In the realm of machinery, comprehending the arrangement and functionality of various elements is crucial for effective maintenance and operation. A clear visualization of these components can significantly enhance the user’s ability to troubleshoot and optimize performance.

By exploring the intricacies of these systems, individuals can gain insights into how each segment interacts with others. This knowledge empowers users to address potential issues proactively and ensure the longevity of their equipment.

Moreover, familiarity with the configuration not only aids in repair efforts but also fosters a deeper appreciation for the engineering that underpins modern tools. Delving into the specifics of each segment reveals the ultimate efficiency achieved through thoughtful design.

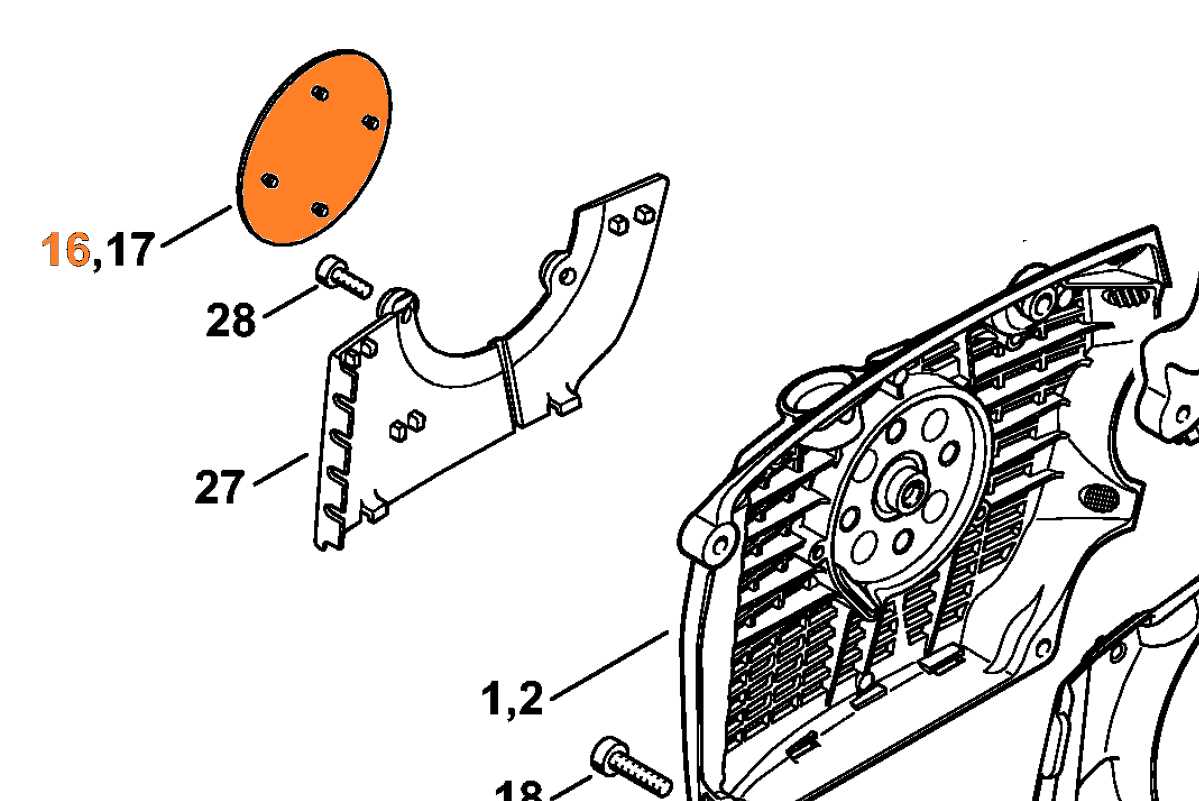

Understanding the Ms461 Parts Diagram

Comprehending the visual representation of components is essential for effective maintenance and repair tasks. This guide aims to clarify the layout and function of each element within the assembly, enhancing your ability to identify and manage various sections.

Key aspects to consider include:

- Identification of essential elements

- Understanding the relationships between components

- Recognizing potential issues through visual cues

To gain deeper insight, it is beneficial to follow these steps:

- Study the layout methodically

- Cross-reference with the manual for detailed descriptions

- Practice disassembly and reassembly to reinforce knowledge

By engaging with this visual guide, you can ultimately enhance your proficiency and confidence in handling the machinery effectively.

