The intricate design of marine engines is a testament to engineering excellence, combining various elements that work harmoniously to deliver optimal performance. This section delves into the essential components that make up a typical outboard motor, offering insights into their functions and interrelations.

Each segment of the engine plays a crucial role in its overall operation, influencing efficiency and durability. By examining the layout and configuration of these elements, enthusiasts and technicians can gain a deeper appreciation of how to maintain and troubleshoot their vessels effectively.

Whether you are a seasoned mechanic or a newcomer to marine technology, understanding these mechanical structures can greatly enhance your ability to diagnose issues and perform repairs. In this exploration, we aim to clarify the relationships between various components and illustrate their significance in the engine’s functionality.

The engine comprises several essential elements that work together to ensure optimal performance and efficiency. Understanding these components is crucial for anyone looking to maintain or troubleshoot the system effectively.

- Powerhead: The upper section of the engine housing critical mechanical components that generate thrust.

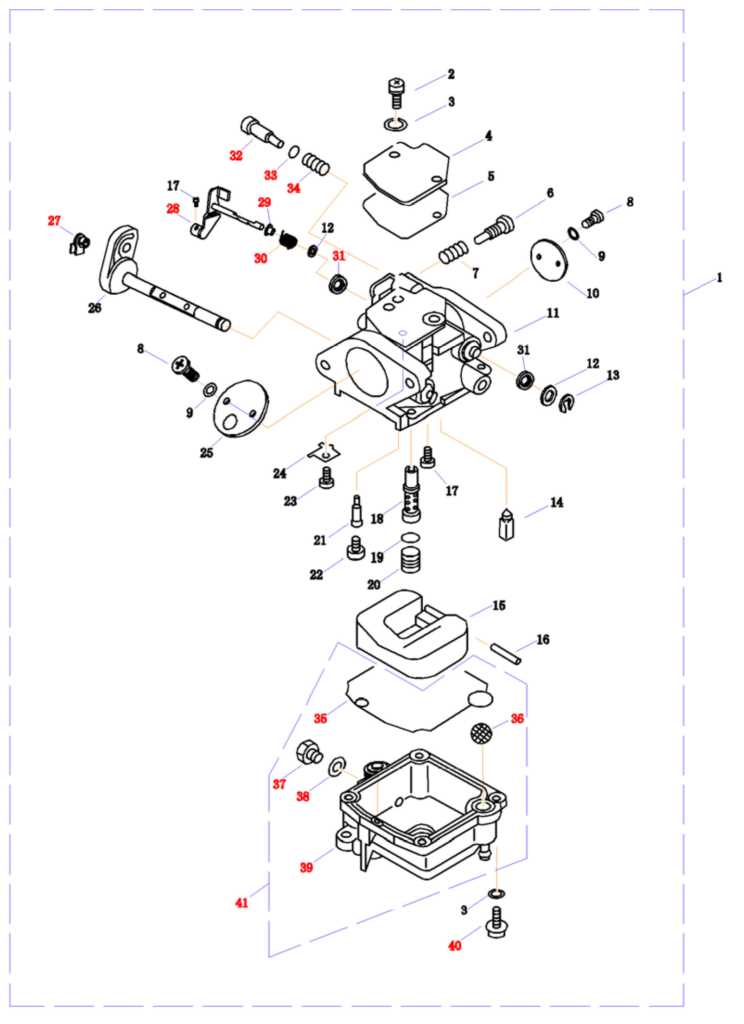

- Fuel System: This includes the fuel tank, lines, and injectors, which are responsible for delivering the necessary fuel to the engine.

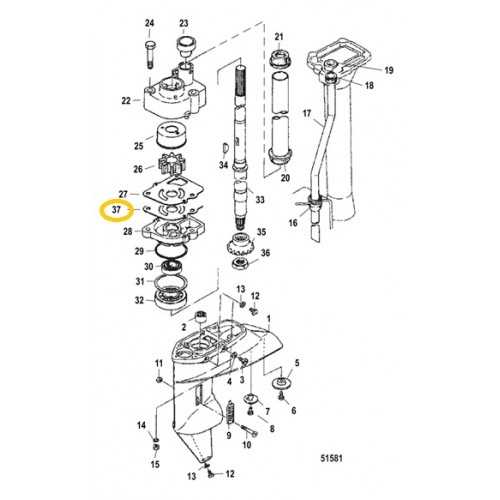

- Cooling System: A network of passages and pumps that circulates coolant to prevent overheating during operation.

