In the realm of farming equipment, comprehending the intricate layout and function of various elements is crucial for efficient operation and maintenance. Whether one is a seasoned farmer or a novice, having a clear understanding of how these machines work can significantly enhance productivity and prolong the lifespan of the equipment.

Detailed visual representations serve as invaluable resources, allowing operators to identify specific components and understand their interrelationships. Such resources facilitate troubleshooting and repairs, ensuring that machinery operates at optimal levels. By examining these illustrations, users can better appreciate the complexity and engineering behind their essential agricultural tools.

Moreover, familiarity with the structure of machinery can empower users to make informed decisions when it comes to upgrades or replacements. This knowledge not only aids in maintaining the functionality of equipment but also fosters a deeper connection to the tools that are integral to modern farming practices.

In the world of agricultural machinery, several challenges can arise that impact efficiency and functionality. Understanding these issues can aid in proper maintenance and enhance overall performance. Below are some prevalent concerns faced by operators regarding their equipment.

Wear and Tear

Over time, components experience degradation due to constant use. This can lead to:

- Reduced cutting efficiency

- Increased fuel consumption

- Frequent breakdowns

Alignment Problems

Improper alignment can result in a range of operational difficulties, including:

- Uneven cutting

- Excessive vibration

- Premature wear on components

Addressing these common issues promptly can significantly extend the lifespan of the machinery and ensure optimal performance during critical harvest periods.

Maintenance Tips for Optimal Performance

To ensure that your equipment operates efficiently and reliably, regular upkeep is essential. Proper maintenance practices can significantly enhance performance and prolong the lifespan of your machinery. By following a systematic approach, you can address potential issues before they escalate, ensuring smooth operation during critical tasks.

Here are some valuable maintenance suggestions to consider:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 100 hours | Replace oil to prevent engine wear and ensure smooth operation. |

| Filter Inspection | Every 50 hours | Check air and oil filters for clogs and replace as necessary to maintain optimal airflow. |

| Belts and Hoses | Every 200 hours | Inspect for wear and tear; replace frayed belts and cracked hoses to avoid breakdowns. |

| Greasing | Weekly | Lubricate moving parts to reduce friction and prevent premature wear. |

| Tire Pressure Check | Before each use | Ensure proper tire inflation for improved traction and fuel efficiency. |

Implementing these maintenance tasks will not only enhance efficiency but also minimize unexpected repairs. Adopting a proactive maintenance strategy is vital for optimal performance and longevity of your machinery.

