The intricate design of any power tool plays a crucial role in its overall functionality. Grasping the layout and connection of various elements is essential for efficient operation and maintenance. This section aims to provide insights into how each component interrelates, ensuring optimal performance.

By delving into the specifics of the machinery’s assembly, users can enhance their troubleshooting skills and repair capabilities. Recognizing each piece’s function will empower operators to address issues swiftly and effectively, ultimately extending the lifespan of their equipment.

Furthermore, a comprehensive exploration of the components will facilitate better understanding and safer usage. Whether you are a novice or an experienced user, familiarizing yourself with the internal workings of your device is an invaluable step toward mastery.

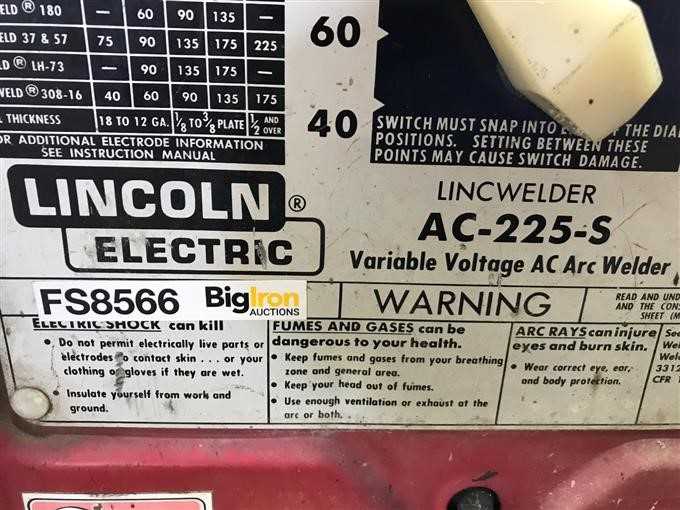

Understanding Lincoln AC-225 Welder

This section explores the fundamentals of a specific type of metal joining equipment widely used in various applications. Known for its reliability and performance, this device caters to both professionals and hobbyists, offering versatility in numerous welding tasks. Understanding its components and functionality is essential for effective usage and maintenance.

Key Features

The equipment is designed to provide a stable power output, making it suitable for various metal types. Users appreciate its portability, allowing for easy transport to different job sites. Additionally, the intuitive controls enhance user experience, promoting accuracy and efficiency during operation.

Maintenance Tips

To ensure longevity, regular inspection of the equipment is vital. Users should check connections and clean components to prevent buildup that could hinder performance. Following the manufacturer’s guidelines for care can significantly extend the life of the machine.

Key Components of the Welder

Understanding the essential elements of an arc machine is crucial for effective operation and maintenance. Each component plays a specific role in ensuring optimal performance and reliability. This section will explore the fundamental parts that contribute to the overall functionality of the equipment.

Power Source

The power source is the heart of the system, providing the necessary electrical energy to generate the arc. This component typically converts alternating current to direct current, facilitating a stable and controlled output. Proper selection and maintenance of the power source are vital for achieving consistent welding results.

Electrode Holder and Ground Clamp

The electrode holder serves as the interface between the welder and the electrode, enabling precise manipulation during the welding process. Meanwhile, the ground clamp establishes a secure electrical connection to the workpiece, completing the circuit and ensuring effective current flow. Both components are integral to achieving quality welds and should be inspected regularly for wear and damage.

