In the realm of machinery maintenance, comprehending the intricate layouts of various components is essential. This knowledge not only facilitates effective repairs but also enhances the overall efficiency of the equipment. By examining the arrangement of parts, operators can identify potential issues and streamline their maintenance processes.

When seeking to optimize performance, a detailed exploration of specific assemblies proves invaluable. These visual representations serve as guides, illuminating the relationships between different elements. Each piece plays a crucial role in the functionality of the machine, making it imperative to grasp their interconnections.

Ultimately, delving into these schematic illustrations empowers users to make informed decisions regarding repairs and replacements. Understanding how each segment fits into the larger system can lead to improved longevity and reliability, ensuring that operations run smoothly and effectively.

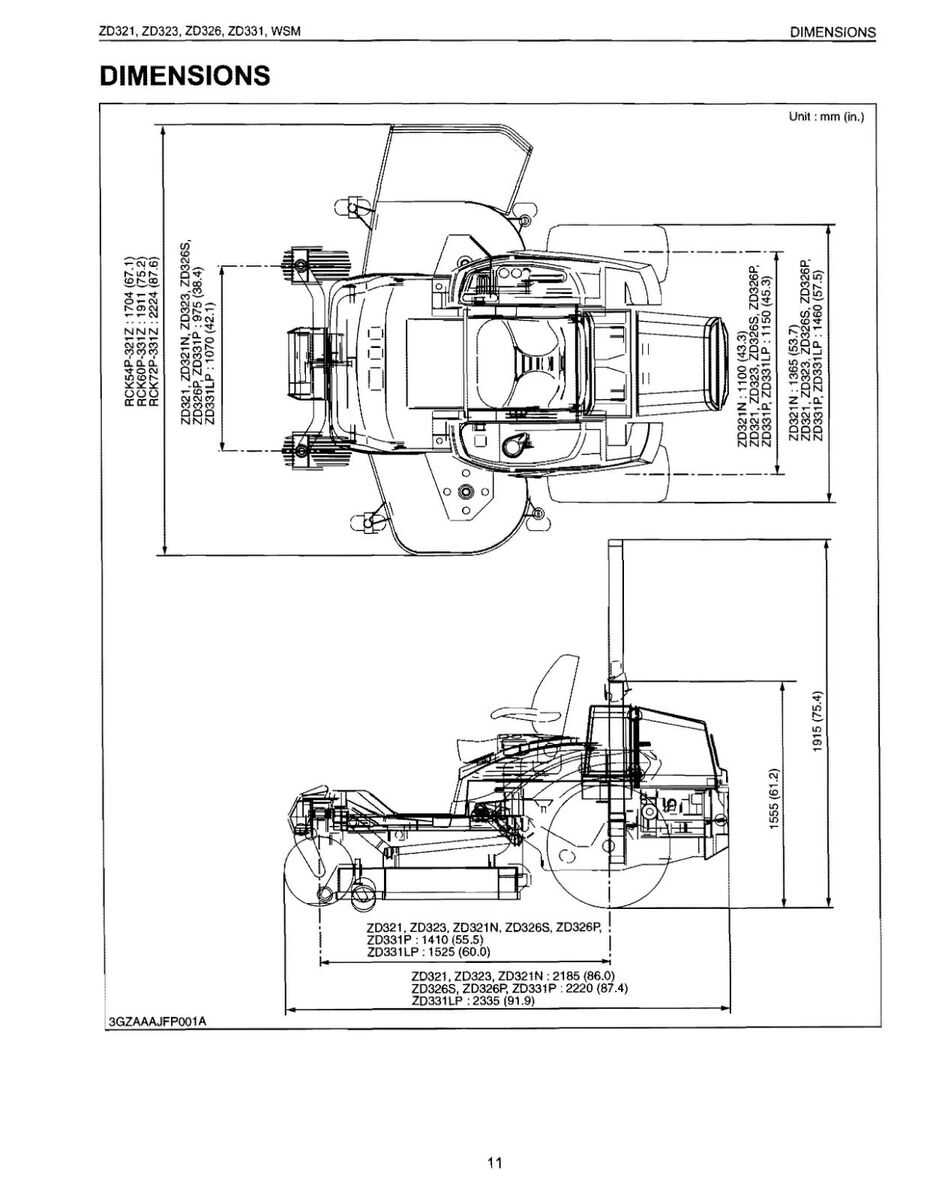

Kubota ZD321 Overview

This section provides an essential understanding of a high-performance mower designed for efficiency and durability in various landscaping tasks. Its robust engineering ensures reliability, making it a preferred choice for both commercial and residential use.

Key Features

The machine is equipped with a powerful engine that delivers exceptional torque, enabling it to tackle challenging terrains. Its advanced cutting system promotes a clean and precise finish, while ergonomic controls enhance user comfort during operation.

Applications

This mower is ideal for maintaining large lawns, parks, and commercial landscapes, where precision and performance are paramount. Its versatility allows for a range of attachments, further expanding its usability across different tasks.