- Exhaust System: This component directs exhaust gases away from the engine, ensuring smooth operation and reducing emissions.

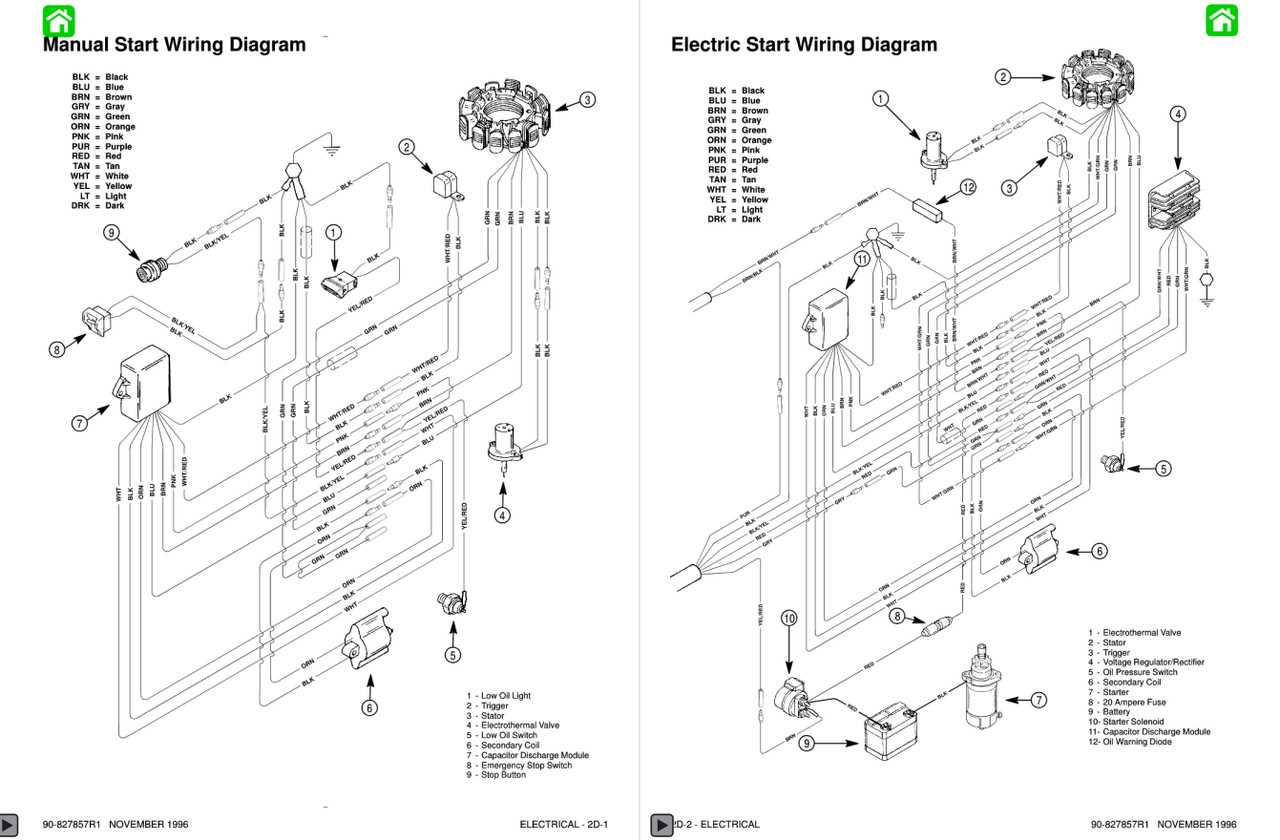

- Ignition System: It consists of spark plugs and coils that initiate the combustion process, enabling the engine to start and run.

