In the realm of automated packaging solutions, a comprehensive grasp of machinery components is essential for optimal performance and maintenance. Each element plays a crucial role in ensuring the efficiency and reliability of operations. By familiarizing oneself with the intricate layout and functionality of these components, operators can enhance their troubleshooting skills and streamline workflows.

Accurate representation of machinery internals provides invaluable insights into the intricate connections and interactions among various units. This knowledge not only aids in effective repairs but also facilitates informed decision-making when it comes to upgrades or modifications. Understanding the structure of such systems empowers users to maintain peak operational standards.

Whether for routine maintenance or troubleshooting, having a detailed visual guide to the internal elements is indispensable. This resource serves as a roadmap, helping technicians and engineers navigate through complex assemblies with ease. By investing time in studying these layouts, one can significantly reduce downtime and ensure that production continues smoothly and efficiently.

Lantech Q300 Overview

This section provides a comprehensive look at a highly efficient and versatile packaging solution designed for modern production environments. With a focus on reliability and functionality, this equipment plays a crucial role in streamlining packaging processes and enhancing productivity.

Key features include:

- Robust construction for durability

- User-friendly interface for easy operation

- Advanced technology for optimal performance

- Flexibility to accommodate various package sizes

The system is engineered to meet the demands of diverse industries, ensuring consistent and effective packaging. Its innovative design minimizes downtime and maximizes output, making it an ideal choice for businesses looking to enhance their operational efficiency.

Consider the following benefits:

- Enhanced efficiency through automated processes

- Reduction in labor costs due to streamlined operations

- Improved safety features to protect operators

- Environmentally friendly options to reduce waste

In conclusion, this packaging solution stands out as a leading choice for organizations aiming to optimize their packaging operations while maintaining high standards of quality and safety.

