In the world of boating, having a thorough understanding of your vessel’s power source is crucial for optimal performance and maintenance. Each engine consists of various elements, each serving a specific function, contributing to the overall efficiency and reliability of your craft. Familiarity with these components not only aids in troubleshooting but also enhances the overall boating experience.

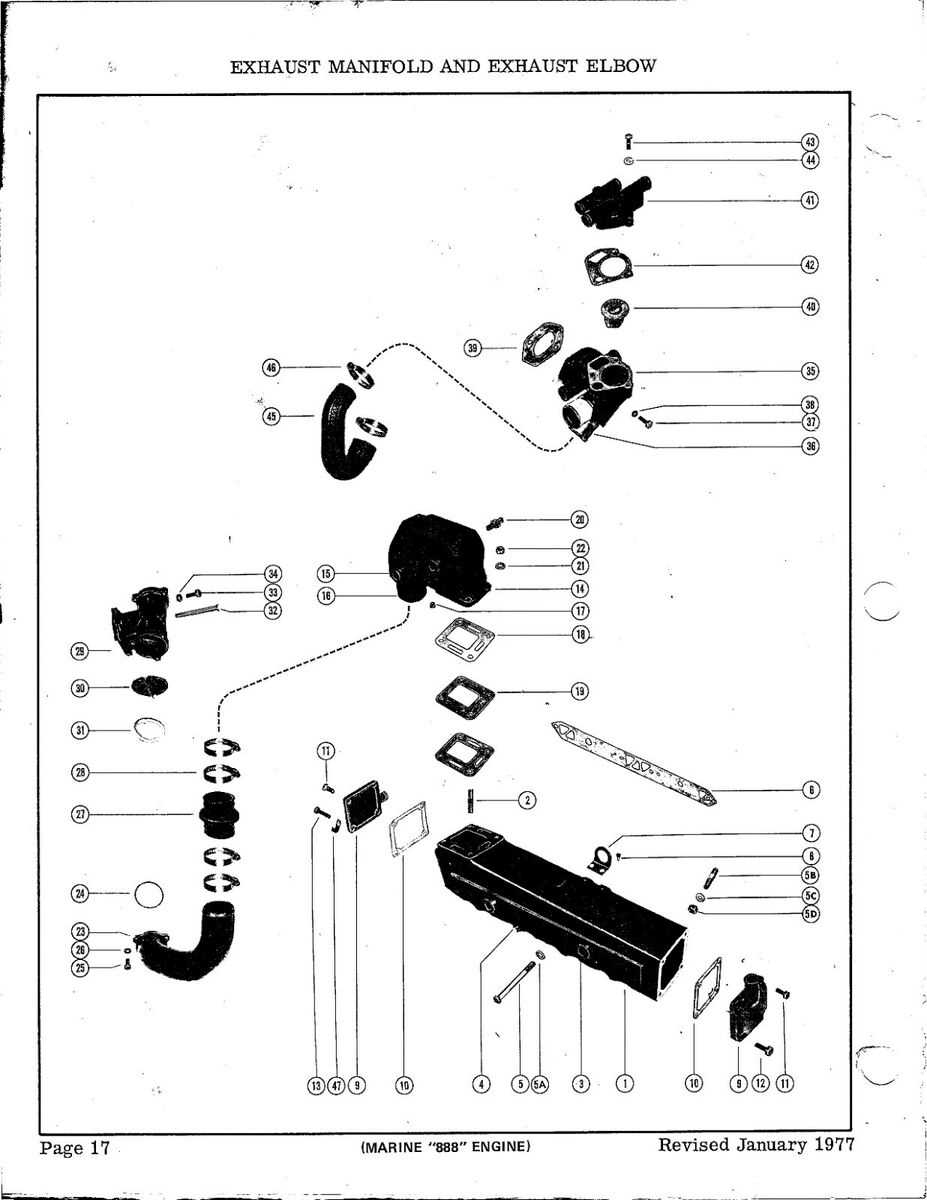

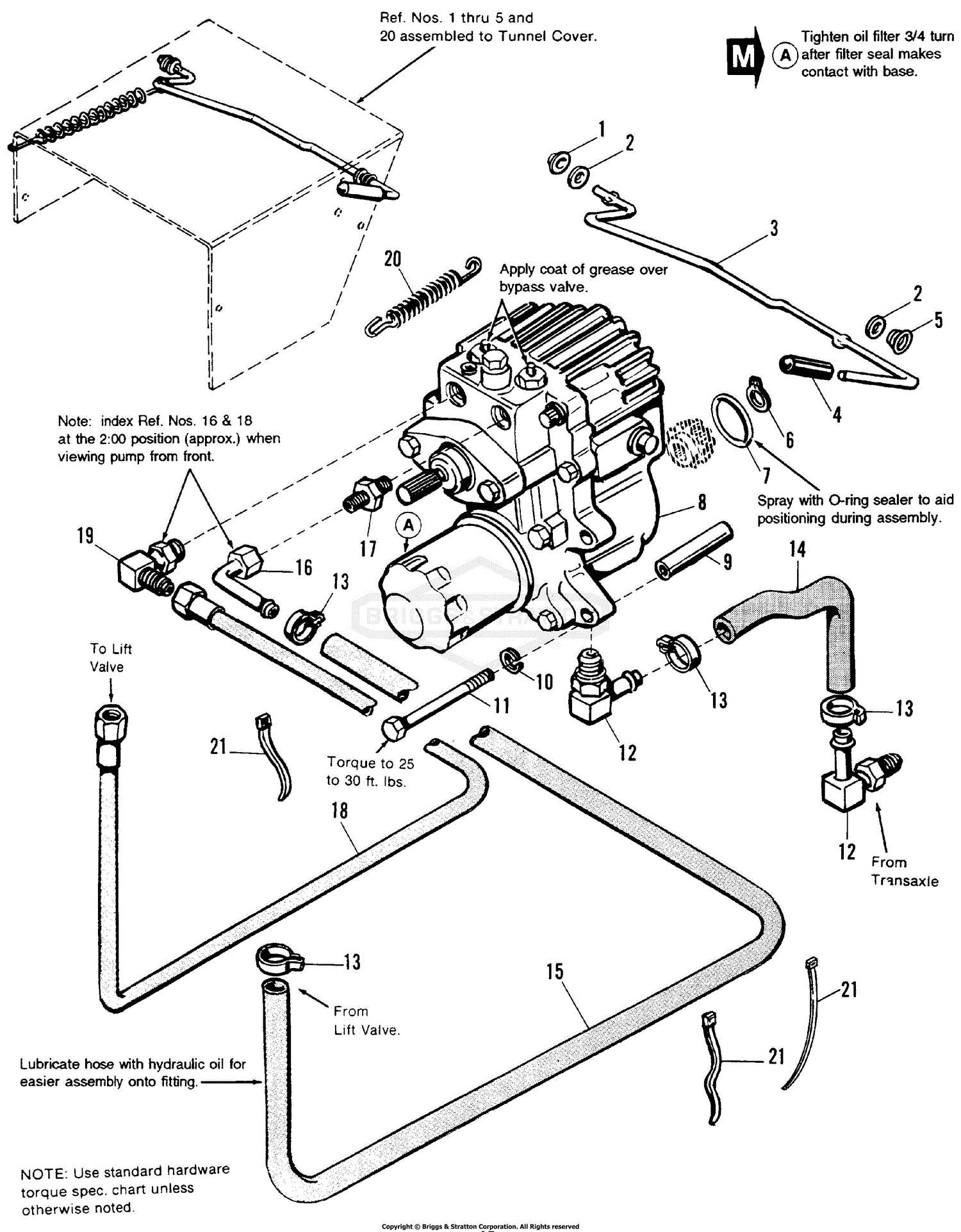

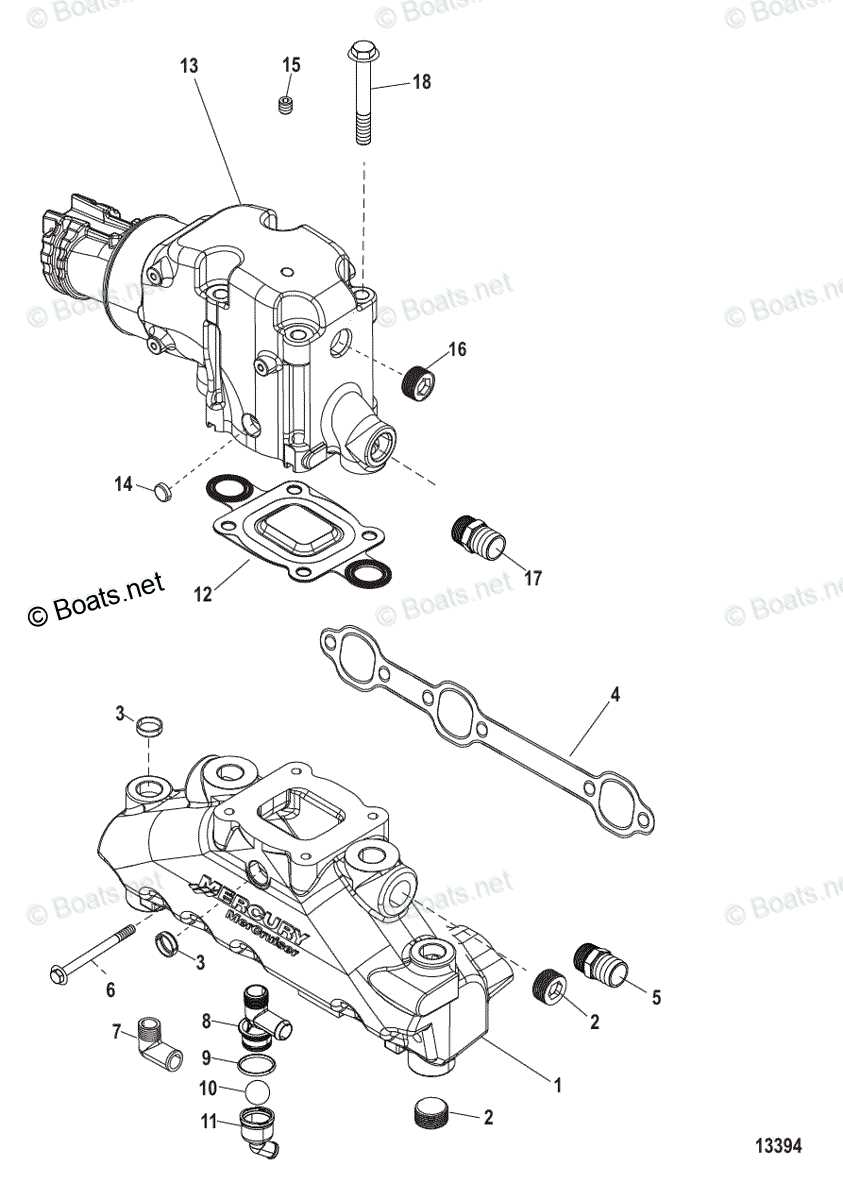

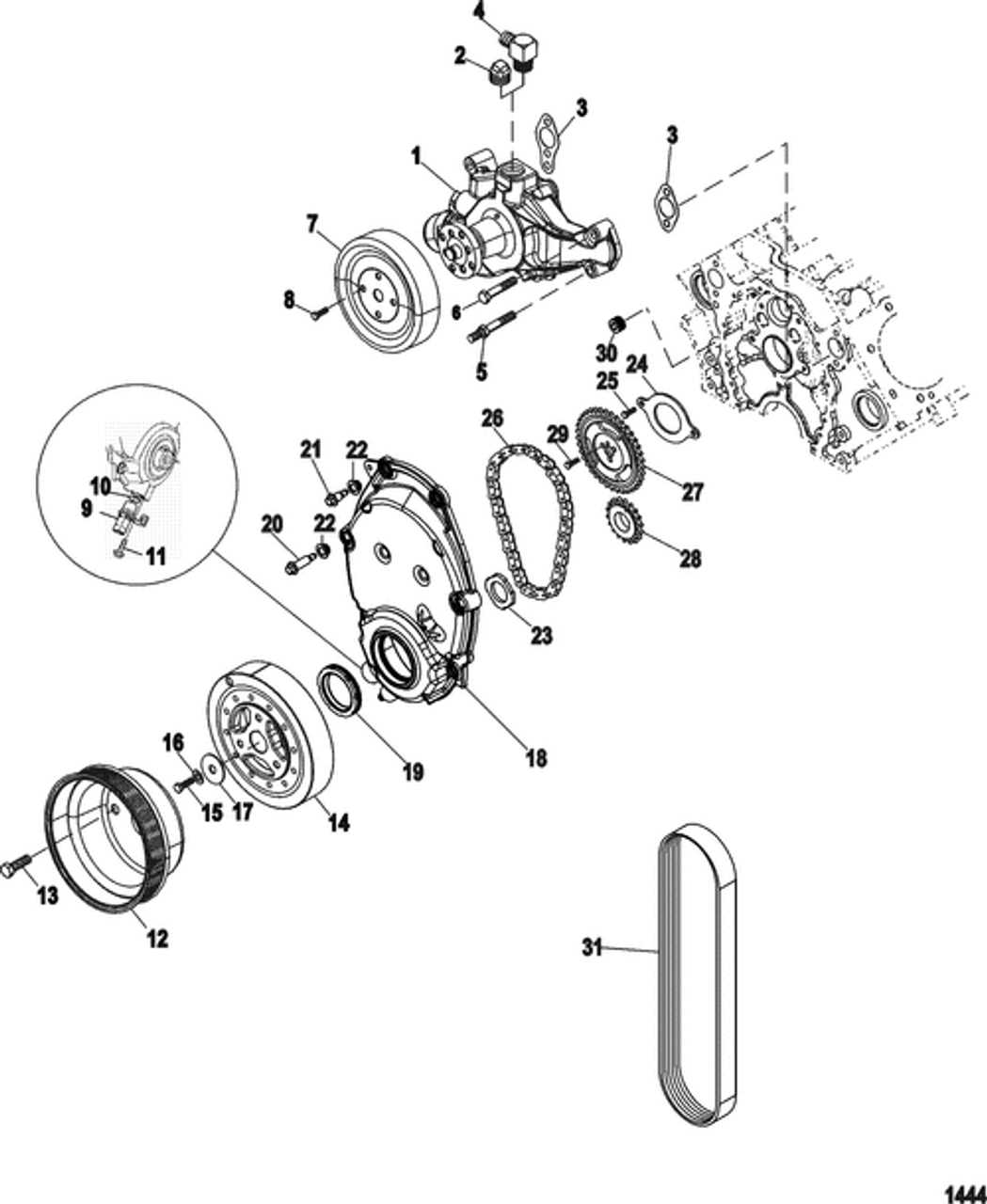