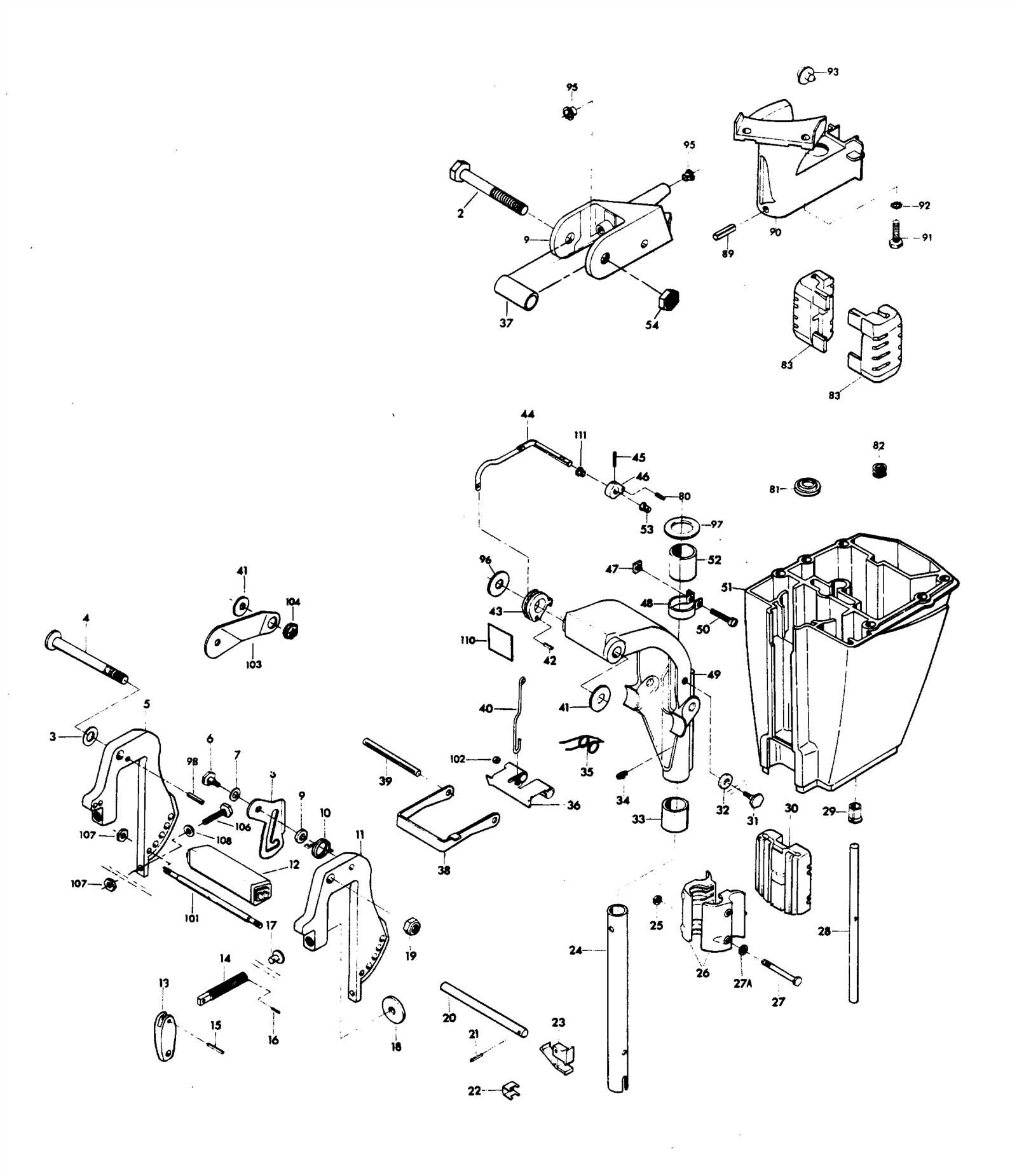

- Transmission: This part transmits power from the engine to the propeller, influencing speed and torque.

Each of these elements plays a vital role in the overall functionality of the engine, contributing to its performance and reliability on the water.

