The intricate world of agricultural equipment encompasses a vast array of machinery, each designed to perform specific tasks efficiently. A comprehensive understanding of these machines’ components is essential for operators and technicians alike. By familiarizing oneself with the various elements that make up these powerful tools, one can enhance performance and streamline maintenance processes.

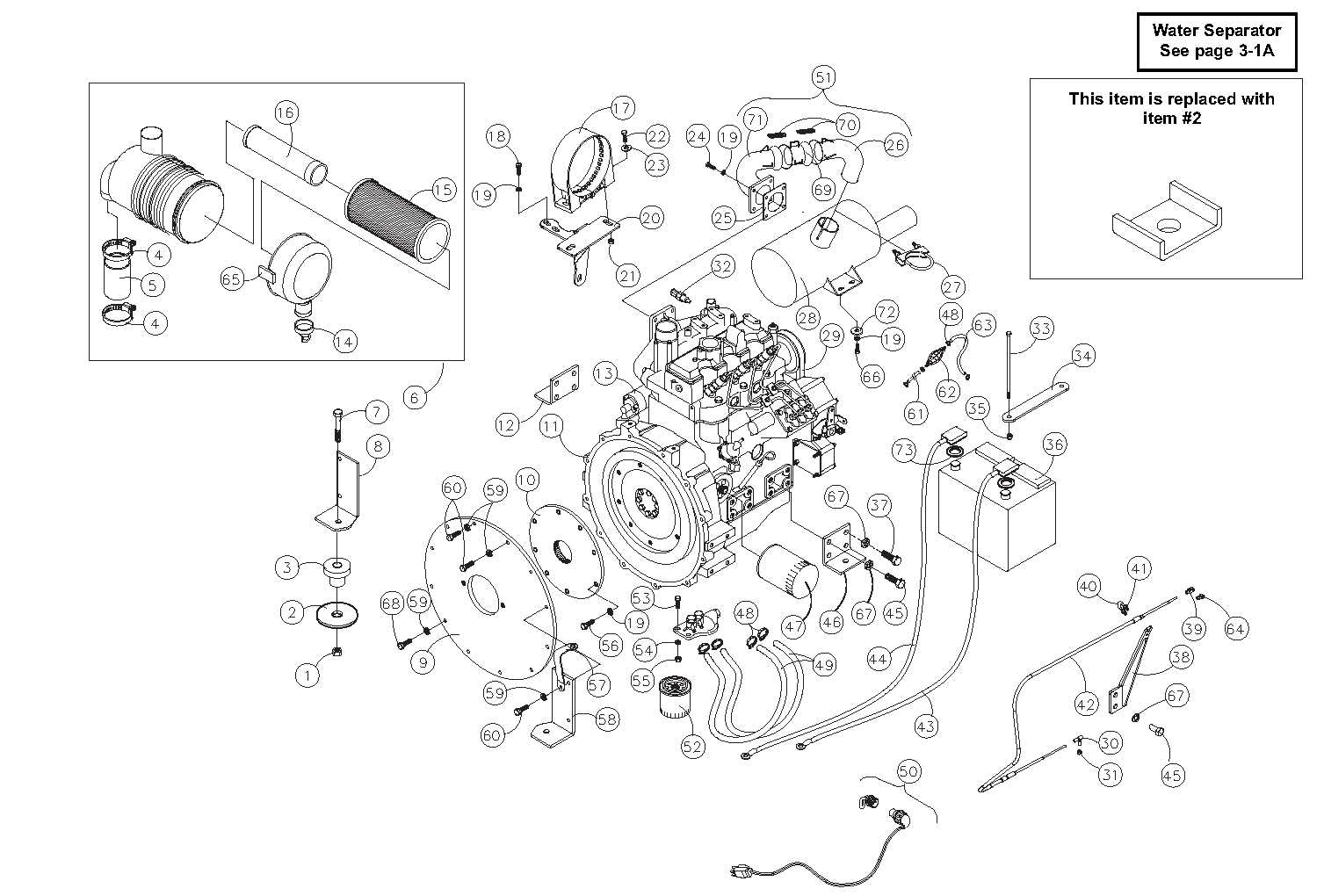

Visual representations of machinery elements provide invaluable insights into their arrangement and functionality. Such illustrations serve as a roadmap for those seeking to repair or upgrade their equipment. Knowing how each part interacts within the whole system not only aids in troubleshooting but also empowers users to make informed decisions regarding their machinery.

As you delve deeper into the specifics of these components, it becomes clear that recognizing individual elements and their respective roles is crucial. Whether you are looking to replace a worn-out piece or simply gain a better understanding of how your equipment operates, having access to detailed visual resources can significantly enhance your knowledge and skills in managing agricultural machinery.

Kubota M9540 Overview

This section provides a comprehensive look at a powerful agricultural machine designed for various farming tasks. Renowned for its efficiency and durability, this vehicle has become a trusted choice among professionals in the agricultural sector. Its advanced features and reliable performance cater to diverse needs, making it an essential asset in modern farming operations.