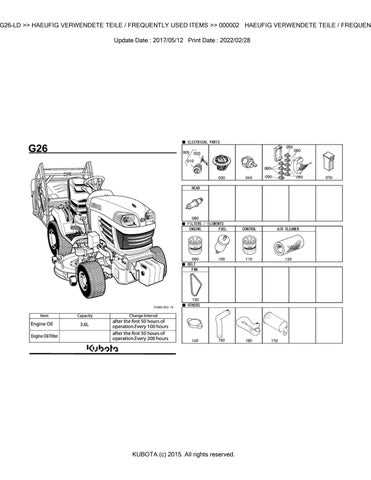

Importance of Parts Diagrams

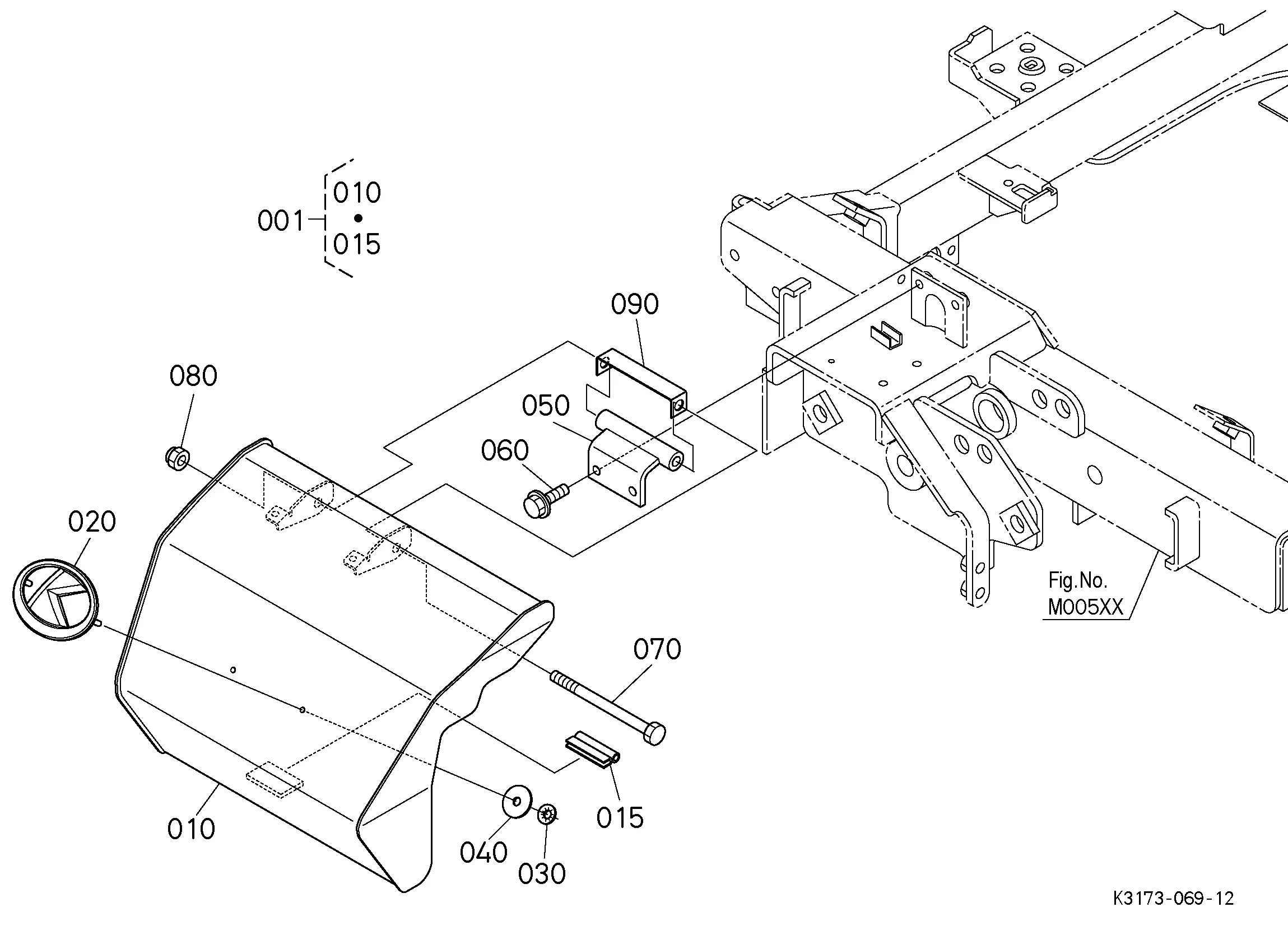

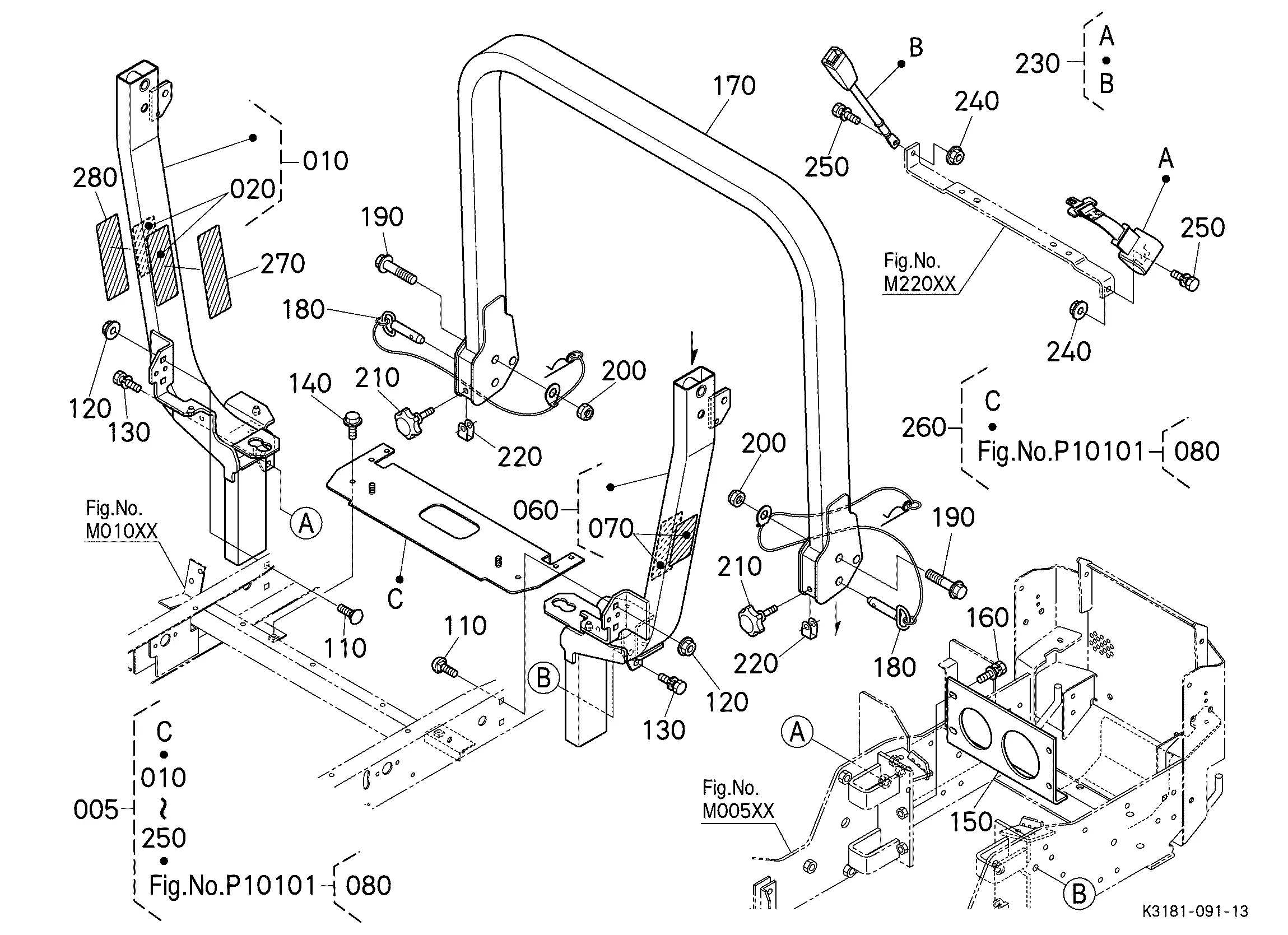

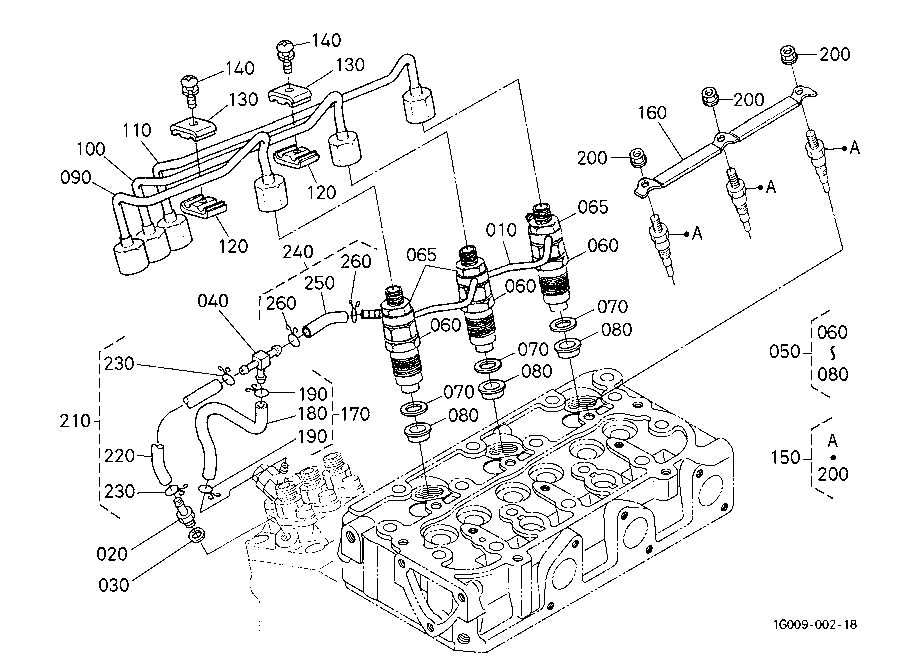

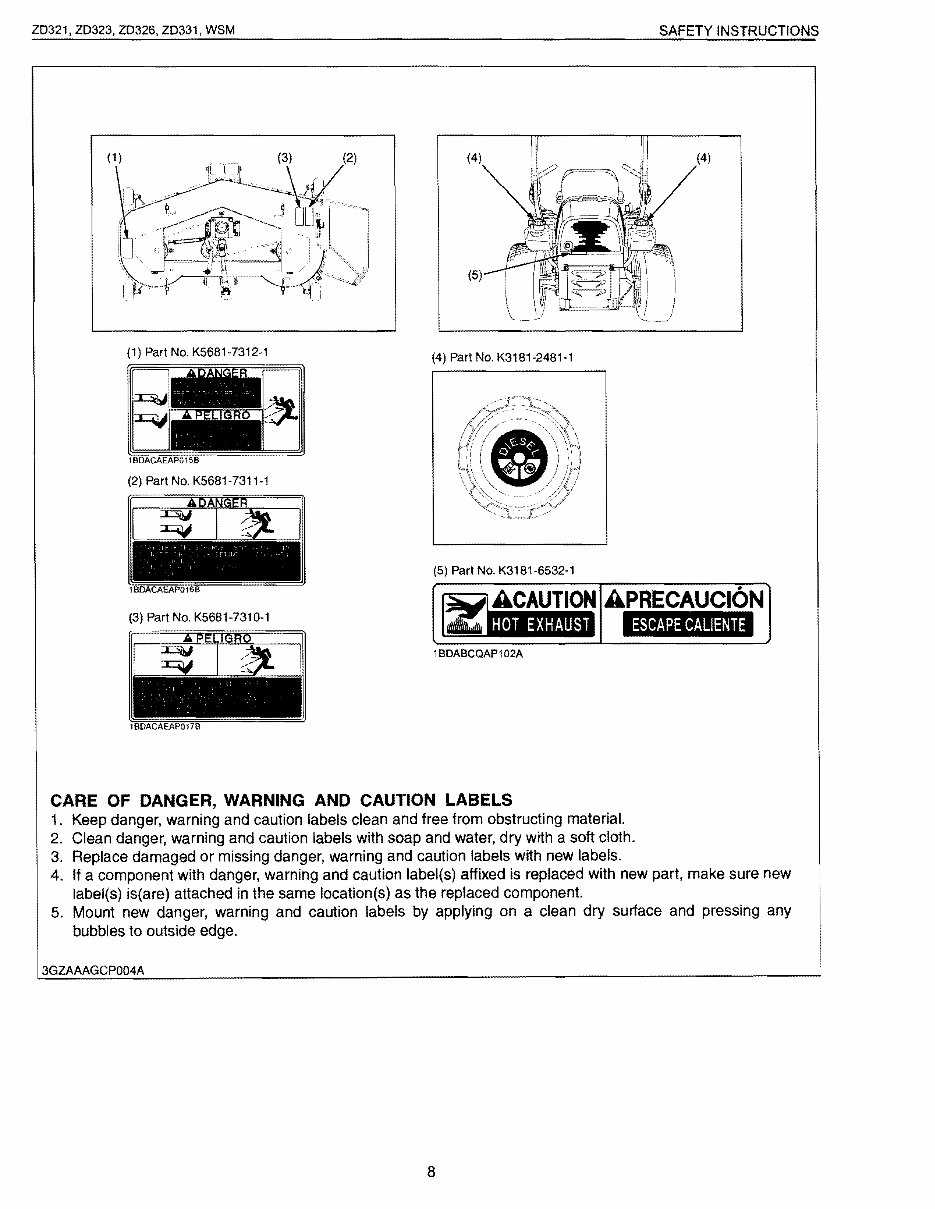

Visual representations of components are crucial for understanding the intricate relationships within machinery. They provide clarity on how individual elements fit together and function as a cohesive whole. This understanding is essential for effective maintenance, repair, and overall operation of complex equipment.

Facilitating Maintenance and Repair

Having a visual guide helps technicians quickly identify issues and locate specific parts needing attention. This streamlines the repair process, minimizing downtime and enhancing efficiency. Moreover, accurate identification of components reduces the risk of errors during maintenance tasks.

Enhancing User Knowledge

For users, these illustrations serve as educational tools, enabling them to gain a deeper insight into the machinery they operate. By familiarizing themselves with the layout and function of various parts, users can enhance their operational skills and troubleshoot minor issues independently.

