In various industries, efficient movement of materials is crucial for streamlined operations. This section delves into the intricate elements that contribute to the effective functioning of these transport mechanisms. Each component plays a significant role in ensuring reliability and performance, making it essential to grasp their relationships and functionalities.

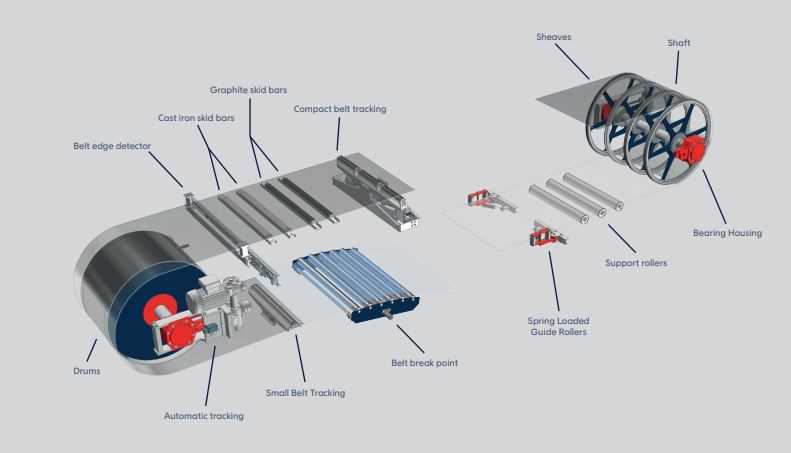

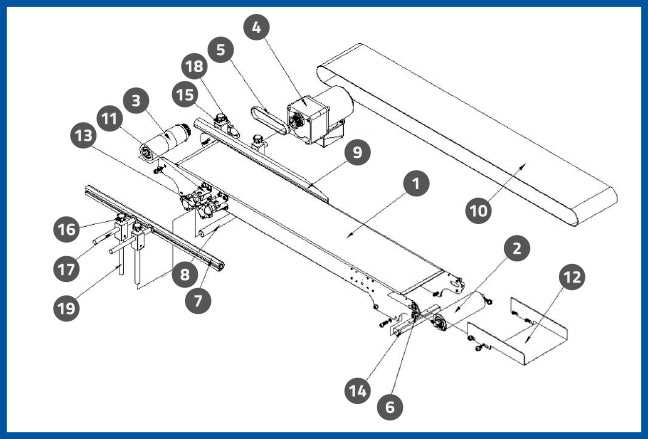

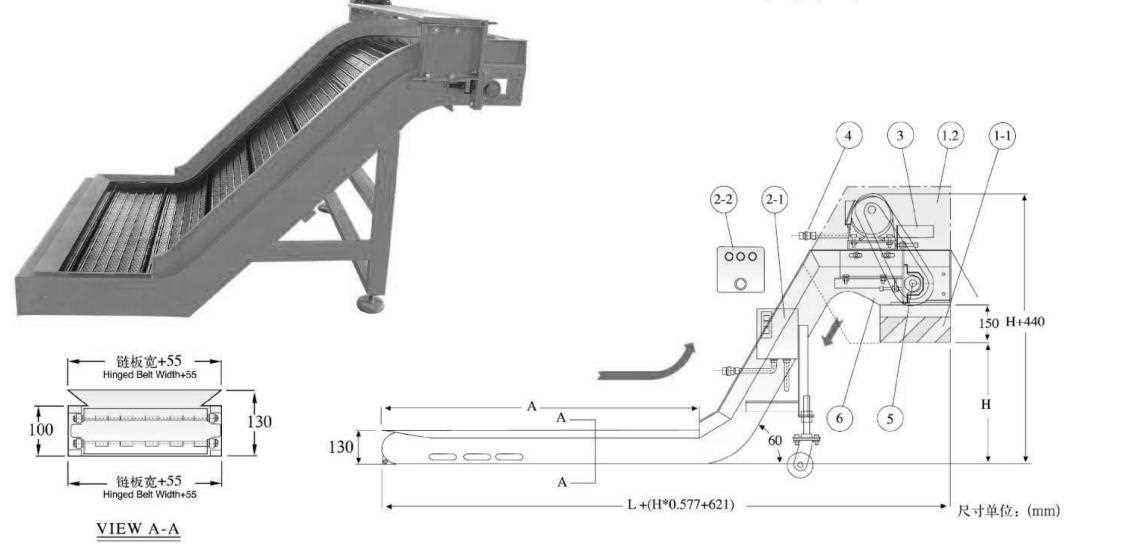

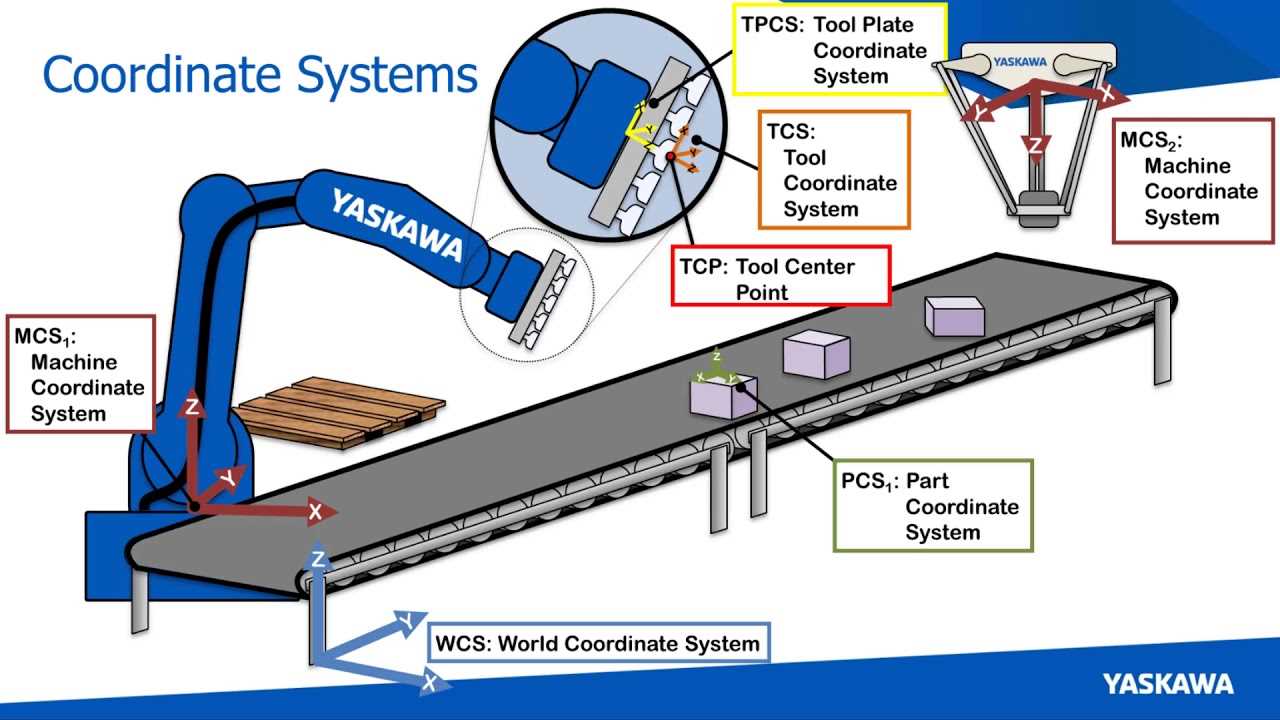

Visual representations of these mechanisms can enhance our comprehension, allowing us to identify how each element interacts within the overall system. By breaking down the structure, we can appreciate the engineering behind the seamless transfer of goods, from raw materials to finished products.

