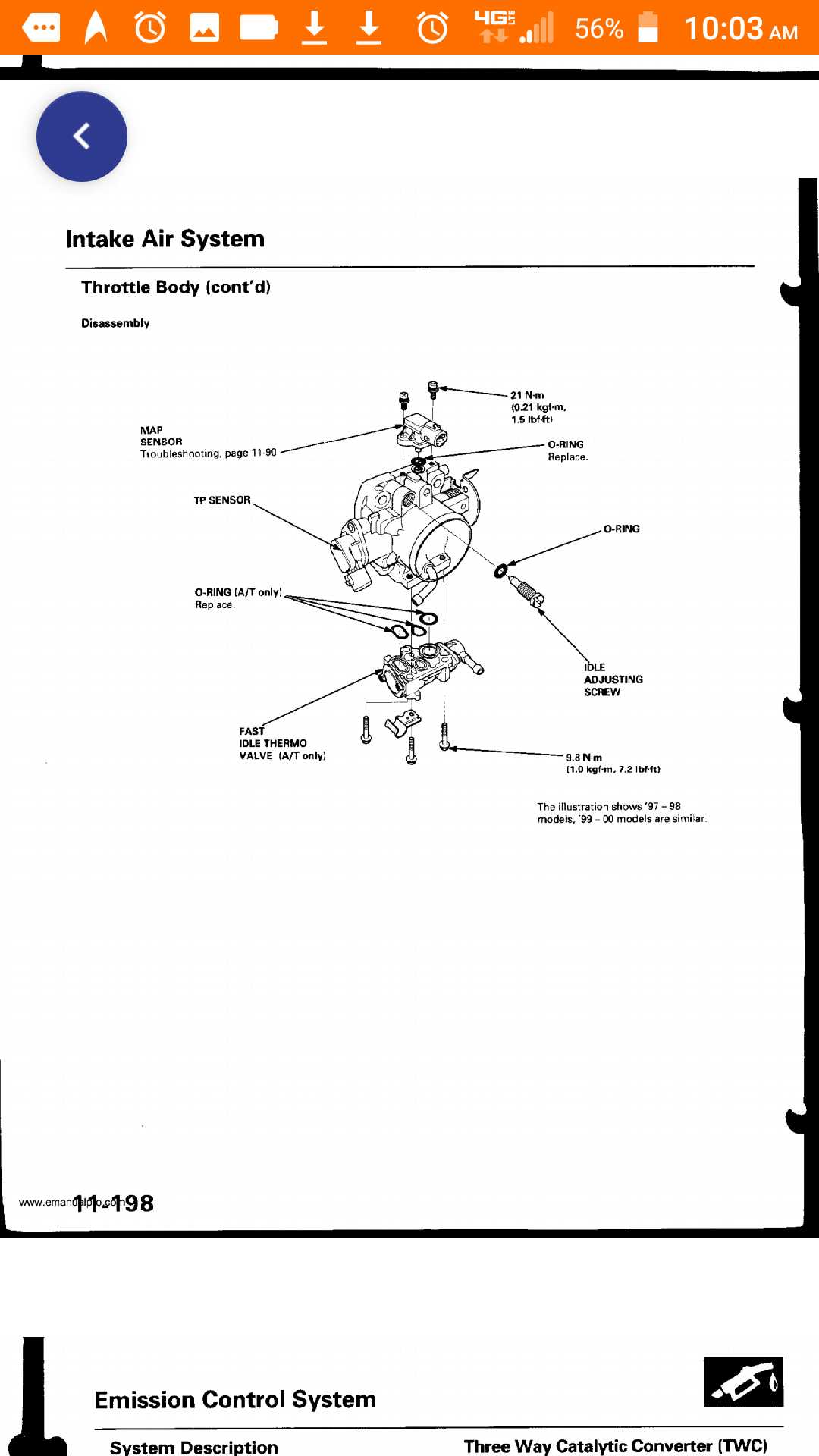

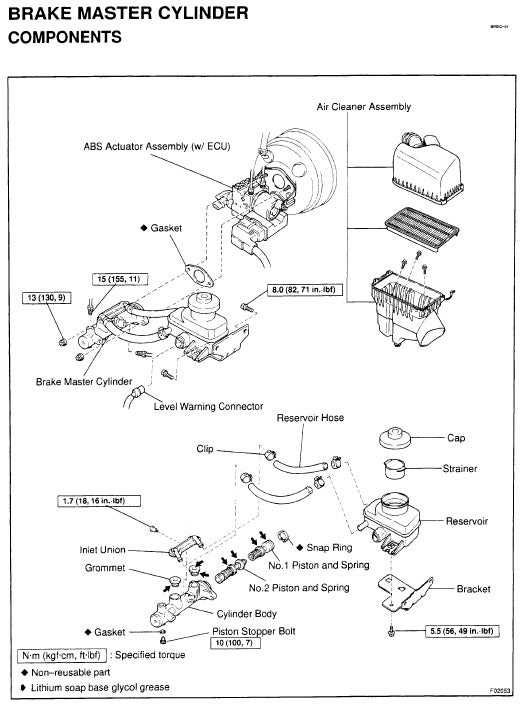

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding complex systems. They enable users to identify individual elements and their relationships, facilitating efficient repairs and maintenance.