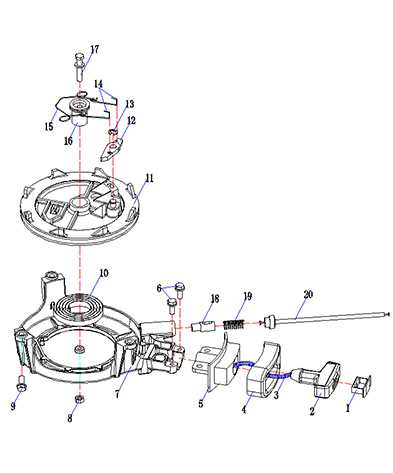

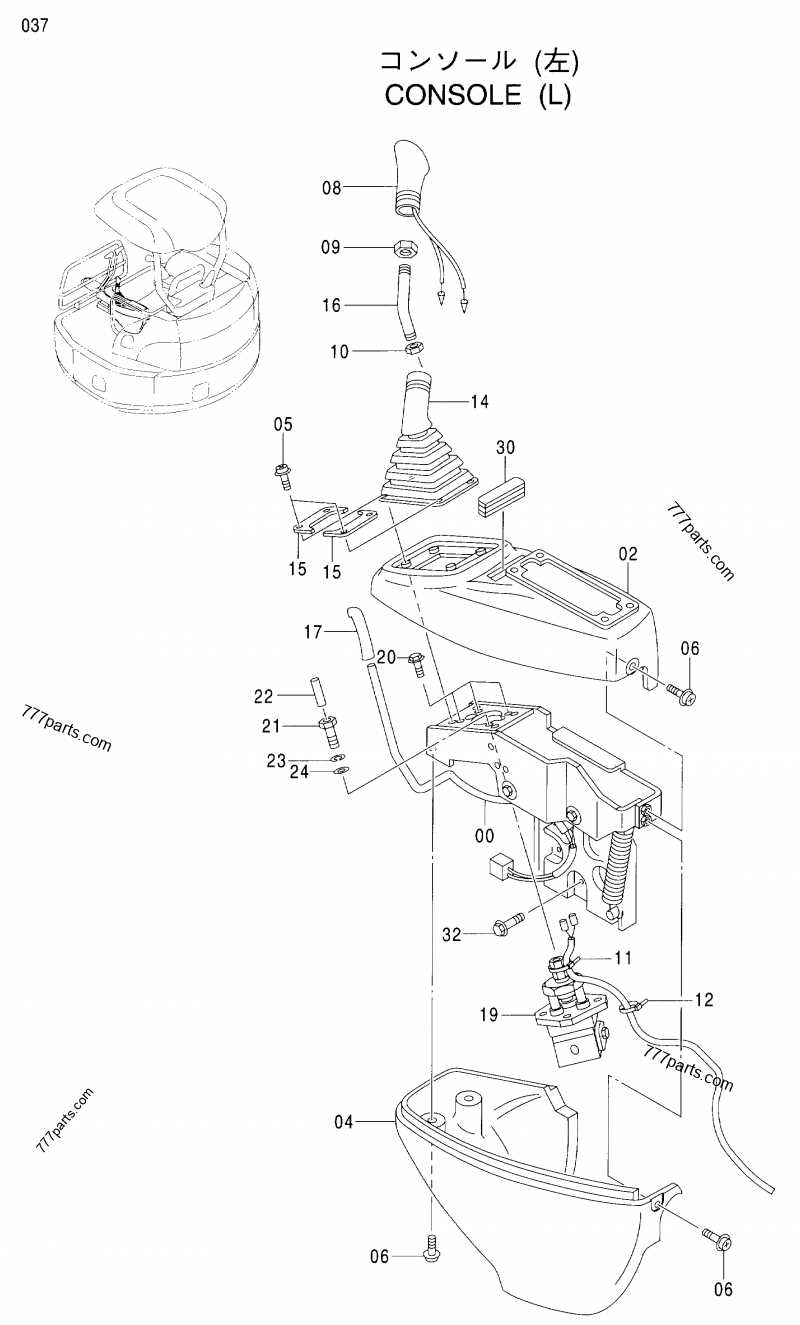

Understanding the Parts Layout

Grasping the configuration of components is essential for effective maintenance and troubleshooting. A comprehensive overview of how these elements are organized allows users to quickly identify and address any issues that may arise. This structured arrangement serves not only as a guide for repair but also enhances overall understanding of the machinery.

In any mechanical system, recognizing the relationship between different components is crucial. Each element plays a unique role, contributing to the overall functionality of the equipment. Familiarity with this arrangement aids in efficient diagnostics and ensures that operators can respond promptly to any challenges.

Moreover, a clear representation of the layout facilitates better planning for upgrades or replacements. By understanding the positioning and interconnections, one can make informed decisions regarding repairs and enhancements. This knowledge ultimately leads to improved performance and longevity of the machine.

Importance of Proper Maintenance

Ensuring the longevity and efficiency of any marine engine requires diligent upkeep and attention. Regular maintenance not only enhances performance but also prevents costly repairs down the line. By dedicating time to care for the engine, users can significantly improve its reliability and functionality, ensuring smooth operation during use.

Benefits of Regular Upkeep

Consistent maintenance offers numerous advantages, including improved fuel efficiency, reduced emissions, and increased safety while navigating. By adhering to a routine check-up schedule, operators can identify potential issues early, preventing them from escalating into major problems that could compromise performance or safety.

Key Maintenance Practices

Essential practices include routine inspections, oil changes, and cleaning components. Checking the cooling system and fuel lines regularly is crucial for preventing overheating and ensuring proper fuel delivery. Staying proactive with these tasks not only enhances the lifespan of the engine but also maximizes the enjoyment of boating experiences.

