When it comes to the maintenance of upright vacuum cleaners, knowing the structure and design of individual components is essential. By familiarizing yourself with the different elements and how they interact, you can better understand how these machines operate and how to keep them in optimal condition for long-term use.

Each element in the cleaner’s construction plays a vital role in ensuring smooth functionality. Whether you’re looking to improve suction power or extend the lifespan of the motor, understanding these components can lead to more efficient troubleshooting and care.

In this guide, we will explore key features and functions, offering a detailed breakdown of what makes up the essential internal and external pieces. This knowledge can empower you to address common issues and perform routine maintenance, ensuring that your device continues to perform at its best.

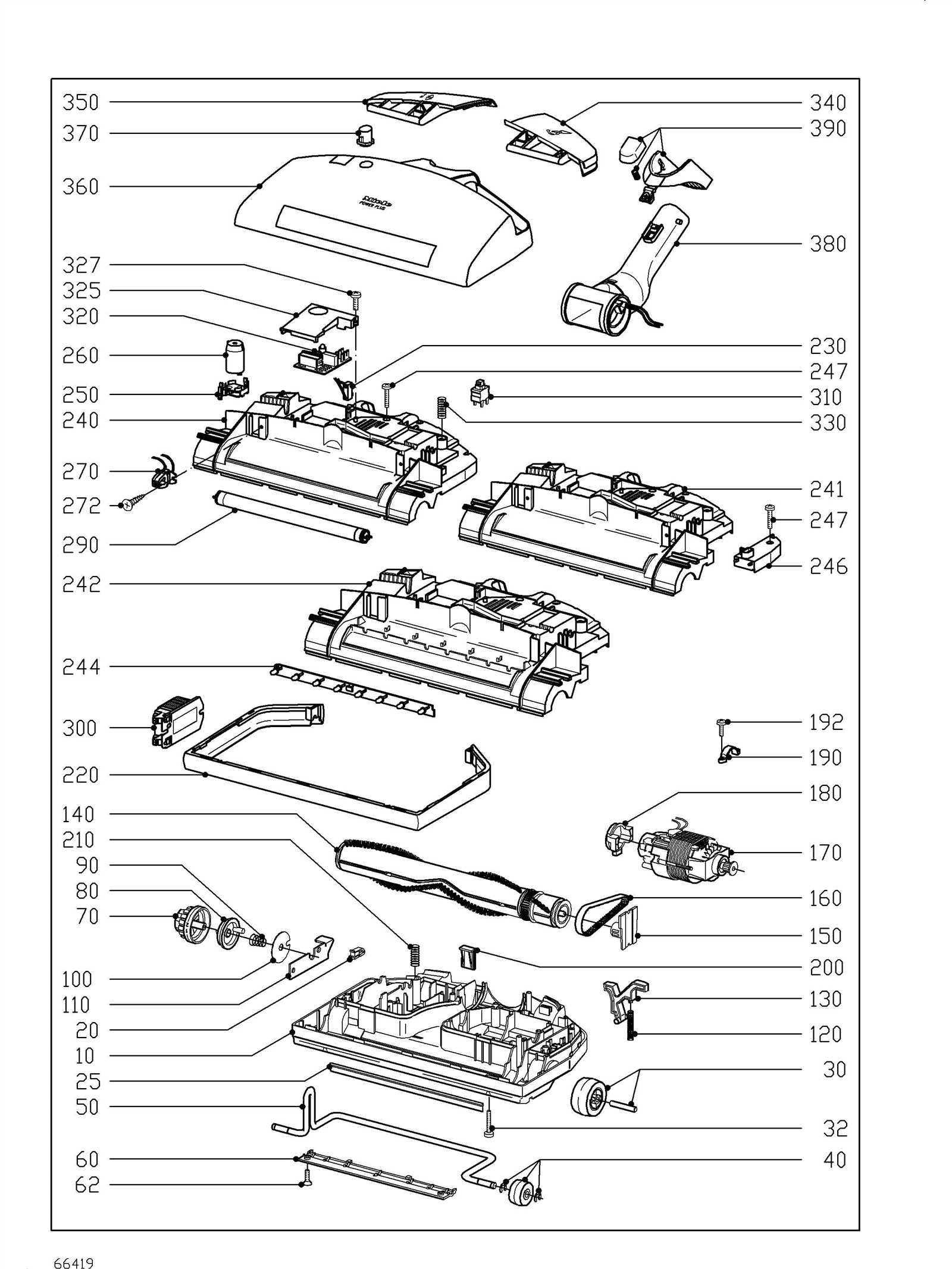

Miele S7210 Parts Overview

This section provides a comprehensive look at the various components and features of the cleaning system, offering insight into the design and functionality. Each element plays a vital role in ensuring smooth operation and effective performance. Below, you’ll find a breakdown of key elements that contribute to its overall efficiency.

Main Structural Components

- Handle and Control Area: Designed for ease of use, the upper section includes controls and ergonomic features that enhance user experience.

- Filtration System: Equipped with advanced layers to capture even the smallest particles, ensuring high air quality during operation.

- Motor Housing: Positioned centrally, this section powers the entire unit, delivering consistent and reliable performance.

Additional Functional Elements

- Brush Mechanism: This rotating component ensures deep cleaning by agitating surfaces and loosening debris.

- Dust Collection Area: Located towards the base, it securely holds waste materials, minimizing the need for frequent disposal.

- Power Cord and Winding System: Conveniently stored and easily extended, ensuring reach without compromising maneuverability.

Internal Components and Mechanisms

The inner workings of any advanced device are a complex system of interrelated parts, designed to perform various tasks efficiently. Understanding these mechanisms allows for better maintenance and troubleshooting, ensuring the device operates smoothly for extended periods. Each element is carefully engineered to serve a specific purpose, contributing to the overall functionality of the system.