Visual aids play a significant role in grasping the intricate details of engine assemblies. By exploring schematic representations, one can easily identify and comprehend the layout and interaction of different elements. This knowledge empowers boat owners and enthusiasts to make informed decisions regarding repairs and upgrades.

Additionally, a well-structured overview of engine components fosters a deeper appreciation for the technology at work beneath the surface. Understanding how each piece functions together can inspire confidence in both routine maintenance and more complex repairs. As you delve into the specifics, you’ll find that each element is not just a separate part, but a vital contributor to the harmony of your maritime journey.

Understanding the Mercruiser 4.3 Engine

This section delves into the intricacies of a popular marine powerplant, highlighting its key components, functionality, and significance in the boating world. With a well-engineered design, this engine is favored by many for its reliability and performance in various aquatic applications.

Key Features

- Compact size that allows for versatile installations.

- Robust construction to withstand harsh marine environments.

- Efficient fuel consumption for extended journeys on the water.

- Strong torque delivery, providing excellent acceleration.

Components Overview

The following components are essential for the optimal functioning of this engine:

- Crankshaft: Transforms linear motion into rotational force.

- Cylinder Heads: Houses the intake and exhaust valves, crucial for air-fuel mixture management.

- Intake Manifold: Distributes the air-fuel mixture evenly to the cylinders.