Common Issues and Solutions

When dealing with small outboard engines, users often encounter a variety of challenges that can hinder performance and functionality. Understanding these common problems, along with their corresponding solutions, can significantly enhance the reliability of the equipment and prolong its lifespan.

Starting Difficulties

One prevalent issue is the difficulty in starting the engine. This can be attributed to several factors, including stale fuel, a clogged fuel filter, or a malfunctioning spark plug. To resolve this, ensure that fresh fuel is used, and check the fuel lines for any blockages. Additionally, inspecting and replacing the spark plug can improve ignition efficiency, allowing for a smoother start.

Overheating Problems

Another common concern is overheating, which can result from inadequate cooling or blockages in the water intake. To address this, regularly inspect the cooling system and clean any debris from the water intake ports. It’s also essential to check the thermostat and ensure it functions correctly, as a malfunctioning thermostat can prevent proper water circulation, leading to overheating.

Visual Guide to Engine Parts

This section provides a comprehensive overview of the various components that make up an outboard motor. Understanding the individual elements is essential for effective maintenance and troubleshooting. Each part plays a crucial role in the overall performance, and recognizing them can enhance your operational knowledge.

Key Components Overview

The engine is comprised of multiple elements, each with a specific function. The powerhead, which houses the combustion chamber, is vital for generating thrust. The lower unit contains the gear assembly that transfers power to the propeller. Additionally, the fuel system, consisting of the tank, lines, and injectors, ensures the engine receives the necessary fuel to operate efficiently.

Maintenance Tips

Regular inspection and maintenance of these components are critical for longevity. Check the ignition system periodically to ensure reliable starting. Clean the fuel lines to prevent clogs and ensure smooth operation. Understanding the role of each part not only aids in repairs but also enhances performance during use.

Replacement Parts and Upgrades

When maintaining and enhancing your watercraft’s engine, understanding available components and enhancements is essential. Upgrading various elements can significantly improve performance, reliability, and longevity.

Here are some common areas where you may consider replacements or enhancements:

- Ignition System: Upgrading spark plugs or ignition coils can lead to better fuel efficiency and smoother starts.

- Fuel System: Replacing fuel filters or upgrading fuel pumps ensures optimal fuel delivery and engine performance.

- Propulsion: Enhancing the propeller or lower unit can improve acceleration and top speed, making your vessel more agile.

- Cooling System: Installing a high-capacity water pump can help maintain engine temperature, preventing overheating during extended use.

- Electrical Components: Upgrading batteries or wiring systems can provide better power management for accessories and overall engine functionality.

Before proceeding with any upgrades, it’s advisable to consult with professionals or refer to detailed manuals to ensure compatibility and proper installation.

Tools Needed for Repairs

When undertaking maintenance or fixing a small marine engine, having the right equipment is crucial for successful repairs. Proper tools not only ensure efficiency but also help in achieving precise adjustments and replacements.

The following is a list of essential implements that will facilitate the repair process, allowing for a thorough and effective service.

| Tool | Purpose |

|---|---|

| Screwdriver Set | For loosening or tightening screws of various sizes. |

| Wrench Set | To adjust and secure nuts and bolts effectively. |

| Pliers | For gripping, twisting, and cutting wires or other materials. |

| Socket Set | To handle bolts in confined spaces where traditional wrenches cannot reach. |

| Torque Wrench | To apply a specific torque to fasteners, ensuring proper tension. |

| Multimeter | For testing electrical systems and diagnosing issues. |

| Oil Filter Wrench | To remove and install oil filters easily. |

| Fuel Line Wrench | To safely disconnect fuel lines without damage. |

Resources for Further Information

For those seeking additional knowledge and assistance regarding their outboard engines, numerous resources are available. These materials can enhance understanding, facilitate repairs, and ensure optimal performance of marine equipment. Engaging with a variety of formats, such as manuals, online forums, and instructional videos, can significantly aid in resolving queries and improving operational proficiency.

| Resource Type | Description | Link |

|---|---|---|

| User Manuals | Official documentation providing detailed instructions and specifications. | View Manuals |

| Online Forums | Community platforms for discussing experiences and troubleshooting issues. | Join Forums |

| Video Tutorials | Visual guides demonstrating various maintenance and repair techniques. | Watch Tutorials |

| Manufacturer Websites | Official sites with resources, FAQs, and customer support options. | Visit Manufacturer Site |