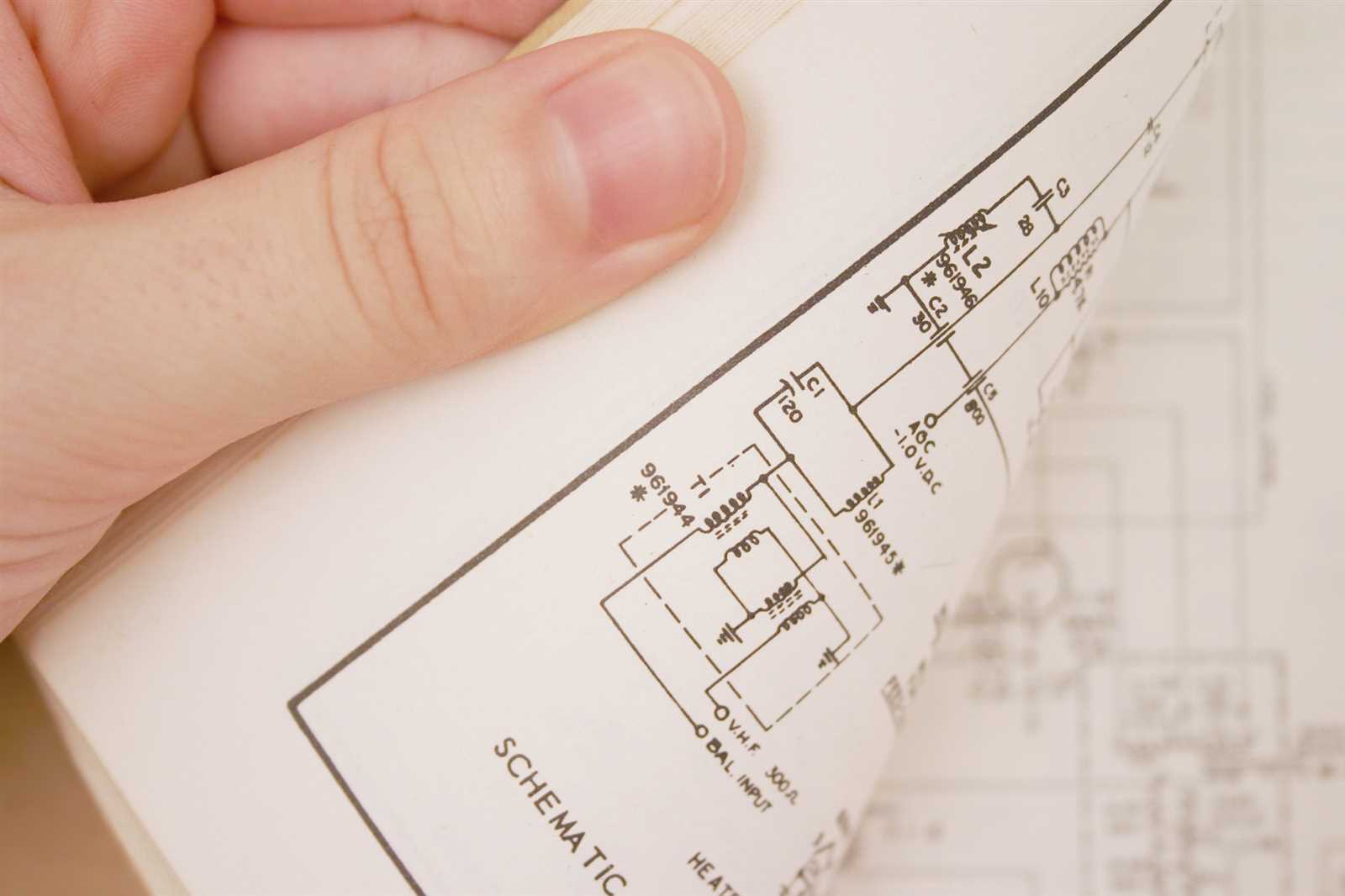

Understanding the Parts Diagram

Comprehending the layout of components is essential for efficient maintenance and troubleshooting. A visual representation serves as a roadmap, guiding users through the various elements that make up a system. Familiarity with this illustration can enhance operational knowledge and facilitate quicker repairs.

Key aspects to consider when examining a component layout include:

- Identification: Recognizing each part and its function is critical for effective operations.

- Connectivity: Understanding how components interact can help diagnose issues more accurately.

- Organization: A well-structured layout simplifies the process of locating and replacing items.

To fully benefit from the schematic, follow these steps:

- Study the Legend: Familiarize yourself with symbols and abbreviations used in the representation.

- Trace Connections: Follow the lines indicating relationships between elements to grasp their interdependencies.

- Cross-reference: Use the visual guide alongside manuals or service documents for deeper insights.

By investing time in understanding the component layout, users can enhance their proficiency, leading to improved performance and longevity of the system.

Key Components of the Q300

The functionality and efficiency of any advanced packaging system heavily rely on its essential elements. Understanding these components can enhance both maintenance and operational performance, ensuring that the equipment runs smoothly and effectively.

Core Elements

- Frame: Provides structural integrity and support for all other components.

- Conveyor System: Facilitates the smooth movement of products through the packaging process.

- Control Panel: Central hub for operation management, allowing users to adjust settings and monitor performance.

Auxiliary Features

- Safety Guards: Protect personnel by minimizing exposure to moving parts.

- Power Supply: Ensures reliable energy delivery to all operational components.

- Pneumatic Systems: Enable efficient handling of packaging materials through air pressure mechanisms.

Familiarity with these crucial parts not only aids in troubleshooting but also empowers operators to optimize performance, ultimately leading to improved productivity.

Importance of Each Part

Understanding the significance of individual components within a machine is crucial for ensuring its optimal performance and longevity. Each element plays a specific role, contributing to the overall functionality and efficiency of the equipment. A thorough comprehension of these elements allows for better maintenance practices and informed troubleshooting when issues arise.

| Component | Function | Impact on Performance |

|---|---|---|

| Drive System | Transmits power to enable movement | Essential for speed and accuracy |

| Control Unit | Regulates operations and settings | Ensures consistency and precision |

| Chassis | Supports and houses internal mechanisms | Affects stability and durability |

| Safety Features | Protects operators and equipment | Critical for risk management |

| Power Supply | Delivers energy to all systems | Determines operational capability |

Recognizing the role of each segment not only enhances understanding but also facilitates effective repairs and improvements, ensuring the machinery operates smoothly and reliably over time.