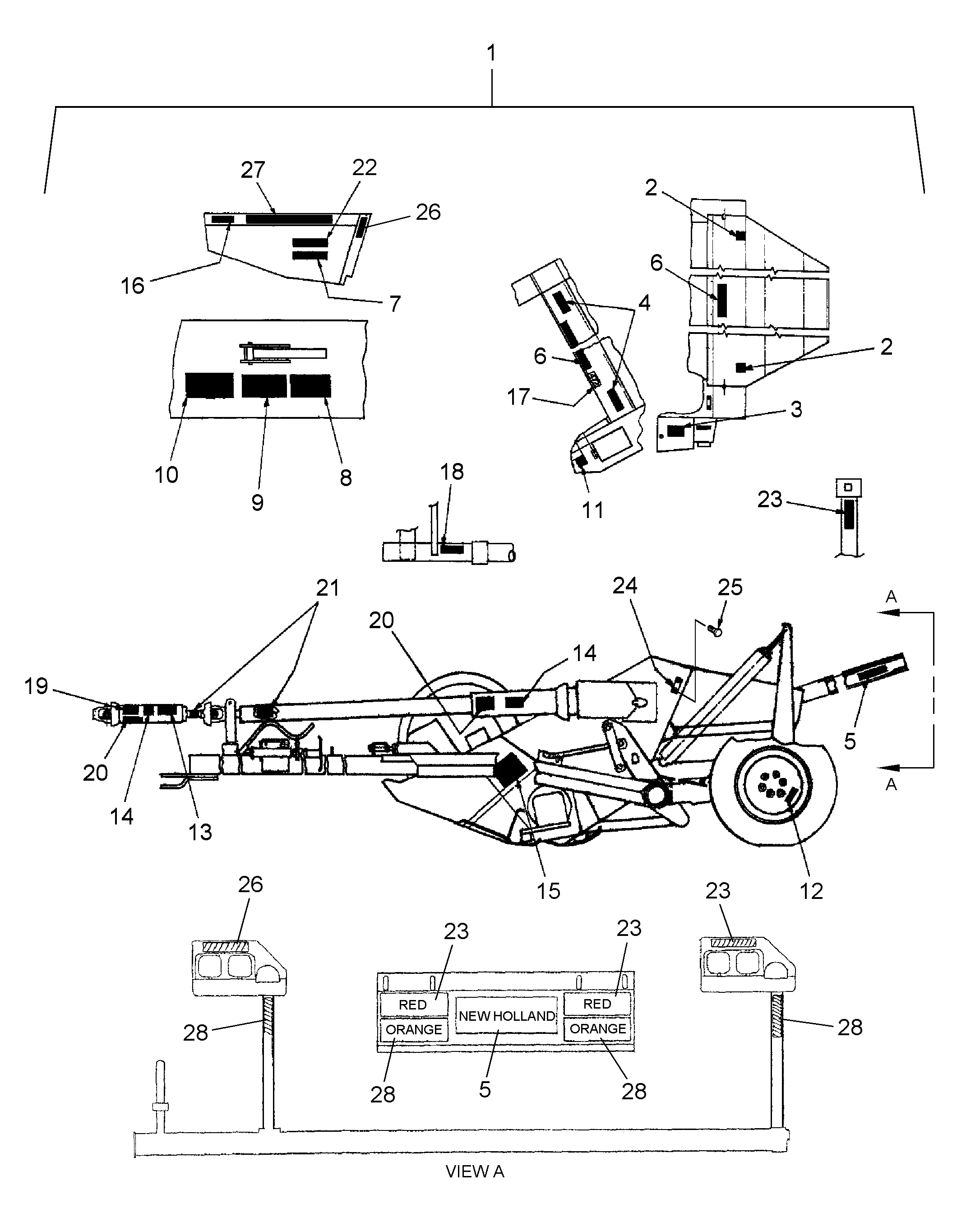

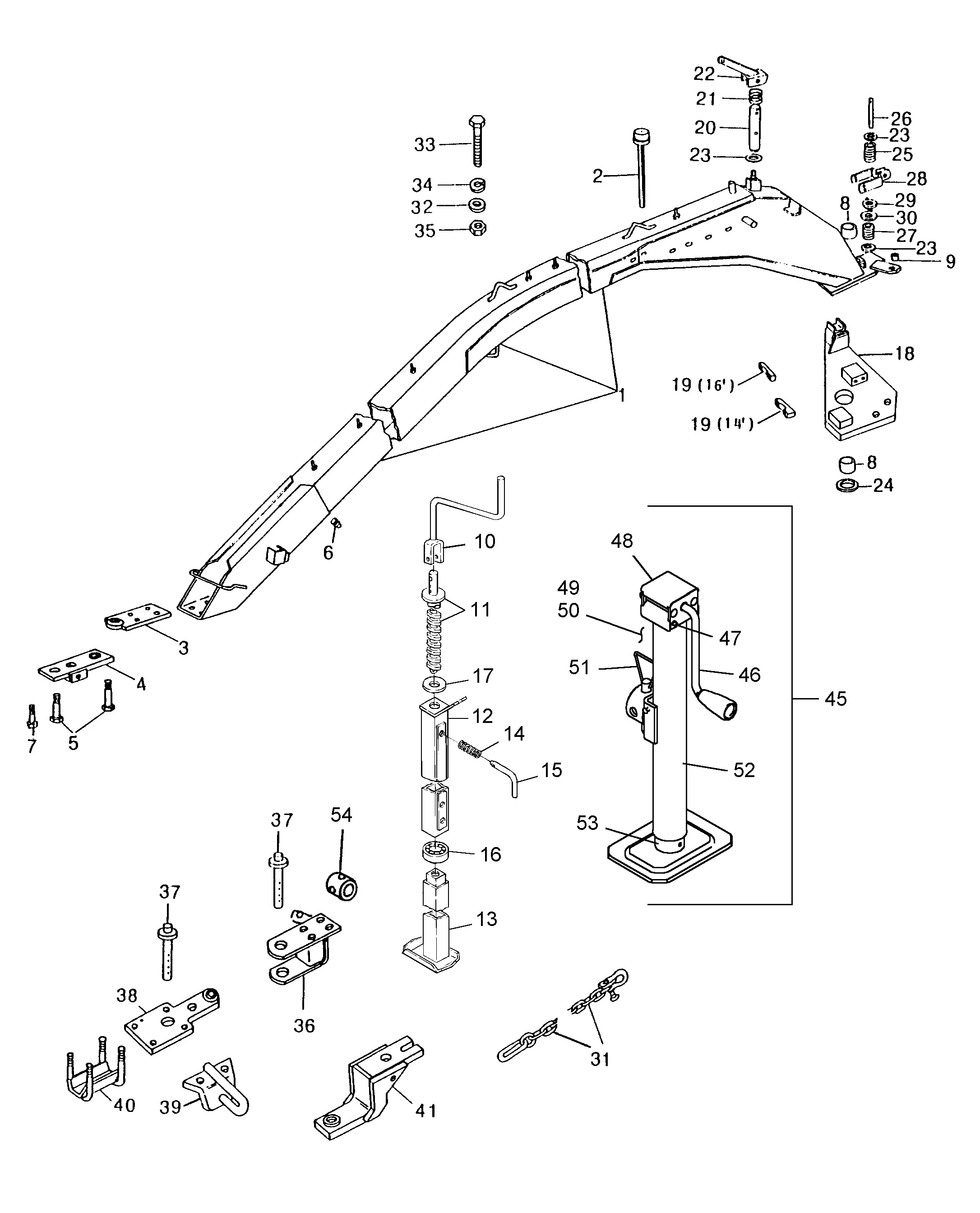

Replacement Parts and Compatibility

When it comes to maintaining agricultural machinery, understanding the available components and their compatibility is essential for ensuring optimal performance. Choosing the right replacements can significantly enhance efficiency and longevity, helping operators manage their tasks effectively.

Understanding Component Compatibility

Compatibility of various elements is crucial to ensure that machinery functions as intended. Components from different manufacturers may vary in specifications, which can affect overall performance. It is advisable to consult manufacturer guidelines and cross-reference with reliable sources to confirm that the selected replacements will integrate seamlessly into the existing system.

Available Replacement Options

A wide array of alternatives exists for machinery upkeep, enabling users to select components that best fit their requirements. Below is a table summarizing common options and their associated features:

| Component Type | Description | Compatibility Notes |

|---|---|---|

| Blades | Essential for cutting through hay and other materials. | Ensure size and mounting match the existing setup. |

| Drive Belts | Transmit power from the engine to the working parts. | Check length and width for proper fit. |

| Rollers | Facilitate the movement of materials through the machine. | Inspect diameter and material for compatibility. |

| Gearbox Components | Manage the speed and torque of the machine. | Consult specifications to ensure correct engagement. |