Key Components of the Ms461

The effectiveness of any high-performance tool relies heavily on its fundamental elements. Understanding these crucial components can enhance user experience and ensure optimal functionality. Each piece plays a vital role, contributing to the overall performance and durability of the equipment.

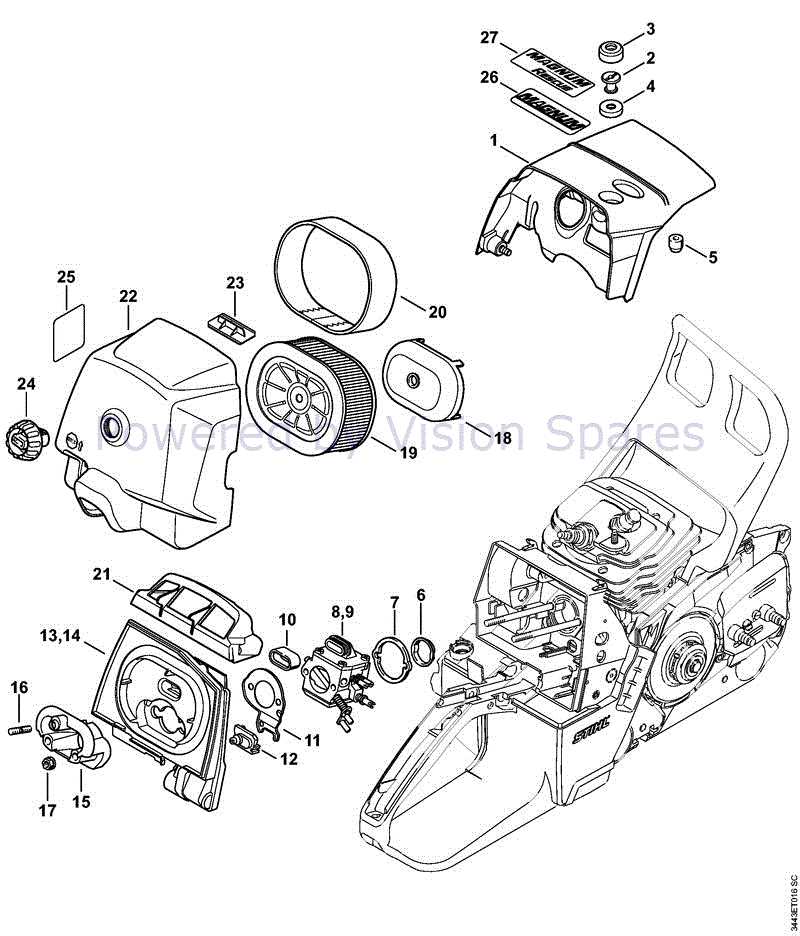

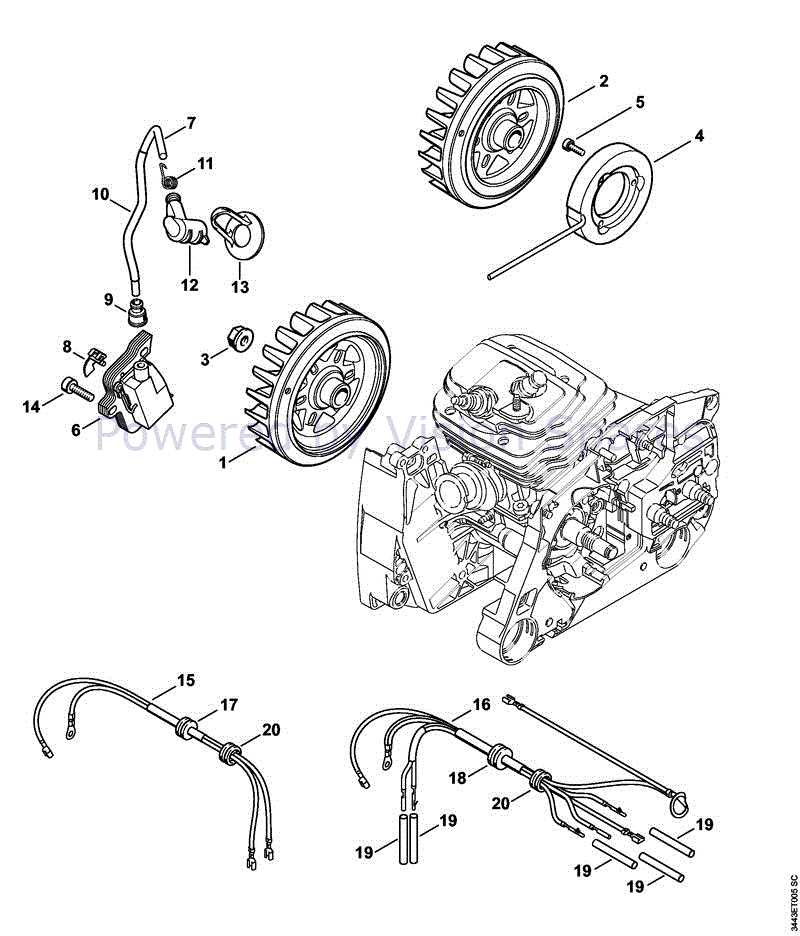

Engine: At the heart of the machine lies the engine, responsible for generating power. A robust engine design ensures reliability and efficiency, enabling users to tackle demanding tasks with ease.

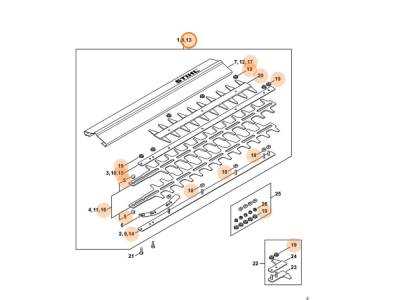

Guide Bar: The guide bar is essential for stability and precision during operation. Its length and construction material influence cutting accuracy and control, making it a critical feature for professional and recreational users alike.

Chain: The chain is the cutting element, designed to provide sharpness and durability. Quality chains are engineered to minimize wear and maximize cutting speed, ensuring that tasks are completed quickly and effectively.

Fuel System: An efficient fuel system is vital for maintaining engine performance. Proper fuel delivery ensures optimal combustion, contributing to the longevity and reliability of the machinery.

Air Filter: The air filter plays a key role in protecting the engine from debris and contaminants. A clean air supply is crucial for maintaining performance, especially in challenging environments.

Clutch: The clutch system allows for smooth engagement and disengagement of power, providing control during operation. A well-functioning clutch enhances safety and precision, particularly in intricate tasks.