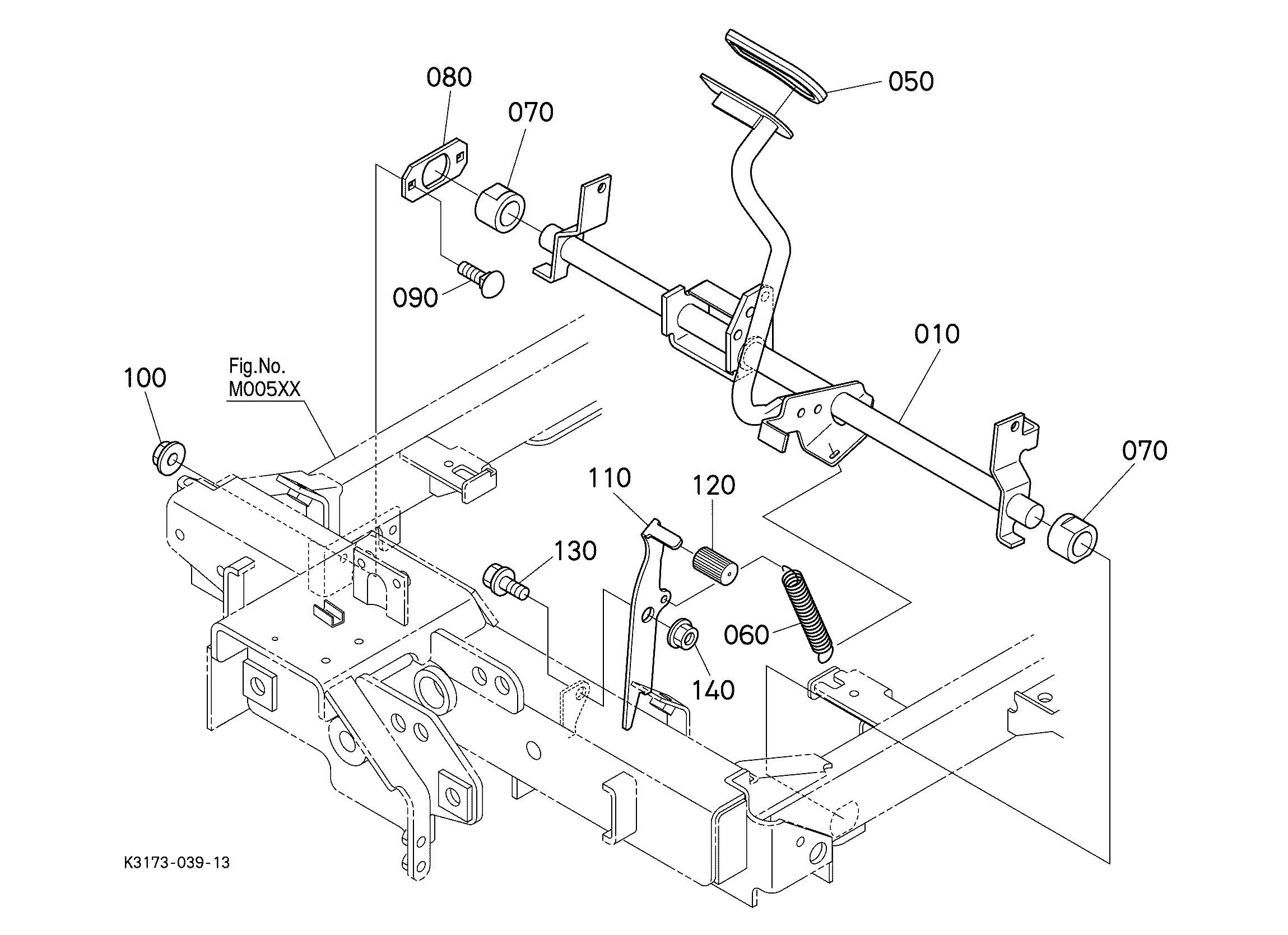

Key Components of ZD321

Understanding the essential elements of this mowing machine is crucial for effective maintenance and operation. Each component plays a vital role in ensuring optimal performance and longevity. Below are the main features that contribute to its efficiency.

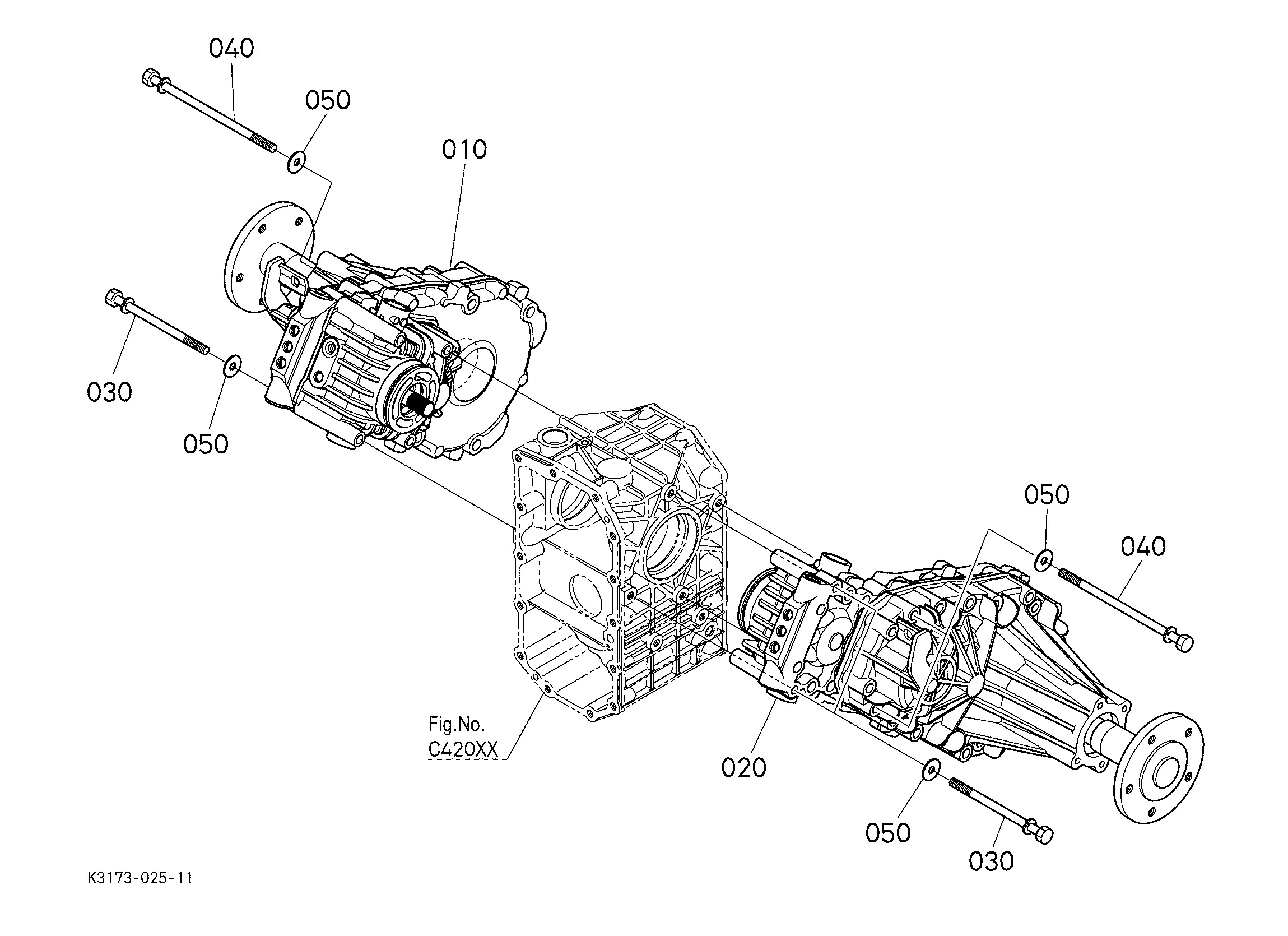

Engine and Transmission

- Power Unit: The engine delivers the necessary power to drive the system, ensuring smooth operation across various terrains.

- Transmission System: This facilitates the transfer of power from the engine to the wheels, allowing for seamless movement and speed adjustments.

Cutting Deck and Blades

- Cutting Deck: The design of the deck influences the mowing capability, providing a wide area for efficient grass cutting.

- Blades: Sharp and durable blades are essential for achieving a clean cut, contributing to the overall health of the lawn.

Each component is intricately designed to work together, ensuring that the machine operates effectively and reliably for its users.

