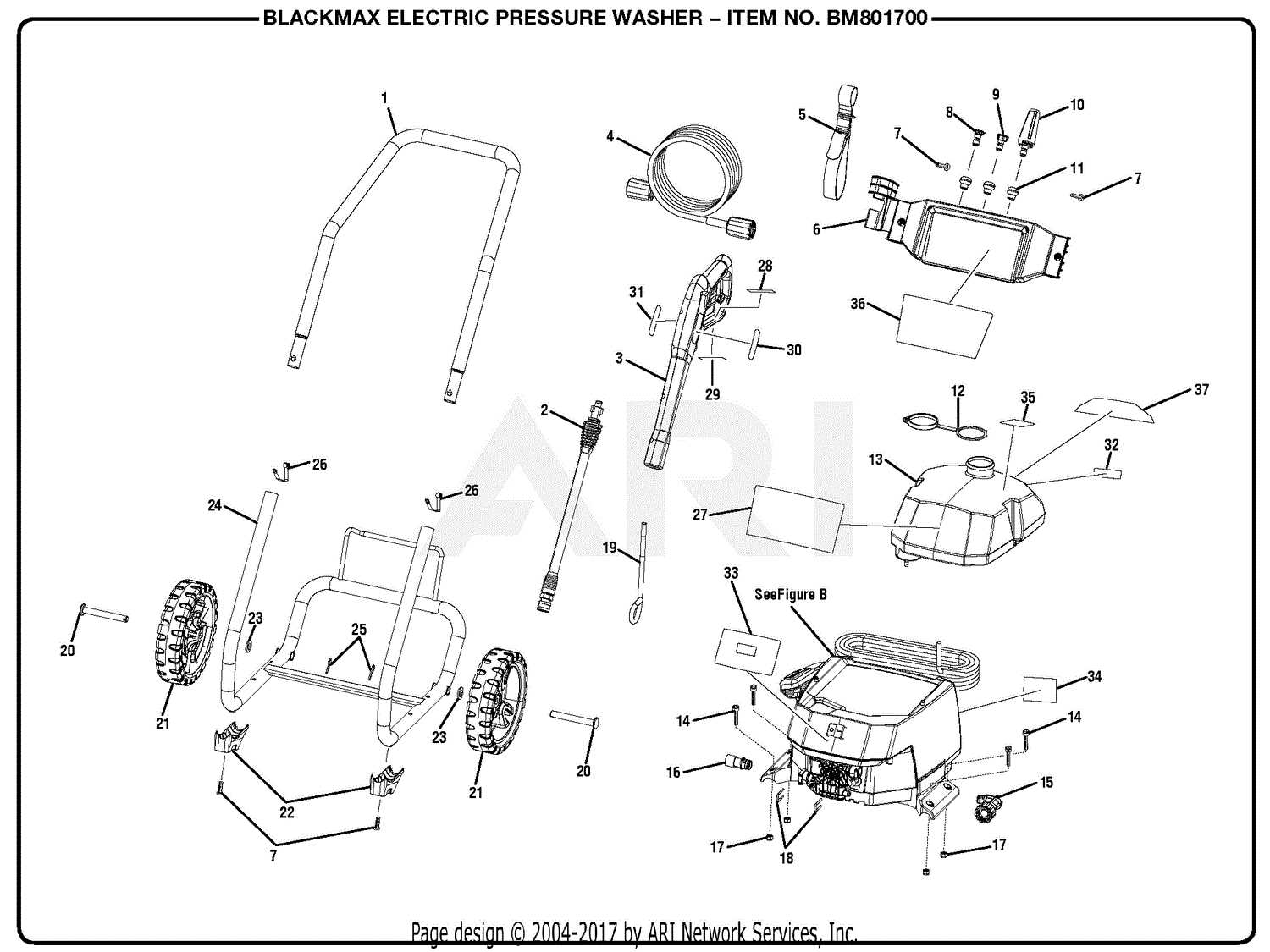

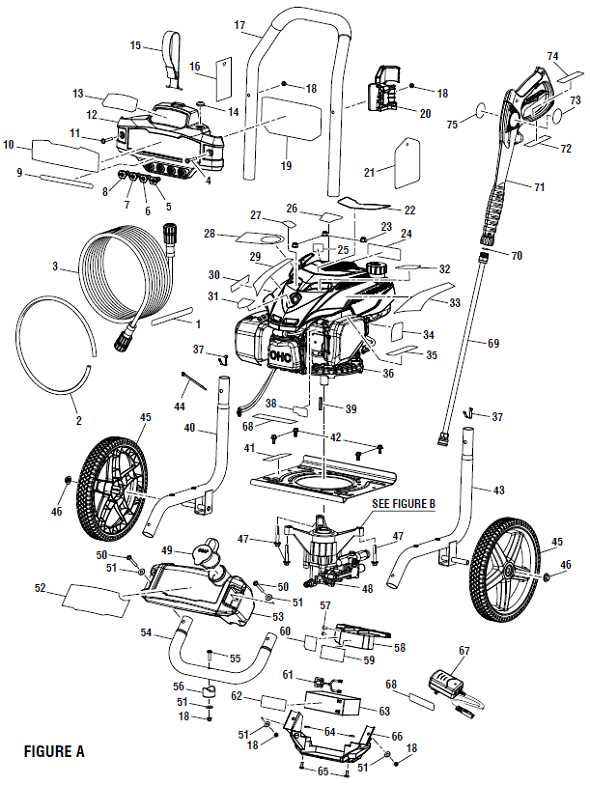

In the realm of home maintenance, having a reliable cleaning device can make all the difference. These machines are engineered to deliver optimal performance, ensuring that various surfaces remain pristine. To maximize efficiency and prolong the lifespan of your cleaning equipment, it is crucial to familiarize yourself with its individual elements.

Each device consists of numerous components, each serving a specific function in the overall operation. By gaining insight into the structure and arrangement of these elements, users can troubleshoot issues more effectively and perform necessary repairs with confidence. This knowledge empowers owners to maintain their equipment in peak condition, thus enhancing its cleaning capabilities.

This guide will delve into the essential components of a specific model, illustrating their roles and interconnections. A clear representation will aid in understanding how each piece contributes to the machine’s functionality. Whether you’re a novice or an experienced user, this information will be invaluable for ensuring optimal performance and addressing any concerns that may arise during operation.

Yamaha MA190 Pressure Washer Overview

This section provides a comprehensive overview of a specific model designed for high-performance cleaning tasks. Its powerful motor and innovative design make it an essential tool for various applications, from home maintenance to professional use.

Key features of this cleaning device include:

- Robust engine that delivers exceptional cleaning power

- Ergonomic design for ease of use and maneuverability

- Variety of nozzles for versatile cleaning options

- Durable construction to withstand rigorous use

The model is equipped with advanced technology that enhances efficiency and performance. Users can expect:

- Quick setup and operation for immediate results

- Effective removal of dirt and grime from multiple surfaces

- Low maintenance requirements for hassle-free ownership

Overall, this device stands out in its category, providing reliability and effectiveness for both residential and commercial cleaning tasks.

Essential Components of the MA190 Washer

This section delves into the fundamental elements that contribute to the efficient operation of the cleaning equipment. Each component plays a critical role in ensuring performance, durability, and user satisfaction. Understanding these elements helps in maintenance and troubleshooting, ultimately enhancing the longevity of the device.