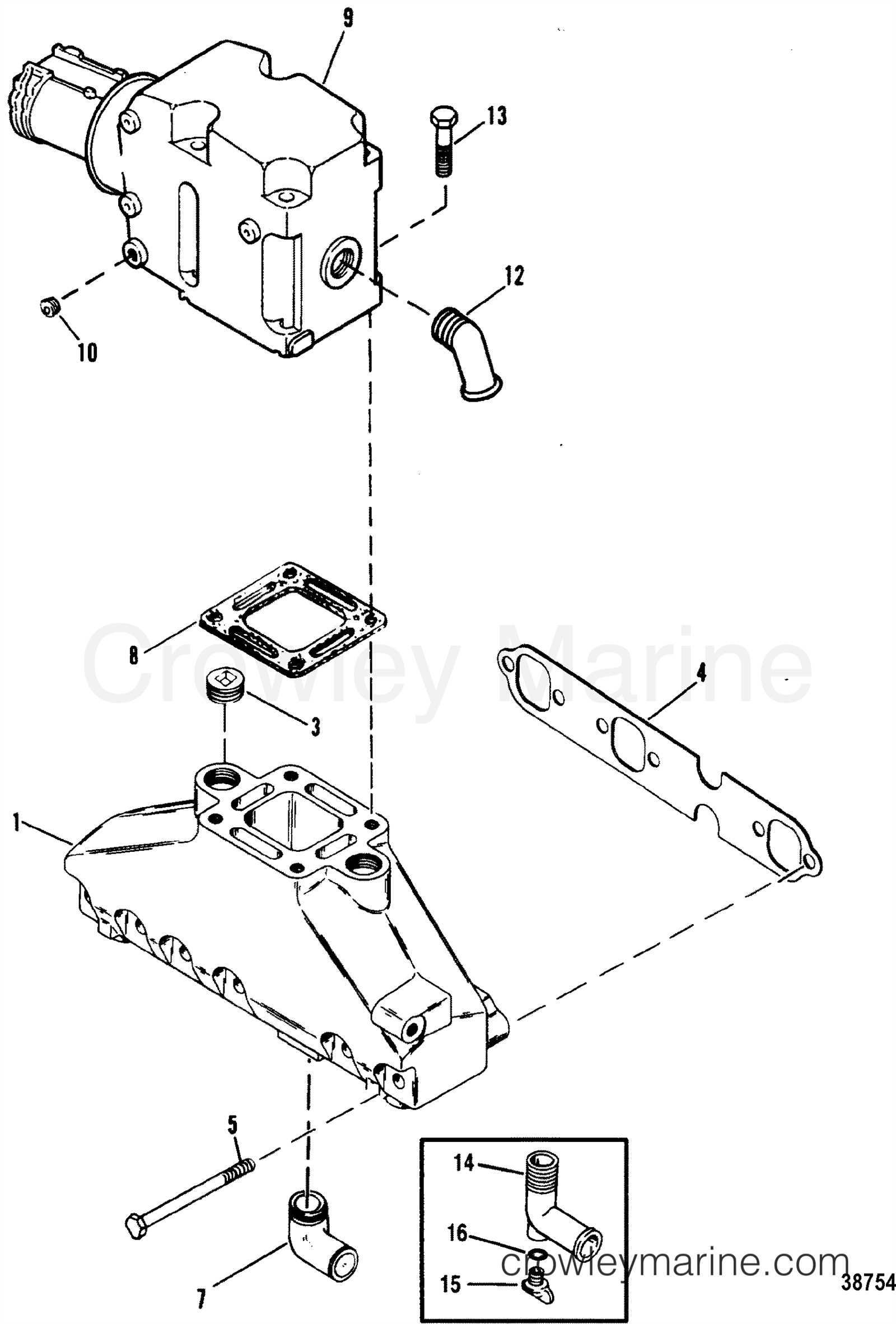

- Exhaust System: Channels exhaust gases away from the engine efficiently.

- Fuel System: Delivers the necessary fuel for combustion, enhancing performance.