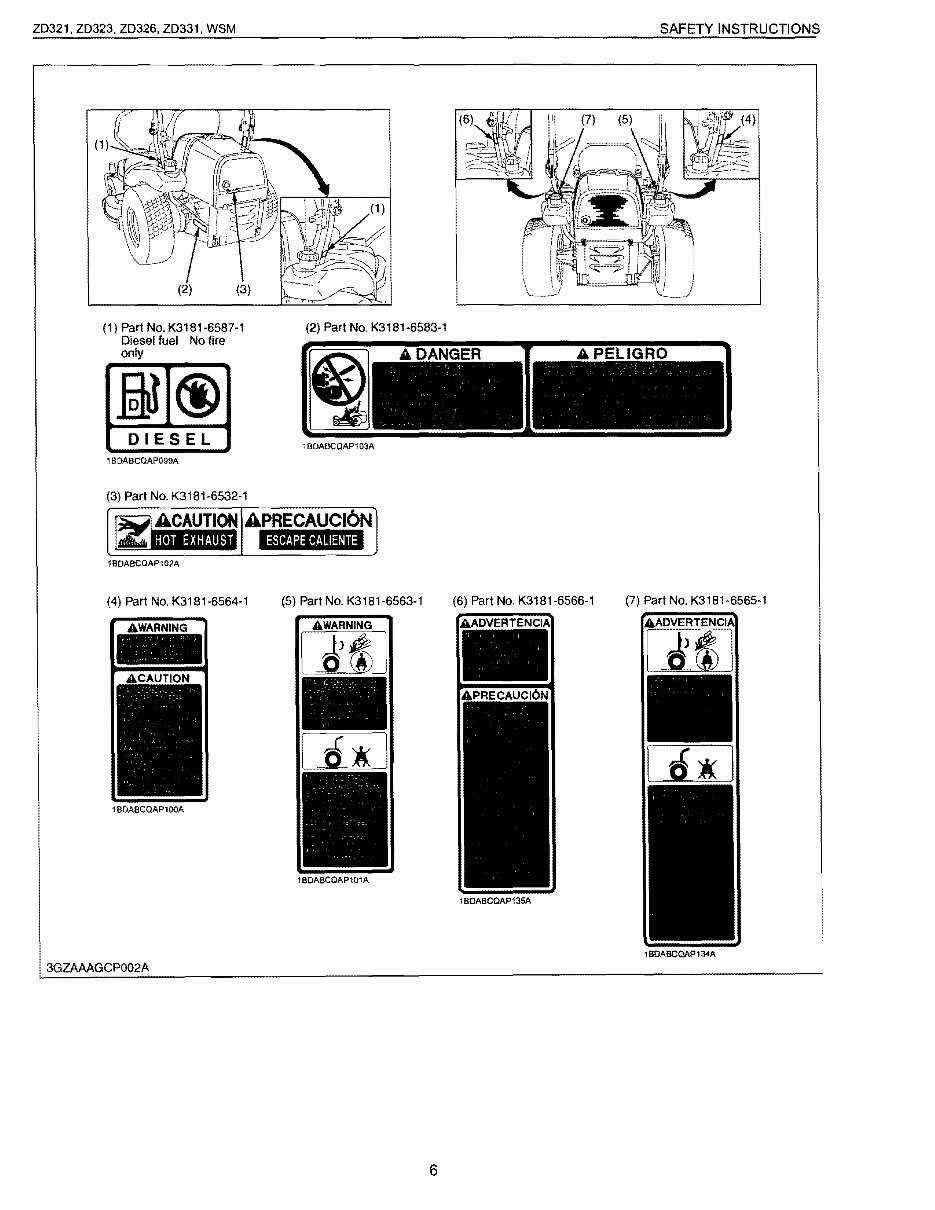

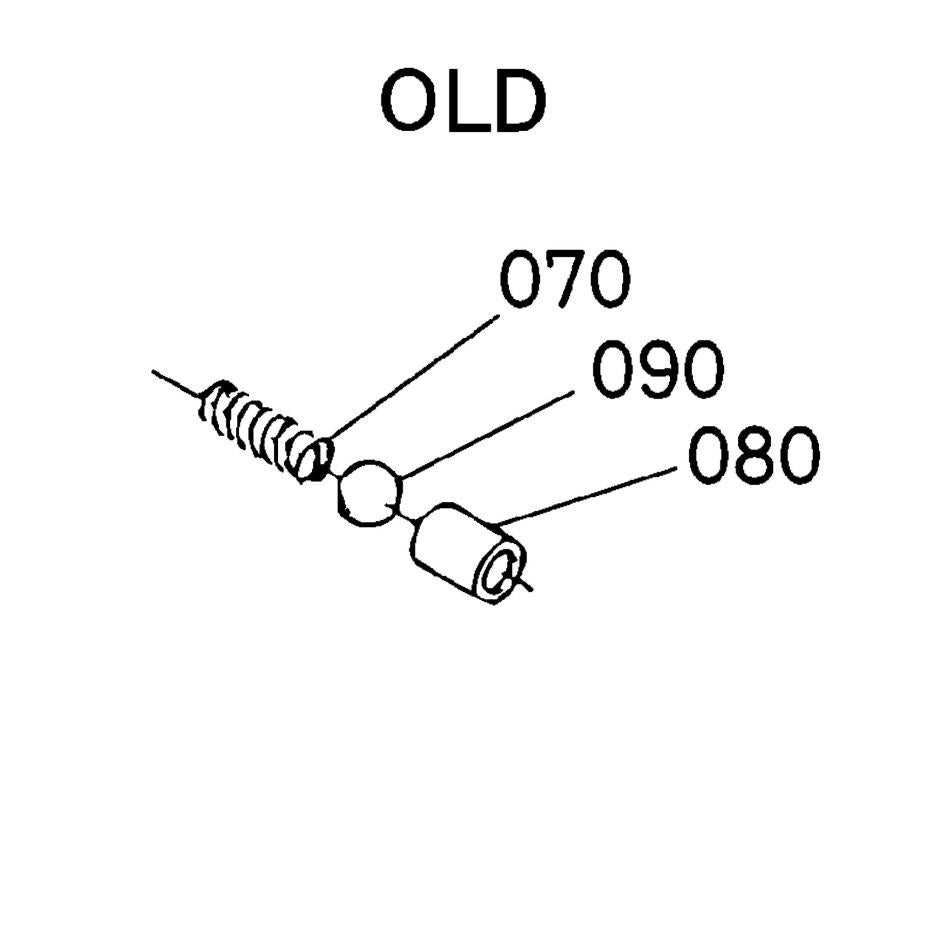

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repair. Such visual aids provide a clear overview of how different elements are interconnected and can simplify the process of identifying what you need.