Key Elements

Several core components are essential for optimal functionality. They work together seamlessly to provide effective cleaning solutions, and knowing their roles can assist in identifying issues when they arise.

| Component | Function |

|---|---|

| Motor | Powers the unit and drives the water pump. |

| Pump | Increases water pressure and regulates flow. |

| Nozzle | Controls the spray pattern and intensity of the water. |

| Hose | Transports water from the unit to the target surface. |

| Trigger Gun | Allows the user to control the water flow and pressure. |

Maintenance Considerations

Regular inspection and care of these key elements are vital for ensuring long-term performance. Addressing any wear or damage promptly can prevent more significant issues down the line, maintaining the efficiency and reliability of the cleaning unit.

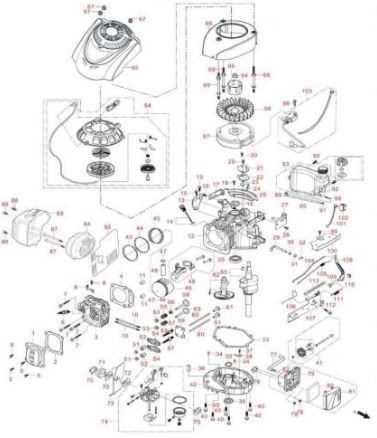

Engine Parts and Maintenance Tips

Maintaining the functionality of a motorized device is essential for ensuring its longevity and efficiency. Regular upkeep of the various components that make up the engine is vital to prevent breakdowns and enhance performance. This section outlines key components of the engine and offers valuable maintenance recommendations to keep it running smoothly.

- Fuel System: Regularly check and replace fuel filters to prevent contaminants from damaging the engine. Use high-quality fuel to ensure optimal combustion.

- Air Intake: Clean or replace air filters to maintain proper airflow. A clogged filter can reduce efficiency and increase fuel consumption.

- Lubrication: Regular oil changes are crucial. Use the recommended oil type and check oil levels frequently to ensure proper lubrication of moving parts.

- Cooling System: Inspect the cooling system for leaks and ensure that coolant levels are adequate. Overheating can cause significant damage to the engine.

- Ignition Components: Check spark plugs and ignition coils for wear. Replace them as needed to ensure reliable starting and smooth operation.

By paying attention to these essential aspects and performing regular inspections, users can significantly extend the lifespan of their equipment. Always consult the manufacturer’s recommendations for specific maintenance schedules and procedures.

Exploring the Pump Assembly

The pump assembly is a crucial component in any cleaning system, responsible for converting mechanical energy into fluid movement. This section delves into the intricacies of this assembly, highlighting its various elements and their respective functions within the overall mechanism. Understanding the assembly is essential for efficient operation and maintenance.

At the heart of the pump lies a series of interconnected parts that work in unison to generate pressure and facilitate the flow of liquid. Here is a breakdown of the key components:

| Component | Description |

|---|---|

| Casing | Encases the internal components and maintains structural integrity. |

| Piston | Moves back and forth to create pressure within the chamber. |

| Valves | Regulate the flow of liquid, ensuring it moves in the correct direction. |

| Connecting Rod | Links the piston to the motor, translating rotary motion into linear motion. |

| Seals | Prevent leaks and maintain pressure within the assembly. |

Each element plays a vital role in ensuring optimal functionality. Regular inspection and maintenance of the pump assembly are essential to prolong its lifespan and maintain efficient performance.

Hose and Nozzle Specifications

This section provides an overview of the specifications for the flexible tubing and attachments used in high-performance cleaning equipment. Understanding these components is essential for optimizing functionality and ensuring compatibility with various applications. The correct selection of hoses and nozzles can significantly enhance efficiency and improve cleaning outcomes.

| Component | Specifications | Description |

|---|---|---|

| Hose Length | 25 ft, 50 ft | Available in different lengths to suit various working environments, allowing for extended reach without sacrificing power. |

| Hose Diameter | 1/4 inch, 3/8 inch | Standard diameters that ensure optimal flow rates and compatibility with numerous attachments. |

| Nozzle Type | Adjustable, Turbo, Fan | Diverse nozzle options that provide different spray patterns, allowing users to customize the cleaning process based on the task at hand. |

| Pressure Rating | 3000 PSI, 4000 PSI | Designed to withstand high pressure, ensuring durability and safety during operation. |

| Material | Rubber, PVC | Constructed from high-quality materials for flexibility and resistance to wear, chemicals, and environmental factors. |

By selecting the appropriate components based on these specifications, users can ensure their equipment operates at peak performance, tailored to meet specific cleaning demands.