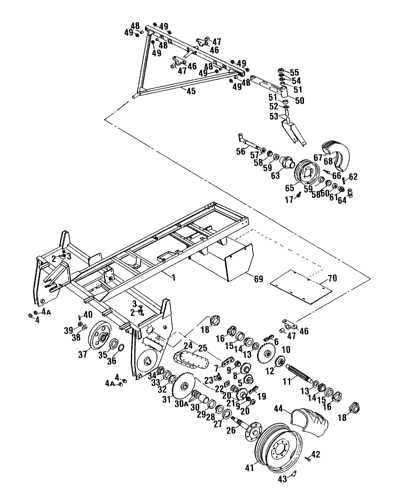

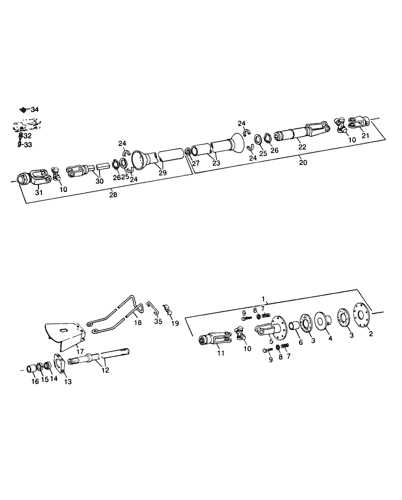

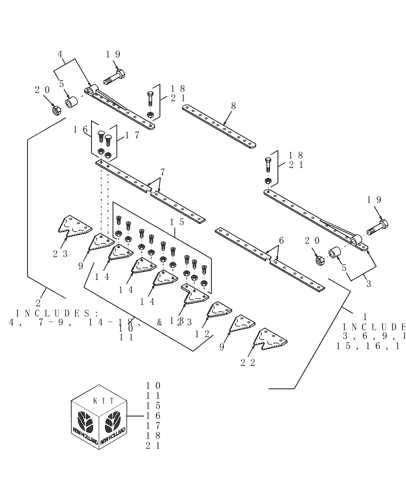

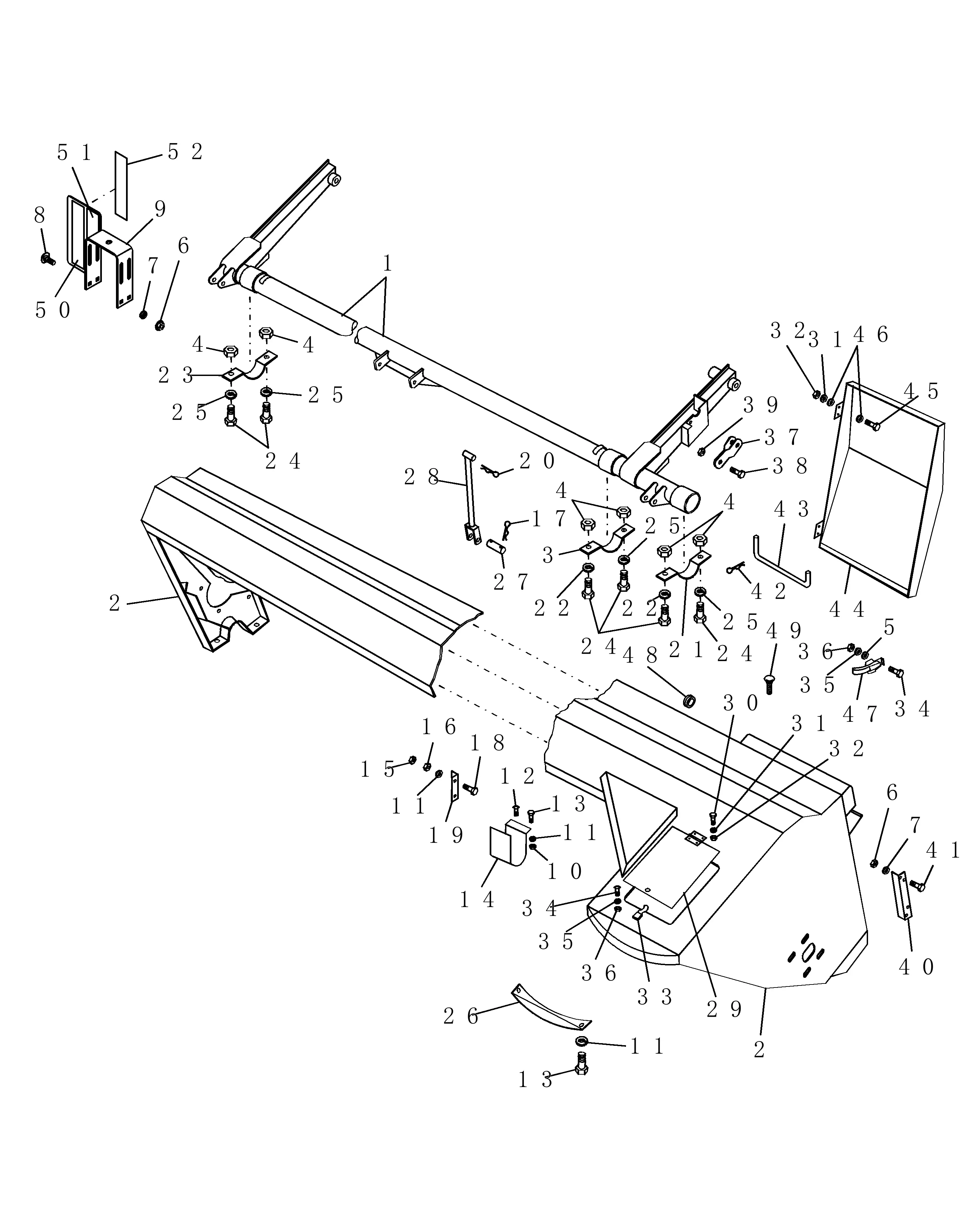

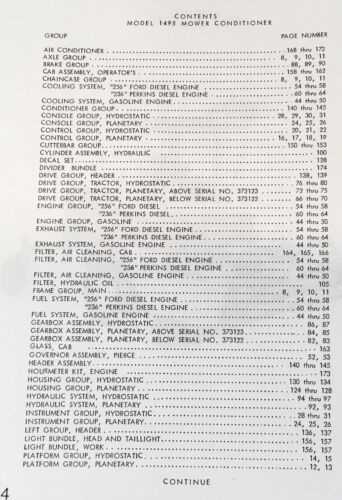

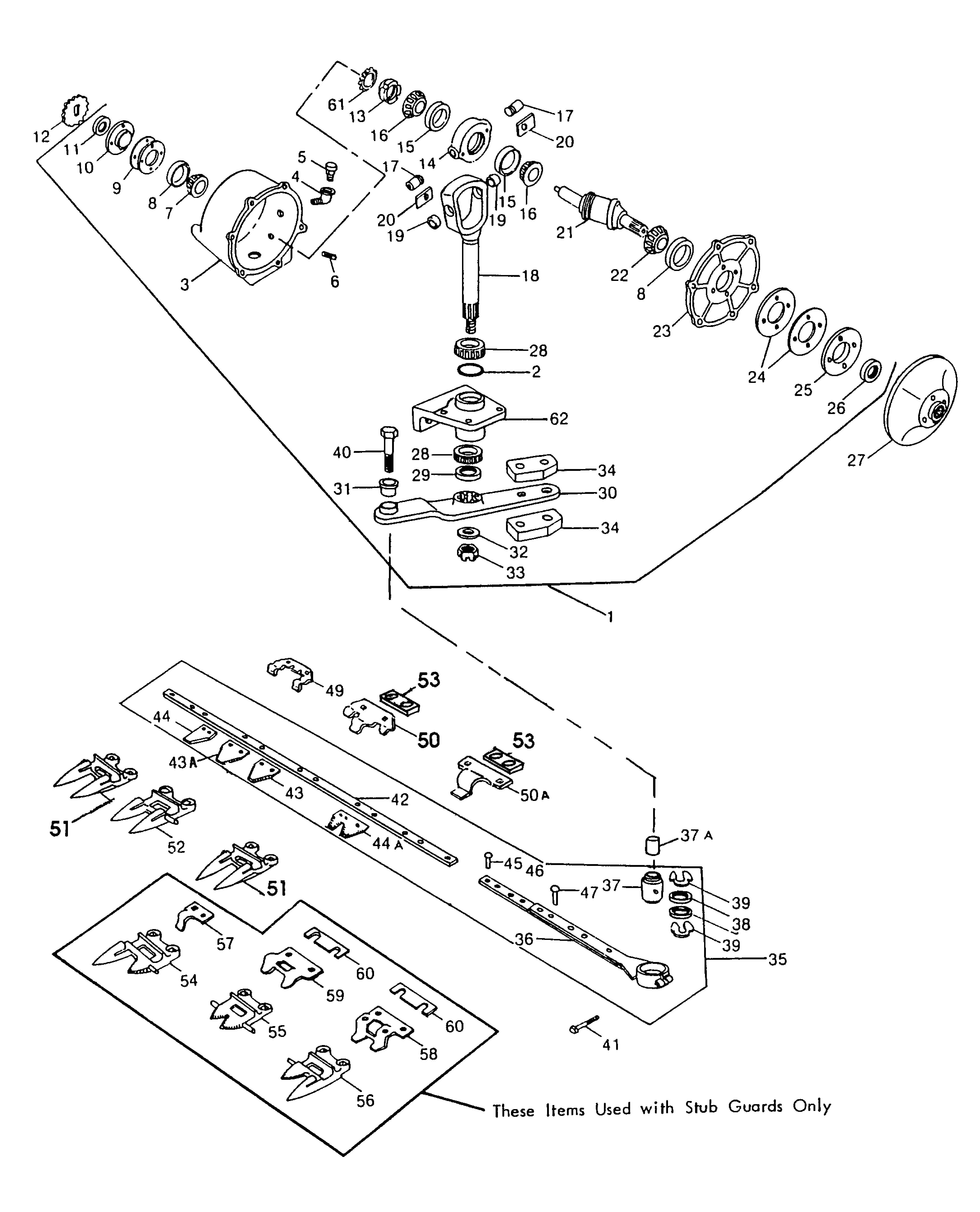

How to Interpret the Diagram

Understanding technical illustrations can greatly enhance your ability to maintain and repair machinery effectively. These visual aids provide crucial information about the components and their relationships, ensuring you can navigate the complexities of assembly and disassembly with confidence.

Begin by familiarizing yourself with the various symbols and notations used in the illustration. Each element typically represents a specific component, often accompanied by numerical identifiers that correspond to a list of descriptions. Pay attention to the layout, as it generally reflects the actual arrangement within the equipment, helping you visualize how parts interact.

Next, identify any highlighted areas or annotations that may indicate areas requiring special attention during maintenance. Understanding these details can prevent common mistakes and enhance your overall efficiency when working with the machinery.

