In the realm of mechanical systems, a thorough comprehension of the individual elements that contribute to overall functionality is essential. This knowledge empowers operators and technicians to diagnose issues effectively and ensure optimal performance. Visual representations play a crucial role in this understanding, providing clarity and insight into the intricate relationships among various components.

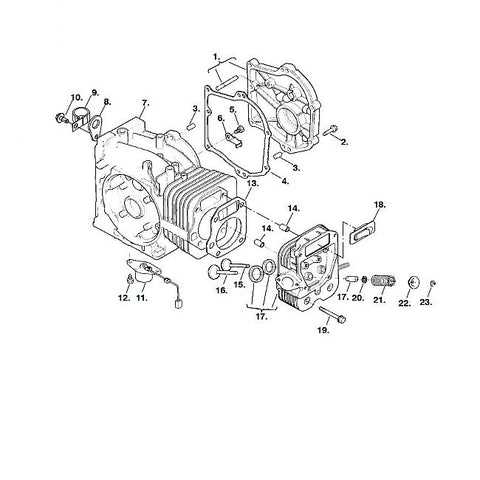

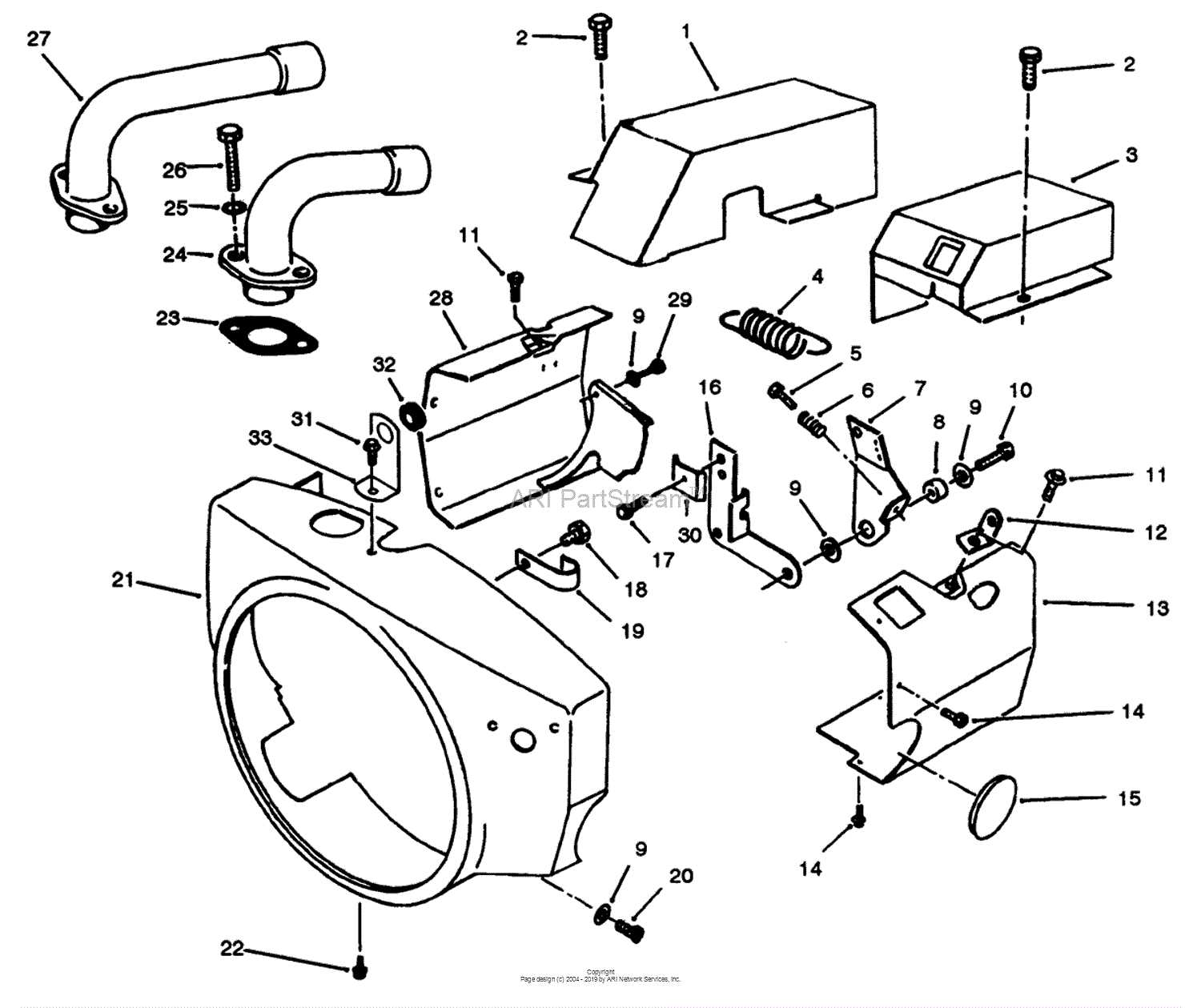

When examining the configuration of a specific power unit, it’s important to recognize how each section interacts within the larger framework. An accurate illustration serves not only as a reference guide but also as a tool for troubleshooting and maintenance. By dissecting the assembly into its fundamental units, users can identify potential points of failure and implement corrective measures swiftly.

Furthermore, a detailed visual guide enhances learning opportunities for both seasoned professionals and newcomers alike. It fosters a deeper appreciation for the engineering principles at play and encourages an analytical approach to machine upkeep. Thus, exploring the layout of vital components is not merely an academic exercise but a practical necessity in ensuring reliability and efficiency in operational environments.

Understanding Onan Engine Components

Grasping the various elements that comprise a power generator is essential for effective operation and maintenance. Each component plays a pivotal role in ensuring optimal performance, and understanding their functions can enhance both efficiency and longevity. This section delves into the intricate network of these crucial elements, shedding light on their interrelationships and individual responsibilities.