The machine is equipped with a robust engine that delivers impressive horsepower, ensuring optimal productivity during demanding tasks. Its user-friendly controls and ergonomic design enhance operator comfort and control, allowing for precise maneuvering in various environments.

| Feature | Description |

|---|---|

| Engine Power | Offers substantial horsepower for heavy-duty applications. |

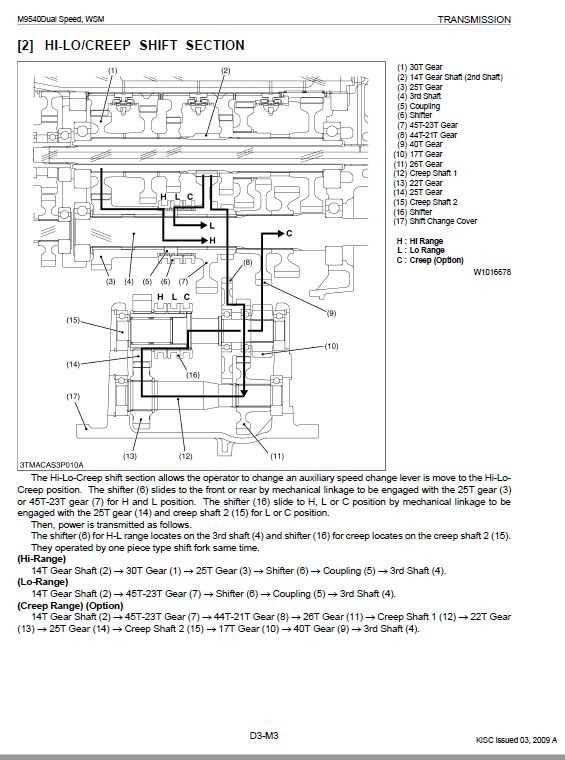

| Transmission | Features an efficient system for smooth gear shifting. |

| Hydraulic System | Provides strong lifting capacity for various implements. |

| Cab Design | Ergonomically designed for comfort and visibility. |

| Versatility | Compatible with a range of attachments for diverse tasks. |

Key Features of the M9540

This powerful agricultural machine is designed to meet the diverse needs of modern farming. Its robust construction and advanced technology ensure high performance and reliability in various tasks, from tilling to hauling heavy loads.

One of the standout attributes is its impressive engine efficiency, which provides ample horsepower while maintaining fuel economy. This balance allows operators to accomplish more with less, ultimately saving on operational costs.

The hydraulic system is another highlight, offering exceptional lifting capacity and responsiveness. This feature enables seamless attachment of implements, making the machine versatile for a range of agricultural applications.

Additionally, the user-friendly control panel enhances the operator experience, providing intuitive access to key functions and settings. This attention to ergonomics ensures comfort during long hours of operation.

Durability is a critical consideration, and the construction materials used in this machine are built to withstand the rigors of heavy use. Regular maintenance is simplified through accessible components, ensuring longevity and dependable performance.

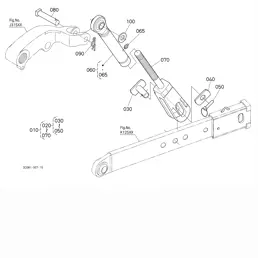

Importance of Parts Diagrams

Understanding the intricate assembly of machinery is crucial for effective maintenance and repair. Visual representations that break down components into easily identifiable sections play a vital role in this process. These tools not only enhance clarity but also streamline troubleshooting and restoration efforts.

Efficiency is significantly improved when users can quickly locate specific elements within complex systems. A well-structured illustration allows technicians to identify the exact pieces they need, reducing the time spent searching for information. This leads to quicker repairs and less downtime for equipment.

Moreover, such visual aids contribute to better training for new operators and mechanics. By providing a clear view of how parts interact, these resources foster a deeper understanding of machine functionality. This knowledge ultimately translates into more competent handling of equipment.

Additionally, having a reference for each component facilitates order accuracy when procuring replacements. Accurate identification minimizes the risk of ordering incorrect items, saving both time and resources in the repair process.

In summary, the significance of visual breakdowns of machinery cannot be overstated. They enhance efficiency, improve training, and ensure accurate procurement, all of which are essential for optimal equipment performance.

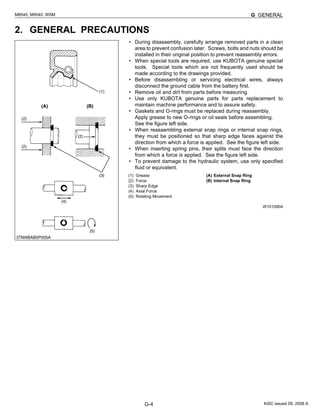

Understanding Component Identification

Identifying components in machinery is essential for effective maintenance and repair. A clear understanding of each part’s function helps ensure the longevity and efficiency of the equipment. This section will explore the methods and importance of recognizing various elements within a mechanical system.

