The efficiency of any kitchen tool often hinges on the seamless interplay of its individual elements. A comprehensive grasp of these components not only enhances operational understanding but also aids in troubleshooting and maintenance. This knowledge is invaluable for both culinary professionals and home cooks alike.

In exploring the intricate assembly of this specific food preparation apparatus, one can appreciate how each section contributes to overall functionality. The relationship between these various pieces plays a crucial role in ensuring optimal performance and longevity. Familiarity with these mechanisms empowers users to make informed decisions regarding care and usage.

By delving into the configuration and arrangement of these crucial components, one can uncover insights that lead to more effective handling and maintenance practices. An in-depth understanding fosters a more confident approach to utilizing such equipment, ultimately enhancing the culinary experience.

Understanding Globe G12 Slicer Components

This section aims to explore the essential elements that contribute to the functionality of a specific food processing machine. Each component plays a pivotal role in ensuring efficiency, safety, and precision during operation. By delving into the various parts, users can gain a clearer understanding of how these pieces work together to achieve ultimate performance.

One of the key components is the motor, which drives the entire mechanism, allowing for seamless slicing of various food items. This part must be powerful and reliable to ensure consistent results.

Another crucial element is the blade assembly, which is designed to provide sharp and clean cuts. The quality of the blade directly impacts the efficiency and safety of the machine.

The feed tray serves to hold and guide the food items into the blade area, facilitating smooth operation. Proper alignment of this component is vital for achieving desired thickness and uniformity.

In addition, the base structure provides stability and support, allowing the machine to endure frequent use without compromising performance. Durability in this aspect ensures long-lasting service life.

Understanding these various components helps users make informed decisions regarding maintenance and usage, ultimately leading to enhanced performance and safety.

Importance of Slicer Maintenance

Regular upkeep of your food preparation equipment is essential for optimal performance and safety. Neglecting maintenance can lead to inefficiencies and potential hazards, impacting both quality and productivity.

- Efficiency: Well-maintained machines operate more smoothly, reducing the risk of jams and malfunctions.

- Longevity: Routine care extends the lifespan of your equipment, saving costs on replacements.

- Safety: Proper maintenance minimizes risks of accidents caused by malfunctioning machinery.

- Quality: Regular checks ensure consistent slicing precision, maintaining the integrity of food products.

In summary, prioritizing maintenance practices is vital for achieving peak performance and ensuring a safe working environment.

Common Issues with G12 Slicers

In the world of food preparation, various challenges can arise when using certain machines designed for cutting. Understanding these frequent problems is essential for maintaining efficiency and ensuring longevity. Identifying these issues early can prevent operational downtime and enhance user experience.

One prevalent concern is uneven cutting, which can stem from dull blades or misalignment. This not only affects presentation but can also impact portion control. Regular maintenance and timely blade replacements are crucial to mitigate this issue.

Another common challenge is the buildup of residue, which can lead to performance degradation. Food particles and grease accumulation may hinder operation, making it essential to implement routine cleaning protocols to keep equipment in optimal condition.

Lastly, electrical malfunctions may occur, often due to wear and tear or improper usage. Monitoring power connections and ensuring that components are intact can help avert these potentially costly disruptions.

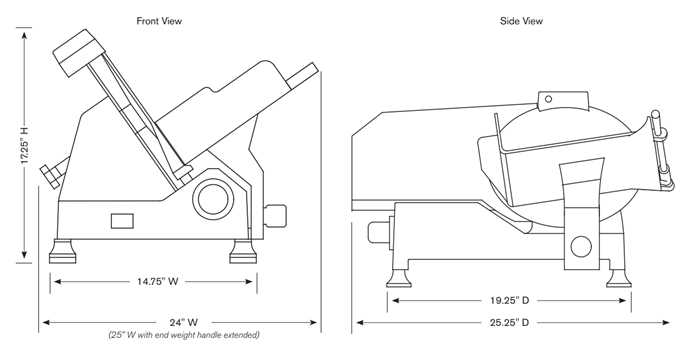

Identifying Key Parts in Diagrams

Understanding the essential components in visual representations is crucial for effective analysis and functionality. Recognizing these elements allows users to grasp the overall structure and operation, enhancing comprehension and performance in practical applications.