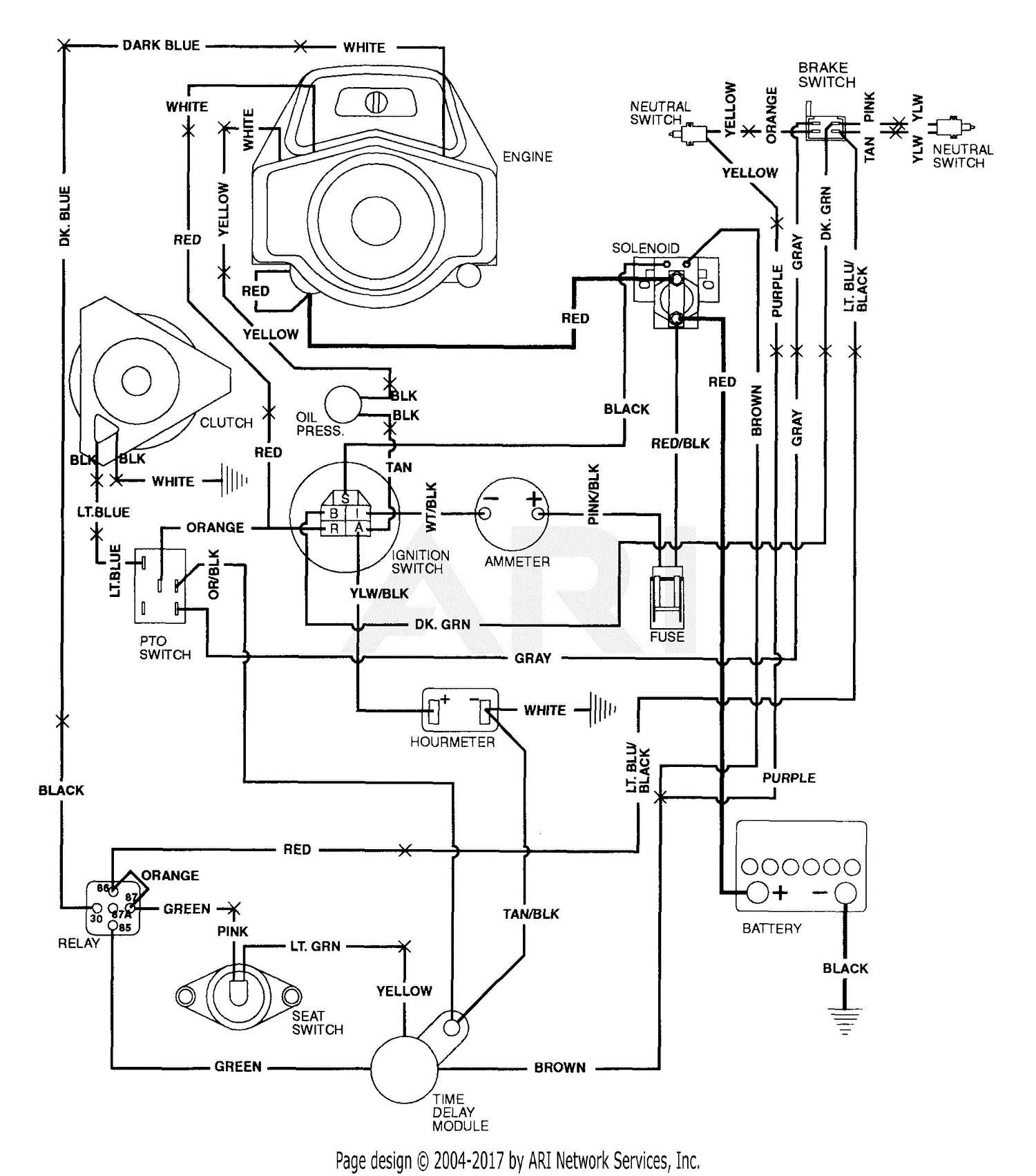

The primary function of the central mechanism is to convert fuel into usable energy, which is facilitated by several auxiliary components. These include systems for air intake, combustion, and exhaust, all designed to optimize the overall process. Additionally, components responsible for lubrication and cooling are vital in preventing overheating and ensuring smooth operation.

Furthermore, the electrical systems within this setup are essential for converting mechanical energy into electrical power. Understanding the wiring, sensors, and control units is critical for troubleshooting and maintenance. Each element, from the starter to the alternator, contributes to the seamless operation of the entire system, highlighting the importance of a comprehensive understanding of their functions and interactions.

In summary, familiarizing oneself with the various components of a power generator not only aids in effective management but also empowers users to tackle maintenance issues proactively. A thorough knowledge of how these elements work together ensures that the machine operates efficiently and reliably.

Overview of Onan Engine Parts

This section delves into the essential components that contribute to the efficient functioning of power-generating machinery. Understanding these elements is crucial for maintenance, repair, and optimal performance.

Key Components

Each individual unit plays a significant role in the overall system. From the core operational units to the auxiliary features, each piece is engineered for specific functions, ensuring reliability and efficiency.

| Component | Function |

|---|---|

| Crankshaft | Converts linear motion into rotational motion |

| Piston | Moves within the cylinder to create pressure |

| Cylinder Head | Houses the combustion chamber and valves |

| Fuel System | Delivers the necessary fuel for combustion |

| Cooling System | Maintains optimal operating temperature |

Maintenance Tips