Here are key steps to effectively interpret a schematic:

- Familiarize Yourself with Symbols:

Each component is represented by specific icons or symbols. Learning these will help you quickly recognize each part’s function.

- Study the Layout:

Observe the overall arrangement. Components are typically organized logically, often grouped by function or location.

- Identify Connections:

Look for lines that indicate how parts interact. These connections are crucial for understanding how the system operates.

- Refer to a Legend:

If available, consult the legend or key that explains the symbols and color coding used in the schematic.

- Note Part Numbers:

Each component usually has a unique identifier. Jotting these down can be helpful when ordering replacements.

By following these steps, you can enhance your ability to navigate visual representations of components, leading to more efficient repairs and maintenance.

Common Maintenance Practices

Regular upkeep is essential for ensuring the longevity and optimal performance of any machinery. By implementing a routine maintenance schedule, operators can identify potential issues before they escalate, thereby saving time and costs associated with extensive repairs. This section outlines effective strategies for maintaining equipment to enhance reliability and efficiency.

Routine Inspections

Conducting frequent checks is crucial. Operators should examine key components for wear and tear, ensuring all parts are functioning properly. Focus on fluid levels, belts, and filters, as these elements significantly affect performance. Addressing minor issues early can prevent major breakdowns in the future.

Cleaning and Lubrication

Keeping the machinery clean is vital for its performance. Dirt and debris can accumulate and cause damage. Regularly clean the exterior and accessible internal parts. Additionally, proper lubrication of moving parts reduces friction and wear. Using the right type of lubricant is critical to ensure smooth operation and prolong the lifespan of the equipment.

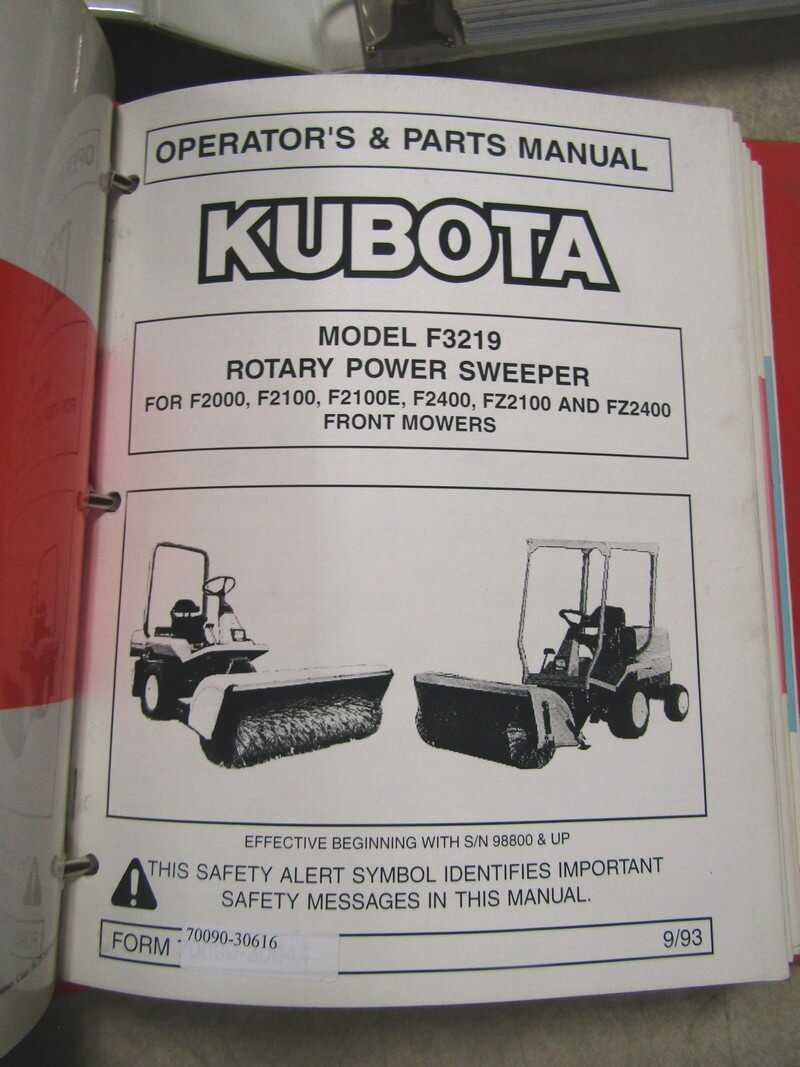

Where to Find Replacement Parts

Locating high-quality components for your machinery can significantly enhance its performance and longevity. Understanding the best sources for these items ensures that you maintain optimal functionality without unnecessary delays.

Online Resources

- Manufacturer’s Website: Check the official site for genuine components.

- Third-Party Retailers: Explore reputable e-commerce platforms offering various options.

- Forums and Community Groups: Join discussions where users share trusted suppliers.

Local Options

- Authorized Dealers: Visit local dealerships that specialize in your equipment.