Common Issues and Solutions

In the world of machinery, encountering problems is a common occurrence. Understanding typical challenges and their resolutions can significantly enhance operational efficiency and reduce downtime. Below are some frequent issues faced by operators, along with effective solutions to address them.

| Issue | Description | Solution |

|---|---|---|

| Inconsistent Performance | Equipment may not function at optimal levels, leading to erratic output. | Check for misalignments and ensure all components are properly lubricated. |

| Frequent Jamming | Material can get stuck during operation, causing interruptions. | Inspect and clean the feed mechanisms regularly; adjust tension settings as necessary. |

| Excessive Wear and Tear | Parts may degrade faster than expected, impacting overall functionality. | Implement a routine maintenance schedule and replace worn components promptly. |

| Electrical Failures | Power supply issues can lead to system shutdowns or malfunctions. | Examine wiring and connections for damage; ensure power sources are stable. |

| Temperature Fluctuations | Unexpected heating or cooling can affect equipment performance. | Monitor ambient conditions and use cooling systems or heaters as needed. |

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the extended functionality and performance of any machinery. Implementing a consistent maintenance routine can prevent costly repairs and downtime, while enhancing efficiency and reliability over time.

Here are some effective strategies to promote longevity:

- Routine Inspections: Conduct regular checks to identify wear and tear. Look for signs of damage or misalignment that may require attention.

- Cleaning Procedures: Keep components clean from dust and debris. Use appropriate cleaning agents to prevent corrosion and buildup.

- Lubrication: Apply lubricants to moving parts to reduce friction and wear. Follow manufacturer recommendations for the right type and frequency.

- Calibration: Ensure that settings are accurately calibrated for optimal performance. Regular calibration can help maintain precision in operations.

- Training Personnel: Educate staff on proper usage and handling techniques. Well-informed operators can minimize the risk of accidental damage.

By adhering to these maintenance practices, users can enhance the lifespan of their equipment and maintain high operational standards.

Where to Find Replacement Parts

Finding components for your machinery can be a straightforward process if you know where to look. Various sources offer the necessary items to keep your equipment running smoothly. Here are some reliable avenues to explore for acquiring the required elements.

| Source | Description |

|---|---|

| Manufacturer’s Website | The official site often provides an extensive catalog of items, complete with specifications and compatibility details. |

| Authorized Dealers | Working with certified distributors ensures you receive genuine components that meet quality standards. |

| Online Marketplaces | Platforms such as eBay and Amazon can be treasure troves for hard-to-find items, often at competitive prices. |

| Local Suppliers | Community hardware stores may stock or can order specific components, providing a convenient option. |

| Salvage Yards | These facilities might have used but functional items at a fraction of the cost, suitable for older models. |

How to Read the Diagram Effectively

Understanding complex visuals can significantly enhance your ability to troubleshoot and maintain equipment. Familiarity with various symbols, lines, and notations used in technical illustrations is essential for grasping how components interact within a system. This knowledge empowers you to identify parts and their functions with ease, leading to more efficient operations and repairs.

Key Elements to Identify

Before diving into the illustration, it’s crucial to recognize the fundamental elements that make up these representations. Below are common features you should look for:

| Element | Description |

|---|---|

| Symbols | Represent various components, such as motors, sensors, and connectors. |

| Lines | Indicate connections and relationships between different parts. |

| Labels | Provide names and specifications for each component, helping to clarify their roles. |

| Legend | A key that explains the symbols and notations used throughout the illustration. |

Steps to Interpret the Visual

Once you are familiar with the essential elements, follow these steps to enhance your interpretation skills:

- Start with the legend to understand the symbols used.

- Identify the main components and their labels to establish context.

- Trace the lines to comprehend how the components are interconnected.

- Refer to any accompanying documentation for additional insights into operation and maintenance.