Each of these essential elements works in harmony to deliver superior performance, making them indispensable for anyone seeking efficiency and reliability in their equipment.

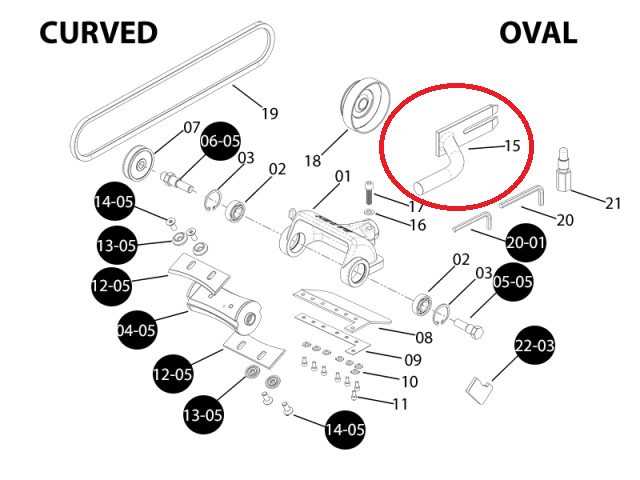

How to Interpret the Diagram

Understanding the layout of components is essential for effective maintenance and repair. A visual representation allows users to identify each element’s location and function, making troubleshooting more efficient. By grasping the relationships between various parts, you can enhance your overall proficiency in handling the equipment.

Recognizing Symbols and Labels

Each icon and label conveys specific information about the elements. Familiarizing yourself with common notations can significantly improve your ability to navigate the representation. Look for any legends or keys that explain the symbols used, as they provide crucial context.

Following Connections and Flow

Pay attention to how the components are interconnected. Understanding the flow of operation will help you visualize how each piece interacts within the system. This perspective is vital for diagnosing issues and planning repairs effectively.

Common Issues and Solutions

In the realm of mechanical devices, certain challenges tend to arise frequently, impacting performance and usability. Understanding these issues and their remedies can enhance efficiency and prolong the lifespan of the equipment. Below are some prevalent problems along with practical solutions.

Frequent Challenges

- Fuel Delivery Problems

- Air Filter Blockage

- Chain Tension Issues

- Ignition Failures

Effective Solutions

- Fuel Delivery Problems: Ensure the fuel is fresh and check for any clogs in the lines. Cleaning or replacing the fuel filter can often resolve this issue.