Importance of Component Recognition

Identifying critical elements in schematics not only facilitates maintenance but also aids in troubleshooting. Knowledge of each section empowers users to make informed decisions and implement necessary adjustments efficiently.

Common Elements to Note

| Element | Description |

|---|---|

| Base | The foundational structure supporting all other components. |

| Blade | The cutting edge responsible for slicing through materials. |

| Control Mechanism | Devices used to operate and adjust the machine. |

| Safety Guard | A protective feature ensuring user safety during operation. |

Step-by-Step Assembly Process

Ensuring a seamless setup involves following a clear and precise sequence of actions. This section provides a detailed guide on how to align and connect each segment of the device, guaranteeing optimal performance and efficiency.

Initial Preparations

Before beginning the assembly, gather all required components and tools. Carefully inspect each piece for any defects to ensure they are in proper working condition. This preparation helps streamline the process and prevents issues during later stages.

Component Alignment and Integration

The process involves systematically aligning each unit in the correct order. Begin by securing the base elements, then proceed to attach the mechanical and control sections. Follow the instructions precisely to achieve a stable and functional configuration.

| Step | Description |

|---|---|

| 1 | Position the foundation piece on a flat surface. |

| 2 | Attach the structural components using the provided connectors. |

| 3 | Integrate the control units, ensuring all connections are secure. |

| 4 | Check the alignment and stability of the assembled

Tools Required for RepairsWhen undertaking equipment maintenance, it’s essential to have the appropriate tools at hand. Having the right set of instruments ensures a smooth process, minimizing the time and effort required for adjustments and replacements. Basic Hand ToolsA selection of screwdrivers, pliers, and adjustable wrenches is often necessary for most repair tasks. These fundamental tools help with loosening and tightening components, allowing precise handling during the repair work. Specialized Instruments

Depending on the complexity of the task, more specific tools like torque wrenches or Allen keys may be required. These instruments are designed to provide accuracy, ensuring that all connections are secure without the risk of overtightening. Upgrading Globe Slicer PartsEnhancing the performance and durability of your kitchen equipment often involves selecting the right components for replacement or improvement. Understanding the upgrade process is key to ensuring that your appliance runs efficiently and meets your needs in a commercial or home setting. Identifying Areas for EnhancementBefore making any modifications, it’s essential to pinpoint which elements of the machine require updates or improvements. Focusing on the most frequently used sections will help maximize efficiency and extend the overall lifespan of the device. Prioritize components that directly impact precision and ease of use. Selecting Compatible Components

When choosing enhancements, compatibility is crucial to ensure a seamless integration with the existing setup. Opt for high-quality materials and modern designs to elevate the equipment’s functionality. This approach not only boosts performance but also reduces the frequency of maintenance and replacements. Safety Precautions When OperatingUnderstanding the necessary precautions is essential to ensure a safe working environment when handling this type of equipment. Following these guidelines can help prevent accidents and maintain the machine’s functionality.

By adhering to these practices, users can operate the equipment with greater confidence and safety, minimizing the chance of mishaps or malfunctions. Finding Replacement Parts OnlineLocating the right components for your equipment can be challenging, but numerous online resources simplify the process. Understanding where and how to search is crucial to ensure you obtain the correct items for repair or maintenance. Identifying Reliable SuppliersWhen searching for replacement elements, focus on reputable suppliers with a history of quality service. Reading customer reviews and checking product ratings can help determine which retailers offer durable and reliable items. Prioritizing suppliers with clear return policies and customer support ensures a smooth purchasing experience. Comparing Prices and Availability

Comparing prices across different platforms is essential for finding the best deals. While some online stores may offer competitive pricing, others might have exclusive items or faster shipping options. Balancing cost with availability and delivery speed will help you make an informed decision and avoid delays in restoring your equipment’s functionality. |