| Control Unit |

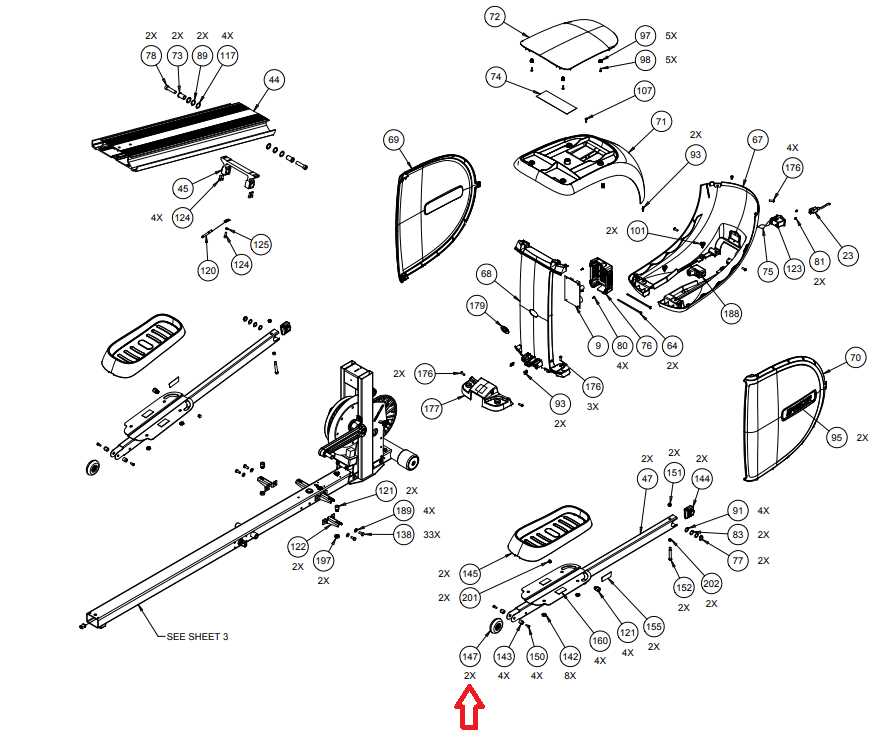

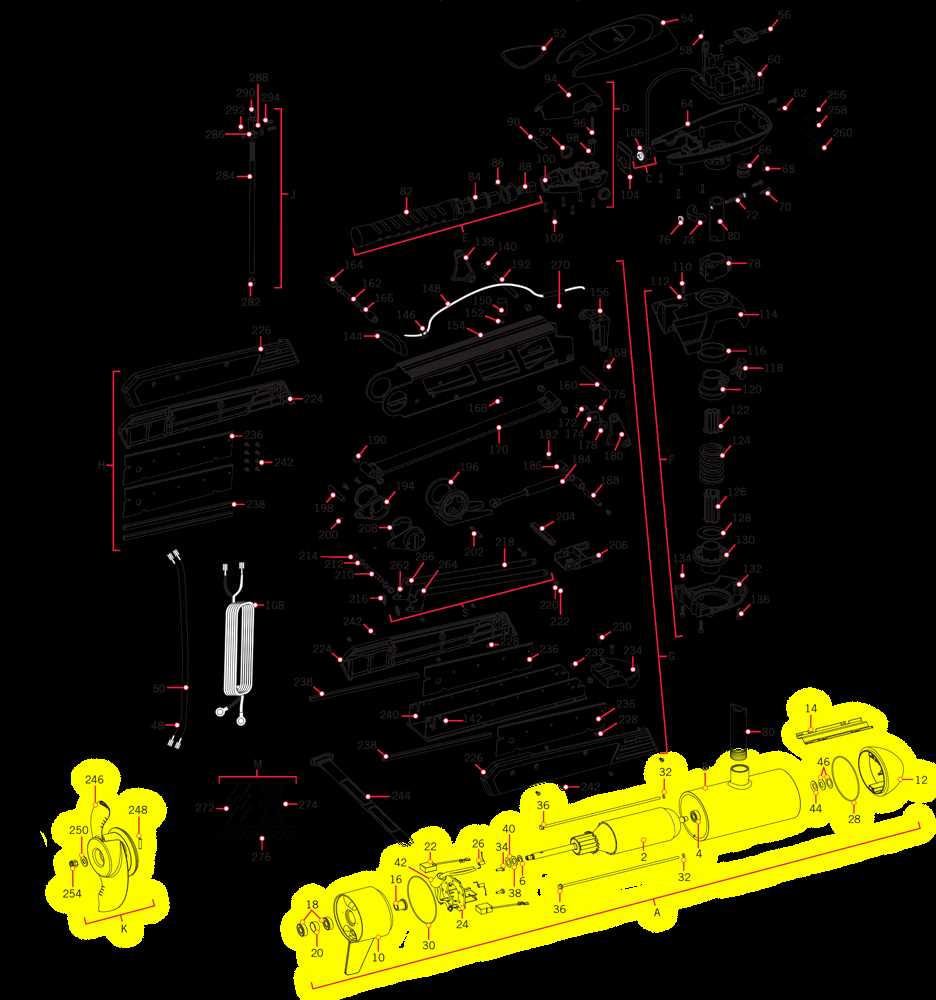

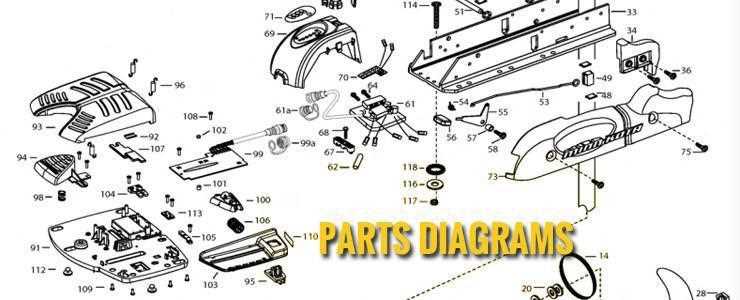

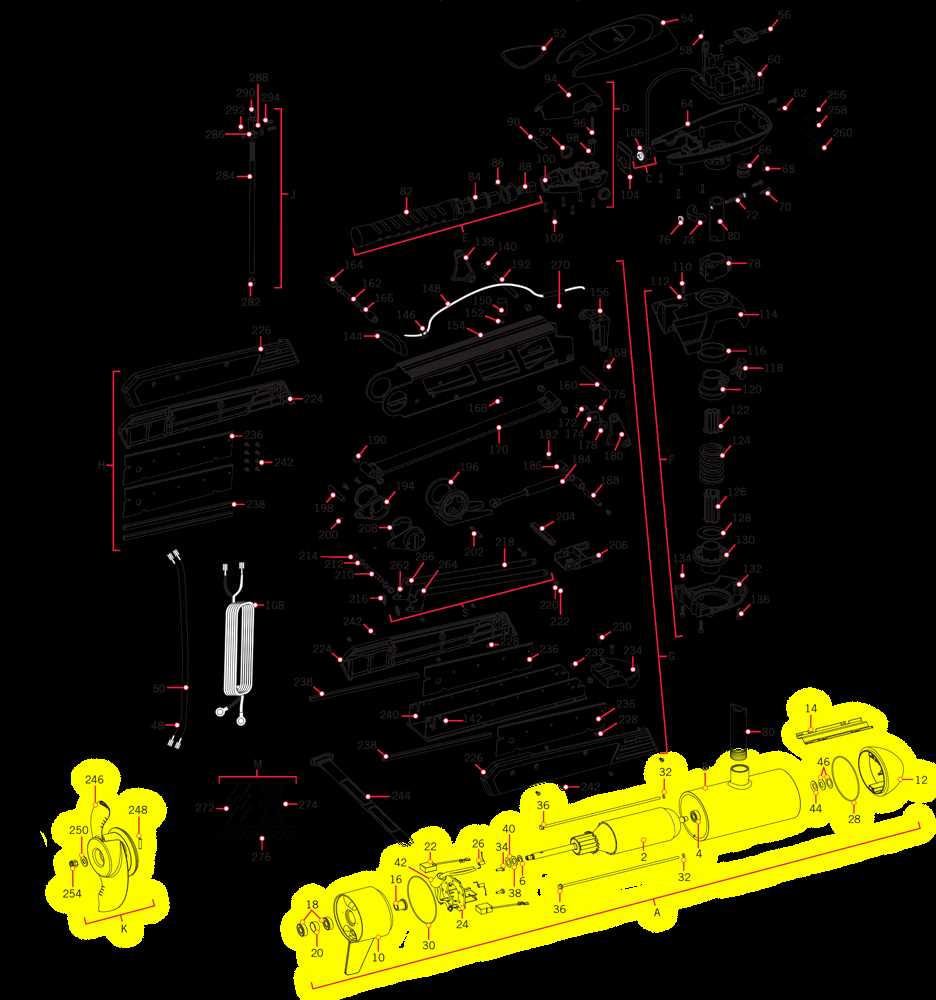

Main Motor Assembly Breakdown

The central propulsion unit relies on a precise arrangement of interconnected elements, ensuring smooth and reliable operation during water navigation. Understanding the structure and the interaction between these components helps in identifying potential issues and ensuring efficient maintenance.

Drive Shaft and Rotor: The core of the assembly, responsible for converting electrical energy into mechanical force. The rotor spins inside the stator, generating the necessary torque to propel the vessel.

Brushes and Commutator: These ensure continuous electrical contact, maintaining consistent power flow. Periodic inspection of brushes is crucial to avoid disruptions in performance

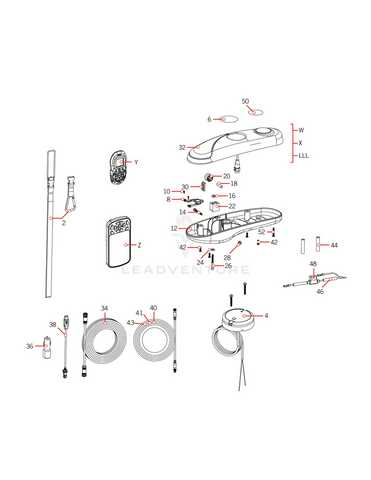

Electrical Wiring Layout and Details

Understanding the arrangement of cables and connections is essential for ensuring smooth operation and long-term reliability of electric-powered systems. A well-planned network of conductors minimizes the risk of faults and simplifies future maintenance, helping to prevent disruptions.

Cable Connections and Power Distribution

Every wire in the system plays a specific role, from delivering energy to control units to ensuring effective communication between components. Careful routing of wires reduces interference and ensures optimal performance. Attention should be given to grounding points and connectors to avoid voltage drops and signal loss.

