In the realm of agricultural equipment, having a comprehensive understanding of the layout of various components is essential for effective maintenance and repair. This section aims to provide a detailed exploration of how different elements are organized within these robust machines. By familiarizing oneself with the arrangement, operators can ensure optimal performance and longevity of their equipment.

Knowing the specific arrangements of the essential elements allows users to identify potential issues swiftly. This understanding can facilitate timely interventions, ultimately minimizing downtime and enhancing productivity. The following discussion will delve into the intricacies of these layouts, providing insights that are invaluable for both seasoned operators and newcomers alike.

As we explore the organization of these crucial components, it becomes clear that a well-structured approach to machinery management not only improves operational efficiency but also contributes to overall safety. Proper knowledge of the configuration can empower users to make informed decisions regarding their machinery, leading to better performance and reduced operational costs.

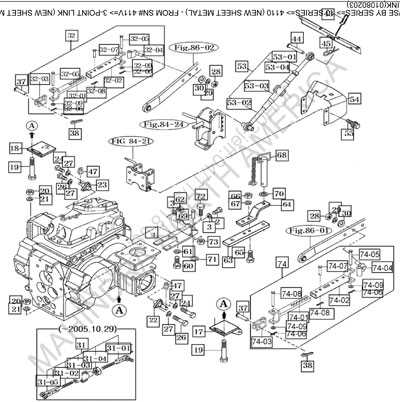

Overview of Mahindra 4110 Components

This section provides a comprehensive look at the various elements that make up a specific agricultural machine, focusing on their functions and interrelationships. Understanding these components is essential for effective maintenance and operation, ensuring the equipment performs optimally in various conditions.

Key Functional Elements

The machine consists of several critical functional elements that work in unison to deliver power and efficiency. These parts include the engine, transmission system, and hydraulic components. Each of these elements plays a vital role in the overall operation, enabling the machine to perform a range of tasks from plowing to hauling.

Maintenance and Care

Proper maintenance of these components is crucial for longevity and reliable performance. Regular inspections and timely replacements can prevent breakdowns and enhance productivity. Understanding the individual parts and their roles can aid operators in troubleshooting and ensuring that the machine runs smoothly over time.