Moreover, understanding these components is vital for maintenance and troubleshooting. Familiarity with the layout and purpose of each section not only aids in identifying potential issues but also promotes informed decision-making when it comes to repairs or upgrades. This knowledge empowers professionals to optimize performance and prolong the lifespan of their equipment.

Understanding Conveyor Belt Components

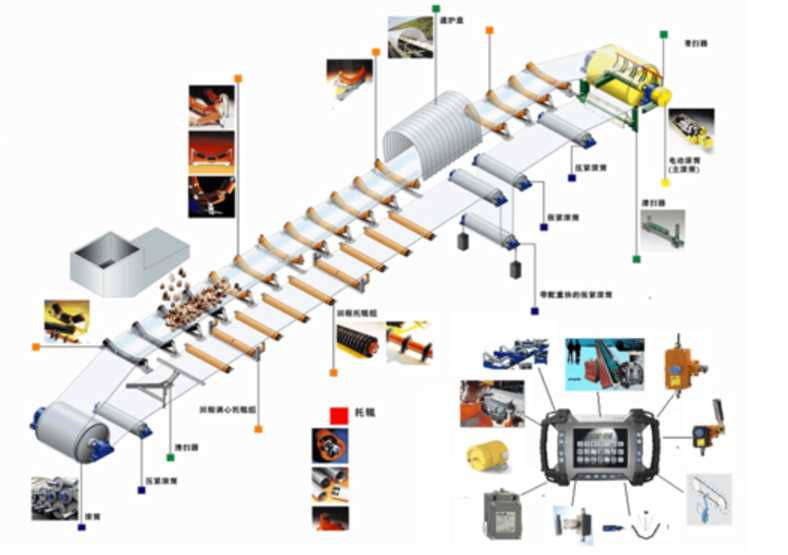

The operation of transport systems relies heavily on various elements that work together seamlessly to facilitate the movement of goods. A solid grasp of these components is essential for optimizing functionality and ensuring longevity. Each component plays a unique role, contributing to the efficiency and effectiveness of the entire mechanism.