Safety Measures and Maintenance Guidelines

Proper insulation and secure attachment of conn

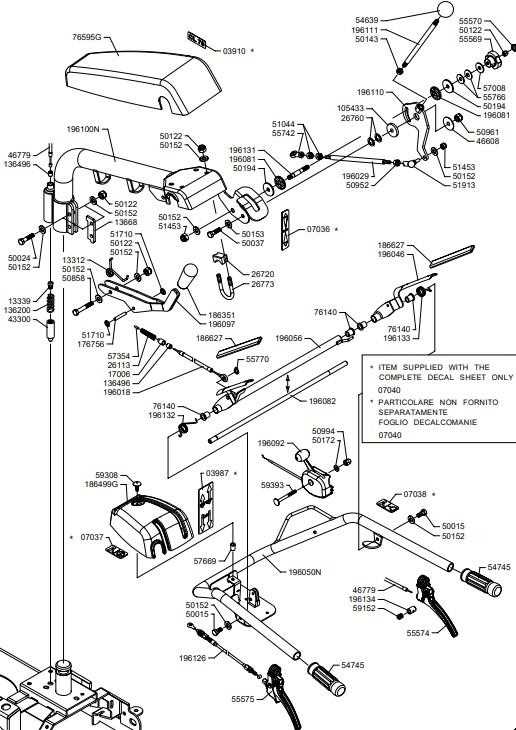

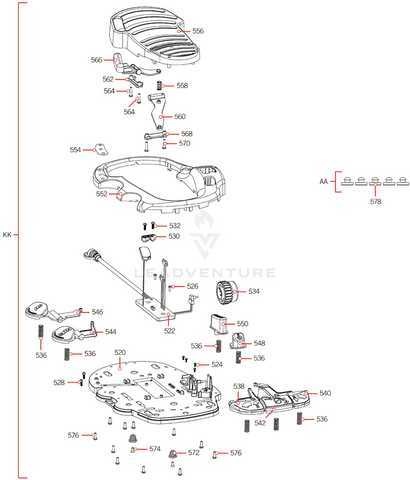

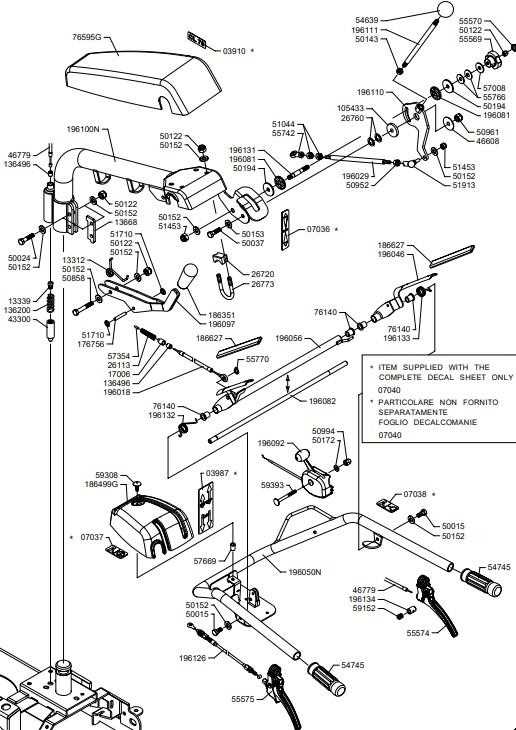

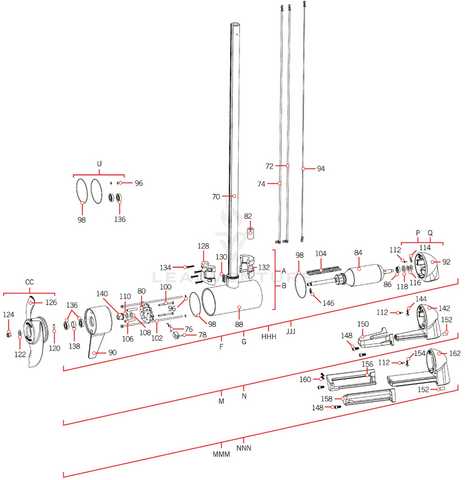

Steering Mechanism Structure

The steering system is designed to provide smooth and precise directional control, allowing seamless navigation across varying water conditions. It integrates multiple components that work in harmony to ensure stability, responsiveness, and reliability throughout the movement process.

At the core of this system lies a motorized assembly that adjusts the heading by rotating the propulsion unit. This motion is achieved through interconnected gears and linkages, translating motor input into controlled turns. The system minimizes effort while maximizing accuracy, ensuring consistent performance even under challenging conditions.