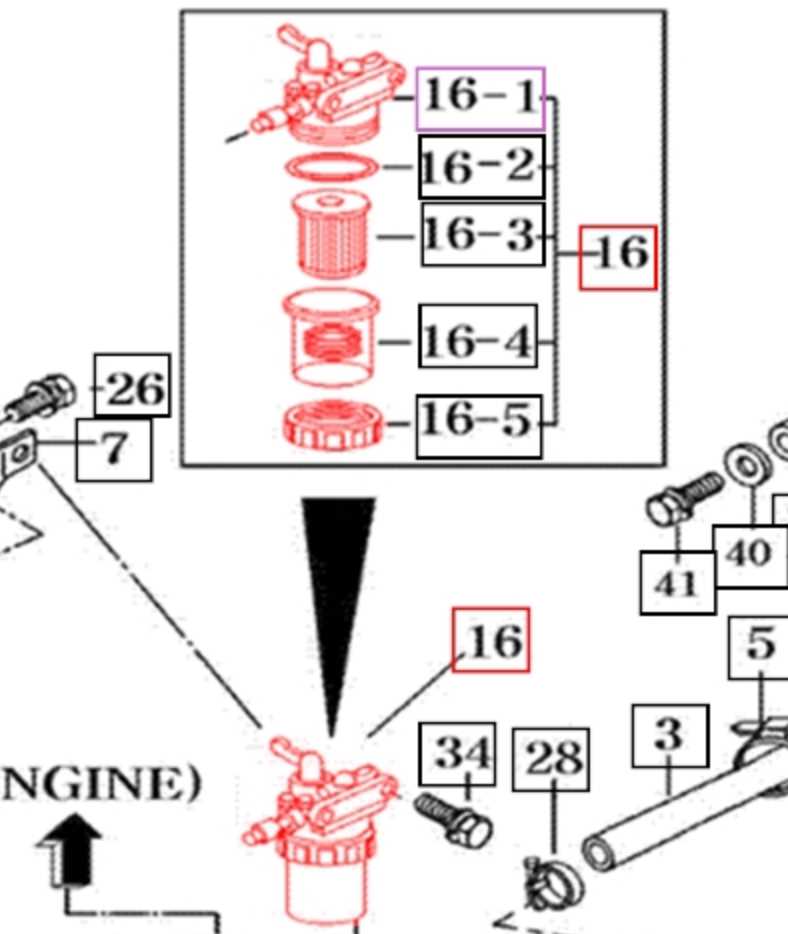

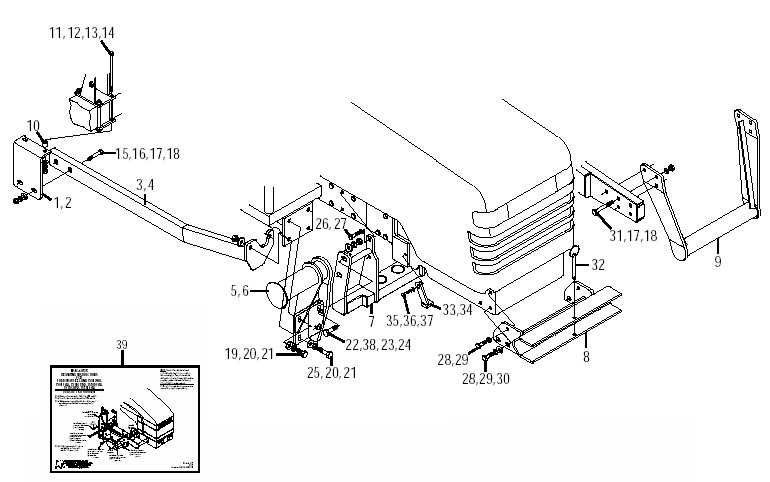

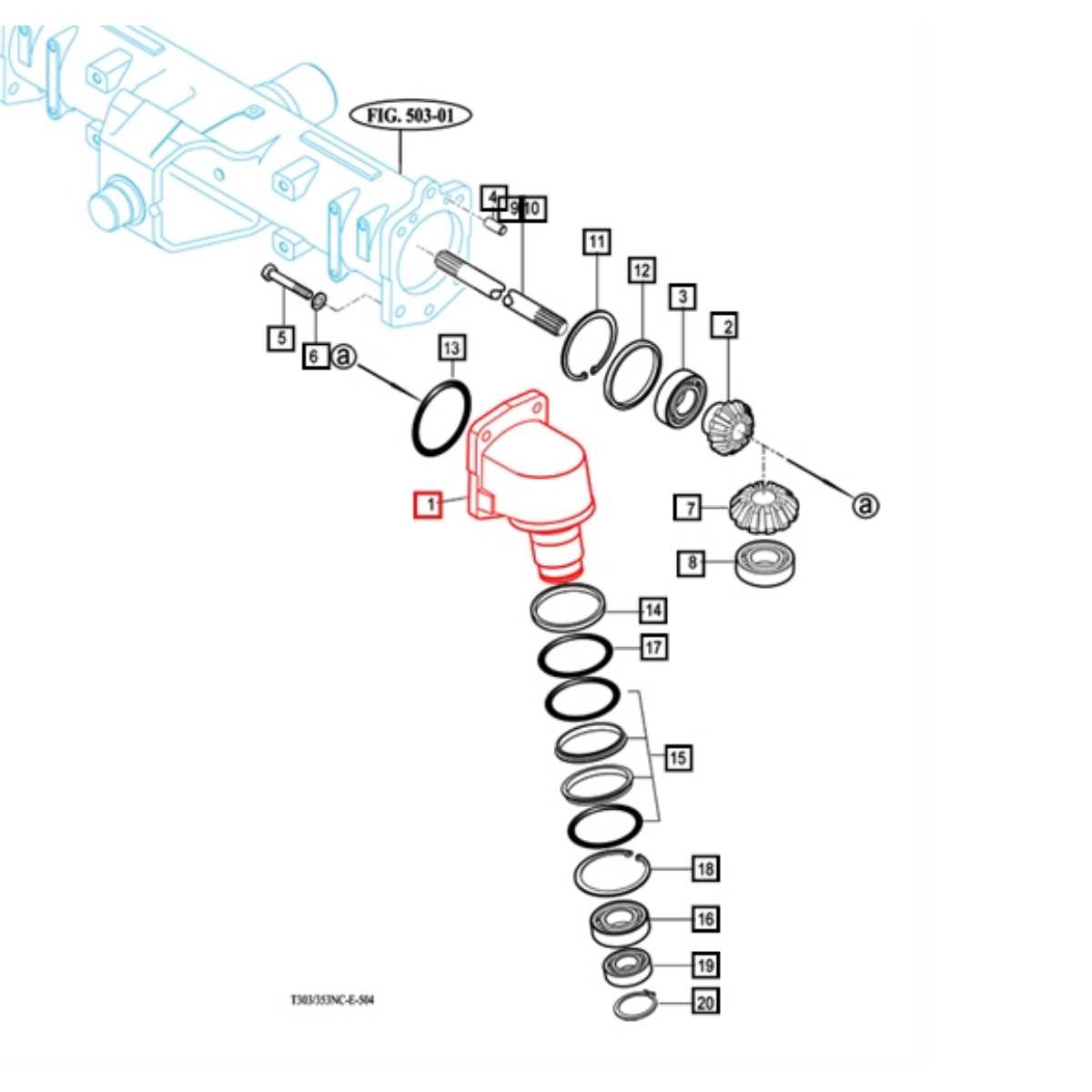

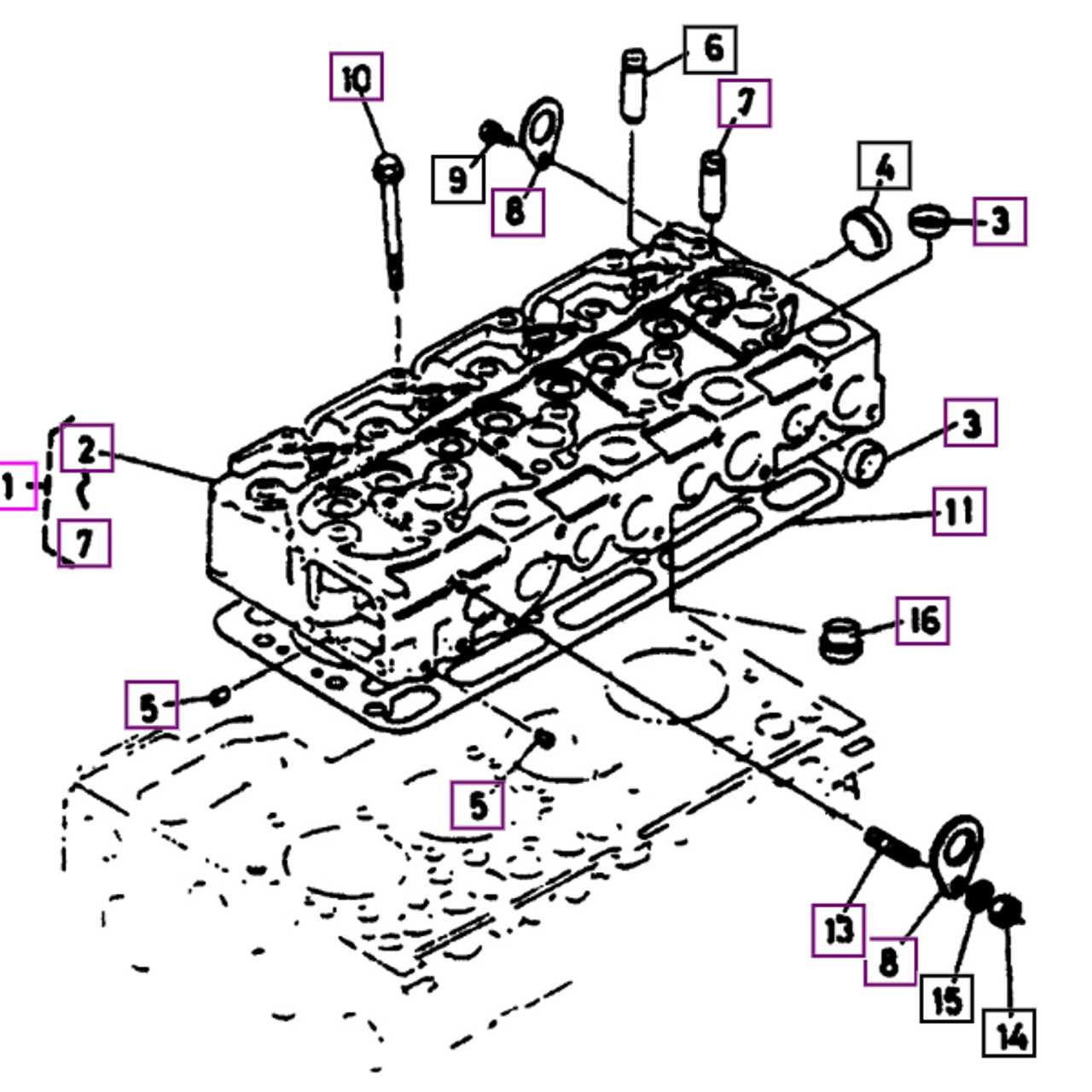

Understanding the Parts Layout

This section aims to provide clarity on the arrangement and organization of various components within a specific machinery framework. By grasping the overall structure, users can better comprehend how each element contributes to the overall functionality.

Key Components and Their Functions

- Engine Unit: Central to the operation, it converts fuel into mechanical energy.

- Transmission System: Responsible for transferring power from the engine to the wheels, ensuring optimal speed and torque.

- Hydraulic System: Utilizes fluid power for various operations, enhancing versatility and efficiency.

- Chassis: The foundational structure that supports all components, providing stability and strength.

Importance of Understanding Layout