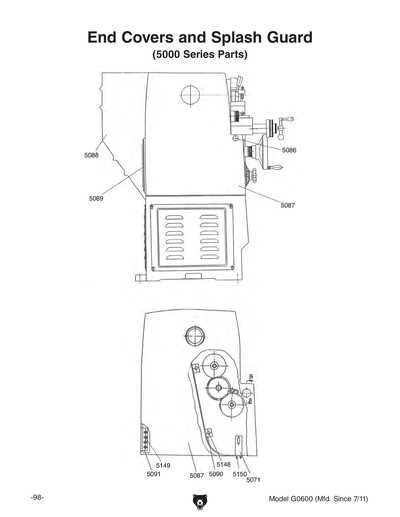

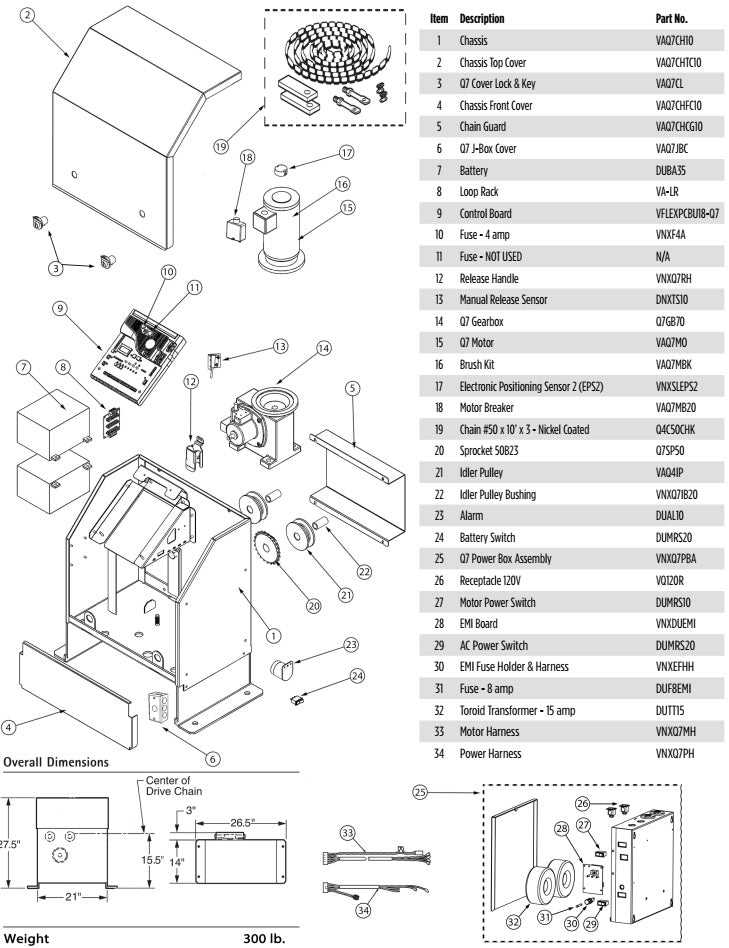

Importance of a Parts Diagram

Understanding the components of any machinery is crucial for efficient maintenance and repair. A visual representation of individual elements allows users to identify and locate specific pieces quickly, ensuring smoother operations and reduced downtime.

Facilitating Maintenance

When users have access to a clear illustration of components, they can perform maintenance tasks with greater accuracy. This visual aid helps in recognizing wear and tear, leading to timely replacements.

Enhancing Troubleshooting

A well-organized visual reference is invaluable during troubleshooting. It enables users to trace problems back to specific elements, minimizing guesswork and expediting solutions.

| Benefits | Description |

|---|---|

| Efficiency | Reduces time spent searching for components. |

| Accuracy | Ensures precise identification of parts needing attention. |

| Cost-Effectiveness | Minimizes unnecessary replacements through targeted maintenance. |

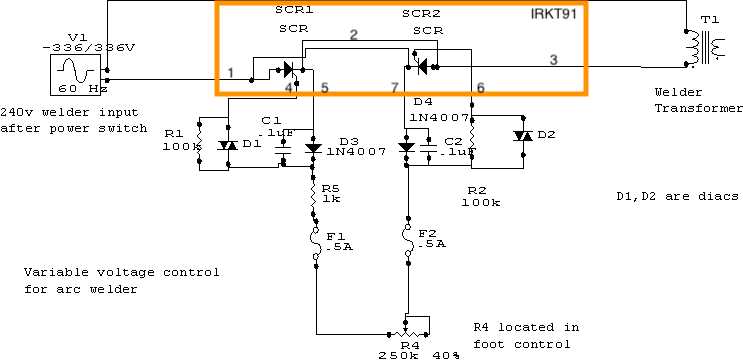

How to Read the Diagram

Understanding a schematic representation is essential for effective maintenance and repair of equipment. This guide will help you navigate the layout and symbols typically found in these illustrations, enabling you to identify components and their relationships with ease.

Familiarize Yourself with Common Symbols

- Look for standard symbols representing electrical elements.

- Identify lines indicating connections or flow of electricity.

- Note any annotations that provide additional context or instructions.

Follow the Flow of the Schematic

- Start from the power source and trace the path to understand how energy flows.

- Observe the connections between components to grasp their interactions.

- Pay attention to any labels that indicate values or specifications for each part.

Common Issues and Troubleshooting

Understanding frequent problems and their solutions can significantly enhance performance and longevity of your equipment. Addressing these concerns promptly ensures efficient operation and minimizes downtime.

| Issue | Symptoms | Troubleshooting Steps |

|---|---|---|

| Inconsistent Arc | Fluctuating intensity, erratic behavior | Check power supply connections and inspect the electrode condition. |

| Overheating | Excessive heat, automatic shutdown | Ensure proper ventilation and clean cooling vents. |

| Excessive Spatter | Unwanted droplets on the workpiece | Adjust the voltage settings and ensure correct filler material. |

| Weak Welds | Poor penetration, low strength | Evaluate the travel speed and angle of the torch. |

Replacing Parts: A Step-by-Step Guide

Maintaining equipment is essential for ensuring optimal performance and longevity. This section provides a comprehensive approach to swapping out components effectively. Whether you’re addressing wear and tear or upgrading features, following a systematic process can streamline your experience and minimize downtime.