A key feature of this design is

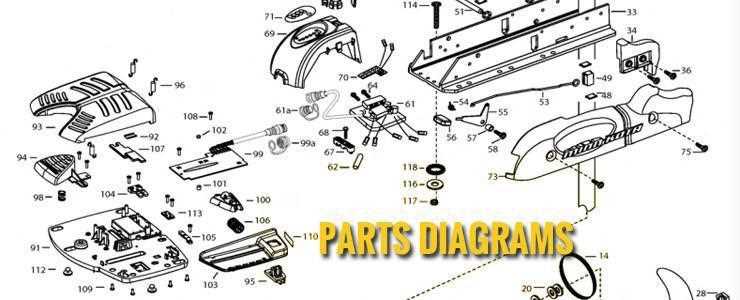

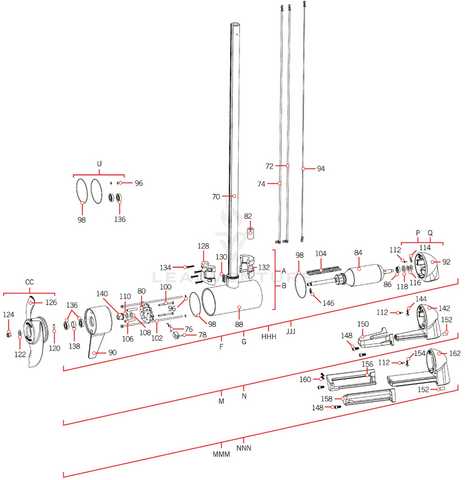

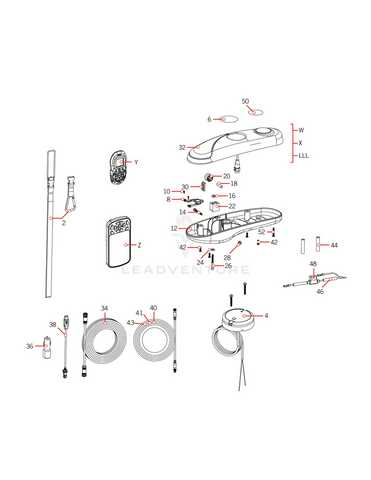

Propeller Unit and Attachments

The rotating blade system plays a key role in ensuring smooth water navigation, efficiently converting motor power into thrust. Its construction involves multiple components working together to provide seamless motion and prevent performance issues during operation. Regular inspection and maintenance of these elements help extend the service life of the system and enhance overall reliability.

Key Components of the Propeller Assembly

The assembly includes the primary rotating blades, fasteners, and a central shaft connector. These elements must be properly aligned to ensure optimal performance. Additionally, securing mechanisms such as pins or washers are essential for maintaining stability during operation.

Mounting and Fast

Control Board and Software Interface

The control board serves as the central hub for the operational management of the system, integrating various components to ensure seamless functionality. This electronic unit interprets user inputs and translates them into actionable commands, facilitating efficient performance and responsive adjustments during operation.

The software interface provides an intuitive platform for users to interact with the system. Through a user-friendly design, it allows for easy navigation and customization of settings, enhancing the overall user experience. By incorporating advanced algorithms, the interface enables real-time monitoring and adjustments, ensuring optimal efficiency and performance in diverse conditions.

Moreover, this integration of hardware and software fosters improved diagnostics and troubleshooting capabilities. Users can quickly identify issues, leading to timely maintenance and ensuring the longevity of the device. As technology advances, updates to the software interface can further enhance functionality, providing users with the latest features and improvements to their experience.