At the core of the machine lies the motor, which generates the power necessary for the device’s operation. Connected to this are various gears and belts, which transfer energy to the appropriate sections, enabling different functions. The filtration system, another essential aspect, works to separate unwanted particles, keeping the internal environment clean and free of blockages. Additionally, the air pathways ensure optimal airflow, helping to regulate the performance.

Moving parts such as brushes or rollers also play a crucial role in ensuring thorough action during use. These components are built for durability but may require regular cleaning or replacement to

Filter and Bag System Details

Understanding how the filtration and collection system works is essential for ensuring optimal performance and longevity. The system is designed to trap dust and debris efficiently while maintaining air quality, reducing the need for frequent cleaning or replacement. The filtration setup plays a crucial role in keeping the air free from particles, while the collection mechanism ensures that waste is stored securely.

Filtration Stages

The filtration process involves multiple stages, each targeting different types of contaminants. These stages include a pre-filter for larger debris, followed by a secondary filter that captures finer particles. This layered approach helps extend the lifespan of the system and ensures thorough cleaning with minimal effort.

Bag Replacement and Maintenance

The collection system is equipped with a specially designed bag that not only holds the debris but also contributes to the filtration process. It’s

Brush Roll and Belt Assembly

The brush roll and belt mechanism plays a vital role in ensuring the efficient functioning of a vacuum cleaner. Together, they work to agitate carpet fibers, lifting dirt and debris, while the belt ensures the continuous rotation of the brush roll. Regular maintenance of these components is crucial for optimal performance.

Key Components

- Brush Roll: A cylindrical component with bristles that rotates to sweep dirt from surfaces. It’s designed to handle various floor types, ensuring thorough cleaning.

- Belt: A flexible rubber or synthetic material that connects the motor to the brush roll, ensuring its rotation during operation.

Maintenance Tips

- Check the brush roll regularly for any hair or debris that may cause obstructions.

- Inspect the belt for wear and tear. A loose or broken

Electrical Wiring and Motor Layout

Understanding the configuration of electrical circuits and motor placement is essential for maintaining and repairing vacuum cleaners. The internal wiring ensures the safe transmission of power, while the motor is responsible for generating suction force. These components are interconnected in a specific manner to provide efficient performance and reliability.