Finally, consult any accompanying literature or manuals that further explain the visual representation. This additional context can provide insights into installation procedures, troubleshooting steps, and maintenance tips that are essential for optimal performance.

Resources for Haybine Owners

For individuals managing forage harvesting equipment, having access to comprehensive resources is essential for optimal maintenance and operation. Various materials can enhance the understanding of machinery, ensuring longevity and efficiency in the field.

Here are some valuable resources to consider:

- User Manuals: Detailed guides often include specifications, maintenance tips, and troubleshooting advice.

- Online Forums: Communities of users share experiences, solutions, and recommendations, providing practical insights.

- Video Tutorials: Visual guides can demonstrate repair processes and maintenance routines effectively.

- Manufacturer Websites: Official sites frequently offer technical documents, updates, and support contact information.

- Local Dealerships: Authorized dealers can provide parts and expert advice tailored to specific machinery needs.

Utilizing these resources can significantly enhance the management and upkeep of forage harvesting tools, leading to improved performance and reduced downtime.

Frequently Asked Questions

This section aims to address common inquiries regarding equipment maintenance and components. Below are some of the most frequently asked questions to assist users in understanding their machinery better.

- What are the essential elements to consider during maintenance?

Regular inspection of critical components, lubrication of moving parts, and timely replacement of worn-out items are crucial for optimal performance.

- How can I identify issues with my machinery?

Listening for unusual noises, checking for leaks, and monitoring performance changes can help pinpoint problems early.

- Where can I find replacement items?

Replacement components can typically be sourced from authorized dealers, online retailers, or local distributors specializing in agricultural equipment.

- How often should I conduct routine checks?

It is advisable to perform routine inspections before each use and more thorough checks at regular intervals, depending on usage frequency.

- Are there specific tools needed for maintenance?

Basic hand tools such as wrenches, screwdrivers, and pliers are essential. Specialized tools may also be required for certain tasks.