Proper identification involves several key factors:

- Visual Recognition: Familiarity with the shapes, colors, and configurations of different components can facilitate quicker diagnostics.

- Labeling: Many machines feature labels or tags that provide critical information about each element, including model numbers and specifications.

- Reference Materials: Manuals and catalogs often include detailed descriptions and images, which serve as valuable resources for identifying parts.

To effectively identify components, consider the following steps:

- Examine the machinery and note any visible signs of wear or damage.

- Consult reference guides to compare what you see with documented information.

- Utilize online resources or community forums for additional insights from experienced users.

In summary, mastering the art of component identification not only enhances repair processes but also contributes to a better understanding of the overall machinery, paving the way for more informed decisions and proactive maintenance strategies.

Common Replacement Parts

When it comes to maintaining agricultural machinery, certain components are more frequently in need of replacement due to wear and tear. Understanding which items are typically required can help ensure your equipment remains in optimal working condition. Regularly checking and replacing these essential elements can enhance performance and extend the lifespan of the machinery.

Key Components for Maintenance

Among the most commonly replaced items are filters, belts, and hydraulic hoses. Filters play a crucial role in keeping the engine and hydraulic systems free from contaminants, while belts ensure proper functioning of various systems by providing necessary power transmission. Additionally, hydraulic hoses are vital for efficient operation, as they facilitate fluid movement between components.

Wear and Tear Items

Another category to consider includes items like tires, batteries, and various seals. Tires endure significant stress during operation, making them prone to wear. Batteries require replacement over time to maintain reliable starting power, and seals can deteriorate, leading to fluid leaks that compromise efficiency. Regular inspections and timely replacements of these elements contribute significantly to the overall reliability of your machinery.

Maintenance Tips for Longevity

Ensuring the durability of your machinery requires a proactive approach to upkeep. Regular attention to specific areas can greatly enhance performance and extend the operational life of your equipment.

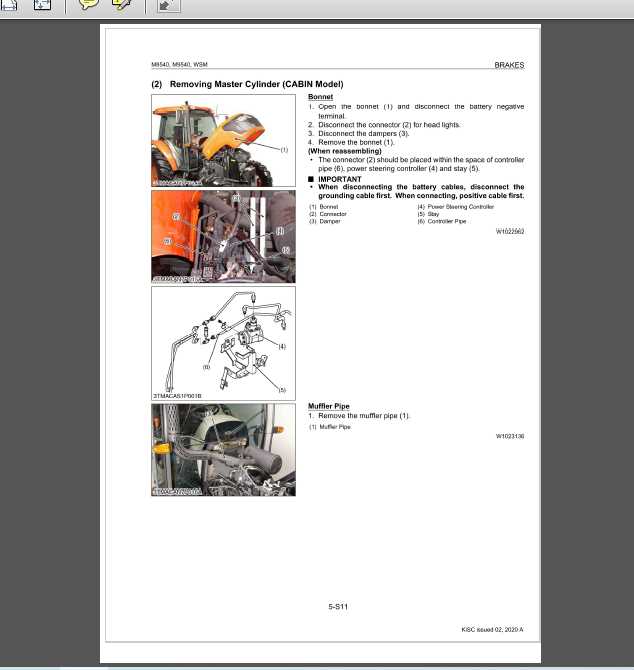

Regular Inspections

Conducting frequent assessments of your machine is essential. Look for signs of wear, unusual sounds, or fluid leaks. Addressing small issues promptly can prevent larger, costly problems down the line.

Fluid Changes and Lubrication

Timely fluid changes and proper lubrication are vital for optimal performance. Ensure that all fluids are at appropriate levels and replace them as per the manufacturer’s recommendations. Regularly lubricating moving parts reduces friction and enhances efficiency.

Sourcing Genuine Kubota Parts

Finding authentic components is crucial for maintaining the performance and longevity of your machinery. Utilizing original products ensures optimal functionality and compatibility, leading to better overall results in operations.

Here are key considerations when sourcing genuine items:

- Verify the supplier’s credibility to avoid counterfeit alternatives.

- Consult official retailers or authorized distributors for reliable sourcing.

- Check for warranty and return policies to safeguard your investment.

Additionally, it’s beneficial to:

- Conduct thorough research on specifications required for your equipment.

- Engage with online forums or communities for recommendations.

- Monitor pricing trends to ensure competitive offers.

By prioritizing genuine components, you can ultimately enhance the efficiency and reliability of your machinery.

Online Resources for Parts Diagrams

Finding the right components for machinery can be simplified by leveraging various digital platforms. These resources offer visual guides that help users identify and acquire the necessary items efficiently.

Types of Online Resources

- Manufacturer Websites

- Dedicated Online Retailers

- Community Forums

- Technical Blogs and Guides

Benefits of Using Online Platforms

- Access to comprehensive visual aids.

- Enhanced understanding of component relationships.

- Convenient comparison of prices and availability.

- Opportunity to connect with experienced users for advice.