The motor is typically located in the central housing, connected to the power supply through insulated wires. These wires follow a structured path, ensuring minimal interference and optimal energy flow. Below is a simple layout illustrating key electrical connections and motor positioning:

Component Function Main Power Cable Transfers electrical power from the outlet to the internal systems. Motor Unit Generates suction force and operates the mechanical components. Handle and Cord Components

This section delves into the essential elements that facilitate the operation and usability of a vacuum cleaner, focusing on the grip and electrical cord. These components play a critical role in ensuring user comfort and efficiency during cleaning tasks.

Handle Design and Functionality

The handle of a cleaning device is crafted to provide a comfortable grip, allowing users to maneuver the appliance with ease. Its ergonomic design reduces strain on the wrist, making extended cleaning sessions more manageable. Many handles also incorporate buttons and controls for seamless operation, enhancing the overall user experience.

Cord Management and Length

The cord serves as the vital link to the power source, and its length is crucial for providing flexibility during use. Proper management systems, such as automatic rewind or hooks, ensure the cord remains tidy when not in use. Durable materials used for the cord protect against wear and tear, ensuring longevity and safety during operation.

External Casing and Protective Parts

The external structure of a vacuum cleaner serves as the first line of defense against environmental elements and physical impacts. It plays a crucial role in maintaining the device’s functionality while also contributing to its overall aesthetic appeal. This section delves into the various components that comprise the outer shell and protective features of such equipment.

These outer parts are designed not only for durability but also for ease of maintenance and user interaction. Key features include:

- Outer Housing: The primary shell that encases internal mechanisms, providing stability and protection.

- Grille and Vent Covers: Essential for airflow management, these components prevent debris from entering critical areas.

- Base Plate: The bottom section that makes contact with surfaces, often reinforced to resist wear and tear.

- Filter Compartments: Designed to securely hold filters, ensuring optimal performance and cleanliness.

- Control Panels: User interfaces integrated into the casing, allowing for easy operation and adjustments.

In addition to these parts, protective features such as bumpers or edge guards are often included to minimize damage during accidental collisions. Understanding the significance of these components helps in appreciating their role in enhancing both performance and longevity.

Proper maintenance of the outer casing and protective elements is essential for ensuring the vacuum cleaner remains effective over time. Regular inspections for signs of wear, such as cracks or loose fittings, can prevent further damage and extend the lifespan of the device.

Replacement Part Compatibility Guide

Understanding the compatibility of various components is crucial when maintaining or repairing your cleaning device. This guide aims to help users navigate the options available for replacements, ensuring that the selected parts will function seamlessly with the existing system.

When selecting replacement components, consider the following factors:

- Model Specifications: Ensure that the new parts are designed for your specific model, as variations can affect performance.

- Quality Standards: Opt for components that meet industry standards to guarantee durability and efficiency.

- Manufacturer Recommendations: Always check the manufacturer’s guidelines for recommended replacement options to avoid compatibility issues.

Here are some common categories of components and their compatibility considerations:

- Filters: Different models may require specific filter sizes and types to ensure optimal air flow and filtration.

- Hoses: Verify the attachment points and lengths to ensure a proper fit and functionality.

- Brushes: Look for variations in bristle type and design, which can impact cleaning performance.

By carefully evaluating these factors, users can select suitable replacement components that enhance the performance and longevity of their cleaning equipment.

Maintenance Tips for Key Parts

Proper care and upkeep of essential components are crucial for ensuring optimal performance and longevity of your cleaning device. Regular maintenance not only enhances efficiency but also minimizes the risk of breakdowns, thereby extending the life of the equipment. Below are some valuable tips to help you maintain the key elements effectively.

Regular Cleaning and Inspection

Routine cleaning and examination of critical components play a significant role in maintaining functionality. Ensure that filters and brushes are cleared of debris and dust buildup. This will not only improve suction power but also prevent overheating. Periodically check for any signs of wear or damage, and replace any compromised elements promptly to maintain peak performance.

Proper Storage and Usage

Storing the device in a dry and safe environment can prevent unnecessary wear and tear. Avoid exposing it to extreme temperatures or humidity, as these conditions can adversely affect various parts. Additionally, using the equipment according to the manufacturer’s guidelines will help prevent potential issues. Being mindful of the surfaces you clean and avoiding overloading the unit will contribute to its durability.