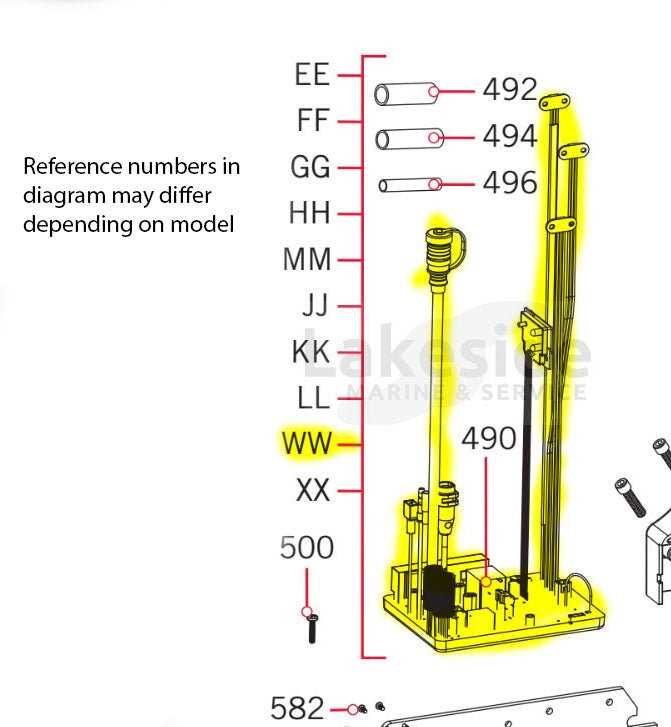

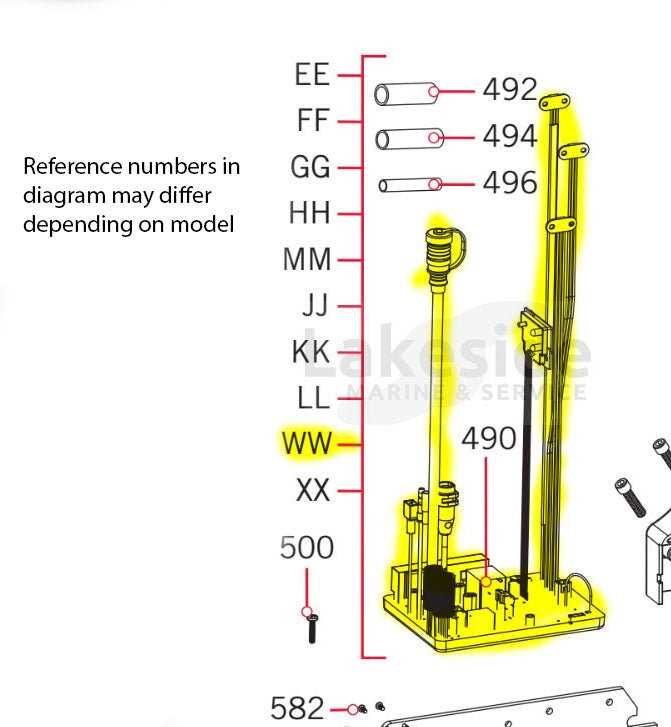

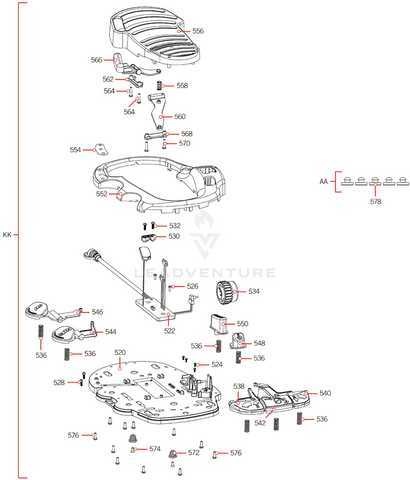

Tilt and Stow System Design

The tilt and stow mechanism is a crucial innovation in modern boating equipment, providing users with an efficient method for managing their devices. This system allows for smooth transitions between operational and storage modes, enhancing overall functionality and convenience.

Key features of this design include:

- Adjustable Angles: The ability to change the angle of the device facilitates better maneuverability and adaptation to various water conditions.

- Secure Locking Mechanism: A robust locking system ensures that the equipment remains securely stowed when not in use, preventing accidental deployment during transport.

- Ease of Use: The intuitive operation of the tilt and stow system allows users to transition seamlessly between settings, promoting a user-friendly experience.

This innovative approach not only improves performance but also adds a layer of safety and reliability to the overall experience. By incorporating advanced materials and engineering principles, the design supports the demands of both casual and professional users.

Battery Connection and Management

Effective energy supply is crucial for the reliable operation of any electric propulsion system. Proper connection and management of the energy source ensure optimal performance, longevity, and safety. This section focuses on essential practices and components necessary for maintaining a robust energy system.

Key Components for Connection

- Battery Type: Selecting the appropriate battery type, such as deep-cycle or lithium, is vital for sustained energy delivery.

- Cables and Connectors: High-quality, appropriately gauged cables and secure connectors prevent energy loss and potential hazards.