- Air Filter Blockage: Regularly inspect and clean the air filter to maintain proper airflow. A clean filter will improve efficiency and reduce strain on the engine.

- Chain Tension Issues: Adjust the chain tension according to the manufacturer’s guidelines. Proper tension prevents excessive wear and ensures optimal performance.

- Ignition Failures: Examine the spark plug and ignition components for wear or damage. Replacing faulty parts can restore proper functionality.

Maintenance Tips for Ms461 Parts

Proper upkeep of your equipment is essential for ensuring optimal performance and longevity. Regular attention to individual components can prevent unexpected failures and maintain efficiency. This section outlines effective strategies to care for your machinery, enhancing its reliability and extending its service life.

1. Regular Cleaning: Keeping all elements free from debris and contaminants is crucial. Use a soft brush or compressed air to remove dirt and sawdust from intricate areas. Regular cleaning not only improves functionality but also helps in spotting potential issues early.

2. Lubrication: Apply appropriate lubricants to moving parts to reduce friction and wear. Ensure you follow the manufacturer’s recommendations for the type and frequency of lubrication to maintain optimal operation.

3. Inspection: Conduct frequent visual inspections to identify any signs of wear, damage, or misalignment. Look for cracks, loose connections, and corrosion. Early detection can prevent larger problems down the line.

4. Replacement of Worn Components: Be proactive in replacing parts that show significant wear or damage. Using genuine replacements ensures compatibility and maintains the integrity of your machinery.

5. Proper Storage: When not in use, store your equipment in a clean, dry environment. Avoid exposure to extreme temperatures and humidity, which can lead to deterioration of materials.

By following these guidelines, you can ensure that your machinery operates at peak performance and enjoys a longer operational lifespan.

Where to Find Replacement Parts

When your equipment requires new components, locating reliable sources is essential for seamless operation. Whether you’re dealing with worn-out items or need enhancements, understanding where to acquire these essentials can save both time and money.

Authorized Dealers

Visiting authorized retailers ensures that you receive genuine replacements that meet the original specifications. These dealers often have extensive inventories and can provide expert advice on the best options for your needs.

Online Marketplaces

The internet offers a plethora of platforms where you can discover various suppliers. Websites like eBay and Amazon not only list numerous options but also feature customer reviews, helping you make informed decisions. Be sure to check for return policies and warranties.

Assembly Instructions for Ms461

This section provides essential guidance for the proper assembly of your equipment, ensuring optimal performance and longevity. Following these steps will help you navigate the assembly process smoothly.

Preparation Steps

- Gather all necessary components and tools.

- Ensure a clean and organized workspace.

- Familiarize yourself with the assembly layout.

Assembly Process

- Begin by attaching the base unit securely.

- Install the intermediate components, ensuring all connections are tight.

- Finish with the outer casing, verifying that all parts align properly.

- Conduct a final inspection to confirm correct assembly.

Importance of Proper Parts Selection

Choosing the right components for machinery is crucial to ensure optimal performance and longevity. Inadequate selection can lead to inefficiencies, increased wear, and even catastrophic failures. Thus, understanding the significance of this process is essential for anyone involved in maintenance or repair tasks.

Benefits of Appropriate Component Choice

- Enhanced Efficiency: Selecting compatible pieces maximizes the operational effectiveness of the equipment.

- Extended Lifespan: Properly matched elements reduce strain and wear, significantly prolonging the life of the machinery.

- Cost Savings: Investing in the correct items prevents frequent replacements and repairs, ultimately saving money.

Key Considerations in Selection

- Compatibility: Ensure that all items work seamlessly together.

- Quality: Opt for high-quality products to avoid premature failures.

- Specifications: Adhere to manufacturer recommendations to maintain performance standards.

In summary, making informed choices when selecting components is vital for maintaining functionality, enhancing efficiency, and ensuring the overall reliability of machinery.

Upgrading Your Ms461 Components

Enhancing the performance and longevity of your equipment involves strategic upgrades to its essential elements. By selecting high-quality components and innovative accessories, you can optimize efficiency and achieve superior results in your tasks. This section will explore key enhancements that can take your machinery to the next level.

Choosing Quality Materials

Investing in premium materials can significantly impact performance. Durability and reliability are paramount, so focus on parts that are designed to withstand rigorous use. Consider upgrades that not only improve function but also enhance overall durability.

Innovative Accessories

Incorporating modern accessories can greatly enhance usability. Look for tools that offer advanced features, such as improved ergonomics or enhanced power output. These innovations can transform the operation, providing the ultimate advantage in your projects.