Understanding these components and their functions will help enthusiasts maintain and optimize their marine engines for peak performance on the water.

Key Components of the 4.3 System

This section explores the essential elements that contribute to the effective operation of the marine engine system. Each component plays a vital role in ensuring optimal performance and reliability in various conditions.

Major Elements

The primary components can be categorized into several groups based on their function and contribution to the overall system. Understanding these elements is crucial for maintenance and troubleshooting.

| Component | Function |

|---|---|

| Engine Block | Houses the cylinders and provides structural integrity. |

| Intake Manifold | Distributes air-fuel mixture to the cylinders. |

| Exhaust Manifold | Directs exhaust gases away from the engine. |

| Cooling System | Maintains optimal operating temperature to prevent overheating. |

| Fuel System | Delivers fuel to the engine for combustion. |

| Ignition System | Creates the spark necessary for combustion in the cylinders. |

Supporting Elements

In addition to the primary components, several supporting elements enhance the functionality and efficiency of the engine system. Regular inspection and upkeep of these parts can significantly extend the lifespan of the engine.

| Supporting Component | Purpose |

|---|---|

| Oil Pump | Circulates oil to lubricate moving parts. |

| Battery | Supplies electrical power to the ignition and other systems. |

| Belts and Hoses | Facilitate movement and fluid transfer throughout the system. |

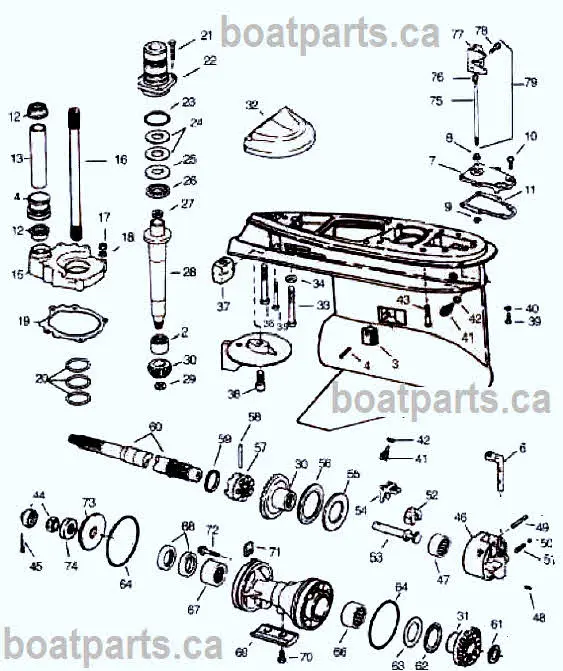

Importance of Accurate Parts Diagrams

In the realm of mechanical maintenance and repair, precise visual representations are essential for ensuring effective assembly and disassembly. These illustrations serve as crucial tools for technicians and enthusiasts alike, guiding them through complex procedures and minimizing errors. The clarity and accuracy of these visuals directly impact the efficiency and success of repairs.

Benefits of Clear Visual Representations

- Enhanced Understanding: Accurate visuals help individuals grasp the configuration and relationship of components, facilitating better comprehension of the system.

- Efficient Troubleshooting: When issues arise, these detailed representations allow for quicker identification of faults, streamlining the repair process.

- Reduced Risk of Errors: Clear illustrations minimize the chances of misassembly, preventing potential damage and costly mistakes.

Impact on Maintenance and Longevity

- Improved Maintenance: Regular upkeep becomes easier when the layout of parts is well-documented, leading to timely servicing.

- Extended Equipment Lifespan: Proper maintenance informed by accurate visuals contributes to the durability and performance of machinery.

- Cost Efficiency: Avoiding missteps through clear guidance ultimately saves time and resources, benefiting both individuals and businesses.

Common Issues with 4.3 Components

Many users encounter challenges when dealing with mechanical systems, particularly as components begin to age or experience wear and tear. Understanding common points of failure can help prevent more serious damage and ensure smooth operation over time.

Overheating Problems

One frequent issue is related to rising engine temperatures. This may occur due to a failing cooling mechanism, blocked passages, or damage to specific elements. Regular inspection and proper maintenance are key to preventing overheating and ensuring stable performance.