Before beginning the replacement process, gather the necessary tools and materials. A clean workspace will also facilitate a smoother operation. Below is a checklist of essential items you might need:

| Item | Description |

|---|---|

| Tool Kit | A set of screwdrivers, pliers, and wrenches |

| Replacement Component | The specific item intended for replacement |

| Safety Gear | Gloves and goggles to protect against hazards |

| Instruction Manual | Manufacturer’s guide for detailed instructions |

Once you have assembled everything, follow these steps to ensure a successful replacement:

- Power down the device and disconnect it from any power source.

- Carefully remove any covers or casings that obstruct access to the component.

- Take note of the configuration and positioning of the existing item before removal.

- Detach the old part, ensuring not to damage surrounding components.

- Install the new component, making sure it is securely fitted in place.

- Replace any covers or casings removed during the process.

- Reconnect the power source and conduct a test to verify proper operation.

By following this methodical approach, you can efficiently replace components and maintain the performance of your equipment, ensuring it serves you well for years to come.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires consistent care and attention. Regular maintenance not only enhances efficiency but also extends the lifespan of the machinery, minimizing the likelihood of unexpected failures.

1. Regular Cleaning: Keep the exterior and interior components free from dust and debris. Use a soft brush or cloth to remove particles that can hinder performance.

2. Check Connections: Periodically inspect electrical connections for signs of wear or corrosion. Secure any loose connections to maintain a stable power supply.

3. Lubrication: Apply appropriate lubricants to moving parts as specified in the manufacturer’s guidelines. This reduces friction and prevents premature wear.

4. Monitor Temperature: Keep an eye on operating temperatures. Overheating can lead to severe damage, so ensure proper ventilation and cooling mechanisms are functioning.

5. Replace Worn Parts: Regularly assess components for signs of deterioration. Timely replacement of worn parts can prevent further damage and maintain efficiency.

6. Follow Operating Guidelines: Adhere to the recommended usage and operational practices. Misuse can lead to excessive wear and tear, compromising the integrity of the machinery.

By implementing these practices, you can significantly improve the reliability and longevity of your equipment, ensuring it continues to perform at its best for years to come.

Where to Find Replacement Parts

Locating suitable components for your equipment can often be a challenge, but with the right resources, it becomes manageable. Whether you are looking to repair or upgrade your machine, various avenues exist to ensure you find what you need efficiently.

Many individuals start their search online, where numerous platforms specialize in supplying essential items. Manufacturer websites and authorized distributors are excellent first stops, as they offer genuine components that match the specifications of your machine. Additionally, online marketplaces may provide a wide range of options, including both new and refurbished items.

Local hardware stores can also be valuable resources. Many of these establishments carry common items or can order specific components for you. Don’t hesitate to ask staff for assistance; their expertise can often lead you to the right solution.

Finally, joining online forums or communities focused on equipment maintenance can yield useful insights. Members often share their experiences and recommendations, helping you discover less-known suppliers or alternative options.

| Resource Type | Description |

|---|---|

| Manufacturer Website | Offers original components and specifications. |

| Authorized Distributors | Specialized retailers providing authentic items. |

| Online Marketplaces | Platforms with a variety of new and used options. |

| Local Hardware Stores | Common items and special orders available. |

| Online Communities | Forums for sharing experiences and supplier recommendations. |

Upgrading Your Welder’s Performance

Enhancing the efficiency of your machine can lead to superior results and increased productivity. By investing in specific components and modifications, you can significantly boost the overall capability of your equipment. This guide will explore various strategies to achieve the ultimate performance enhancements.

Key Components for Improvement

Identifying essential elements that can be upgraded is crucial. Focus on components that impact power output, duty cycle, and cooling efficiency. Below is a table summarizing critical upgrades and their benefits.

| Upgrade Component | Benefit |

|---|---|

| High-Performance Torch | Improved heat control and precision |

| Enhanced Cooling System | Increased duty cycle and reduced overheating |

| Advanced Control Module | Greater control over settings for varied tasks |

| Quality Electrode Holder | Better grip and stability during use |

Maintenance Practices

Regular upkeep is vital to ensure that your upgraded components function effectively. Implementing a routine maintenance schedule will prolong the life of your equipment and maintain optimal performance. Simple tasks like cleaning connections and checking for wear can make a significant difference.