- Repair Shops: Consult local mechanics who often have access to essential components.

- Salvage Yards: Consider visiting yards that specialize in machinery for used items.

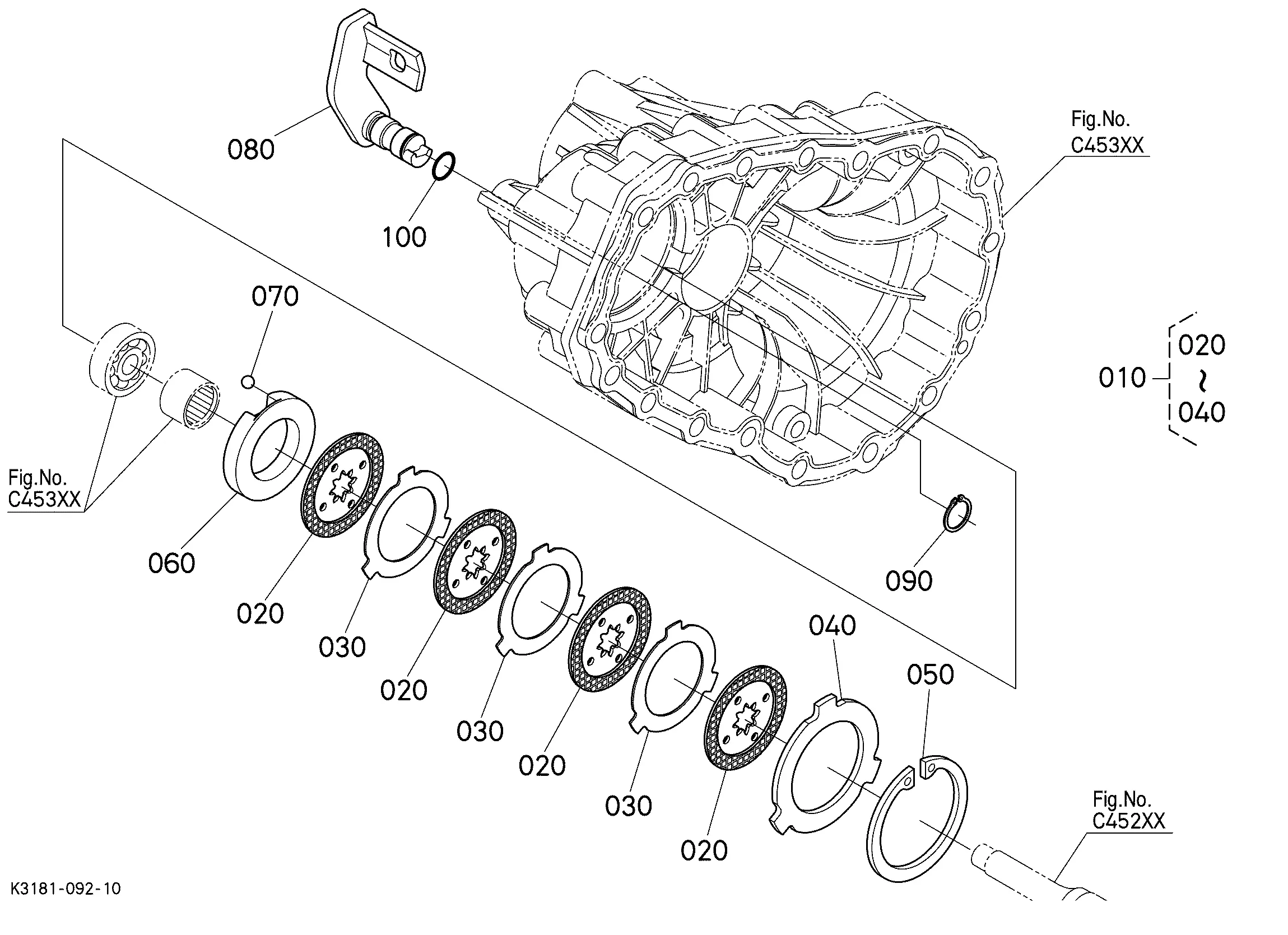

Troubleshooting Using Parts Diagrams

Understanding the layout and components of machinery is essential for effective problem-solving. Visual aids that illustrate the various elements of equipment can significantly enhance the troubleshooting process. By referring to these guides, operators can quickly identify malfunctioning parts and understand their relationship within the system.

When faced with an issue, the first step is to consult the visual representations to pinpoint the area of concern. This approach allows for a systematic examination, facilitating the identification of worn or damaged components. With a clear view of the assembly, it becomes easier to devise a plan for repairs or replacements, reducing downtime and improving overall efficiency.

Additionally, these illustrations often include part numbers and specifications, making it straightforward to order the correct replacements. This accuracy not only speeds up the repair process but also ensures compatibility and functionality once the new parts are installed. Overall, leveraging visual references can streamline troubleshooting and maintenance efforts, leading to better operational performance.

Benefits of OEM vs. Aftermarket Parts

When it comes to maintaining machinery, the choice between original components and third-party alternatives is crucial. Each option presents distinct advantages that can impact performance, reliability, and overall cost-effectiveness.

Original components are designed specifically for particular machines, ensuring perfect compatibility and adherence to manufacturer standards. This often results in superior performance, longevity, and warranty protection. Users can be confident that these components have undergone rigorous testing and quality control processes.

On the other hand, third-party alternatives frequently offer more competitive pricing and availability. They can provide cost savings, especially for users with tight budgets. Some aftermarket options are developed with innovative designs that may enhance functionality or provide unique features not found in original components.

Ultimately, the decision should be based on individual needs, preferences, and the specific context of use. Understanding the pros and cons of both choices can help ensure the best outcomes for machinery maintenance and longevity.