Main Elements of the System

This section highlights the primary components involved in the movement mechanism. Understanding their functions will help in identifying potential areas for improvement and maintenance.

| Component | Description |

|---|---|

| Support Frame | Provides structural integrity and support for the entire assembly. |

| Drive Mechanism | Enables movement through motorized components that generate power. |

| Transfer Mechanism | Facilitates the smooth transition of items along the transport route. |

| Idler Rollers | Assist in maintaining the path and alignment of the moving surface. |

| Monitoring Devices | Ensure the system operates efficiently by tracking performance and detecting issues. |

Importance of Each Component

Every element is crucial to the overall effectiveness of the transport mechanism. Regular maintenance and timely replacements of any worn-out parts can significantly enhance operational efficiency and minimize downtime. Understanding these components not only aids in troubleshooting but also empowers users to make informed decisions regarding upgrades and repairs.

Key Elements of Conveyor Belt Systems

Efficient transport systems are essential in various industries, enabling seamless movement of materials from one point to another. Understanding the crucial components that contribute to this efficiency is vital for optimizing operations and ensuring longevity. Each element plays a distinct role in the overall functionality and reliability of the mechanism.

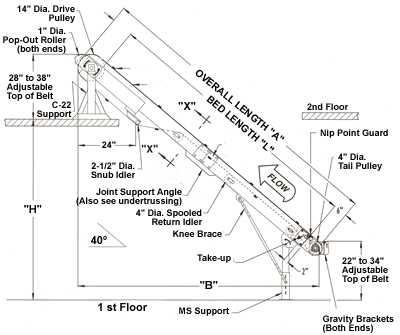

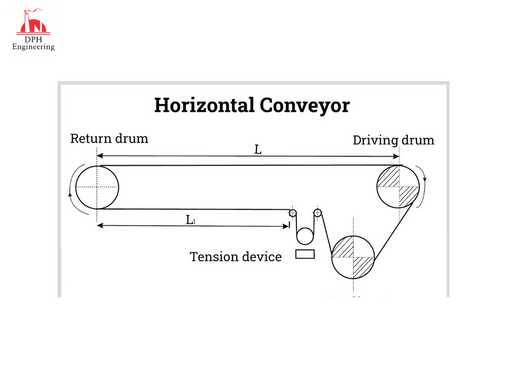

One of the fundamental components is the driving mechanism, which provides the necessary power to initiate movement. This element ensures consistent operation and can vary in design based on specific requirements. Additionally, the structure that supports the load is critical for maintaining stability and alignment, preventing potential disruptions during operation.

Another important feature is the system of rollers or pulleys, which facilitate smooth movement and reduce friction. These components are designed to bear heavy loads while minimizing wear and tear. Furthermore, the surface material involved is tailored to different applications, providing traction and durability essential for various types of goods.

Finally, monitoring and control systems are implemented to oversee performance and ensure safety. These systems allow for adjustments in speed and direction, enhancing adaptability to different operational demands. Together, these elements create a cohesive and efficient transport solution, integral to modern industrial processes.

Types of Conveyor Belt Designs

Various configurations are utilized in material handling systems, each tailored to meet specific operational needs. These arrangements differ in terms of structure, movement, and functionality, allowing for efficient transport of goods across diverse environments.

Modular Systems

Modular designs are characterized by their flexibility and adaptability. Constructed from interlocking components, these systems can be easily reconfigured to suit different layouts. They are ideal for facilities requiring frequent adjustments, offering quick installation and maintenance.

Wire Mesh Options

Wire mesh configurations provide excellent ventilation and drainage, making them suitable for applications involving hot or wet materials. Their open design allows for easy cleaning and visibility of transported items, ensuring operational efficiency in food processing and packaging industries.

Materials Used in Conveyor Manufacturing

The selection of appropriate materials is crucial in the production of transport systems, as they directly influence durability, efficiency, and performance. Various substances are employed, each chosen for their unique properties that cater to specific operational requirements and environmental conditions.

Metals are commonly utilized due to their strength and longevity. Steel, for instance, is favored for its robustness, making it ideal for heavy loads and rigorous applications. Aluminum offers a lighter alternative, providing excellent corrosion resistance while maintaining structural integrity.

