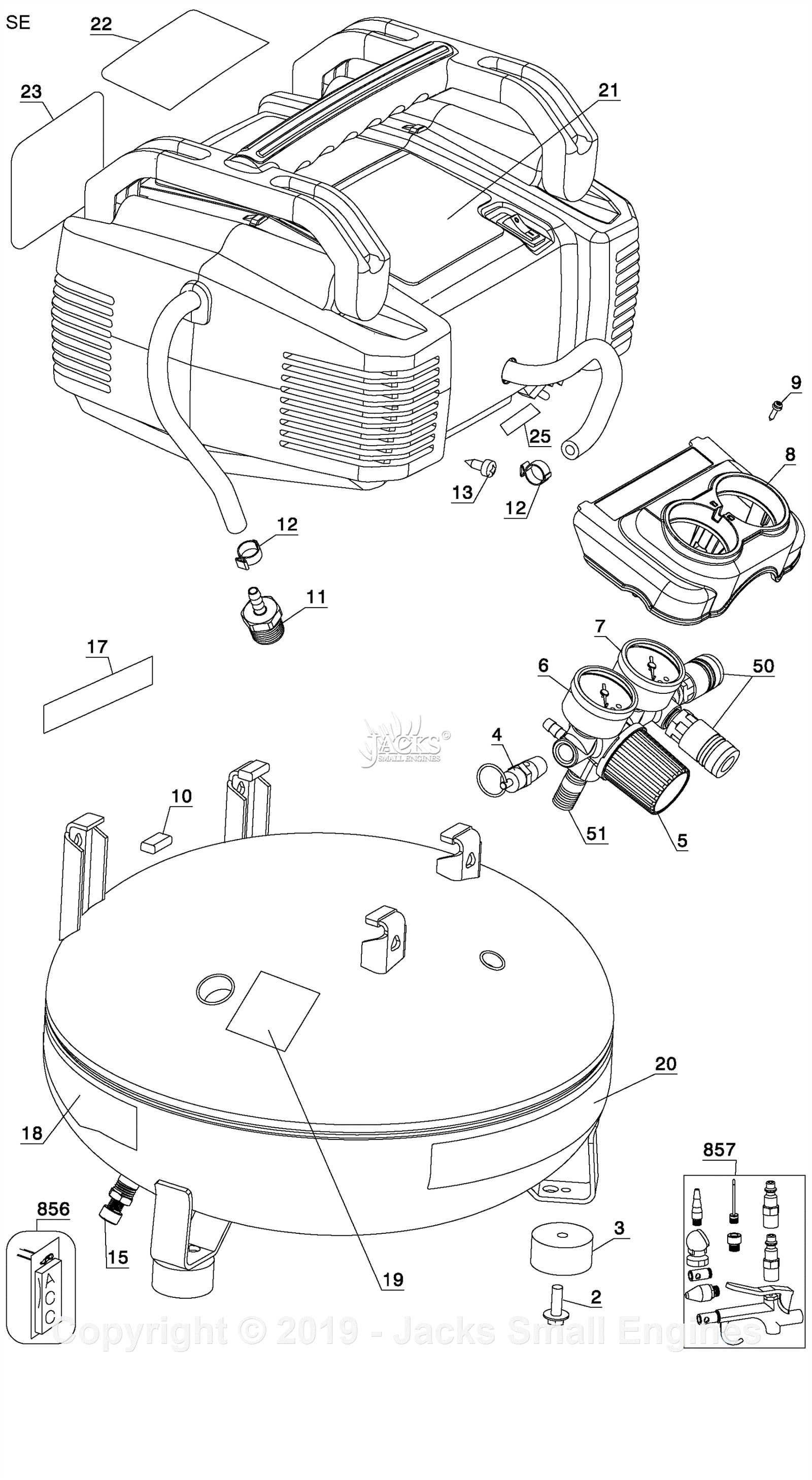

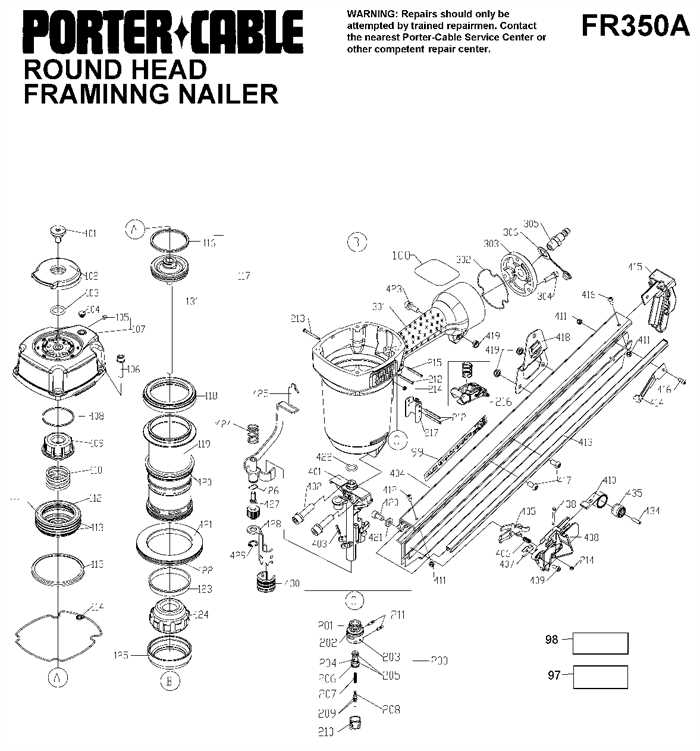

In the world of power tools, comprehending the various components that make up these machines is essential for effective maintenance and repair. A clear visualization of each element not only aids in troubleshooting issues but also enhances the overall user experience. By familiarizing oneself with the intricate details of these devices, operators can ensure their tools function optimally and last longer.

Such illustrations serve as a valuable reference for anyone looking to disassemble, reassemble, or replace specific elements. Understanding how each part fits together can significantly simplify the repair process, reducing the time and effort required to address common problems. Whether for professional use or personal projects, having a solid grasp of the essential features of a tool can lead to more efficient and successful operations.

When dealing with various components of a specific tool, users may encounter a range of challenges that affect its performance. Understanding these common problems can significantly aid in maintaining the device’s efficiency and longevity. This section explores typical issues that arise with these components, offering insights for troubleshooting and preventive measures.

One frequent concern involves wear and tear of the internal mechanisms, which can lead to decreased functionality. Other typical problems include improper alignment, which may cause jams, and issues with power supply affecting overall operation. Each of these matters can manifest in different ways, often requiring careful inspection and maintenance.

| Issue | Description | Possible Solution |

|---|---|---|

| Worn Mechanisms | Parts may lose efficiency over time due to constant use. | Regularly inspect and replace worn components. |

| Misalignment | Components may become misaligned, causing operational difficulties. | Adjust and realign parts as needed. |

| Power Supply Issues | Inconsistent power can hinder performance. | Check connections and replace faulty power sources. |

Replacing Worn or Damaged Components

Over time, tools can experience wear and tear, leading to decreased performance and efficiency. Identifying and replacing worn or damaged elements is essential for maintaining optimal functionality. Regular maintenance not only prolongs the life of the equipment but also ensures safety during operation.

When considering component replacement, follow these key steps:

- Inspect the tool for signs of damage or wear, such as cracks, rust, or abnormal noises during operation.

- Consult the user manual or manufacturer’s resources for specific guidance on the components that may need replacement.