These illustrations serve multiple purposes, including enhancing communication among technicians and providing clarity for troubleshooting. Without them, the intricacies of assembly and disassembly can lead to confusion and errors.

| Benefits | Description |

|---|---|

| Clarity | Helps users grasp the arrangement and function of components. |

| Efficiency | Speeds up repair processes by providing clear reference points. |

| Training | Acts as a valuable educational tool for new technicians. |

Common Issues with Hrr216vka Parts

Understanding the frequent complications that can arise with equipment components is essential for effective maintenance. By identifying these issues early, users can ensure optimal performance and longevity of their machinery.

Wear and Tear

One of the most prevalent concerns involves degradation due to regular use. Components may experience fatigue, leading to reduced efficiency and potential failure. Regular inspection can mitigate these risks.

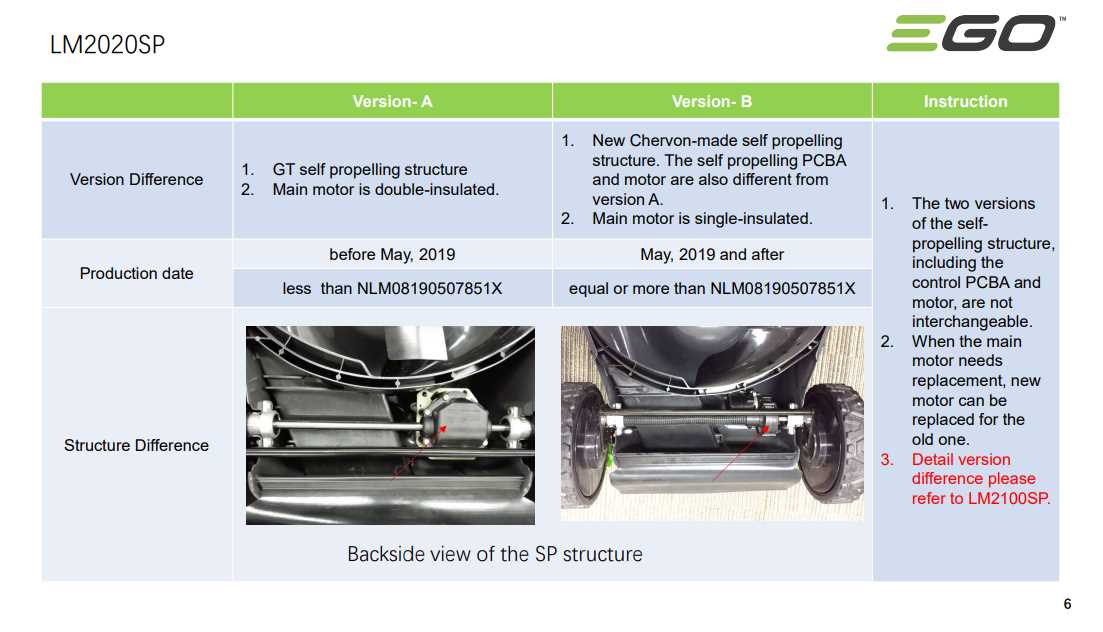

Compatibility Problems

Another common challenge arises from using non-original replacements. Mismatched pieces can cause operational inconsistencies and even damage. It is crucial to ensure all components meet the specified standards for seamless functionality.

How to Read a Parts Diagram

Understanding a visual representation of components is essential for effective maintenance and repairs. These illustrations provide a clear layout of various elements, helping users identify each part’s function and location within the assembly.

Identifying Components

Begin by familiarizing yourself with the symbols and labels used in the illustration. Each item is typically numbered or marked, corresponding to a list that details specifications or replacement information. Pay close attention to the layout, as it reveals how each piece interacts with others.

Interpreting Connections

Look for lines or arrows indicating relationships between elements. These connections often show how parts fit together or highlight crucial links that affect functionality. Understanding these relationships will ultimately enhance your ability to troubleshoot issues effectively.

Where to Find Accurate Diagrams

When seeking precise visual representations of mechanical components, it’s essential to know where to turn for reliable resources. Whether for repair, maintenance, or assembly, accessing the right materials can greatly enhance your understanding and efficiency. Several avenues exist to locate trustworthy illustrations that detail the intricacies of machinery.

Online Resources are among the most convenient options. Websites dedicated to machinery often host extensive libraries of schematics. Look for platforms that are well-reviewed and widely recognized in the industry to ensure accuracy.