Cleaning Solutions for Optimal Performance

Maintaining the efficiency of your cleaning equipment requires not only routine checks but also the right cleaning agents. Utilizing appropriate solutions can significantly enhance the performance and longevity of your machinery. This section focuses on various types of cleaners that can be effectively employed to achieve optimal results.

Biodegradable Cleaners: These eco-friendly alternatives are designed to break down naturally, minimizing environmental impact while delivering effective cleaning power. Their formulation typically includes plant-based ingredients that tackle grime without harsh chemicals.

Concentrated Solutions: Concentrated cleaning products are highly efficient as they require dilution before use. This means that a small amount can yield a large volume of cleaning solution, making them cost-effective and space-saving options for any user.

Heavy-Duty Degreasers: For tackling stubborn stains and built-up grease, heavy-duty degreasers are essential. These products are formulated to penetrate and dissolve tough residues, restoring the surfaces to their original state.

Gentle Foaming Agents: Gentle foaming cleaners are perfect for sensitive surfaces, providing a thorough clean without causing damage. The foam action helps to lift dirt and debris, ensuring a meticulous finish without the need for aggressive scrubbing.

Choosing the right cleaning agents tailored to specific needs not only improves effectiveness but also helps in prolonging the life of your equipment. Regularly incorporating these solutions into your maintenance routine will ensure sustained performance over time.

Replacement Parts for Long-Term Use

Ensuring the longevity of any machine requires a thoughtful approach to maintenance, including the use of high-quality replacement components. Over time, certain elements may wear down or fail, affecting overall performance. It is crucial to identify and replace these key components regularly to keep your device running smoothly and efficiently.

Identifying Essential Components

When considering replacements, it’s important to focus on parts that significantly contribute to the functionality of the equipment. Components such as seals, filters, and hoses are often subject to wear and tear, making them prime candidates for replacement. Using reliable substitutes will enhance performance and extend the lifespan of the equipment.

Benefits of Using Quality Replacements

Investing in quality replacements yields multiple advantages. Premium components often come with better warranties and are designed to withstand the rigors of usage. Furthermore, they typically provide improved efficiency, which can result in reduced operational costs over time. Choosing the right replacements is essential for maintaining optimal performance.

| Component | Purpose | Recommended Replacement Interval |

|---|---|---|

| Seals | Prevent leaks and maintain pressure | Every 6 months |

| Filters | Ensure clean fluid flow | Annually |

| Hoses | Transport fluid efficiently | Every 2 years |

Common Issues and Troubleshooting Advice

This section aims to provide valuable insights into frequent problems that users may encounter with their cleaning equipment. Understanding these issues and implementing effective solutions can enhance the overall performance and longevity of the device.

Frequent Problems

Users may experience a variety of challenges with their cleaning units. These can include reduced efficiency, unusual noises, or difficulty starting the machine. Identifying the root cause of these problems is crucial for effective resolution.

Troubleshooting Tips

Here are some common issues along with troubleshooting suggestions:

| Issue | Potential Cause | Suggested Solution |

|---|---|---|

| Loss of power | Clogged inlet filter | Clean or replace the filter to restore functionality. |

| Unusual noise | Loose components | Tighten all screws and bolts; inspect moving parts for wear. |

| Difficulty starting | Insufficient fuel or battery charge | Check fuel levels or recharge the battery as necessary. |

| Water leakage | Worn seals or hoses | Inspect and replace any damaged seals or hoses. |