- Gather necessary tools and replacement components before starting the repair process.

- Follow a systematic approach to disassemble the tool carefully, noting the position of each component for reassembly.

- Replace the worn or damaged components with new parts, ensuring proper alignment and secure fittings.

- Reassemble the tool carefully, following the notes taken during disassembly to ensure everything is placed correctly.

- Conduct a thorough inspection and test the tool to ensure it operates correctly and safely after replacement.

By adhering to these guidelines, users can effectively restore their equipment’s performance and reliability.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your tools requires regular care and attention. By implementing a few essential maintenance practices, you can extend the life of your equipment and enhance its efficiency. Simple tasks, such as cleaning and inspection, play a crucial role in preventing common issues that can arise over time.

Regular Cleaning

Keeping your equipment clean is fundamental to its longevity. After each use, remove any debris or dust from the surface and internal components. Use a soft brush or cloth to prevent damage while ensuring that no particles hinder the operation of moving parts. Regular cleaning not only maintains appearance but also prevents wear and tear.

Periodic Inspections

Routine inspections are vital for identifying potential problems before they escalate. Check for any signs of wear, loose components, or other issues that may affect performance. Addressing minor concerns promptly can save you from more significant repairs in the future. Establish a regular schedule for these checks to stay proactive in your maintenance efforts.

Finding Genuine Replacement Parts

When it comes to maintaining the longevity and performance of your equipment, sourcing authentic components is crucial. Utilizing high-quality replacements ensures optimal functionality and safety. Here are some key considerations for identifying genuine replacements.

- Research the Manufacturer: Start by identifying the brand behind your equipment. Official websites often provide resources for locating authorized dealers.

- Check Compatibility: Ensure that any components you consider are compatible with your specific model. Review specifications and compare with your current items.

- Look for Certifications: Genuine items typically have certification marks or labels indicating their authenticity. Be cautious of generic alternatives that may compromise quality.

By following these guidelines, you can confidently select authentic components that will enhance your equipment’s performance and reliability.