Regular inspection and servicing of each element are vital to prolonging the lifespan and enhancing performance. Keeping components clean and ensuring proper lubrication can prevent common issues and ensure smooth operation.

Importance of Accurate Diagrams

Precise representations play a crucial role in the comprehension and maintenance of complex machinery. They serve as essential tools for technicians and engineers, offering a clear visual guide that enhances understanding and minimizes errors. When details are accurately depicted, the likelihood of mistakes during assembly or repair significantly decreases, leading to increased efficiency and reliability.

Benefits of Clarity

Clear illustrations contribute to effective communication among team members. They facilitate collaboration by providing a common reference point, ensuring everyone is on the same page. This clarity is vital in training new personnel, as it enables them to grasp intricate systems quickly and effectively.

Impact on Maintenance and Troubleshooting

Well-crafted visual aids streamline the troubleshooting process. By highlighting specific components and their functions, these resources enable technicians to diagnose issues swiftly, reducing downtime and associated costs. Inaccurate or vague representations can lead to confusion, potentially exacerbating problems rather than solving them.

| Aspect | Impact of Accuracy |

|---|---|

| Understanding | Enhances clarity and comprehension |

| Collaboration | Fosters teamwork and effective communication |

| Efficiency | Reduces errors and improves workflow |

| Troubleshooting | Facilitates quick diagnosis and repair |

Common Onan Engine Models Explained

This section offers insights into widely used models from a renowned brand, highlighting their unique features and applications. Understanding these variations can help users choose the right option for their specific needs.

Popular Models

- Model A: Known for its reliability and efficiency in various settings.

- Model B: Offers enhanced performance, ideal for demanding tasks.

- Model C: A compact choice, perfect for limited spaces without sacrificing power.