- Fuse and Circuit Breaker: These components protect against overcurrent situations, safeguarding both the battery and connected devices.

Best Practices for Energy Management

- Regular Maintenance: Check connections regularly for corrosion or damage, ensuring a secure and efficient system.

- Battery Monitoring: Use a battery management system to monitor voltage levels and state of charge, which helps in optimizing usage.

- Proper Charging: Always follow manufacturer guidelines for charging to avoid overcharging or undercharging, which can affect battery life.

- Storage Conditions: Store batteries in a cool, dry place and disconnect them during long periods of inactivity to preserve their lifespan.

Maintenance Tips for Longevity

To ensure the extended life of your equipment, regular upkeep is essential. This involves not only routine inspections but also proper care and timely repairs. By adopting a proactive approach, you can prevent potential issues and enhance the overall performance of your device.

Regular Inspections

Conducting periodic checks is crucial for identifying wear and tear. Look for signs of damage, corrosion, or any loose components. Early detection allows for swift intervention, which can save time and resources in the long run.

Cleaning and Care

Maintaining a clean environment for your device helps in preventing unnecessary wear. Ensure that debris and saltwater do not accumulate, as they can cause significant damage. Use suitable cleaning agents and tools to keep all surfaces in optimal condition.

| Action |

Frequency |

Purpose |

| Inspect components |

Monthly |

Identify potential issues |

| Clean surfaces |

After each use |

Prevent corrosion and buildup |

| Check connections |

Bi-monthly |

Ensure secure operation |

| Lubricate moving parts |

Quarterly |

Reduce friction and wear |