- Improves maintenance efficiency by identifying critical areas requiring attention.

- Facilitates troubleshooting by enabling quick identification of issues.

- Enhances user knowledge, allowing for more effective operation of the equipment.

Key Features of Mahindra 4110

This model is known for its impressive blend of functionality and efficiency, making it a popular choice in the agricultural sector. Designed with the user in mind, it offers numerous benefits that enhance productivity and ease of use.

Powerful Engine: Equipped with a robust engine, this machine delivers exceptional performance, allowing users to tackle a variety of tasks with ease. Its high torque output ensures efficient operation, even under heavy loads.

Compact Design: The compact structure of this vehicle provides excellent maneuverability, making it ideal for navigating tight spaces on farms or construction sites. This feature allows for versatility in different working environments.

Advanced Transmission: Featuring a sophisticated transmission system, this model ensures smooth shifting and enhanced control, resulting in a better overall driving experience. Operators can easily adjust speeds to suit specific tasks.

Enhanced Comfort: With an ergonomic operator station, the design prioritizes user comfort. It includes adjustable seating and intuitive controls, allowing for extended periods of use without fatigue.

Durable Build: Constructed with high-quality materials, this vehicle is designed to withstand harsh conditions, ensuring longevity and reliability in the field. Its robust frame contributes to overall stability during operation.

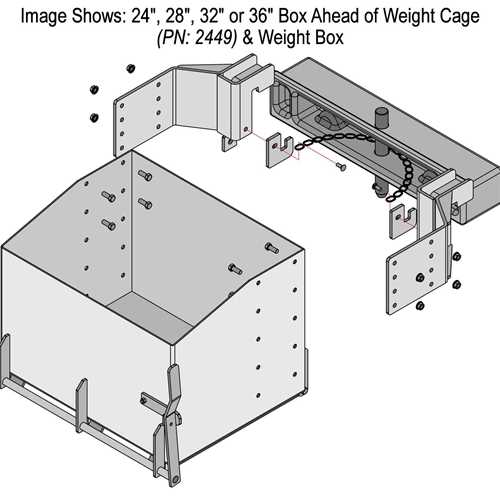

Versatile Attachments: This model supports a wide range of attachments, increasing its functionality for various tasks, such as plowing, lifting, and transporting materials. This adaptability makes it a valuable asset for any operation.