Key Features

- Durability: Designed to withstand challenging conditions.

- Fuel Efficiency: Engineered to maximize fuel usage, reducing operational costs.

- Maintenance: Simplified service requirements for user convenience.

Identifying Key Engine Elements

Understanding the fundamental components of a mechanical system is essential for effective maintenance and troubleshooting. Each element plays a crucial role in the overall functionality, and recognizing them can significantly enhance your ability to diagnose issues and optimize performance.

Main Components

- Crankshaft

- Pistons

- Camshaft

- Valves

- Fuel Injectors

Each of these components interacts harmoniously to convert fuel into mechanical energy, driving the entire system. Familiarizing yourself with their arrangement and function will lead to better decision-making during repairs or upgrades.

Functional Roles

- Crankshaft: Converts linear motion of pistons into rotational motion.

- Pistons: Move up and down within the cylinders, compressing the fuel-air mixture.

- Camshaft: Controls the timing of valve openings and closings.

- Valves: Regulate the intake of air and fuel as well as the exhaust of combustion gases.

- Fuel Injectors: Deliver the precise amount of fuel into the combustion chamber for efficient combustion.

By studying these critical elements, you will gain valuable insights into how they work together, enabling you to maintain and enhance the system’s overall efficiency.

Maintenance Tips for Onan Engines

Proper care is essential for the longevity and efficiency of your machinery. Regular attention to key areas can prevent issues and enhance performance over time.

- Check oil levels frequently and change as recommended.

- Inspect filters regularly for dirt and replace as necessary.

- Keep cooling systems clean to avoid overheating.

- Examine belts and hoses for signs of wear or damage.

- Clean air intake to ensure optimal airflow.

By following these guidelines, you can maintain the ultimate functionality of your equipment and extend its lifespan significantly.

Where to Find Quality Diagrams

Locating high-quality visual references can significantly enhance your understanding and maintenance of various machinery. Whether you are a professional or a hobbyist, having access to clear and detailed illustrations is crucial for effective troubleshooting and repair. Here are some reliable sources where you can find these valuable resources.

| Source | Description |

|---|---|

| Manufacturer Websites | Official sites often provide technical manuals and detailed visual aids tailored to specific models. |

| Online Forums | Community-driven platforms can offer shared resources and diagrams created by experienced users. |

| Specialized Retailers | Many online stores selling machinery may include documentation and illustrations for their products. |

| Technical Libraries | Academic institutions often maintain archives that include maintenance guides and technical visuals. |

| YouTube Tutorials | Video guides frequently show parts and assemblies, providing a visual context that can enhance understanding. |

DIY Repairs: Using Engine Diagrams

When tackling maintenance tasks on machinery, having a clear visual reference can significantly enhance the repair process. Understanding how different components interact allows for more effective troubleshooting and replacement, empowering individuals to undertake repairs with confidence.

Utilizing visual guides can streamline the identification of components, making it easier to pinpoint issues and apply the correct solutions. These references are particularly valuable for those venturing into hands-on repairs for the first time or for seasoned enthusiasts looking to refresh their knowledge.

| Benefits | Description |

|---|---|

| Improved Understanding | Visual aids help clarify the relationship between various components. |

| Efficient Troubleshooting | Quickly identify potential problems by referencing visual guides. |

| Increased Confidence | Gain assurance in performing repairs with detailed illustrations. |

| Time Savings | Streamlined processes can lead to quicker and more effective repairs. |

In conclusion, leveraging visual references during maintenance work not only aids in the understanding of machinery but also enhances the overall repair experience. Embracing these resources can transform daunting tasks into manageable projects, making DIY repairs accessible to everyone.

Troubleshooting Common Engine Issues

Identifying and resolving frequent mechanical problems is essential for optimal performance. This section explores typical symptoms and solutions, enabling users to address challenges effectively.

Common Symptoms

| Symptom | Possible Causes | Solutions |

|---|---|---|

| Difficulty starting | Battery issues, fuel blockage | Check battery connections and fuel flow |

| Overheating | Coolant leaks, clogged radiator | Inspect hoses and flush the cooling system |

| Unusual noises | Loose components, wear | Tighten fasteners and check for damage |

Preventative Measures

Regular maintenance and inspections can significantly reduce the likelihood of issues. Routine checks of fluids, filters, and belts help ensure longevity and reliability.