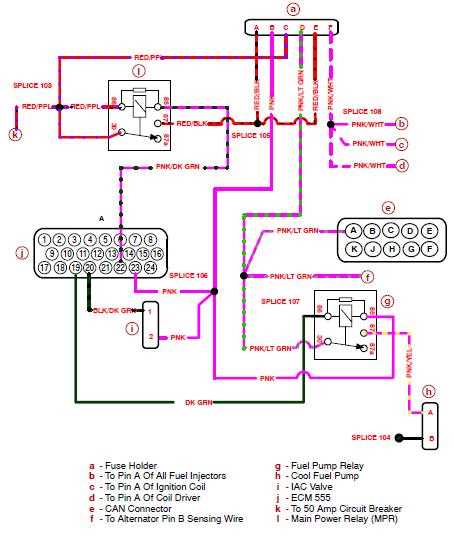

Electrical Failures

Another common problem involves malfunctioning electrical connections, which can result in unpredictable engine behavior. Faulty wires, corrosion, or loose connectors can disrupt the flow of current, causing issues that range from intermittent power loss to complete system failure. Addressing these problems promptly helps avoid further complications.

How to Read a Parts Diagram

Understanding mechanical illustrations is essential for anyone working with complex machinery. These visual guides provide a breakdown of components, showing how various elements fit together within a larger system. By familiarizing yourself with the layout and symbols, you can easily identify each element and its function, ensuring proper assembly and maintenance.

Step-by-Step Approach: Start by locating the reference numbers or labels in the illustration. These indicators correspond to specific descriptions or item listings, which explain the function or specification of each component. By following this system, you can trace the flow of the mechanism and comprehend the interconnections between different units.

Decoding Symbols: Many technical drawings utilize symbols or abbreviations to represent common parts or features. Learning these icons will save time and reduce confusion, as you’ll be able to quickly understand what each part represents without needing additional explanations.

Essential Maintenance for Longevity

Regular upkeep is key to ensuring the long-lasting performance of any mechanical system. By following consistent care practices, you can prevent wear and tear, minimize unexpected breakdowns, and maintain overall efficiency over time.

- Check fluid levels regularly to avoid any potential overheating or mechanical failures.

- Inspect the cooling system to ensure optimal temperature control during operation.

- Replace filters periodically to maintain clean airflow and protect vital components.

- Keep an eye on the condition of belts and hoses, ensuring there are no cracks or signs of deterioration.

- Schedule periodic tune-ups to adjust and optimize the system’s performance.

By adhering to these basic practices, you can extend the life of your equipment, ensuring reliable and efficient function for years to come.

Where to Find Genuine Parts

When it comes to ensuring the longevity and reliability of your equipment, sourcing authentic components is crucial. Identifying the right suppliers guarantees that the materials you obtain are not only compatible but also meet quality standards. Knowing where to look for original elements can save you both time and money, ensuring the maintenance and performance of your system.

Authorized dealers, specialized online platforms, and certified retailers are the primary sources for acquiring original components. These outlets provide the assurance of quality and typically offer warranties or support services, adding an extra layer of security to your purchase. For those seeking the most reliable options, it’s best to rely on trusted providers who offer verified selections tailored to your specific needs.

Upgrading Your Engine System

Enhancing the performance of your marine propulsion unit can significantly improve efficiency, longevity, and power output. Whether you’re aiming for a more responsive throttle or greater fuel efficiency, there are several key modifications that can elevate the overall performance of your setup.

Performance Tuning: One of the first steps in upgrading is tuning the system for optimal performance. Adjustments in ignition timing, fuel delivery, and airflow can unlock hidden potential, ensuring smoother operation and enhanced power delivery.

Component Replacement: Upgrading certain components, such as the intake manifold or exhaust system, can lead to noticeable improvements in both power and fuel efficiency. These modifications allow for better air circulation, reducing strain on the system and improving overall functionality.

Routine Maintenance: Keeping the system in top shape is crucial for longevity. Regular maintenance, combined with upgraded parts, can extend the lifespan of your marine engine, preventing costly repairs and downtime on the water.