Manufacturer Websites frequently provide comprehensive guides and illustrations. Many companies offer downloadable resources directly on their sites, ensuring that you receive the most up-to-date and relevant information.

User Forums and communities can also be invaluable. Enthusiasts and professionals alike often share their own findings and experiences. Engaging with these communities can lead you to lesser-known but reliable sources.

Technical Manuals are another excellent option. These documents, which may be available in print or digital format, often contain detailed visual aids that are essential for understanding the relationships between different components.

By exploring these various sources, you can find the accurate representations needed for any mechanical task, ensuring you are well-prepared and informed.

Essential Tools for Hrr216vka Maintenance

Proper upkeep of your equipment requires specific tools that facilitate efficient servicing and repairs. Having the right instruments at hand not only simplifies tasks but also ensures that maintenance is performed correctly, enhancing the longevity and performance of your machinery.

Basic Tools

The foundation of any maintenance toolkit consists of essential hand tools that are versatile and reliable. These tools help tackle a variety of tasks, from simple adjustments to more complex repairs.

| Tool | Purpose |

|---|---|

| Screwdrivers | For loosening and tightening screws on various components. |

| Wrenches | To adjust bolts and nuts securely. |

| Pliers | For gripping, twisting, and cutting wires or small parts. |

| Socket Set | To provide a variety of sizes for more efficient fastening. |

Specialized Equipment

In addition to basic tools, having specialized equipment can significantly enhance your maintenance capabilities. These instruments are designed for specific tasks, making them invaluable for more intricate procedures.

| Equipment | Function |

|---|---|

| Torque Wrench | To ensure bolts are tightened to the manufacturer’s specifications. |

| Multimeter | For diagnosing electrical issues and testing connections. |

| Oil Filter Wrench | To easily remove and replace oil filters during servicing. |

| Cleaning Brushes | For maintaining cleanliness and preventing buildup on components. |

Replacing Worn-Out Components

Maintaining the efficiency of machinery requires regular attention to its individual elements. Over time, certain parts may degrade, leading to reduced performance and potential failures. Identifying and replacing these worn components is crucial for optimal operation and longevity.

To effectively manage replacements, consider the following steps:

- Assessment: Regularly inspect the machine to identify signs of wear, such as unusual noises, decreased efficiency, or physical damage.

- Documentation: Keep a detailed record of the condition of each element, noting when replacements are necessary. This will help in planning maintenance schedules.

- Selection: Choose high-quality substitutes that meet or exceed the original specifications. This ensures compatibility and performance.

- Installation: Follow proper procedures for removing old parts and installing new ones. This often requires specific tools and techniques to avoid further damage.

- Testing: After replacement, conduct tests to verify that the machine operates smoothly and efficiently. Monitor performance closely during the initial usage period.

By systematically addressing the replacement of worn components, you can enhance the reliability and functionality of your equipment, ultimately reducing downtime and repair costs.

Tips for Effective Repairs

Successfully addressing mechanical issues requires careful planning and execution. By understanding the components involved and applying effective techniques, you can ensure a smooth repair process and prolong the life of your equipment. Here are some practical suggestions to help you navigate your repair tasks efficiently.

1. Gather the Right Tools

Before starting any repair work, ensure you have all necessary tools on hand. Using the correct instruments not only speeds up the process but also minimizes the risk of damage to the device. Make a checklist of the tools required and verify their condition prior to beginning your project.

2. Follow a Step-by-Step Approach

Taking a methodical approach can significantly enhance your repair efforts. Document each step you take and avoid skipping any phases, as this can lead to mistakes or oversights. Break down the repair into manageable tasks, and focus on one section at a time to maintain clarity and organization.

Upgrading Your Hrr216vka Parts

Improving the components of your lawn maintenance equipment can significantly enhance its performance and longevity. Whether you’re seeking better efficiency or aiming for a smoother operation, various upgrades can make a noticeable difference. This section will explore some effective modifications that can elevate your machine’s capabilities.

Key Upgrades to Consider

When thinking about enhancements, several critical areas deserve attention. Upgrading specific elements not only boosts functionality but can also lead to a more enjoyable user experience. Below are some popular enhancements you might want to explore:

| Component | Upgrade Option | Benefits |

|---|---|---|

| Engine | High-performance air filter | Improved airflow and efficiency |

| Blades | High-lift blades | Better grass cutting and bagging |

| Wheels | All-terrain tires | Enhanced traction on varied surfaces |

| Deck | Reinforced material | Increased durability and resistance |

Maintenance Considerations

Upgrading components is only part of the equation; regular maintenance is essential to ensure optimal performance. Keeping your equipment clean and well-lubricated will maximize the benefits of any modifications. Additionally, regularly inspecting for wear and tear will help you maintain peak efficiency throughout the season.