Plastics play a significant role as well, particularly in environments where weight reduction and chemical resistance are priorities. Polyethylene and polyurethane are often selected for their flexibility and ease of maintenance, enabling smooth operation and reduced wear.

In addition, composite materials are increasingly popular, combining the advantages of different substances to enhance overall performance. These engineered materials can be tailored to meet specific needs, balancing factors such as weight, strength, and thermal resistance.

Finally, the choice of surface coatings is essential for protecting against wear and environmental factors. Specialized coatings can improve grip, reduce friction, and prolong the lifespan of components, making them indispensable in modern applications.

Functions of Each Conveyor Part

Understanding the roles of individual components within a transport system is essential for efficient operation and maintenance. Each element contributes to the overall functionality, ensuring smooth movement of materials and enhancing productivity in various applications.

Drive Mechanism: This component is responsible for powering the entire system. It converts electrical energy into mechanical energy, enabling the movement of materials along the track.

Support Framework: The structural backbone provides stability and alignment for the moving elements. It ensures that all components are securely in place, allowing for consistent performance under different loads.

Loading and Unloading Zones: These areas facilitate the efficient transfer of goods in and out of the transport system. They are designed to minimize disruption during material handling, contributing to a seamless workflow.

Guiding System: This set of elements ensures that items remain on the intended path throughout the transport process. It helps prevent misalignment and reduces the risk of damage to goods.

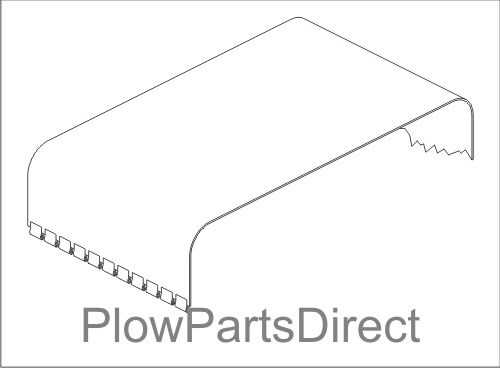

Protective Covers: Safety is a priority; these enclosures safeguard both the materials being transported and the operators. They help prevent accidental contact with moving parts, ensuring a secure working environment.

Control Mechanism: This system allows for the regulation of speed and direction, providing flexibility based on operational requirements. It enhances user control over the movement of materials, adapting to varying production needs.

Maintenance Tips for Conveyor Belts

Regular upkeep is essential for ensuring the longevity and efficiency of transport systems. Proper care not only minimizes downtime but also enhances overall productivity. Here are some key recommendations for maintaining these essential mechanisms.

- Regular Inspections: Conduct routine checks for wear and tear, misalignment, and any signs of damage.

- Proper Tensioning: Ensure that the system is appropriately tensioned to prevent slippage and premature wear.

- Cleaning: Keep the surfaces clear of debris and contaminants that can impede movement.

- Lubrication: Apply lubrication to moving components to reduce friction and prevent overheating.

- Alignment Checks: Regularly verify that all components are aligned to avoid unnecessary strain.

By following these maintenance tips, you can significantly extend the lifespan of your transport systems and maintain their efficiency over time.

Common Issues and Solutions

In any automated system, certain challenges can arise that may disrupt functionality or efficiency. Identifying these obstacles is crucial for maintaining optimal performance. Below, we outline frequent problems encountered in these mechanisms and propose effective remedies to ensure smooth operation.

Wear and Tear

Issue: Over time, components may experience deterioration due to constant friction and stress, leading to potential breakdowns.

Solution: Regular inspection and timely replacement of worn-out elements are essential. Implementing a routine maintenance schedule can help identify issues before they escalate, ensuring longevity and reliability.

Misalignment

Issue: Components may become misaligned due to improper installation or external factors, resulting in inefficiency or damage.

Solution: Periodic alignment checks should be performed, and adjustments made as necessary. Utilizing alignment tools can simplify this process, helping to maintain the integrity of the entire system.

Innovations in Conveyor Technology

The evolution of material handling systems has significantly transformed industries by enhancing efficiency and productivity. Recent advancements focus on integrating smart technologies, automation, and sustainable practices to create more adaptable and efficient solutions for transporting goods.

Smart Automation and Control Systems

Modern systems increasingly incorporate intelligent sensors and real-time data analytics to optimize operations. These technologies enable predictive maintenance, reduce downtime, and enhance operational efficiency. Automation also streamlines processes, allowing for smoother transitions between different phases of production and distribution.

Sustainability and Energy Efficiency

Innovations emphasize reducing environmental impact through energy-efficient designs and materials. Eco-friendly alternatives are being utilized, along with systems that minimize waste and lower energy consumption. This shift not only supports corporate social responsibility but also meets growing consumer demand for sustainable practices.