Maintenance Tips for Optimal Performance

Regular upkeep is crucial for ensuring the longevity and efficiency of your machinery. Implementing effective maintenance practices not only enhances performance but also prevents unexpected breakdowns and costly repairs. This section outlines essential strategies that can help maintain optimal functionality.

Routine Inspections

Conducting frequent inspections is vital. Check for any signs of wear and tear, such as leaks or unusual noises. Regularly examining fluid levels and replacing filters when necessary can significantly contribute to the smooth operation of your equipment.

Lubrication and Cleaning

Proper lubrication is essential to minimize friction and wear on moving parts. Use high-quality lubricants suitable for your specific machinery. Additionally, keep all components clean to prevent debris accumulation, which can hinder performance and lead to premature damage.

Common Issues and Solutions

In the realm of machinery, various challenges can arise that may hinder optimal performance. Understanding these frequent problems and their respective solutions is essential for ensuring smooth operation and longevity of equipment. This section outlines common difficulties encountered by users and provides effective strategies to resolve them.

Frequent Problems

- Engine starting issues, often related to fuel supply or battery health.

- Hydraulic system malfunctions, which may stem from leaks or low fluid levels.

- Electrical failures, frequently caused by worn wiring or blown fuses.

- Excessive vibrations that could indicate imbalances or loose components.

Effective Solutions

- For starting problems, check the fuel tank and battery connections to ensure adequate power and supply.

- Inspect hydraulic lines for leaks and verify that fluid levels are within recommended ranges.

- Examine electrical components for any signs of damage or wear, and replace faulty parts as necessary.

- Tighten loose bolts and align components to minimize vibrations and improve stability.

Upgrading Parts for Enhanced Functionality

Improving components within machinery can significantly boost performance and efficiency. By selecting higher-quality or more advanced elements, users can experience enhanced capabilities that meet their specific needs. Upgrading not only prolongs the lifespan of the equipment but also ensures it operates at optimal levels, providing better results for various tasks.

Benefits of Enhanced Components

Upgrading to superior components can lead to several advantages, such as increased reliability and improved operational speed. Enhanced elements often come with advanced technologies that allow for better adaptability to different conditions. As a result, users may notice a marked improvement in productivity and efficiency, ultimately translating to cost savings over time.

Choosing the Right Upgrades

When considering enhancements, it is crucial to evaluate compatibility and functionality. Researching various options and consulting with experts can help identify which upgrades will provide the most benefit. Additionally, ensuring that new components align with existing systems is vital for achieving the desired improvements without compromising performance.

Resourceful Links for Parts Procurement

When it comes to maintaining machinery and ensuring optimal performance, having access to reliable sources for acquiring necessary components is crucial. This section aims to provide useful links that can facilitate the procurement process, helping you find the right items efficiently.

Online Marketplaces

Numerous online platforms offer a wide range of components suitable for various machinery. Websites like eBay, Amazon, and specialized automotive or agricultural equipment retailers can serve as excellent starting points. These platforms often feature user reviews and competitive pricing, aiding in making informed purchasing decisions.

Manufacturer Resources

Visiting the official websites of manufacturers can be invaluable. They frequently provide detailed catalogs and lists of authorized dealers. This ensures that you are purchasing authentic components, reducing the risk of compatibility issues or substandard quality.

Safety Precautions During Maintenance

Ensuring safety during upkeep and repair activities is crucial for both the operator and the equipment involved. Implementing appropriate safety measures helps prevent accidents, injuries, and damage, promoting a secure working environment. By following established protocols and guidelines, one can effectively mitigate risks associated with maintenance tasks.

Personal Protective Equipment

Utilizing suitable personal protective gear is essential when conducting maintenance activities. This includes wearing gloves, goggles, and sturdy footwear to safeguard against potential hazards. Additionally, using hearing protection and respiratory masks in noisy or dusty environments can significantly enhance safety. Ensuring that all team members are equipped with the necessary safety gear fosters a culture of precaution and responsibility.

Proper Tool Handling

Using the correct tools for specific tasks is vital for maintaining safety. Familiarize yourself with each tool’s intended use and ensure they are in good working condition before starting any work. Properly storing tools after use prevents accidents and keeps the workspace organized. Moreover, following manufacturer instructions for tool usage can help avoid mishaps and promote efficient operations.